Abstract

Objectives

To compare stress distribution and failure probability in maxillary premolars restored by simple occlusal veneer (SOV) and buccal-occlusal veneer (BOV) with 3 different CAD/CAM materials.

Materials and methods

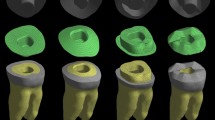

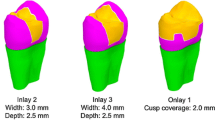

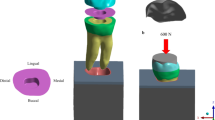

A maxillary premolar was digitized by a micro-CT scanner. Three-dimensional dynamic scan data were transformed, and finite element models of 2 different models (SOV and BOV restored teeth) were designed. Three different CAD/CAM materials, including lithium disilicate glass ceramic (LD) IPS e.max CAD, polymer-infiltrated ceramic-network (PICN) Vita Enamic, and resin nano-ceramic (RNC) Lava Ultimate, were designated to both veneers. Maximum principle stresses were determined by applying a 300-N axial load to the occlusal surface. Weibull analyses were performed to calculate the failure probability of the models.

Results

LD-restored teeth showed the highest stress in the veneer, lowest stress in substrate teeth, and lowest failure probability for the overall system; RNC-restored teeth showed the lowest stress in the veneer, highest stress in substrate teeth, and highest failure probability. No significant differences were found in the cement layer among the different models. No significant differences of stress and failure probability existed between SOV and BOV preparations.

Conclusions

CAD/CAM composite resin occlusal veneers bear lower maximum stress than ceramic veneers. Teeth restored by composite veneers are more prone to failure than those restored by ceramic veneers. Additional reduction of the buccal surface did not increase the stress on the occlusal veneer under axial load.

Clinical relevance

Both occlusal veneers could be used under physiological masticatory force. CAD/CAM glass ceramic was safer than composite resins.

Similar content being viewed by others

References

van Dijken JW, Hasselrot L (2010) A prospective 15-year evaluation of extensive dentin-enamel-bonded pressed ceramic coverages. Dent Mater 26:929–939. https://doi.org/10.1016/j.dental.2010.05.008

Sasse M, Krummel A, Klosa K, Kern M (2015) Influence of restoration thickness and dental bonding surface on the fracture resistance of full-coverage occlusal veneers made from lithium disilicate ceramic. Dent Mater 31:907–915. https://doi.org/10.1016/j.dental.2015.04.017

Schlichting LH, Maia HP, Baratieri LN, Magne P (2011) Novel-design ultra-thin CAD/CAM composite resin and ceramic occlusal veneers for the treatment of severe dental erosion. J Prosthet Dent 105:217–226. https://doi.org/10.1016/S0022-3913(11)60035-8

Zhu J, Rong Q, Wang X, Gao X (2017) Influence of remaining tooth structure and restorative material type on stress distribution in endodontically treated maxillary premolars: a finite element analysis. J Prosthet Dent 117:646–655. https://doi.org/10.1016/j.prosdent.2016.08.023

Duan Y, Griggs JA (2015) Effect of elasticity on stress distribution in CAD/CAM dental crowns: glass ceramic vs. polymer-matrix composite. J Dent 43:742–749. https://doi.org/10.1016/j.jdent.2015.01.008

Lambert H, Durand JC, Jacquot B, Fages M (2017) Dental biomaterials for chairside CAD/CAM: state of the art. J Adv Prosthodont 9:486–495. https://doi.org/10.4047/jap.2017.9.6.486

Belli R, Wendler M, de Ligny D, Cicconi MR, Petschelt A, Peterlik H et al (2017) Chairside CAD/CAM materials. Part 1: measurement of elastic constants and microstructural characterization. Dent Mater 33:84–98. https://doi.org/10.1016/j.dental.2016.10.009

Wendler M, Belli R, Petschelt A, Mevec D, Harrer W, Lube T et al (2017) Chairside CAD/CAM materials. Part 2: flexural strength testing. Dent Mater 33:99–109. https://doi.org/10.1016/j.dental.2016.10.008

de Kok P, Pereira G, Fraga S, de Jager N, Venturini AB, Kleverlaan CJ (2017) The effect of internal roughness and bonding on the fracture resistance and structural reliability of lithium disilicate ceramic. Dent Mater 33:1416–1425. https://doi.org/10.1016/j.dental.2017.09.018

