Abstract

Objectives

To investigate the surface roughness of CAD/CAM materials immediately after milling and after different chairside and labside polishing procedures. A two-body wear test was performed to compare the different wear characteristics of the materials and the corresponding antagonists.

Materials and methods

Specimens (n = 12 per series) from different CAD/CAM materials (three composites: Lava Ultimate, Cerasmart, BRILLIANT Crios; one hybrid ceramic: VITA Enamic; three ceramics: Celtra Duo, VITA Suprinity, IPS Emax.CAD) were polished according to the manufacturer’s instructions. The effect of different polishing procedures was investigated by comparing surface roughness (Ra, Rmax) after labside polishing and after chairside polishing. Wear behavior (mean, volume, and maximum wear) of specimens and antagonists as well as changes in surface roughness were determined in a pin-on-block wear test. Statistical analysis was performed with a one-way analysis of variance (ANOVA)/Bonferroni multiple-comparison post hoc test and a multifactorial ANOVA/Tukey’s significant difference post hoc test (α = 0.05). SEM micrographs were used for the qualitative evaluation of surfaces and wear traces.

Results

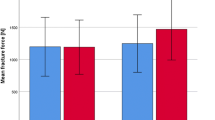

After chairside high-gloss polishing, ceramics and composites exhibited Ra values between 0.08 and 0.10 μm and between 0.11 and 0.13 μm, respectively. After labside high-gloss polishing, values varied between 0.02 and 0.09 μm for ceramics and between 0.06 and 0.16 μm for resin composites. No significant differences were found between labside and chairside pre- and high-gloss polishing. For the ceramics, lower mean wear depths (between − 132.2 ± 19.9 and − 137.0 ± 19.0 μm) were identified compared to the resin composites (which exhibited wear depths between − 159.1 ± 19.4 and − 176.3 ± 23.9 μm). For maximum wear depth and volume, a different ranking of the materials was found. Antagonistic wear varied between 12.0 ± 6.4% and 30.6 ± 9.9% and was higher for the ceramic materials and Lava Ultimate. For all materials, a smoothing between 0.20 and 2.70 μm (Ra) was identified after wear simulation.

Conclusions

Chairside polishing is as effective as labside polishing, although surfaces were directly adjusted (roughened) only before the chairside polishing. Wear was lowest for ceramics, followed by the resin-infiltrated material and the resin composites.

Clinical relevance

Polishing after milling or adjustment is essential to guaranteeing optimal clinical performance. Chairside polishing after adjustment leads to comparably smooth surfaces as labside polishing after milling and grinding. Ceramics are expected to exhibit lower wear than resin composites under clinical conditions.

Similar content being viewed by others

References

Rekow ED (2006) Dental CAD/CAM systems: a 20-year success story. J Am Dent Assoc 137:5–6

Conrad HJ, Seong WJ, Pesun IJ (2007) Current ceramic materials and systems with clinical recommendations: a systematic review. J Prosthet Dent 98:389–404

Nguyen JF, Migonney V, Ruse ND, Sadoun M (2012) Resin composite blocks via high-pressure high-temperature polymerization. Dent Mater 28:529–534

Kunzelmann KH, Jelen B, Mehl A, Hickel R (2001) Wear evaluation of MZ100 compared to ceramic CAD/CAM materials. Int J Comput Dent 4:171–184

Sripetchdanond J, Leevailoj C (2014) Wear of human enamel opposing monolithic zirconia, glass ceramic, and composite resin: an in vitro study. J Prosthet Dent 112:1141–1150

Ghazal M, Hedderich J, Kern M (2008) Wear of feldspathic ceramic, nano-filled composite resin and acrylic resin artificial teeth when opposed to different antagonists. Eur J Oral Sci 116:585–592

Belli R, Wendler M, Ligny D, Cicconi MR, Petschelt A, Peterlik H, Lohbauer U (2017) Chairside CAD/CAM materials. Part 1: measurement of elastic constants and microstructural characterization. Dent Mater 33:84–98

Fasbinder DJ (2006) Clinical performance of chairside CAD/CAM restorations. J Am Dent Assoc 137:22–31

Fasbinder DJ, Neiva GF (2016) Surface evaluation of polishing techniques for new resilient CAD/CAM restorative materials. J Esthet Restor Dent 28:56–66

Oliveira-Junior OB, Buso L, Fujiy FH et al (2013) Influence of polishing procedures on surface roughness of dental ceramics made by different techniques. Gen Dent 61:4–8

Bollen CML, Lambrechts P, Quirynen M (1997) Comparison of surface roughness of oral hard materials to the threshold surface roughness for bacterial plaque retention: a review of the literature. Dent Mater 13:258–269

Anusavice KJ, Kakar K, Ferree N (2007) Which mechanical and physical testing methods are relevant for predicting the clinical performance of ceramic-based dental prostheses? Clin Oral Implants Res 18:218–231

de Jager N, Feilzer AJ, Davidson CL (2000) The influence of surface roughness on porcelain strength. Dent Mater 16:381–388

Preis V, Behr M, Handel G, Schneider-Feyrer S, Hahnel S, Rosentritt M (2012) Wear performance of dental ceramics after grinding and polishing treatments. J Mech Behav Biomed Mater 10:13–22

Heintze SD, Cavalleri A, Forjanic M, Zellweger G, Rousson V (2008) Wear of ceramic and antagonist–a systematic evaluation of influencing factors in vitro. Dent Mater 24:433–449

