Abstract

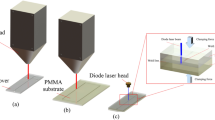

A new PMMA microfluidic chip fabrication method by combining laser ablation technology with low-temperature bonding using optically clear adhesive (OCA) film and liquid optically clear adhesive (LOCA) was presented in this paper. The deformation and clogging issues of the microfluidic channel were well solved. The effective bonding area ratio of microfluidic chips could be greatly improved by adjusting bonding temperature and bonding time. The crevices around the microchannels were effectively eliminated by coating treatment of LOCA. The bonding strength and waterproof of PMMA microfluidic chips coating with/without LOCA were also evaluated in this paper.

Similar content being viewed by others

References

Attia UM, Marson S, Alcock JR (2009) Micro-injection moulding of polymer microfluidic devices. Microfluid Nanofluid 1:1–28. doi:10.1007/s10404-009-0421-x

Chen YT, Naessens K, Baets R, Liao YS, Tseng AA (2005) Ablation of Transparent Materials Using Excimer Lasers for Photonic Applications. Opt Rev 6:427–441. doi:10.1007/s10043-005-0427-x

Chung CK, Tu KZ (2014) Application of metal film protection to microfluidic chip fabrication using CO2 laser ablation. Microsyst Technol 10-11:1987-1992. doi:10.1007/s00542-013-2041-3

Costela A, García-Moreno I, Florido F, Figuera JM, Sastre R, Hooker SM (1995) Laser ablation of polymeric materials at 157 nm. J Appl Phys 6:2343–2350. doi:10.1063/1.358756

Crabtree HJ, Lauzon J, Morrissey YC, Taylor BJ, Liang T, Johnstone RW, Stickel AJ, Manage DP, Atrazhev A (2012) Inhibition of on-chip PCR using PDMS–glass hybrid microfluidic chips. Microfluid Nanofluid 3:383–398. doi:10.1007/s10404-012-0968-9

Daridon A, Fascio V, Lichtenberg J, Wütrich R, Langen H, Verpoorte E, De Rooij N (2001) Multi-layer microfluidic glass chips for microanalytical applications. Fresenius’ J Anal Chem 2:261–269. doi:10.1007/s002160101004

Du L, Chang H, Song M, Liu C (2012) A method of water pretreatment to improve the thermal bonding rate of PMMA microfluidic chip. Microsyst Technol 4:423–428. doi:10.1007/s00542-012-1466-4

Du L, Chang H, Song M, Liu C (2012) The effect of injection molding PMMA microfluidic chips thickness uniformity on the thermal bonding ratio of chips. Microsyst Technol 6:815-822. doi:10.1007/s00542-012-1514-0

Dyer PE (2003) Excimer laser polymer ablation: twenty years on. Appl Phys A 2:167-173. doi:10.1007/s00339-003-2137-1

Evstrapov AA (2012) Microfluidic chips for biological and medical research. Russ J Gen Chem 12:2132–2145. doi:10.1134/S107036321212033X

Fan Y, Li H, Yi Y, Foulds I (2014) PMMA to Polystyrene bonding for polymer based microfluidic systems. Microsyst Technol 1:59–64. doi:10.1007/s00542-013-1778-z

Fu LM, Ju WJ, Yang RJ, Wang YN (2012) Rapid prototyping of glass-based microfluidic chips utilizing two-pass defocused CO2 laser beam method. Microfluid Nanofluid 3:479-487. doi:10.1007/s10404-012-1066-8

Guan X, Zhang Hj, Bi YN, Zhang L, Hao Dl (2010) Rapid detection of pathogens using antibody-coated microbeads with bioluminescence in microfluidic chips. Biomed Microdevices 4:683–691. doi:10.1007/s10544-010-9421-6

Habouti S, Kunstmann-Olsen C, Hoyland JD, Rubahn H-G, Es-Souni M (2014) In situ ZnO–PVA nanocomposite coated microfluidic chips for biosensing. Appl Phys A 2:645–649. doi:10.1007/s00339-014-8397-0

Heiskanen A, Coman V, Kostesha N, Sabourin D, Haslett N, Baronian K, Gorton L, Dufva M, Emnéus J (2013) Bioelectrochemical probing of intracellular redox processes in living yeast cells-application of redox polymer wiring in a microfluidic environment. Anal Bioanal Chem, 11:3847-3858. doi:10.1007/s00216-013-6709-4

Herbst L, Klaft I, Wenzel T, Rebhan U (2003) High-repetition-rate excimer laser for micromachining. Proc SPIE 4971:87-95. doi:10.1117/12.479174