Pieger S, Salman A, Bidra AS (2014) Clinical outcomes of lithium disilicate single crowns and partial fixed dental prostheses: a systematic review. J Prosthet Dent 112:22–30. https://doi.org/10.1016/j.prosdent.2014.01.005

Reich S, Schierz O (2013) Chair-side generated posterior lithium disilicate crowns after 4 years. Clin Oral Investig 17:1765–1772. https://doi.org/10.1007/s00784-012-0868-0

El ZA, De Gee AJ, Mohsen MM, Feilzer AJ (2003) Microtensile bond strength testing of luting cements to prefabricated CAD/CAM ceramic and composite blocks. Dent Mater 19:575–583. https://doi.org/10.1016/S0109-5641(02)00107-0

Goujat A, Abouelleil H, Colon P, Jeannin C, Pradelle N, Seux D et al (2018) Mechanical properties and internal fit of 4 CAD-CAM block materials. J Prosthet Dent 119:384–389. https://doi.org/10.1016/j.prosdent.2017.03.001

Lauvahutanon S, Takahashi H, Shiozawa M, Iwasaki N, Asakawa Y, Oki M et al (2014) Mechanical properties of composite resin blocks for CAD/CAM. Dent Mater J 33:705–710. https://doi.org/10.4012/dmj.2014-208

Coldea A, Swain MV, Thiel N (2013) Mechanical properties of polymer-infiltrated-ceramic-network materials. Dent Mater 29:419–426. https://doi.org/10.1016/j.dental.2013.01.002

Sonmez N, Gultekin P, Turp V, Akgungor G, Sen D, Mijiritsky E (2018) Evaluation of five CAD/CAM materials by microstructural characterization and mechanical tests: a comparative in vitro study. BMC Oral Health 18:5. https://doi.org/10.1186/s12903-017-0458-2

Bernhardt O, Gesch D, Schwahn C, Mack F, Meyer G, John U et al (2006) Epidemiological evaluation of the multifactorial aetiology of abfractions. J Oral Rehabil 33:17–25. https://doi.org/10.1111/j.1365-2842.2006.01532.x

Peumans M, Van Meerbeek B, Lambrechts P, Vanherle G (2000) Porcelain veneers: a review of the literature. J Dent 28:163–177. https://doi.org/10.1016/S0300-5712(99)00066-4

Motta AB, Pereira LC, Duda FP, Anusavice KJ (2014) Influence of substructure design and occlusal reduction on the stress distribution in metal ceramic complete crowns: 3D finite element analysis. J Prosthodont 23:381–389. https://doi.org/10.1111/jopr.12119

Sato Y, Yuasa Y, Abe Y, Akagawa Y (1995) Finite element and Weibull analysis to estimate failure risk in resin-bonded retainers. Int J Prosthodont 8:73–78 http://europepmc.org/abstract/MED/7710630

Kelly JR, Tesk JA, Sorensen JA (1995) Failure of all-ceramic fixed partial dentures in vitro and in vivo: analysis and modeling. J Dent Res 74:1253–1258. https://doi.org/10.1177/00220345950740060301

Arat BS, Baykasoglu C, Bilhan H, Kutay O, Mugan A (2015) Effect of attachment types and number of implants supporting mandibular overdentures on stress distribution: a computed tomography-based 3D finite element analysis. J Biomech 48:130–137. https://doi.org/10.1016/j.jbiomech.2014.10.022

Lin CL, Chang YH, Pa CA (2009) Estimation of the risk of failure for an endodontically treated maxillary premolar with MODP preparation and CAD/CAM ceramic restorations. J Endod 35:1391–1395. https://doi.org/10.1016/j.joen.2009.06.020

Magne P, Stanley K, Schlichting LH (2012) Modeling of ultrathin occlusal veneers. Dent Mater 28:777–782. https://doi.org/10.1016/j.dental.2012.04.002

Nasrin S, Katsube N, Seghi RR, Rokhlin SI (2017) Survival predictions of ceramic crowns using statistical fracture mechanics. J Dent Res 96:509–515. https://doi.org/10.1177/0022034516688444

