Abstract

A new category of structural metals with high strength and good ductility is coarse-grained metals strengthened by nanotwinned (NT) regions. This unique combination makes them particularly suitable for applications in bulletproof targets. The extent of this improvement, however, depends on the volume fraction of the NT regions and multiple other microstructural features. Here, a numerical model based on the strain gradient plasticity and the Johnson–Cook failure criterion is developed to study the effects of these attributes. The ballistic performance is quantified by two indices: the limit velocity that measures its ability to resist failure and the limit displacement that measures its ability to resist deformation. The results obtained indicate that, in general, a relatively small twin spacing and a moderate volume fraction of NT regions can achieve both excellent limit velocity and limit displacement. Moreover, array-arranged NT regions are more effective than staggered NT regions in enhancing the limit velocity, but the influence of the array group tends to depend more on the volume fraction of NT regions than the latter one. Mechanism analyses based on the three stages of the impact process and two categories of low-speed impact are performed. The simulated results could provide significant insights into the NT structures for a superior class of nanotwin-strengthened metals for ballistic protection.

Similar content being viewed by others

References

Nobili, A., Radi, E., Lanzoni, L.: On the effect of the backup plate stiffness on the brittle failure of a ceramic armor. Acta Mech. 227, 159–172 (2016)

Buchely, M.F., Maranon, A.: An engineering model for the penetration of a rigid-rod into a Cowper–Symonds low-strength material. Acta Mech. 226, 2999–3010 (2015)

Kumar, S., Gupta, D.S., Singh, I., Sharma, A.: Behavior of Kevlar/epoxy composite plates under ballistic impact. J. Reinf. Plast. Compos. 29, 2048–2064 (2010)

Sun, L.Y., Gibson, R.F., Gordaninejad, F., Suhr, J.: Energy absorption capability of nanocomposites: A review. Compos. Sci. Technol. 69, 2392–3409 (2009)

Erkendirci, O.F., Haque, B.Z.: Quasi-static penetration resistance behavior of glass fiber reinforced thermoplastic composites. Compos. Part B Eng. 43, 3391–3405 (2012)

Jin, L.M., Hu, H., Sun, B.Z., Gu, B.H.: A simplified microstructure model of bi-axial warp-knitted composite for ballistic impact simulation. Compos. Part B Eng. 41, 337–353 (2010)

Shokrieh, M.M., Javadpour, G.H.: Penetration analysis of a projectile in ceramic composite armor. Compos. Struct. 82, 269–276 (2008)

Tan, P.: Numerical simulation of the ballistic protection performance of a laminated armor system with pre-existing debonding/delamination. Compos. Part B Eng. 59, 50–59 (2014)

Jena, P.K., Ramanjeneyulu, K., Kumar, K.S., Bhat, T.B.: Ballistic studies on layered structures. Mater. Des. 30, 1922–1929 (2009)

Ubeyli, M., Deniz, H., Demir, T., Ogel, B., Gurel, B., Keles, O.: Ballistic impact performance of an armor material consisting of alumina and dual phase steel layers. Mater. Des. 32, 1565–1570 (2011)

Guo, X., Sun, X., Tian, X., Weng, G.J., Ouyang, Q.D., Zhu, L.L.: Simulation of ballistic performance of a two-layered structure of nanostructured metal and ceramic. Compos. Struct. 157, 163–173 (2016)

Yuan, C., Qin, Q., Wang, T.J.: Simplified analysis of large deflection response of a metal sandwich beam subjected to impulsive loading. Acta Mech. 226, 3639–3651 (2015)

Ma, E.: Eight routes to improve the tensile ductility of bulk nanostructured metals and alloys. JOM 58, 49–53 (2006)

Lu, L., Chen, X., Huang, X., Lu, K.: Revealing the maximum strength in nanotwinned copper. Science 323, 607–610 (2009)

Lu, K., Lu, L., Suresh, S.: Strengthening materials by engineering coherent internal boundaries at the nanoscale. Science 324, 349–352 (2009)

Chen, A.Y., Liu, J.B., Wang, H.T., Lu, J., Wang, Y.M.: Gradient twinned 304 stainless steels for high strength and high ductility. Mater. Sci. Eng. A 667, 179–188 (2016)

Dao, M., Lu, L., Asaro, R., Hosson, J.D., Ma, E.: Toward a quantitative understanding of mechanical behavior of nanocrystalline metals. Acta Mater. 55, 4041–4065 (2007)

Sennour, M., Korinek, S.L., Champion, Y., Hytch, M.J.: HRTEM study of defects in twin boundaries of ultra-fine grained copper. Philos. Mag. 87, 1465–1486 (2007)

Qin, E.W., Lu, L., Tao, N.R., Tan, J., Lu, K.: Enhanced fracture toughness and strength in bulk nanocrystalline Cu with nanoscale twin bundles. Acta Mater. 57, 6215–6225 (2009)

Wang, G., Jiang, Z., Lian, J.: Enhanced tensile ductility in an electrodeposited Cu with nano-sized growth twins. Int. J. Mod. Phys. B 24, 2537–2542 (2010)

Zhang, Y., Tao, N.R., Lu, K.: Mechanical properties and rolling behaviors of nano-grained copper with embedded nano-twin bundles. Acta Mater. 56, 2429–2440 (2008)

Li, Y.S., Zhang, Y., Tao, N.R., Lu, K.: Effect of thermal annealing on mechanical properties of a nanostructured copper prepared by means of dynamic plastic deformation. Scr. Mater. 59, 475–478 (2008)

