Abstract

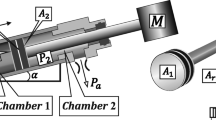

This paper presents the effect of vacuum packaging on the band-width of push–pull type capacitive accelerometer structure. The accelerometer structure (for ± 30 g application) consists of silicon proof mass (1000 μm × 1000 μm × 30 μm) suspended by four L-shaped beams over 1 μm deep cavity. The fixed electrodes (Au) are on Pyrex glass substrates which are anodically bonded to the Si substrate. The squeeze film damping factor (ς) arising due to the trapped air between the electrodes is found to be ~ 2600 at atmospheric pressure. Introduction of holes in the proof-mass reduces ς to 750. In such a highly damped environment, the operational bandwidth (3 dB) bandwidth is found to be only around 20 Hz which is not suitable for many of the navigation applications. With vacuum packaging (vacuum level 100–760 Torr), there is not much noticeable improvement in the bandwidth due to high level of ς (> 150). In the 1–100 Torr range, the bandwidth is found to be improving linearly (from 20 Hz to 2 kHz) with the improving vacuum level. Further improvement of vacuum level (< 1 Torr) leads to the under-damped (ς < 1) condition and the proof mass start oscillating which also undesirable. Thus, vacuum packaging in the 1–10 Torr range (having ς: 2–15) is found to be suitable for achieving optimum operation bandwidth for the current accelerometer sensor.

Similar content being viewed by others

References

Aydemir A, Terzioglu Y, Akin T (2016) A new design and a fabrication approach to realize a high performance three axes capacitive MEMS accelerometer. Sens Act A 244:324

Bao M (2005) Analysis and design principles of MEMS Devices. Elsevier Publication, Amstrerdam

Bao M, Yang H, Yin H, Sun Y (2002) Energy transfer model for squeeze-film air damping in low vacuum. J Micromech Microeng 12:341

Benmessaoud M, Nasreddine MM (2013) Optimization of MEMS capacitive accelerometer. Microsyst Technol 19:713

Bhan RK, Shaveta Imran Md, Pal R, Dutta S (2015a) An improved analytical approach for estimation of misalignment error of sensing axis in MEMS accelerometers using simple tilt measurements. Sensors Transducers 189(6):128

Bhan RK, Shaveta Panchal A, Parmar Y, Sharma C, Pal R, Dutta S (2015b) Determination of multiple spring constants, gaps and pull down voltages in MEMS crab type micro-accelerometer using near pull down capacitance voltage measurements. Sensors Transducers 192(9):44

Bhan RK, Shaveta Imran Md, Pal R, Dutta S, Yadav I (2016) Development of unified fabrication process and testing of MEMS based comb and crab type capacitive accelerometers for navigational applications. Sensors Transducers 203(8):8

Chan CK, Lo SC, Huang YC, Wu M, Wang MY, Fang W (2012) Poly-Si based two-axis differential capacitive-sensing accelerometer. IEEE Sensors 12(12):3301

Dai G, Li M, He X, Du L, Shao B, Su W (2011) Thermal drift analysis using a multiphysics model of bulk silicon MEMS capacitive accelerometer. Sens Actuators A 172:369

Dutta S, Shaveta Pal R, Bhattacharya DK, Datta P, Chatterjee R (2008) Design and analysis of wet etching based comb type capacitive accelerometer. Sensors Transducers 91(4):31

Dutta S, Pal R, Kumar P, Hooda OP, Singh J, Shaveta Saxena G, Datta P, Chatterjee R (2009) Fabrication challenges for realization of wet etching based comb type capacitive microaccelerometer structure. Sensors Transducers 111(12):18

Dutta S, Kumar M, Kumar S, Imran Md, Yadav I, Kumar A, Kumar P, Pal R (2014a) Lapping assisted dissolved wafer process of silicon for MEMS structures. J Mater Sci Mater Electron 25:1984

