Abstract

An incremental crack extension procedure is implemented for simulating the growth of an interface defect in an electronic flip-chip device subjected to fatigue temperature cycling. The distributions of fracture mechanics parameters including the strain energy release rate, the stress intensity factors and phase angles along the curvilinear front of an embedded corner defect on the interface of silicon die and underfill are estimated and substituted into a subcritical crack growth model to predict the evolution of the defect under cyclic loading condition. It is observed from the analysis that the corner defect is under crack faces contact condition during temperature cycling, and consequently, the delamination growth is under mode-II and mode-III driving forces. In addition, the crack growth rate is highest in the middle of the crack front, and the corner crack evolves from an initially concave front to a quarter-circular front under temperature cycling.

Similar content being viewed by others

References

Nied H.F.: Mechanics of interface with applications in electronic packaging. IEEE Trans. Device Mater. Reliab. 3, 129–143 (2003)

Jakschik, S., Feustel, F., Meusel, E.: Mechanism and growth rate of underfill delaminations in flip chips. In: Proceedings of the 51st Electronic Components and Technology Conference (ECTC 2001), pp. 98–103. Orlando, Florida (2001)

Wang, B., Sun, X., Fan, Q.S., Yin, Y.: Numerical simulation of interfacial delamination in electronic packaging. In: Proceedings of the 7th Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITHERM 2000), vol. 1, pp. 400–404. Las Vegas, Nevada (2000)

Lau J.H., Lee S.-W.R., Chang C.: Effects of underfill material properties on the reliability of solder bumped flip chip on board with imperfect underfill encapsulants. IEEE Trans. Compon. Packag. Technol. 23, 323–333 (2000)

Zhai C.J., SidharthBlish R.C. II, Master R.N.: Investigation and minimization of underfill delamination in flip chip packages. IEEE Trans. Device Mater. Reliab. 4, 86–91 (2004)

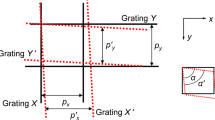

Ozkan, U., Nied, H.F.: Finite element based three dimensional crack propagation simulation on interfaces in electronic packages. In: Proceedings of the 58th electronic components and technology conference (ECTC 2008), pp. 1606–1613. Lake Buena Vista, Florida (2008)

Chiu T.-C., Lin H.-C.: Analysis of stress intensity factors for three-dimensional interface crack problems in electronic packages using the virtual crack closure technique. Int. J. Fract. 156, 75–96 (2009)

Paris P.C., Erdogan F.: A critical analysis of crack propagation laws. J. Basic Eng. 85, 528–534 (1963)

Rybicki E.F., Kanninen M.F.: A finite element calculation of stress intensity factors by a modified crack closure integral. Eng. Fract. Mech. 9, 931–938 (1977)

Shivakumar K.N., Tan P.W., Newman J.C. Jr: A virtual crack closure technique for calculating stress intensity factors for cracked three dimensional bodies. Int. J. Fract. 36, R43–R50 (1988)

Raju, I.S.: Simple formulas for strain-energy release rates with higher order and singular finite elements. NASA/CR-1986-178186 (1986)

De Roeck G., AbdelWahab M.M.: Strain energy release rate formulae for 3D finite element. Eng. Fract. Mech. 50, 569–580 (1995)

Chiu T.-C., Chen C.-H.: A numerical procedure for simulating delamination growth on interfaces of interconnect structures. Microelectron. Reliab. 52, 1464–1474 (2012)

Rice J.R.: Elastic fracture mechanics concepts for interfacial cracks. J. Appl. Mech. 55, 98–103 (1988)

ANSYS, Ver. 11, ANSYS, Inc. Canonsburg, Pennsylvania (2007)

Rahim M.K., Suhling J.C., Copeland D.S., Islam M.S., Jaeger R.C., Lall P., Johnson R.W.: Die stress characterization in flip chip on laminate assemblies. IEEE Trans. Compon. Packag. Technol. 28, 415–429 (2005)

Zhu, S.-W., Shih, C.-P., Chiu, T.-C., Shen, G.S.: Delamination fracture characteristics for polyimide-related interfaces under fatigue loadings. In: Proceedings of the 5th International Microsystems, Packaging, Assembly and Circuits Technology Conference (IMPACT 2010). Taipei, Taiwan, TW076-1 (2010)

Author information

Authors and Affiliations

Corresponding author

Additional information

Presented at the Third Asian Conference on Mechanics of Functional Materials and Structures at the Indian Institute of Technology Delhi in New Delhi, India, December 5–8, 2012.

Rights and permissions

About this article

Cite this article

Lai, YS., Chen, CH. & Chiu, TC. Analysis of fatigue delamination growth in flip-chip package. Acta Mech 225, 2761–2773 (2014). https://doi.org/10.1007/s00707-014-1201-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-014-1201-6