Abstract

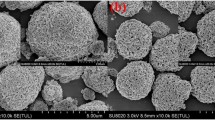

Although LiNi0.8Co0.15Al0.05O2 (NCA) has various merits such as a high discharge capacity of ~ 195 mAh g−1, improved stability, and low cost, intergranular cracks in the NCA structure can suppress the electronic/ionic motion in the cathode. Thus, in this study, to minimize crack portions in the NCA cathode, we synthesized dense NCA cathode materials using micelle structures controlled with pluronic acid (F127) and polyvinyl alcohol (PVA) as polymer templates and evaluated the electrochemical performance in LIBs using coin-type cells. We found that all the as-prepared samples showed the LiNiO2-based structures doped with Co and Al. With an increasing amount of PVA, the 1st particles can be more agglomerated during heating and thus increase the size of the 2nd particles. Consequently, a significantly dense NCA structure consisting of less cracked 2nd particles can be prepared in the presence of F127 and PVA. In particular, the NCA cathode prepared with an optimal ratio of F127 to PVA exhibited the best electrochemical properties, i.e., high capacity and superior cycle life.

Similar content being viewed by others

References

Nitta N, Wu F, Lee JT, Yushin G (2015) Li-ion battery materials: present and future. Mater Today 18(5):252–264

Xie Y, Lou XW, Yuan C et al (2014) Mixed transition-metal oxides : design, Synthesis, and Energy-Related Applications. Angew Chem Int Ed 53:1488–1504

Choi JW, Aurbach D (2016) Promise and reality of post-lithium-ion batteries with high energy densities. Nat Rev Mater 1(4):16013

Tang Y, Zhang Y, Li W, Ma B, Chen X (2015) Rational material design for ultrafast rechargeable lithium-ion batteries. Chem Soc Rev 44(17):5926–5940

Schuld S, Hausbrand R, Fingerle M, Jaegermann W, Weitzel KM (2018) Experimental studies on work functions of Li+ions and electrons in the battery electrode material LiCoO2: a thermodynamic cycle combining ionic and electronic structure. Adv Energy Mater 8(18):1703411

Aravindan V, Gnanaraj J, Lee YS, Madhavi S (2013) LiMnPO4—a next generation cathode material for lithium-ion batteries. J Mater Chem A 1(11):3518–3539. https://doi.org/10.1039/c2ta01393b

Liu W, Oh P, Liu X, Lee MJ, Cho W, Chae S, Kim Y, Cho J (2015) Nickel-rich layered Lithium transition-metal oxide for high-energy lithium-ion batteries. Angew Chem Int Ed 54(15):4440–4457

Wang J, Sun X (2015) Olivine LiFePO4 the remaining challenges for future energy storage. Energy Environ Sci 8(4):1110–1138

Yang Q, Huang J, Li Y, Wang Y, Qiu J, Zhang J, Yu H, Yu X, Li H, Chen L (2018) Surface-protected LiCoO2 with ultrathin solid oxide electrolyte film for high-voltage lithium ion batteries and lithium polymer batteries. J Power Sources 388:65–70

Cho Y, Oh P, Cho J (2013) A new type of protective surface layer for high-capacity Ni-based cathode materials: Nanoscaled surface pillaring layer. Nano Lett 13(3):1145–1152

Manthiram A, Song B, Li W (2017) A perspective on nickel-rich layered oxide cathodes for lithium-ion batteries. Energy Storage Mater 6:125–139

Ko HS, Kim JH, Wang J, Lee JD (2017) Co/Ti co-substituted layered LiNiO2 prepared using a concentration gradient method as an effective cathode material for Li-ion batteries. J Power Sources 372:107–115

Hayashi T, Okada J, Toda E, Kuzuo R, Oshimura N, Kuwata N, Kawamura J (2014) Degradation mechanism of LiNi0.82Co0.15Al0.03O2 positive electrodes of a lithium-ion battery by a long-term cycling test. J Electrochem Soc 161(6):A1007–A1011

Yoon CS, Kim UH, Park GT, Kim SJ, Kim KH, Kim J, Sun YK (2018) Self-passivation of a LiNiO2 cathode for a lithium-ion battery through Zr doping. ACS Energy Lett 3(7):1634–1639

Cao C, Zhang J, Xie X, Xia B (2017) Composition, structure, and performance of Ni-based cathodes in lithium ion batteries. Ionics 23(6):1337–1356

Li Y, Deng S, Chen Y, Gao J, Zhu J, Xue L, Lei T, Cao G, Guo J, Wang S (2019) Dual functions of residue Li-reactive coating with C4H6CoO4 on high-performance LiNiO2 cathode material. Electrochim Acta 300:26–35