Celebi AT, Icer E, Eren MM, Baykasoglu C, Mugan A, Yildiz E (2017) Thermal-stress analysis of ceramic laminate veneer restorations with different incisal preparations using micro-computed tomography-based 3D finite element models. J Mech Behav Biomed Mater 75:302–313. https://doi.org/10.1016/j.jmbbm.2017.07.039

Dejak B, Mlotkowski A (2008) Three-dimensional finite element analysis of strength and adhesion of composite resin versus ceramic inlays in molars. J Prosthet Dent 99:131–140. https://doi.org/10.1016/S0022-3913(08)60029-3

Hidaka O, Iwasaki M, Saito M, Morimoto T (1999) Influence of clenching intensity on bite force balance, occlusal contact area, and average bite pressure. J Dent Res 78:1336–1344. https://doi.org/10.1177/00220345990780070801

Gonzaga CC, Cesar PF, Miranda WJ, Yoshimura HN (2011) Slow crack growth and reliability of dental ceramics. Dent Mater 27:394–406. https://doi.org/10.1016/j.dental.2010.10.025

Shahrbaf S, Van Noort R, Mirzakouchaki B, Ghassemieh E, Martin N (2013) Effect of the crown design and interface lute parameters on the stress-state of a machined crown-tooth system: a finite element analysis. Dent Mater 29:e123–e131. https://doi.org/10.1016/j.dental.2013.04.002

Qian L, Todo M, Morita Y, Matsushita Y, Koyano K (2009) Deformation analysis of the periodontium considering the viscoelasticity of the periodontal ligament. Dent Mater 25:1285–1292. https://doi.org/10.1016/j.dental.2009.03.014

Daher R, Feilzer AJ, Krejci I (2016) Novel non-invasive reinforcement of MOD cavities on endodontically treated teeth. J Dent 54:77–85. https://doi.org/10.1016/j.jdent.2016.09.008

Rodrigues RF, Ramos CM, Francisconi PA, Borges AF (2015) The shear bond strength of self-adhesive resin cements to dentin and enamel: an in vitro study. J Prosthet Dent 113:220–227. https://doi.org/10.1016/j.prosdent.2014.08.008

Ozturk E, Bolay S, Hickel R, Ilie N (2013) Shear bond strength of porcelain laminate veneers to enamel, dentine and enamel-dentine complex bonded with different adhesive luting systems. J Dent 41:97–105. https://doi.org/10.1016/j.jdent.2012.04.005

Morimoto S, Rebello DSF, Braga MM, Sesma N, Ozcan M (2016) Survival rate of resin and ceramic inlays, onlays, and overlays: a systematic review and meta-analysis. J Dent Res 95:985–994. https://doi.org/10.1177/0022034516652848

Vanoorbeek S, Vandamme K, Lijnen I, Naert I (2010) Computer-aided designed/computer-assisted manufactured composite resin versus ceramic single-tooth restorations: a 3-year clinical study. Int J Prosthodont 23:223–230 http://europepmc.org/abstract/MED/20552087

Sorrentino R, Apicella D, Riccio C, Gherlone E, Zarone F, Aversa R et al (2009) Nonlinear visco-elastic finite element analysis of different porcelain veneers configuration. J Biomed Mater Res B Appl Biomater 91:727–736. https://doi.org/10.1002/jbm.b.31449

Barao VA, Delben JA, Lima J, Cabral T, Assuncao WG (2013) Comparison of different designs of implant-retained overdentures and fixed full-arch implant-supported prosthesis on stress distribution in edentulous mandible--a computed tomography-based three-dimensional finite element analysis. J Biomech 46:1312–1320. https://doi.org/10.1016/j.jbiomech.2013.02.008

Funding

This study was supported by the Sun Yat-sen University Clinical Research 5010 Programme (grant number 2016006).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

All procedures performed in studies involving human participants were in accordance with the ethical standards of the institutional and/or national research committee and with the 1964 Helsinki declaration and its later amendments or comparable ethical standards.

Informed consent

Informed consent was obtained from all individual participants included in the study.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, Xq., Hong, Nr., Zou, Ly. et al. Estimation of stress distribution and risk of failure for maxillary premolar restored by occlusal veneer with different CAD/CAM materials and preparation designs. Clin Oral Invest 24, 3157–3167 (2020). https://doi.org/10.1007/s00784-019-03190-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00784-019-03190-7