Abstract

All-atomistic (AA) molecular dynamics (MD) is considered as one of the desirable methods for studying glass transition temperatures (Tg) of specific polymers. However, heavy computational efforts are generally required, and the simulated Tg values are not always in good agreement with the experimental data. In this work, a multiscale scheme is proposed: first, the structural and volumetric properties based multiscale modeling is employed to parameterize the coarse-grained (CG) potentials against the AA simulations of an oligomeric melt; with the CG potentials, MD simulations are then carried out on a serial of oligomer bulks and polymer systems of interests, for which the dynamical Tg values are determined. With poly(ethylene oxide) and poly(methyl methacrylate) as typical examples, the simulated dynamical Tg values of the oligomeric bulks exhibit a linear relation with the empirical values, which is used to determine the “actual Tg” for the polymer bulk. The so-obtained Tg is found to compare very well with the experimental data. Such a computational framework can be quite promising in investigating the effects of various complex factors on polymer Tg.

The actual Tg for a polymer can be reliably predicted by rescaling the simulated dynamical Tg.

Similar content being viewed by others

References

Bicerano J (2002) Prediction of polymer properties, third edn. Dekker, New York

van_Krevelen DW, Nijenhuis KT (2010) Properties of polymers their correlation with chemical structure; their numerical estimation and prediction from additive group contributions. Elsevier, Amsterdam

Askadskii AA (2003) Computational materials science of polymers. Cambridge International Science, Cambridge

Porter D (1995) Group interaction modelling of polymer properties. CRC, Boca Raton

Han J, Gee RH, Boyd RH (1994) Glass transition temperatures of polymers from molecular dynamics simulations. Macromolecules 27:7781–7784

Rigby D, Roe R-J (1987) Molecular dynamics simulation of polymer liquid and glass. I. Glass transition. J Chem Phys 87:7285–7292

Godey FO, Fleury A, Ghoufi A, Soldera A (2018) The extent of the glass transition from molecular simulation revealing an overcrank effect. J Comput Chem 39:255–261

Lyulin SV, Gurtovenko AA, Larin SV, Nazarychev VM, Lyulin AV (2013) Microsecond atomic-scale molecular dynamics simulations of polyimides. Macromolecules 46:6357–6363

Khare KS, Frederick R, Phelan J (2018) Quantitative comparison of atomistic simulations with experiment for a cross-linked epoxy: a specific volume-cooling rate analysis. Macromolecules 51:564–575

Tschop W, Kremer K, Batoulis J, Burger T, Hahn O (1998) Simulation of polymer melts. I. Coarse-graining procedure for polycarbonates. Acta Polym 49:61–74

Muller-Plathe F (2002) Coarse-graining in polymer simulation: from the atomistic to the mesoscopic scale and back. ChemPhysChem 3:754–769

Karimi-Varzaneh HA, Muller-Plathe F (2012) Coarse-grained modeling for macromolecular chemistry. Top Curr Chem 307:295–322

Brini E, Algaer EA, Ganguly P, Li C, RodriguezRopero F, van_der_Vegt NFA (2013) Systematic coarse-graining methods for soft matter simulations -a review. Soft Matter 9:2108–2119

Carbone P, Avendano C (2014) Coarse-grained methods for polymeric materials: Enthalpyand entropy-driven models. WIREs Comput Mol Sci 4:62–70

Ingolfsson H, Lopez CA, Uusitalo JJ, de_Jong DH, Gopal SM, Periole X, Marrink SJ (2014) The power of coarse graining in biomolecular simulations. WIREs Comput Mol Sci 4:225–248

Carbone P, Varzaneh HAK, Chen X, Müller-Plathe F (2008) Transferability of coarse-grained force fields: the polymer case. J Chem Phys 128:064904

Qian H-J, Carbone P, Chen X, Karimi-Varzaneh HA, Liew CC, Muller-Plathe F (2008) Temperature-transferable coarse-grained potentials for ethylbenzene, polystyrene, and their mixtures. Macromolecules 41:9919–9929

