Abstract

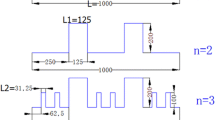

The application of micromixer in many fields is becoming more and more important, and lots of researchers have proposed different designs. In this paper, in order to improve the efficiency of the micromixer, we propose a novel fractal micromixer based on Cantor fractal principle. The mixing performance of the device is investigated by numerical simulation. We discuss the influence of primary fractal obstacle and secondary fractal obstacle (SFO) on the mixing efficiency. And we compare two micromixers: SFO micromixer and TFO (third fractal obstacle) micromixer. When Re > 10, their mixing efficiency can be more than 90%. Then, the effects of SFO and TFO on the mixing efficiency are deeply studied. We compare the velocity streamline and velocity cross section of the fluid, and analyze the effect of SFO on the concentration trend. The results reveal that SFO can effectively improve the mixing efficiency. SFO can break the laminar flow, and it makes the fluid more likely to produce mixing convection and can increase the contact area of the fluid by folding and deflecting.

Similar content being viewed by others

References

Ansari MA, Kim KY, Anwar K et al (2010) A novel passive micromixer based on unbalanced splits and collisions of fluid streams. J Micromech Microeng 20(5):055007

Aoki N, Umei R, Yoshida A et al (2011) Design method for micromixers considering influence of channel confluence and bend on diffusion length. Chem Eng J 167(2–3):643–650

Bhagat AAS, Peterson ETK, Papautsky I (2007) A passive planar micromixer with obstructions for mixing at low Reynolds numbers. J Micromech Microeng 17(5):1017

Chau JLH, Leung AYL, Yeung KL (2003) Zeolite micromembranes. Lab on a Chip 3(2):53–55

Chen X, Li T (2017) A novel passive micromixer designed by applying an optimization algorithm to the zigzag microchannel. Chem Eng J 313:1406–1414

Chen X, Shen J (2017a) Numerical analysis of mixing behaviors of two types of E-shape micromixers. Int J Heat Mass Transf 106:593–600

Chen X, Shen J (2017b) Numerical analysis of mixing behaviors of two types of E-shape micromixers. Int J Heat Mass Transf 106:593–600

Chen X, Zhang L (2017) Review in manufacturing methods of nanochannels of bio-nanofluidic chips. Sens Actuators B Chem. https://doi.org/10.1016/j.snb.2017.07.139.1

Chen X, Zhao Z (2017) Numerical investigation on layout optimization of obstacles in a three-dimensional passive micromixer. Anal Chim Acta 964:142–149

Chen X, Liu C, Xu Z, Pan Y, Liu J, Du L (2013) An effective PDMS microfluidic chip for chemiluminescence detection of cobalt (II) in water. Microsyst Technol 19(1):99–103

Chen X, Li T, Zeng H, Hu Z, Fu B (2016a) Numerical and experimental investigation on micromixers with serpentine microchannels. Int J Heat Mass Transf 98:131–140

Chen X, Shen J, Zhou M (2016b) Rapid fabrication of a four-layer PMMA-based microfluidic chip using CO2-laser micromachining and thermal bonding. J Micromech Microeng 26(10):107001

Chen X, Li T, Shen J, Hu Z (2017) From structures, packaging to application: a system-level review for micro direct methanol fuel cell. Renew Sustain Energy Rev 80:669–678

Hessel V, Löwe H, Schönfeld F (2005) Micromixers—a review on passive and active mixing principles. Chem Eng Sci 60(8):2479–2501

Hong CC, Choi JW, Ahn CH (2001) A novel in-plane passive micromixer using Coanda effect. Micro Total Analysis Systems. Springer, Amsterdam, pp 31–33

Jeon W, Shin CB (2009) Design and simulation of passive mixing in microfluidic systems with geometric variations. Chem Eng J 152(2):575–582

Lin YC, Chung YC, Wu CY (2007) Mixing enhancement of the passive microfluidic mixer with J-shaped baffles in the tee channel. Biomed Microdevices 9(2):215–221

Lu LH, Ryu KS, Liu C (2002) A magnetic microstirrer and array for microfluidic mixing. J Microelectromech Syst 11(5):462–469

Nimafar M, Viktorov V, Martinelli M (2012a) Experimental comparative mixing performance and pressure drop simulation of three passive micromixers. Majlesi J Mechatron Syst 1(4):20–29

Nimafar M, Viktorov V, Martinelli M (2012b) Experimental investigation of split and recombination micromixer in confront with basic T-and O-type micromixers. Int J Mech Appl 2(5):61–69

Nimafar M, Viktorov V, Martinelli M (2012c) Experimental comparative mixing performance of passive micromixers with H-shaped sub-channels. Chem Eng Sci 76:37–44

Niu X, Liu L, Wen W et al (2006) Active microfluidic mixer chip. Appl Phys Lett 88(15):153508

Oddy MH, Santiago JG, Mikkelsen JC (2001) Electrokinetic instability micromixing. Anal Chem 73(24):5822–5832

Sritharan K, Strobl CJ, Schneider MF et al (2006) Acoustic mixing at low Reynolds numbers. Appl Phys Lett 88(5):054102

Tofteberg T, Skolimowski M, Andreassen E et al (2010) A novel passive micromixer: lamination in a planar channel system. Microfluid Nanofluid 8(2):209–215

Viktorov V, Nimafar M (2013) A novel generation of 3D SAR-based passive micromixer: efficient mixing and low pressure drop at a low Reynolds number. J Micromech Microeng 23(5):055023

Whitesides GM (2006) The origins and the future of microfluidics. Nature 442(7101):368–373

Wu CY (2007) Mixing enhancement of the passive microfluidic mixer with J-shaped baffles in the tee channel. Biomed Microdevices 9(2):215–221

Acknowledgements

This work was supported by The Key Project of Department of Education of Liaoning Province (JZL201715401). We sincerely thank Prof. Chong Liu for his kind guidance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, Z., Chen, X. Design and numerical study on a novel micromixer based on Cantor fractal structure. Microsyst Technol 24, 4863–4873 (2018). https://doi.org/10.1007/s00542-018-3900-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-018-3900-8