Dutta S, Shaveta Imran Md, Pal R, Bhan RK (2014b) Diffusion induced residual stress in comb-type microaccelerometer structure. J Mater Sci Mater Electron 25:3828

Ishfaque A, Kim B (2016) Analytical modeling of squeeze air film damping of biomimetic MEMS directional microphone. J Sound Vib 375:422

Jeong Y, Serrano DE, Ayazi F (2017) Low-pressure wafer-level-packaged capacitive accelerometers with high dynamic range and wide bandwidth using nano-gap sloped electrode design. IEEE MEMS 26:1335

Li P, Fang Y (2010) A molecular dynamics simulation approach for the squeeze-film damping of MEMS devices in the free molecular regime. J Micromech Microeng 20:035005

Li P, Fang Y, Xu F (2014) Analytical modeling of squeeze-film damping for perforated circular micro plates. J Sound Vibration 333:2688

Mahmood MdS, Butler ZC, Butler DP (2017) Design, fabrication and characterization of flexible MEMS accelerometer using multi-Level UV-LIGA. Sensors Actuators A 263:530

Mistry KK, Swamy KBM, Sen S (2010) Design of an SOI-MEMS high resolution capacitive type single axis accelerometer. Microsyst Technol 16:2057

Mo Y, Du L, Qu BB, Peng B, Yang J (2017) Squeeze film air damping ratio analysis of a silicon capacitive micromechanical accelerometer. Microsyst Technol. https://doi.org/10.1007/s00542-017-3464-z

Mohammed Z, Dushaq G, Chatterjee A, Rasras M (2017) An optimization technique for performance improvement of gap-changeable MEMS accelerometers. Mechatronics. https://doi.org/10.1016/j.mechatronics.2017.10.011

Santos De Los HJ (2004) Introduction to micro-electro-mechanical (MEMS) microwave systems, Chap. 1 & 2, 2nd edn. Artech House, Boston, London

Seshia AA, Palaniapan M, Roessig TA, Howe RT, Gooch RW, Schimert TR, Montague S (2002) A vacuum packaged surface micromachined resonant accelerometer. IEEE MEMS 11:784

Shaeffer DK (2013) MEMS inertial sensors: a tutorial overview. IEEE Commun Mag 51:100

Tez S, Aykutlu U, Torunbalci MM, Aki T (2015) A Bulk-micromachined three-axis capacitive MEMS accelerometer on a single die. IEEE MEMS 24:1264

Wang C, Tsai MH, Sun CM, Fang W (2007) A novel CMOS out-of-plane accelerometer with fully differential gap-closing capacitance sensing electrodes. J Micromech Microeng 17:1275

Xiao D, Li Q, Hou Z, Xia D, Xu X, Wu X (2017) A double differential torsional micro-accelerometer based on V-shape beam. Sensors Actuators A 258:182

Zhou X, Che L, Wu J, Li X, Wang Y (2012) A novel sandwich capacitive accelerometer with a symmetrical structure fabricated from a D-SOI wafer. J Micromech Microeng 22:085031

Zhou X, Che L, Liang S, Lin Y, Li X, Wang Y (2015) Design and fabrication of a MEMS capacitive accelerometer with fully symmetrical double-sided H-shaped beam structure. Microelectron Eng 131:51

Zook JD, Burns DW, Guckel H, Sniegowski JJ, Englestad RL, Feng Z (1992) Characteristics of polysilicon resonant microbeams. Sensors Actuators A 35:51

Zotov SA, Simon BR, Trusov AA, Shkel AM (2015) High quality factor resonant MEMS accelerometer with continuous thermal compensation. IEEE Sensors 15:5045

Acknowledgements

Authors would like to thank Director SSPL for his kind permission to publish this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dutta, S., Saxena, P., Panchal, A. et al. Effect of vacuum packaging on bandwidth of push–pull type capacitive accelerometer structure. Microsyst Technol 24, 4855–4862 (2018). https://doi.org/10.1007/s00542-018-3899-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-018-3899-x