Abstract

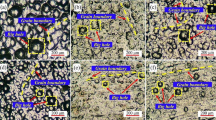

Al-0.05Ga-0.05Sn-0.05Pb-xMg alloys with different Mg content have been prepared. Electrochemical tests including constant current discharge test, current polarization test, electrochemical impedance spectroscopy (EIS) test, and Tafel test are performed. The surface states of the alloys after constant current discharge were analyzed by scanning electron microscopy (SEM) and energy disperse spectroscopy (EDS). X-ray diffraction (XRD) analysis was carried out. We find that different Mg contents have great influence on discharge performance of aluminum alloy anodes by changing the corrosion behavior. The SEM and XRD show that Mg can influence the distribution of corrosion and change the grain size to improve the discharge performance of aluminum anodes. Al-0.05Ga-0.05Sn-0.05Pb-0.1Mg shows the best electrochemical performance due to uniform corrosion and proper grain size. At 800 mA cm−2 constant current discharge, the potential of the aluminum anode can reach − 1.54 V (vs Hg/HgO), and the utilization ratio is over 98%.

Similar content being viewed by others

References

Blurton KF, Sammells AF (1979) Metal/air batteries: their status and potential—a review. J Power Sources 4(4):263–279

Kraytsberg A, Ein-Eli Y (2013) The impact of nano-scaled materials on advanced metal–air battery systems. Nano Energy 2(4):468–480

Kar M, Simons TJ, Forsyth M, MacFarlane DR (2014) Ionic liquid electrolytes as a platform for rechargeable metal-air batteries: a perspective. Phys Chem Chem Phys 16(35):18658–18674

Wang ZL, Xu D, Xu JJ, Zhang XB (2014) Oxygen electrocatalysts in metal-air batteries: from aqueous to nonaqueous electrolytes. Chem Soc Rev 43(22):7746–7786

Lee J, Tai Kim S, Cao R, Choi N, Liu M, Lee KT, Cho J (2011) Metal-air batteries with high energy density: Li-air versus Zn-air. Adv Energy Mater 1(1):34–50

Chen R, Luo R, Huang Y, Wu F, Li L (2016) Advanced high energy density secondary batteries with multi-electron reaction materials. Adv Sci 3:1600051

Mokhtar M, Talib MZM, Majlan EH, Tasirin SM, Ramli WMFW, Daud WRW, Sahari J (2015) Recent developments in materials for aluminum–air batteries: a review. J Ind Eng Chem 32:1–20

Zhang Z, Zuo C, Liu Z, Yu Y, Zuo Y, Song Y (2014) All-solid-state Al–air batteries with polymer alkaline gel electrolyte. J Power Sources 251:470–475

Cho Y, Park I, Lee H, Kim J (2015) Aluminum anode for aluminum–air battery—part I: influence of aluminum purity. J Power Sources 277:370–378

Jingling M, Jiuba W, Hongxi Z, Quanan L (2015) Electrochemical performances of Al–0.5Mg–0.1Sn–0.02In alloy in different solutions for Al–air battery. J Power Sources 293:592–598

Gelman D, Lasman I, Elfimchev S, Starosvetsky D, Ein-Eli Y (2015) Aluminum corrosion mitigation in alkaline electrolytes containing hybrid inorganic/organic inhibitor system for power sources applications. J Power Sources 285:100–108

Pino M, Herranz D, Chacón J, Fatás E, Ocón P (2016) Carbon treated commercial aluminium alloys as anodes for aluminium-air batteries in sodium chloride electrolyte. J Power Sources 326:296–302

Wang LLYL (2010) Electrochemical corrosion behavior of nanocrystalline materials a review. J Mater Sci Technol 26:1–14

Zhang B, Li Y, Wang F (2007) Electrochemical corrosion behaviour of microcrystalline aluminium in acidic solutions. Corros Sci 49(5):2071–2082

Amin MA, Abd El-Rehim SS, El-Sherbini EEF, Mahmoud SR, Abbas MN (2009) Pitting corrosion studies on Al and Al–Zn alloys in SCN− solutions. Electrochim Acta 54(18):4288–4296

Flamini DO, Saidman SB, Bessone JB (2007) Electrodeposition of gallium and zinc onto aluminium. Influence of the electrodeposited metals on the activation process. Thin Solid Films 515(20-21):7880–7885