Hsu DD, Xia W, Arturo SG, Keten S (2014) Systematic method for thermomechanically consistent coarsegraining: a universal model for methacrylate-based polymers. J Chem Theory Comput 10:2514–2527

Yang S, Cui Z, Qu J (2014) A coarse-grained model for epoxy molding compound. J Phys Chem B 118:1660–1669

Hsu DD, Xia W, Arturo SG, Keten S (2015) Thermomechanically consistent and temperature transferable coarse-graining of atactic polystyrene. Macromolecules 48:3057–3068

Palczynski K, Wilke A, Paeschke M, Dzubiella J (2017) Molecular modeling of polycarbonate materials: glass transition and mechanical properties. Phys Rev Mat 1:043804

Xia W, Song J, Jeong C, Hsu DD, Frederick R, Phelan J, Douglas JF, Keten S (2017) Energy-renormalization for achieving temperature transferable coarse-graining of polymer dynamics. Macromolecules 50:8787–8796

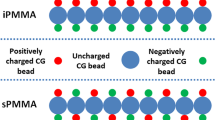

Wu C (2013) A combined scheme for systematically coarse-graining of stereoregular polymer blends. Macromolecules 46:5751–5761

Wu C (2015) Coarse-grained molecular dynamics simulations of stereoregular poly(methyl methacrylate)/poly(vinyl chloride) blends. J Polym Sci B Polym Phys 53:203–212

Wu C (2016) Phase morphologies of binary polymer blends predicted by systematically coarse-grained models. Macromol Theory Simul 25:336–347

Wu C (2018) Multiscale modeling scheme for simulating polymeric melts: application to poly(ethylene oxide). Macromol Theory Simul 27:1700066

Wu C (2017) Glass transition in single poly(ethylene oxide) chain: a molecular dynamics simulation study. J Polym Sci B Polym Phys 55:178–188

Ruhle V, Junghans C, Lukyanov A, Kremer K, Andrienko D (2009) Versatile object-oriented toolkit for coarse-graining applications. J Chem Theory Comput 5:3211–3223

van_der_Spoel D, Lindahl E, Hess B, Groenhof G, Mark AE, Berendsen HJC (2005) Gromacs: fast, flexible, and free. J Comput Chem 26:1701–1718

Hess B, Kutzner C, van_der_Spoel D, Lindahl E (2008) Gromacs 4: algorithms for highly efficient, load-balanced, and scalable molecular simulation. J Chem Theory Comput 4:435–447

Hockney RW, Goel SP, Eastwood J (1974) Quiet high resolution computer models of a plasma. J Comput Phys 14:148–158

Berendsen HJC, Postma JPM, DiNola A, Haak JR (1984) Molecular dynamics with coupling to an external bath. J Chem Phys 81:3684–3690

Doi M, Edwards SF (1986) The theory of polymer dynamics. Clarendon, Oxford

Bayramoglu B, Faller R (2012) Coarse-grained modeling of polystyrene in various environments by iterative boltzmann inversion. Macromolecules 45:9205–9219

Glova AD, Falkovich SG, Dmitrienko DI, Lyulin AV, Larin SV, Nazarychev VM, Karttunen M, Lyulin SV (2018) Scale-dependent miscibility of polylactide and polyhydroxybutyrate: molecular dynamics simulations. Macromolecules 51:552–563

Ellis B, Smith R (2009) Polymers: a property database. CRC, New York

Wu C (2011) Simulated glass transition of poly(ethylene oxide) bulk and film: a comparative study. J Phys Chem B 115:11044–11052

Wu C (2019) Bulk modulus of poly(ethylene oxide) simulated using the systematically coarse-grained model. Comput Mater Sci 156:89–95

Wu C (2017) Re-examining the procedure for simulating polymer tg using molecular dynamics. J Mod Model 23:270

Patrone PN, Dienstfrey A, Browning AR, Tucker S, Christensen S (2016) Uncertainty quantification in molecular dynamics studies of the glass transition temperature. Polymer 87:246–259

Zhou Y, Milner ST (2017) Short-time dynamics reveals tg suppression in simulated polystyrene thin films. Macromolecules 50:5599–5610