Xiao, G.H., Tao, N.R., Lu, K.: Strength–ductility combination of nanostructured Cu–Zn alloy with nanotwin bundles. Scr. Mater. 65, 119–122 (2011)

Lu, K., Yan, F.K., Wang, H.T., Tao, N.R.: Strengthening austenitic steels by using nanotwinned austenitic grains. Scr. Mater. 66, 878–883 (2012)

Yan, F.K., Liu, G.Z., Tao, N.R., Lu, K.: Strength and ductility of 316L austenitic stainless steel strengthened by nano-scale twin bundles. Acta Mater. 60, 1059–1071 (2012)

Wang, H.T., Tao, N.R., Lu, K.: Strengthening an austenitic Fe–Mn steel using nanotwinned austenitic grains. Acta Mater. 60, 4027–4040 (2012)

Liu, G.Z., Tao, N.R., Lu, K.: 316L Austenite stainless steels strengthened by means of nano-scale twins. J. Mater. Sci. Technol. 26, 289–292 (2010)

Zhang, Z.B., Mishin, O.V., Tao, N.R., Pantleon, W.: Microstructure and annealing behavior of a modified 9Cr–1Mo steel after dynamic plastic deformation to different strains. J. Nucl. Mater. 458, 64–69 (2015)

Yi, H.Y., Yan, F.K., Tao, N.R., Lu, K.: Comparison of strength–ductility combinations between nanotwinned austenite and martensite–austenite stainless steels. Mater. Sci. Eng. A 647, 152–156 (2015)

Frontan, J., Zhang, Y., Dao, M., Lu, J., Galvez, F., Jerusalem, A.: Ballistic performance of nanocrystalline and nanotwinned ultrafine crystal steel. Acta Mater. 60, 1353–1367 (2012)

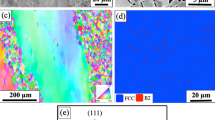

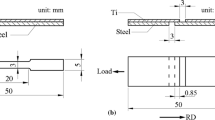

Yang, G., Guo, X., Weng, G.J., Zhu, L.L., Ji, R.: Simulation of ballistic performance of coarse-grained metals strengthened by nanotwinned regions. Model. Simul. Mater. Sci. Eng. 23, 085009 (2015)

Guo, X., Ji, R., Weng, G.J., Zhu, L.L., Lu, J.: Computer simulation of strength and ductility of nanotwin-strengthened coarse-grained metals. Model. Simul. Mater. Sci. Eng. 22, 075014 (2014)

Guo, X., Ouyang, Q.D., Weng, G.J., Zhu, L.L.: The direct and indirect effects of nanotwin volume fraction on the strength and ductility of coarse-grained metals. Mater. Sci. Eng. A 657, 234–243 (2016)

ABAQUS/Explicit, ABAQUS Theory Manual and User’s Manual, version 6.10. Dassault, Providence, RI (2013)

Li, J.J., Soh, A.K.: Modeling of the plastic deformation of nanostructured materials with grain size gradient. Int. J. Plast. 39, 88–102 (2012)

Liu, J.X., Soh, A.K.: Strain gradient elasto-plasticity with a new Taylor-based yield function. Acta Mech. 227, 3031–3048 (2016)

Zhu, L.L., Ruan, H.H., Li, X.Y., Dao, M., Gao, H.J., Lu, J.: Modeling grain size dependent optimal twin spacing for achieving ultimate high strength and related high ductility in nanotwinned metals. Acta Mater. 59, 5544–5557 (2011)

Xie, Q.J., Zhu, Z.W., Kang, G.Z.: Dislocation-dynamics-based dynamic constitutive model of magnesium alloy. Acta Mech. 228, 1415–1422 (2017)

Johnson, G.R., Cook, W.H.: A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. In: Proceedings of the 7th International Symposium on Ballistics, The Hague, The Netherlands (1983)

Johnson, G.R., Cook, W.H.: Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 21, 31–48 (1985)

Dabboussi, W., Nemes, J.A.: Modeling of ductile fracture using the dynamic punch test. Int. J. Mech. Sci. 47, 1282–1299 (2005)

Gao, H., Huang, Y., Nix, W.D., Hutchinson, J.W.: Mechanism-based strain gradient plasticity—I. Theory. J. Mech. Phys. Solids 47, 1239–1263 (1999)

Huang, Y., Qu, S., Hwang, K.C., Li, M., Gao, H.J.: A conventional theory of mechanism-based strain gradient plasticity. Int. J. Plast. 20, 753–782 (2004)

Kocks, U.F., Mecking, H.: Physics and phenomenology of strain hardening: the FCC case. Prog. Mater. Sci. 48, 171–273 (2003)

Lu, L., Schwaiger, R., Shan, Z.W., Dao, M., Lu, K., Suresh, S.: Nano-sized twins induce high rate sensitivity of flow stress in pure copper. Acta Mater. 53, 2169–2179 (2005)

Zhang, X., Wang, H., Chen, X.H., Lu, L., Lu, K., Hoagland, R.G., Misra, A.: High-strength sputter-deposited Cu foils with preferred orientation of nanoscale growth twins. Appl. Phys. Lett. 88, 173116 (2006)

Tadmor, E.B., Bernstein, N.: A first-principles measure for the twinnability of FCC metals. J. Mech. Phys. Solids 52, 2507–2519 (2004)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ouyang, Q.D., Soh, A.K., Weng, G.J. et al. The limit velocity and limit displacement of nanotwin-strengthened metals under ballistic impact. Acta Mech 229, 1741–1757 (2018). https://doi.org/10.1007/s00707-017-2062-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-017-2062-6