Jefferies SR (2007) Abrasive finishing and polishing in restorative dentistry: a state-of-the-art review. Dent Clin N Am 51:380–381

Tsujimoto A, Barkmeier WW, Takamizawa T, Latta MA, Miyazaki M (2017) Influence of thermal cycling on flexural properties and simulated wear of computer-aided design/computer-aided manufacturing resin composites. Oper Dent 42:101–110

Lawson NC, Bansal R, Burgess JO (2016) Wear, strength, modulus and hardness of CAD/CAM restorative materials. Dent Mater 32:275–283

Rosentritt M, Hahnel S, Engelhardt F, Behr M, Preis V (2016) In vitro performance and fracture resistance of CAD/CAM-fabricated implant supported molar crowns. Clin Oral Invest 4:1213–1219

Wendler M, Belli R, Petschelt A, Mevec D, Harrer W, Lube T, Danzer R, Lohbauer U (2017) Chairside CAD/CAM materials. Part 2: flexural strength testing. Dent Materials 33:99–109

Mota EG, Nunes LS, Fracasso SM, Burnett LH Jr, Spohr AM (2017) The effect of milling and postmilling procedures on the surface roughness of CAD/CAM materials. J Esthet Restor Dent 29:450–458

Alao A-R, Stoll R, Song X-F, Abbott JR, Zhang Y, Abduo J, Yin L (2017) Fracture, roughness and phase transformation in CAD/CAM milling and subsequent surface treatments of lithium metasilicate/disilicate glass-ceramics. J Mech Behav Biomed Mater 74:251–260

Curran P, Cattani-Lorente M, Wiskott HWA, Durual S, Scherrer SS (2016) Grinding damage assessment for CAD-CAM restorative materials. Dent Mater 33:294–308

Mohammadibassir M, Rezvani MB, Golzari H, Moravej Salehi E, Fahimi MA, Kharazi Fard MJ (2017) Effect of two polishing systems on surface roughness, topography, and flexural strength of a monolithic lithium disilicate ceramic. Int J Prosthodont:1–9

Aykent F, Yondem I, Ozyesil AG, Gunal SK, Avunduk MC, Ozkan S (2010) Effect of different finishing techniques for restorative materials on surface roughness and bacterial adhesion. J Prosthet Dent 103:221–227

Flury S, Lussi A, Zimmerli B (2010) Performance of different polishing techniques for direct CAD/CAM ceramic restorations. Oper Dent 35:470–481

Zhi L, Bortolotto T, Krejci I (2016) Comparative in vitro wear resistance of CAD/CAM composite resin and ceramic materials. J Prosthet Dent 115:199–202

D’Arcangelo C, Vanini L, Rondoni GD, De Angelis F (2016) Wear properties of dental ceramics and porcelains compared with human enamel. J Prosthet Dent 115:350–355

Lauvahutanon S, Takahashi H, Oki M, Arksornnukit M, Kanehira M, Finger WJ (2015) In vitro evaluation of the wear resistance of composite resin blocks for CAD/CAM. Dent Mater J 34:495–502

Heintze SD (2006) How to qualify and validate wear simulation devices and methods. Dent Mater 22:712–734

Rosentritt M, Behr M, Gebhard R, Handel G (2006) Influence of stress simulation parameters on the fracture strength of all-ceramic fixed-partial dentures. Dent Mater 22:176–182

Yoshimora M (1988) Phase stability zirconia. Am Ceram Soc Bull 67:1950–1955

Bl A (2002) Transformation-toughened zirconia for dental inlays, crowns and bridges: chemical stability and effect of low temperature aging on flexual strength and surface structure. Dent Mater 18:590–595

Ferracane JL, Berge HX, Condon JR (1998) In vitro aging of dental composites in water—effect of degree of conversion, filler volume, and filler/matrix coupling. J Biomed Mater Res B Appl Biomater 42:465–472

Druck CC, Pozzobon JL, Callegari GL, Dorneles LS, Valandro LF (2015) Adhesion to Y-TZP ceramic: study of silica nanofilm coating on the surface of Y-TZP. J Biomed Mater Res B Appl Biomater 103:143–150

Swain MV, Coldea A, Bilkhair A, Guess PC (2016) Interpenetrating network ceramic-resin composite dental restorative materials. Dent Mater 32:34–42

Samuel SP, Li S, Mukherjee I, Guo Y, Patel AC, Baran G, Wei Y (2009) Mechanical properties of experimental dental composites containing a combination of mesoporous and nonporous spherical silica as fillers. Dent Mater 25:296–301

Oliveira GU, Mondelli RF, Charantola Rodrigues M, Franco EB, Ishikiriama SK, Wang L (2012) Impact of filler size and distribution on roughness and wear of composite resin after simulated toothbrushing. J Appl Oral Sci 20:510–516

Bayne SC, Taylor DF, Heymann HO (1994) Protection hypothesis for composite wear. Dent Mater 8:305–309

Sumino N, Tsubota K, Takamizawa T, Shiratsuchi K, Miyazaki M, Latta MA (2013) Comparison of the wear and flexural characteristics of flowable resin composites for posterior lesions. Acta Odontol Scand 71:820–827

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

For this type of study, formal consent is not required.

Rights and permissions

About this article

Cite this article

Matzinger, M., Hahnel, S., Preis, V. et al. Polishing effects and wear performance of chairside CAD/CAM materials. Clin Oral Invest 23, 725–737 (2019). https://doi.org/10.1007/s00784-018-2473-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00784-018-2473-3