Kleiner K, Dixon D, Jakes P et al (2014) Fatigue of LiNi0.8Co0.15Al0.05O2 in commercial Li ion batteries. J Power Sources 273:70–82

Zhao J, Zhang W, Huq A et al (2017) In situ probing and synthetic control of cationic ordering in Ni-rich layered oxide cathodes. Adv Energy Mater 7:1–13

Shin S-M, Lee D-W, Wang J-P (2018) Fabrication of nickel nanosized powder from LiNiO2 from spent lithium-ion battery. Metals (Basel) 8(1):79

Do SJ, Santhoshkumar P, Kang SH, Prasanna K, Jo YN, Lee CW (2019) Al-doped Li[Ni0.78Co0.1Mn0.1Al0.02]O2 for high performance of lithium ion batteries. Ceram Int 45(6):6972–6977

Trease NM, Seymour ID, Radin MD, Liu H, Liu H, Hy S, Chernova N, Parikh P, Devaraj A, Wiaderek KM, Chupas PJ, Chapman KW, Whittingham MS, Meng YS, van der van A, Grey CP (2016) Identifying the distribution of Al3+ in LiNi0.8Co0.15Al0.05O2. Chem Mater 28(22):8170–8180

Yamamoto Y, Ohtsuka M, Azuma Y, Takahashi T, Muto S (2018) Cation mixing in LiNi0.8Co0.15Al0.05O2 positive electrode material studied using high angular resolution electron channeling X-ray spectroscopy. J Power Sources 401:263–270

Sun S, Liu T, Niu Q, Sun X, Song D, Liu H, Zhou X, Ohsaka T, Wu J (2019) Improvement of superior cycle performance of LiNi0.8Co0.15Al0.05O2 cathode for lithium-ion batteries by multiple compound modifications. J Electroanal Chem 838:178–185

Zhou P, Zhang Z, Meng H, Lu Y, Cao J, Cheng F, Tao Z, Chen J (2016) SiO2 -coated LiNi0.915Co0.075Al0.01O2 cathode material for rechargeable Li-ion batteries. Nanoscale 8(46):19263–19269

Chen T, Li X, Wang H, Yan X, Wang L, Deng B, Ge W, Qu M (2018) The effect of gradient boracic polyanion-doping on structure, morphology, and cycling performance of Ni-rich LiNi0.8Co0.15Al0.05O2 cathode material. J Power Sources 374:1–11

Gui S, Zhang Q, Zhuo H, Liu J (2019) Enhancing the electrochemical performance of LiNi0.8Co0.15Al0.05O2 by a facile doping method: spray-drying doping with liquid polyacrylonitrile. J Power Sources 409:102–111

Xiao Y, Liu T, Liu J, He L, Chen J, Zhang J, Luo P, Lu H, Wang R, Zhu W, Hu Z, Teng G, Xin C, Zheng J, Liang T, Wang F, Chen Y, Huang Q, Pan F, Chen H (2018) Insight into the origin of lithium nickel ions exchange in layered Li(NixMnyCoz)O2 cathode materials. Nano Energy 49:77–85. https://doi.org/10.1016/j.nanoen.2018.04.020

Zhang Q, Su Y, Chen L, Lu Y, Bao L, He T, Wang J, Chen R, Tan J, Wu F (2018) Pre-oxidizing the precursors of nickel-rich cathode materials to regulate their Li+/Ni2+ cation ordering towards cyclability improvements. J Power Sources 396:734–741. https://doi.org/10.1016/j.jpowsour.2018.06.091

Gao S, Cheng Y, Shirpour M (2019) E effects of cobalt deficiency on nickel-rich layered LiNi0.8Co0.1Mn0.1O2 positive electrode materials for Lithium-ion batteries. ACS Appl Mater Interfaces 11(1):982–989. https://doi.org/10.1021/acsami.8b19349

Yu H, Qian Y, Otani M, Tang D, Guo S, Zhu Y, Zhou H (2014) Study of the lithium/nickel ions exchange in the layered LiNi0.42Mn0.42Co0.16O2 cathode material for lithium ion batteries: experimental and first-principles calculations. Energy Environ Sci 7(3):1068–1078. https://doi.org/10.1039/C3EE42398K

Kalyani P, Kalaiselvi N (2005) Various aspects of LiNiO2 chemistry: a review. Sci Technol Adv Mater 6(6):689–703

Molenda J, Wilk P, Marzec J (2017) Structural, electrical and electrochemical properties of LiNiO2. Solid State Ionics 146:73–79

