Abstract

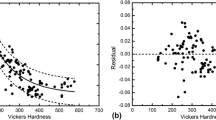

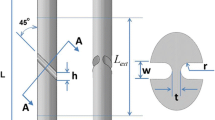

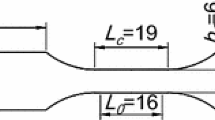

Results of 61 uniaxial compression tests on the welded Topopah Spring tuff are presented. The tests were carried out under constant strain rates at room temperature. Stress–strain analysis indicates that dilatancy and compaction start at about 50% of ultimate strength. A sudden stress drop occurs at about 90% of the ultimate strength, which indicates the onset of specimen failure. Both strength and peak axial strain decrease with strain rate as power functions. Based on the strain rate dependence of strength and peak axial strain, it is inferred that the elastic modulus is strain rate dependent. A relationship between stress, axial strain, and axial strain rate is developed. The parameters in this relation are estimated using multivariate regression to fit stress–axial strain–strain rate data.

Résumé

Les résultats de 61 essais de compression simple sur les ignimbrites de Topopah Spring sont présentés. Les essais ont été réalisés avec une vitesse de déformation constante à la température du laboratoire. L’analyse en contrainte-déformation montre que la dilatance ou la contractance commence à environ 50% de la résistance ultime. Une chute brutale de résistance apparaît à environ 90% de la résistance ultime, ce qui rend compte de l’initiation de la rupture de l’échantillon. A la fois la résistance ultime et la déformation au pic de résistance diminuent avec la vitesse de déformation suivant des fonctions puissance. Sur la base de ces observations, il est conclu que le module d’élasticité dépend de la vitesse de déformation. Une relation entre contrainte, déformation axiale et vitesse de déformation axiale est mise en évidence. Les paramètres intervenant dans cette relation sont estimés à partir des techniques de régression linéaire sur les données expérimentales.

Similar content being viewed by others

References

ASTM (American Society for Testing and Materials D 4543–85) (Reapproved 1991) Standard practice for preparing rock core specimens and determining dimensional and shape tolerances. Annual Book of ASTM Standards, Section 4, Construction, Vol 04.08 Soil and Rock; Building Stones. Conshohocken, PA

Bieniawski ZT (1967) Mechanism of brittle fracture of rock: Part I-theory of the fracture process. Int J Rock Mech Min Sci 4:395–406

Brace WF (1978) Volume changes during fracture and frictional sliding: a review. Pure Appl Geophys 116:603–614

Brace WF, Paulding BW Jr and Scholz CH (1966) Dilatancy in the fracture of crystalline rocks. J Geophys Res 71:3939–3953

Buesch DC, Spengler RW (1998) Character of the middle nonlithophysal zone of the Topopah Spring Tuff at Yucca Mountain. In: High-level radioactive waste management. Proceedings of the Eighth International Conference, Las Vegas, Nevada

Costin LS (1985) Time-dependent damage and creep of brittle rock. In: Stubbs N, Krajcinovic D (eds) Damage mechanics and continuum modeling. Proceedings of 2 Sessions Sponsored by the Engineering Mechanics Division of the American Society of Civil Engineers in Conjunction with the ASCE Convention, Detroit, Michigan

Costin LS, Holcomb DJ (1983) A continuum model of inelasticity deformed brittle rock based on the mechanics of microcracks. In: Desai CS, Gallagher RH (eds) Constitutive laws for engineering materials theory and application. Proceedings of the International Conference. Tucson, Arizona, USA

Cruden DM (1971) The form of the creep law for rock under uniaxial compression. Int J Rock Mech Min Sci 8:105–126

Desai CS, Siriwardane HJ (1994) Constitutive laws for engineering materials with emphasis on geologic materials. Prentice-Hall, Englewood Cliffs

DOE/RW-0549 (2002) Yucca Mountain site suitability evaluation. DOE report. Website: http://www.yucca-web2.ymp.gov/documents/sse_a

Eberhardt E, Stead D, Stimpson B and Read RS (1998) Identifying crack initiation and propagation threshold in brittle rock. Can Geotech J 35:222–233

Engstrom DA, Rautman CA (1996) Geology of the USW SD-9, Drill Hole Yucca Mountain, Nevada. Sandia Report, SAND96–2030, UC-814, Sandia National Laboratories

Fernandez G (2003) Data mining using SAS applications. Chapman and Hall/CRC, London/USA

Hoek E, Brown ET (1980) Underground excavations in rock. Institution of Mining and Metallurgy, London

Holcomb DJ (1981) Memory, relaxation, and microfracturing in dilatant rock. J Geophys Res 86:6235–6248

