Abstract

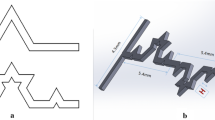

This paper demonstrates a novel and low-cost method for fabricating microchannel on polycarbonate (PC) sheet using CO2 laser. In the work, many microchannels are processed by CO2 laser beam of two-pass. Three sheets with different films are researched for increasing the cleanliness of PC sheet surface after CO2 laser processing. The experimental results show the surface of PC sheet with transparent wallpaper is most clear, but it has very large influence on width and depth of microchannel. In the next experiment, Taguchi method is used for optimizing CO2 laser processing parameters for decreasing the deviation of width and depth of microchannel. In the study, smaller-the-better signal-to-noise ratio is calculated. The result shows laser power is maximum influence factor and microchannel length is minimum influence factor on the deviation of width and depth of microchannel. The optimal processing parameters are laser power of 8 W, laser moving velocity of 15 mm/s and microchannel length of 100 mm. A verified experiment is preformed using the optimal processing parameters.

Similar content being viewed by others

References

Antończak AJ, Nowak M, Szustakiewicz K, Pigłowski J, Abramski KM (2013) The influence of organobentonite clay on CO2 laser grooving of nylon 6 composites. Int J Adv Manuf Technol 69(5–8):1389–1401

Chen X, Hu Z (2017) An effective method for fabricating microchannels on the polycarbonate (PC) substrate with CO2 laser. Int J Adv Manuf Technol 92:1365–1370

Chen X, Li T (2016) A novel design for passive misscromixers based on topology optimization method. Biomed Microdevice 18(4):1–15

Chen X, Zhang L (2018) Review in manufacturing methods of nanochannels of bio-nanofluidic chips. Sens Actuators B Chem 254:648–659

Chen X, Zhao Z (2017) Numerical investigation on layout optimization of obstacles in a three-dimensional passive micromixer. Anal Chim Acta 964:142–149

Chen JJ, Shen CM, Ko YW (2013a) Analytical study of a microfluidic DNA amplification chip using water cooling effect. Biomed Microdevice 15(2):261–278

Chen X, Liu C, Xu Z et al (2013b) An effective PDMS microfluidic chip for chemiluminescence detection of cobalt (II) in water. Microsyst Technol 19(1):99–103

Chen X, Li T, Zeng H et al (2016a) Numerical and experimental investigation on micromixers with serpentine microchannels. Int J Heat Mass Transf 98:131–140

Chen XY, Gao Q, Wang XL, Li XD (2016b) Experimental design and parameter optimization for laser three-dimensional (3-D) printing Lasers in engineering. Old City Publishing, Philadelphia, p 33

Chen X, Li T, Shen J (2016c) CO2 laser ablation of microchannel on PMMA substrate for effective fabrication of microfluidic chips. Int Polym Proc 31(2):233–238

Chen X, Shen J, Zhou M (2016d) Rapid fabrication of a four-layer PMMA-based microfluidic chip using CO2-laser micromachining and thermal bonding. J Micromech Microeng 26(10):107001

Chen X, Li T, Fu B (2016e) Surface roughness study on microchannels of CO2 laser fabricating PMMA-based microfluidic chip. Surf Rev Lett 24:1750017

Chen X, Li T, Shen J et al (2017a) From structures, packaging to application: a system-level review for micro direct methanol fuel cell. Renew Sustain Energy Rev 80:669–678

Chen X, Li T, Hu Z (2017b) A novel research on serpentine microchannels of passive micromixers. Microsyst Technol 2017:1–8

Cortes-Quiroz CA, Zangeneh M, Goto A (2009) On multi-objective optimization of geometry of staggered herringbone micromixer. Microfluid Nanofluid 7(1):29–43

Do MT, Li Q, Nguyen TTN et al (2014) High aspect ratio submicrometer two-dimensional structures fabricated by one-photon absorption direct laser writing. Microsyst Technol 20(10–11):2097–2102

Hansen CL, Quake SR, Berger JM (2014) Microfluidic protein crystallography techniques: U.S. Patent 8709153

Hsu YC, Chen TY (2007) Applying Taguchi methods for solvent-assisted PMMA bonding technique for static and dynamic μ-TAS devices. Biomed Microdevice 9(4):513–522

Huang BL, Ren L, Zhao J et al (2013) Solvothermal synthesis of carboxyl functionalized mesoporous resins in microfluidic chip for water treatments. Adv Mater Res Trans Tech Publ 750:1300–1303

Jeng JY, Wong YS, Ho CT (2001) Over-curing reduction of parts fabricated by the solid laser-diode plotter rapid prototyping system using the Taguchi method. Int J Adv Manuf Technol 18(9):683–691

Li H, Fan Y, Kodzius R et al (2012) Fabrication of polystyrene microfluidic devices using a pulsed CO2 laser system. Microsyst Technol 18(3):373–379

Lin YC, Lee CC, Lin HS et al (2017) Fabrication of microfluidic structures in quartz via micro machining technologies. Microsyst Technol 23(6):1661–1669

Liu Z, Shum HC (2013) Fabrication of uniform multi-compartment particles using microfluidic electrospray technology for cell co-culture studies. Biomicrofluidics 7(4):044117

Prakash S, Kumar S (2015) Profile and depth prediction in single-pass and two-pass CO2 laser microchanneling processes. J Micromech Microeng 25(3):035010

Qi H, Chen T, Yao L, Zuo T (2009) Micromachining of microchannel on the polycarbonate substrate with CO2 laser direct-writing ablation. Opt Lasers Eng 47(5):594–598

Rötting O, Röpke W, Becker H et al (2002) Polymer microfabrication technologies. Microsyst Technol 8(1):32–36

Sun Y, Satyanarayan MVD, Nguyen NT, Kwok YC (2008) Continuous flow polymerase chain reaction using a hybrid PMMA-PC microchip with improved heat tolerance. Sens Actuators B Chem 130(2):836–841

Syrcos GP (2003) Die casting process optimization using Taguchi methods. J Mater Process Technol 135(1):68–74

Ta BQ, Le Thanh H, Dong T et al (2015) Geometric effects on mixing performance in a novel passive micromixer with trapezoidal-zigzag channels. J Micromech Microeng 25(9):094004

Yang CB, Deng CS, Chiang HL (2012) Combining the Taguchi method with artificial neural network to construct a prediction model of a CO2 laser cutting experiment. Int J Adv Manuf Technol 59(9):1103–1111

Yang W, Zhu T, Jin Y et al (2017) Facile fabrication of helical microfluidic channel based on rope coiling effect. Microsyst Technol 23(7):2957–2964

Acknowledgements

This work was supported by National Natural Science Foundation of China (51405214), The Key Project of Department of Education of Liaoning Province (JZL201715401).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, Z., Chen, X., Yao, Z. et al. Fabricated polycarbonate microchannel with different films using CO2 laser beam of two-pass for microfluidic chip. Microsyst Technol 24, 2325–2331 (2018). https://doi.org/10.1007/s00542-017-3648-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-017-3648-6