Abstract

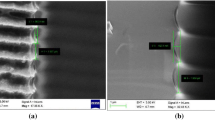

Side etching and scalloping are unwanted but unavoidable phenomenon occurring during fabrication process of micro electro-mechanical system devices with the deep reactive ion etching technology. This paper reports the influence of deep reactive ion etching fabrication errors on the geometrical dimension (as a comb finger shape, width of the suspension beam), electrostatic force and displacement of electrostatic linear comb-drive actuators. A number of deep reactive ion etching experiments were carried out in order to find out the optimal etching and passivation time, which allows to achieve vertical and smooth sidewall, as well as acceptable side etching value. Discussion and evaluation of deviation between the theoretically calculated and measured displacements of the electrostatic linear comb-drive actuator were also reported.

Similar content being viewed by others

References

Azimi S et al (2011) Three-dimensional etching of silicon substrates using a modified deep reactive ion etching technique. J Micromech Microeng 21:10

Becker H, Heim U (2000) Hot embossing as a method for the fabrication of polymer high aspect ratio structures. Sens Actuators A83:130–135

Cai Chunhua, Qin Ming (2017) Fringing capacitance and tolerance of DRIE effect on the performance of bulk silicon comb-drive actuator. Microsyst Technol 23(7):2727–2738

Dao DV, Pham PH, Sugiyama S (2011) Multimodule micro transportation system based on electrostatic comb-drive actuator and ratchet mechanisms. J Microelectromech Syst 20:140–149

Dinh T, Phan H-P, Kozeki T, Qamar A, Fujii T, Namazu T, Nguyen N-T, Dao DV (2016) High thermosensitivity of silicon nanowires induced by amorphization. Mater Lett 177:80–84

Gao JX et al (2006) Antistick postpassivation of high-aspect ratio silicon molds fabricated by deep-reactive ion etching. J Microelectromech Syst 15(1):84–93

Kakara H, Goswami M, Singh BR (2012) Design and simulation of low-g single-axis SOI-MEMS capacitive accelerometer. Int J Contemp Res Engg Tech 2(1):63–69

Kozeki T, Phan H-P, Dao DV, Inoue S, Namazu T (2016) Influence of gallium ion beam acceleration voltage on the bend angle of amorphous silicon cantilevers. Jpn J Appl Phys 55(06GL02):6

Li J, Liu AQ, Zhang QX (2006) Tolerance analysis for comb-drive actuator using DRIE fabrication. Sens Actuators A125:494–503

Nilsson D, Jensen S, Menon A (2003) Fabrication of silicon molds for polymer optics. J Micromech Microeng 13:S57–S61

Pant BD, Dhakar L, George PJ, Ahmad S (2009) Design of a MEMS capacitive comb-drive micro-accelerometer with sag optimization. Sens Transducers J 109(10):92–107

Pham PH, Dao DV, Amaya S, Kitada R, Sugiyama S (2007) Fabrication and characterization of smooth si mold for hot embossing process. IEEJ Trans Sens Micromach 127(3):187–191

Pham PH, Dao DV, Dang LB, Sugiyama S (2012) Single mask, simple structure micro rotational motor driven by electrostatic comb-drive actuators. J Micromech Microeng 22(015008):7

Pham PH, Dang LB, Nguyen VH, Dau VT (2017) Development of new electrostatic micro cam system driven by elastic wings. Microsyst Technol 23(12):5669–5675

Sun Y, Nelson BJ, Potasek DP, Enikov E (2002) A bulkmicrofabricated multi-axis capacitive cellular force sensor using transverse comb drives. J Micromech Microeng 12:832–840

Tang WC, Nguyen TH, Michael WJ, Howe RT (1990) Electrostatic-comb drive of lateral polysilicon resonators. Sens Actuators A21–23:328–331

Tang Y, Sandoughsaz A, Najafi K (2017) Ultra high aspect-ratio and thick deep silicon etching (UDRIE). MEMS conference 2017, Las Vegas, NV, USA, January 22–26, pp 700–703

Yeh R, Hollar S, Pister KSJ (2002) Single mask, large force, and large displacement electrostatic linear inchworm motors. J Microelectromech Syst 11:330–336

Yeh JA, Chen C-N, Lui Y-S (2005) Large rotation actuated by in-plane rotary comb-drives with serpentine spring suspension. J Micromech Microeng 15:201–206

Zhao Y, Cui T (2003) Fabrication of high-aspect-ratio polymer-based electrostatic comb drives using the hot embossing technique. J Micromech Microeng 13:430–435

Zhao Y, Cui T (2004) SOI wafer mold with high-aspect-ratio microstructures for hot embossing process. Mircosyst Technol 10:544–546

Acknowledgements

This research is funded by Vietnam National Foundation for Science and Technology Development (NAFOSTED) under Grant number “107.01-2015.18”.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Pham, P.H., Dang, L.B. Influence of the side etching effect in DRIE on performance of electrostatic linear comb-drive actuators. Microsyst Technol 24, 2215–2222 (2018). https://doi.org/10.1007/s00542-017-3685-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-017-3685-1