Horii H, Nemat-Nasser S (1985) Compression-induced microcrack growth in brittle solids: axial splitting and shear failure. J Geophys Res 90:3105–3125

ISRM (1979) Suggested method for determination of the uniaxial compressive strength of rock materials. Int J Rock Mech Min Sci Geomech Abstr 16:137–140

Jaeger JC and Cook NGW (1979) Fundamentals of rock mechanics, 3rd edn. Chapman and Hall, London

Kranz RL, Scholz CH (1977) Critical dilatant volume of rocks at the onset of tertiary creep. J Geophys Res 82:4893–4898

Ladanyi B (1993) Time-dependent response of rock around tunnels. In: Hudson JA (ed) Comprehensive rock engineering, principles, practice and projects. Pergamon, Oxford 3:77–112

Lajtai EZ (1971) A theoretical and experimental evaluation of the Griffith theory of brittle fracture. Tectonophysics 11:129–156

Lajtai EZ (1998) Microscopic fracture processes in a granite. Rock Mech Rock Eng 31:237–250

Lauterbach B and Gross D (1998) Crack growth in brittle solids under compression. Mech Materials 29:81–92

Lemaitre J (1992) A course on damage mechanics. Springer, Berlin Heidelberg New York

Ma L (2004) Experimental investigation of time dependent behavior of Welded Topopah Spring Tuff. Dissertation, University of Nevada, Reno

Ma L, Daemen JJK (2004) Strain rate-dependence of mechanical properties of Welded Topopah Spring Tuff. Int J Rock Mech Min Sci, 41:395 (Spec Issu)

Martin CD, Chandler NA (1994) The progressive fracture of Lac du Bonnet Granite. Int J Rock Mech Min Sci Geomech Abstr 31:643–659

Martin RJ, Noel JS, Boyd PJ, Price RH (1997) Creep properties of the Paintbrush Tuff recovered from Borehole USW NRG-7/7A: Data report. SAND95–1759, UC-814, Sandia National Laboratories

OCRWM (2004) Website: http://www.ocrwm.doe.gov

OCRWM (Office of Civilian Radioactive Waste Management) (1999) Geology of the ECRB Cross Drift—exploratory studies facility, Yucca Mountain Project, Yucca Mountain, Nevada, prepared by Mongano GS, Singleton WL, Moyer TC, Beason SC, Eatman GLW, Albin AL, and Lung RC, Bureau of Reclamation and U.S. Geological Survey. Denver, Colorado

Rautman CA, Engstrom DA (1996a) Geology of the USW SD-12 Drill Hole Yucca Mountain, Nevada. Sandia Report, SAND96-1368, UC-814, Sandia National Laboratories

Rautman CA, Engstrom DA (1996b) Geology of the USW SD-7, Drill Hole Yucca Mountain, Nevada. Sandia Report, SAND96-1474, UC-814, Sandia National Laboratories

Scholz CH (1968) Experimental study of the fracturing process in brittle rock. J Geophys Res 73:1447–1454

Vajdova V, Braud P, Wong T (2004) Compaction, dilatancy, and failure in porous carbonate rocks. J Geophys Res 109 (B5)

Walsh JB (1965) The effect of cracks on the uniaxial elastic compression of rocks. J Geophys Res 70:399–411

Zheng Y (1988) Theoretical foundations of elasticity, plasticity and viscosity for rock mechanics (in Chinese). Coal Industry Press, Beijing

Acknowledgements

The authors thank Mr. Jaime Gonzalez, DOE Contract Manager, Mr. Rick Blitz for experimental work and for valuable discussions and Dr. Mark Board for most helpful discussions and suggestions. This paper was prepared by the University of Nevada Reno pursuant to a Cooperative Agreement fully funded by the United States Department of Energy, and neither University and Community College System of Nevada nor any of its contractors or subcontractors nor the United States Department of Energy, nor any person acting on behalf of either: (a) Makes any warranty or representation, express or implied, with respect to the accuracy, completeness, or usefulness of the information contained in this report, or that the use of any information, apparatus, method, or process disclosed in this report may not infringe privately-owned rights; or (b) Assumes any liabilities with respect to the use of, or for damages resulting from the use of, any information, apparatus, method or process disclosed in this report. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise, does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States Department of Energy. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Department of Energy.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, L., Daemen, J.J.K. Strain rate dependent strength and stress–strain characteristics of a welded tuff. Bull Eng Geol Environ 65, 221–230 (2006). https://doi.org/10.1007/s10064-005-0038-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-005-0038-6