Elango A, Periasamy VM, Paramasivam M (2009) Study on polyaniline-ZnO used as corrosion inhibitors of 57S aluminium in 2 M NaOH solution. Anti-Corros Method M 56(5):266–270

Egan DR, Ponce De León C, Wood RJK, Jones RL, Stokes KR, Walsh FC (2013) Developments in electrode materials and electrolytes for aluminium–air batteries. J Power Sources 236:293–310

Wang D, Zhang D, Lee K, Gao L (2015) Performance of AA5052 alloy anode in alkaline ethylene glycol electrolyte with dicarboxylic acids additives for aluminium-air batteries. J Power Sources 297:464–471

Wang D, Ma ZY, Gao ZM (2009) Effects of severe cold rolling on tensile properties and stress corrosion cracking of 7050 aluminum alloy. Mater Chem Phys 117(1):228–233

Ma Z, Li X (2011) The study on microstructure and electrochemical properties of Al–Mg–Sn–Ga–Pb alloy anode material for Al/AgO battery. J Solid State Electrochem 15(11-12):2601–2610

Moghadam Z, Shabani-Nooshabadi M, Behpour M (2017) Electrochemical performance of aluminium alloy in strong alkaline media by urea and thiourea as inhibitor for aluminium-air batteries. J Mol Liq 242:971–978

Mutlu RN, Ateş S, Yazıcı B (2017) Al-6013-T6 and Al-7075-T7351 alloy anodes for aluminium-air battery. Int J Hydrog Energy 42(36):23315–23325

Bessone JB, Flamini DO, Saidman SB (2005) Comprehensive model for the activation mechanism of Al–Zn alloys produced by indium. Corros Sci 47(1):95–105

Sun H, Liu L, Li Y, Ma L, Yan Y (2013) The performance of Al–Zn–In–Mg–Ti sacrificial anode in simulated deep water environment. Corros Sci 77:77–87

Keywni MRSA (2011) Optimization of manganese and magnesium contents in As-cast aluminum-zinc-indium alloy as sacrificial anode. J Mater Sci Technol 27:785–792

Doche ML, Novel-Cattin F, Durand R, Rameau JJ (1997) Characterization of different grades of aluminum anodes for aluminum/air batteries. J Power Sources 65(1-2):197–205

Ghali E (2010) Corrosion resistance of aluminum and magnesium alloys understanding, performance and testing. Corros Eng Sci Technol:8–16

Emregül KC, Aksüt AA (2000) The behavior of aluminum in alkaline media. Corros Sci 42(12):2051–2067

Tamada A, Tamura Y (1993) The electrochemical characteristics of aluminum galvanic anodes in an arctic seawater. Corros Sci 34(2):261–277

Fan L, Lu H, Leng J (2015) Performance of fine structured aluminum anodes in neutral and alkaline electrolytes for Al-air batteries. Electrochim Acta 165:22–28

Ma J, Wen J, Gao J, Li Q (2014) Performance of Al–0.5 Mg–0.02 Ga–0.1 Sn–0.5 Mn as anode for Al–air battery in NaCl solutions. J Power Sources 253:419–423

Galicia G, Pébère N, Tribollet B, Vivier V (2009) Local and global electrochemical impedances applied to the corrosion behaviour of an AZ91 magnesium alloy. Corros Sci 51(8):1789–1794

Hong T, Sun YH, Jepson WP (2002) Study on corrosion inhibitor in large pipelines under multiphase flow using EIS. Corros Sci 44(1):101–112

Salinas DR, García SG, Bessone JB (1999) Influence of alloying elements and microstructure on aluminium sacrificial anode performance: case of Al–Zn. J Appl Electrochem 29(9):1063–1071

Acknowledgements

This research is financially supported by the National Natural Science Foundation of China (Grant No. 21273058 and 21673064), China Postdoctoral Science Foundation (Grant No. 2017M621284), Heilongjiang Postdoctoral Fund (Grant No. LBH-Z17074), HIT Environment and Ecology Innovation Special Funds (Grant No. HSCJ201620), and the Research Fund of State Key Laboratory for Marine Corrosion and Protection of Luoyang Ship Material Research Institute (LSMRI) under the contract No. KF160410.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liang, R., Su, Y., Sui, XL. et al. Effect of Mg content on discharge behavior of Al-0.05Ga-0.05Sn-0.05Pb-xMg alloy anode for aluminum-air battery. J Solid State Electrochem 23, 53–62 (2019). https://doi.org/10.1007/s10008-018-4093-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-018-4093-x