Abstract

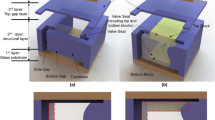

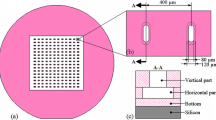

This paper describes the fabrication of a vertically-allocated SU-8 cantilever in a closed fluidic channel. The difficulties to fabricate the vertically-allocated SU-8 cantilever inside the closed channel mainly lie in which kinds of sacrificial layers under the cantilever and sealing methods for enclosing the channel are utilized for the movability of the cantilever. To obtain a suitable sacrificial layer and high sealing quality, the selectivity of sacrificial layers and the sealing conditions based on the SU-8 adhesive are discussed in this paper. The experiments to test different photoresist lead to the conclusion that AZ 5214E is adequate for the sacrificial layer. Also, the bonding results indicate that the thickness of the uncrosslinked SU-8 solid layer is the most important factor which affects the formation of a proper gap between the top coverglass and the SU-8 cantilever. The photos of the movement of the cantilever also show that the free-standing SU-8 cantilever is successfully fabricated by releasing the suitable sacrificial layer and is allocated inside the closed channel by the method of SU-8 adhesive. The fabrication method in this paper is also useful for other microfluidic applications.

Similar content being viewed by others

References

Abgrall P, Lattes C, Dollat X (2005) A novel fabrication method of flexible and monolithic 3D microfluidic structures using lamination of SU-8 films. J Micromech Microeng 16:113

Agirregabiria M, Blanco F, Berganzo J, Arroyo M, Fullaondo A, Mayora K, Ruano-Lopez J (2005) Fabrication of SU-8 multilayer microstructures based on successive CMOS compatible adhesive bonding and releasing steps. Lab Chip 5:545–552

Amirouche F, Zhou Y, Johnson T (2009) Current micropump technologies and their biomedical applications. Microsyst Technol 15:647–666

Blanco F et al (2004) Novel three-dimensional embedded SU-8 microchannels fabricated using a low temperature full wafer adhesive bonding. J Micromech Microeng 14:1047

Bouwstra S, Legtenberg R, Tilmans HA, Elwenspoek M (1990) Resonating microbridge mass flow sensor. Sensors Actuators A Phys 21:332–335

Calleja M, Rasmussen PA, Johansson A, Boisen A (2003) Polymeric mechanical sensors with piezoresistive readout integrated in a microfluidic system. In: Smart sensors, actuators, and MEMS. International society for optics and photonics, pp 314–322

Cheng C-H, Tseng Y-P (2013) Characteristic studies of the piezoelectrically actuated micropump with check valve. Microsyst Technol 19:1707–1715

Chuang Y-J, Tseng F-G, Cheng J-H, Lin W-K (2003) A novel fabrication method of embedded micro-channels by using SU-8 thick-film photoresists. Sensors Actuators A Phys 103:64–69

Dy AJ, Cosmanescu A, Sluka J, Glazier JA, Stupack D, Amarie D (2014) Fabricating microfluidic valve master molds in SU-8 photoresist. J Micromech Microeng 24:057001

Ezkerra A, Fernandez L, Mayora K, Ruano-Lopez J (2007) Fabrication of SU-8 free-standing structures embedded in microchannels for microfluidic control. J Micromech Microeng 17:2264

Helbo B, Kristensen A, Menon A (2003) A micro-cavity fluidic dye laser. J Micromech Microeng 13:307

Kim J-W, Nguyen TV, Edamura K, Yokota S (2016) Triangular prism and slit electrode pair for ECF jetting fabricated by thick micromold and electroforming as micro hydraulic pressure source for soft microrobots. Int J Autom Technol 10:470–478

Li L, Xiao Z, Tan S, Pu L, Zhang Z (2004) Composite PDMS membrane with high flux for the separation of organics from water by pervaporation. J Membr Sci 243:177–187

Lin C-H, Lee G-B, Chang B-W, Chang G-L (2002) A new fabrication process for ultra-thick microfluidic microstructures utilizing SU-8 photoresist. J Micromech Microeng 12:590

Lorenz H, Despont M, Fahrni N, LaBianca N, Renaud P, Vettiger P (1997) SU-8: a low-cost negative resist for MEMS. J Micromech Microeng 7:121

Luo C, Govindaraju A, Garra J, Schneider T, White R, Currie J, Paranjape M (2004) Releasing SU-8 structures using polystyrene as a sacrificial material. Sensors Actuators A Phys 114:123–128

Mao Z, Zhao J, Xuan W, Wang W, Luo J, Xie J (2017) Distilling determination of water content in hydraulic oil with a ZnO/glass surface acoustic wave device. Microsyst Technol 23:1841–1845

Maszara W, Goetz G, Caviglia A, McKitterick J (1988) Bonding of silicon wafers for silicon-on-insulator. J Appl Phys 64:4943–4950

Nguyen N (1997) Micromachined flow sensors—a review. Flow Meas Instrum 8:7–16

Nguyen N-T, Truong T-Q (2004) A fully polymeric micropump with piezoelectric actuator. Sensors Actuators B Chem 97:137–143

Ni J, Wang B, Chang S, Lin Q (2014) An integrated planar magnetic micropump. Microelectron Eng 117:35–40

Pan C, Yang H, Shen S, Chou M, Chou H (2002) A low-temperature wafer bonding technique using patternable materials. J Micromech Microeng 12:611

Piotter V, Bauer W, Benzler T, Emde A (2001) Injection molding of components for microsystems. Microsyst Technol 7:99–102

Rahbar M, Shannon L, Gray BL (2016) Design, fabrication and characterization of an arrayable all-polymer microfluidic valve employing highly magnetic rare-earth composite polymer. J Micromech Microeng 26:055012

Vilkner T, Janasek D, Manz A (2004) Micro total analysis systems. Recent developments. Anal Chem 76:3373–3386

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mao, Z., Yoshida, K. & Kim, Jw. Study on the fabrication of a SU-8 cantilever vertically-allocated in a closed fluidic microchannel. Microsyst Technol 24, 2473–2483 (2018). https://doi.org/10.1007/s00542-017-3611-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-017-3611-6