Marvin MD, Lang RJ, Simmons DS (2014) Nanoconfinement effects on the fragility of glass formation of a model freestanding polymer film. Soft Matter 10:3166–3170

Hsu DD, Xia W, Song J, Keten S (2016) Glass-transition and side-chain dynamics in thin films: explaining dissimilar free surface effects for polystyrene vs poly(methyl methacrylate). ACS Macro Lett 5:481–486

Wu R, Qiu X, Zhang T, Fu K, Yang X (2015) Atomistic molecular insight into the time dependence of polymer glass transition. J Phys Chem B 119:9959–9969

Xia W, Hsu DD, Keten S (2015) Molecular weight effects on the glass transition and confinement behavior of polymer thin films. Macromol Rapid Commun 36:1422–1427

Soldera A, Metatla N (2005) Study of the glass transition temperatures of stereoregular pmmas using different force fields. Internet Electron J Mol Des 4:721–736

Lyulin AV, Balabaev NK, Michels MAJ (2003) Molecular-weight and cooling-rate dependence of simulated tg for amorphous polystyrene. Macromolecules 36:8574–8575

Niedzwiedz K, Wischnewski A, Pyckhout-Hintzen WJ, Allgaier DR, Faraone A (2008) Chain dynamics and viscoelastic properties of poly(ethylene oxide). Macromolecules 41:4866–4872

Ellis B (2000) Polymers—a property database, edn. Chapman & Hall, Sheffield

Ute K, Miyatake N, Hatada K (1995) Glass transition temperature and melting temperature of uniform isotactic and syndiotactic poly(methyl methacrylate)s from 13mer to 50mer. Polymer 36:1415–1419

Soldera A (1998) Comparison between the glass transition temperatures of the two pmma tacticities: a moleculardynamics simulation point ofview. Macromol Symp 133:21–32

Wu C (2018) Multiscale modeling of glass transition in polymeric films: application to stereoregular poly(methyl methacrylate)s. Polymer 146:91–100

Soldera A, Metatla N (2006) Glass transition of polymers: atomistic simulation versus experiments. Phys Rev E 74:061803

Soldera A (2012) Atomistic simulations of vinyl polymers. Mol Simul 38:762–771

Hess B, Leon S, van_der_Vegt N, Kremer K (2006) Long time atomistic polymer trajectories from coarse grained simulations: bisphenol-a polycarbonate. Soft Matter 2006:409–414

Harmandaris VA, Kremer K (2009) Predicting polymer dynamics at multiple length and time scales. Soft Matter 5:3920–3926

Harmandaris VA, Kremer K (2009) Dynamics of polystyrene melts through hierarchical multiscale simulations. Macromolecules 42:791–802

Accary JB, Teboul V (2012) Time versus temperature rescaling for coarse grain molecular dynamics simulations. J Chem Phys 136:094502

Morita H, Tanaka K, Kajiyama T, Nishi T, Doi M (2006) Study of the glass transition temperature of polymer surface by coarse-grained molecular dynamics simulation. Macromolecules 39:6233–6237

Ediger MD, Forrest JA (2014) Dynamics near free surfaces and the glass transition in thin polymer films: a view to the future. Macromolecules 47:471–478

Acknowledgments

This work is financially supported by the Natural Science Foundation of Hunan Province (2017JJ2125), the Planned Science and Technology Project of Hunan Province (2016TP1028), the Innovative Research Team in Higher Educational Institute of Hunan Province, and the Talent Support Plan of Hunan University of Humanities Science & Technology (HUHST). The author is indebted to the Molecular Simulation Center of Hunan Province (situated at Hunan University), which provided the commercial software (Materials Studio-4.0) to build the initial structural models and to perform the empirical calculations, and the Laboratory for High Performance Computing (HPC) of the Key Discipline “Computer Applied Techniques” of Hunan Province (located at HUHST), which provided the generous CPU times for completing this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, C. A multiscale scheme for simulating polymer Tg. J Mol Model 24, 335 (2018). https://doi.org/10.1007/s00894-018-3867-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00894-018-3867-5