Morales J, Pérez-Vicente C, Tirado JL (1990) Cation distribution and chemical deintercalation of Li1_xNi1+xO2. Mater Res Bull 25:56–79

Hou P, Yin J, Ding M, Huang J, Xu X (2017) Surface/interfacial structure and chemistry of high-energy nickel-rich layered oxide cathodes: advances and perspectives. Small 13:1701802

Zhang X, Jiang WJ, Mauger A, Qilu, Gendron F, Julien CM (2010) Minimization of the cation mixing in Li1+x(NMC)1-xO2 as cathode material. J Power Sources 195(5):1292–1301

Park S-H, Kang S-H, Belharouak I et al (2007) Physical and electrochemical properties of spherical Li1+x(Ni1/3Co1/3Mn1/3)1−xO2 cathode materials. J Power Sources 177:177–183

Sun G, Yin X, Yang W, Song A, Jia C, Yang W, du Q, Ma Z, Shao G (2017) The effect of cation mixing controlled by thermal treatment duration on the electrochemical stability of lithium transition-metal oxides. Phys Chem Chem Phys 19(44):29886–29894

Qu Y, Mo Y, Jia X, Zhang L, du B, Lu Y, Li D, Chen Y (2019) Flux growth and enhanced electrochemical properties of LiNi0.5Co0.2Mn0.3O2 cathode material by excess lithium carbonate for lithium-ion batteries. J Alloys Compd 788:810–818

Sun HH, Manthiram A (2017) Impact of microcrack generation and surface degradation on a nickel-rich layered Li[Ni0.9Co0.05Mn0.05]O2 cathode for lithium-ion batteries. Chem Mater 29(19):8486–8493

Seok JY, Park W, Park H et al (2017) Thermo-sensitive injectable hydrogel based on the physical mixing of hyaluronic acid and Pluronic F-127 for sustained NSAID delivery. Carbohydr Polym 156:403–408

Ryu H, Park K et al (2018) Capacity fading of Ni-rich Li[NixCoyMn1−x−y]O2 (0.6 ≤ x ≤ 0.95) cathodes for high-energy-density Lithium-ion batteries bulk or surface degradation. Chem Mater 30:1155–1163

Hou P, Zhang H, Zi Z, Zhang L, Xu X (2017) Core-shell and concentration-gradient cathodes prepared via co-precipitation reaction for advanced lithium-ion batteries. J Mater Chem A 5(9):4254–4279

Shaju KM, Subba Rao GV, Chowdari BVR (2002) Performance of layered Li(Ni1/3Co1/3Mn1/3)O2 as cathode for Li-ion batteries. Electrochim Acta 48:145–151

Hou P, Zhang H, Deng X, Xu X, Zhang L (2017) Stabilizing the electrode/electrolyte Interface of LiNi0.8Co0.15Al0.05O2 through tailoring aluminum distribution in microspheres as long-life, high-rate, and safe cathode for lithium-ion batteries. ACS Appl Mater Interfaces 9(35):29643–29653

Yu J, Li H, Zhang G et al (2017) Carbon nanotubes coating on LiNi0.8Co0.15Al0.05O2 as cathode materials for lithium battery. Int J Electrochem Sci 12:11892–11903

Liu BS, Wang ZB, Da Yu F et al (2016) Facile strategy of NCA cation mixing regulation and its effect on electrochemical performance. RSC Adv 6(110):108558–108565

Li W, Reimers JN, Dahn JR (1993) In situ x-ray diffraction and electrochemical studies of Li1-xNiO2. Solid State Ionics 67(1-2):123–130

Huang HY, Hu SH, Chian CS, Chen SY, Lai HY, Chen YY (2012) Self-assembling PVA-F127 thermosensitive nanocarriers with highly sensitive magnetically-triggered drug release for epilepsy therapy in vivo. J Mater Chem 22(17):8566–8573

Acknowledgments

This research was supported by the Technology Development Program to Solve Climate Changes and the Hydrogen Energy Innovation Technology Development Program of the National Research Foundation (NRF) funded by the Ministry of Science, ICT (NRF-2017M1A2A2086648 and No. 2019M3E6A1104186).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 30 kb).

Rights and permissions

About this article

Cite this article

Moon, SH., Kim, ES., Lee, JE. et al. Improved electrochemical properties of LiNi0.8Co0.15Al0.05O2 cathode materials synthesized using micelle structures. J Solid State Electrochem 24, 2233–2240 (2020). https://doi.org/10.1007/s10008-020-04680-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-020-04680-5