Hong TF, Ju WJ, Wu MC, Tai CH, Tsai CH, Fu LM (2010) Rapid prototyping of PMMA microfluidic chips utilizing a CO2 laser. Microfluid Nanofluid 6:1125-1133. doi:10.1007/s10404-010-0633-0

Jensen MF, Noerholm M, Christensen LH, Geschke O (2003) Microstructure fabrication with a CO2 laser system: characterization and fabrication of cavities produced by raster scanning of the laser beam. Lab Chip 4:302-307. doi:10.1039/B308153B

Kanamori Y, Hane K (2002) Broadband Antireflection Subwavelength Gratings for Polymethyl Methacrylate Fabricated with Molding Technique. Opt Rev 5:183-185. doi:10.1007/s10043-002-0183-0

Klank H, Kutter JP, Geschke O (2002) CO2-laser micromachining and back-end processing for rapid production of PMMA-based microfluidic systems. Lab Chip 4:242-6. doi:10.1039/b206409j

Lankard JR, Wolbold G (1992) Excimer laser ablation of polyimide in a manufacturing facility. Appl Phys A 4:355-359. doi:10.1007/bf00324201

Lei KF, Li WJ, Yam Y (2005) Effects of contact-stress on hot-embossed PMMA microchannel wall profile. Microsyst Technol 4-5:353-357. doi:10.1007/s00542-004-0454-8

McGinty S, O'Connor GM, Glynn TJ (2005) A comparative study of channel formation in polymer materials using VUV and UV nano-second laser sources for use in micro-fluidic applications. Proc SPIE 5825:622-633. doi:10.1117/12.605144

Obata K, Sugioka K, Shimazawa N, Midorikawa K (2006) Fabrication of microchip based on UV transparent polymer for DNA electrophoresis by F2 laser ablation. Appl Phys A 3:251-255. doi:10.1007/s00339-006-3618-9

Pemg BY, Wu CW, Shen YK, Lin Y (2010) Microfluidic chip fabrication using hot embossing and thermal bonding of COP. Polym Adv Technol 7:457-466. doi:10.1002/pat.1447

Prakash S, Kumar S (2015) Fabrication of microchannels on transparent PMMA using CO2 Laser (10.6 μm) for microfluidic applications: An experimental investigation. Int J Precis Eng Manuf 2:361-366. doi:10.1007/s12541-015-0047-8

Qi H, Wang X, Chen T, Ma X, Zuo T (2009) Fabrication and characterization of a polymethyl methacrylate continuous-flow PCR microfluidic chip using CO2 laser ablation. Microsyst Technol 7:1027-1030. doi:10.1007/s00542-009-0843-0

Queste S, Salut R, Clatot S, Rauch J-Y, Khan Malek CG (2010) Manufacture of microfluidic glass chips by deep plasma etching, femtosecond laser ablation, and anodic bonding. Microsyst Technol 8:1485-1493. doi:10.1007/s00542-010-1020-1

Song S, Lee K (2006) Polymers for Microfluidic Chips. Macromol Res 2:121-128. doi:10.1007/BF03218498

Thian SCH, Fuh JYH, Wong YS, Loh HT, Gian PW, Tang Y (2008) Fabrication of microfluidic channel utilizing silicone rubber with vacuum casting. Microsyst Technol 8:1125-1135. doi:10.1007/s00542-008-0640-1

Wang L, Liu W, Li S, Liu T, Yan X, Shi Y, Cheng Z, Chen C (2015) Fast fabrication of microfluidic devices using a low-cost prototyping method. Microsyst Technol 1-10. doi:10.1007/s00542-015-2465-z

Wang X, Zhang L, Chen G (2011) Hot embossing and thermal bonding of poly(methyl methacrylate) microfluidic chips using positive temperature coefficient ceramic heater. Anal Bioanal Chem 8:2657-2665. doi:10.1007/s00216-011-5377-5

Wu CL, Li CC, Lu CF, Yang SY (2012) Development of two step carbon dioxide assisted thermal fusion PMMA bonding process. Microsyst Technol 4:409-414. doi:10.1007/s00542-012-1427-y

Yan J, Yang X, Wang E (2005) Electrogenerated chemiluminescence on microfluidic chips. Anal Bioanal Chem 1:48-50. doi:10.1007/s00216-004-2857-x

Ye MY, Yin XF, Fang ZL (2005) DNA separation with low-viscosity sieving matrix on microfabricated polycarbonate microfluidic chips. Anal Bioanal Chem 4:820-827. doi:10.1007/s00216-004-2988-0

Zhang Z, Luo Y, Wang X, Zheng Y, Zhang Y, Wang L (2010) A low temperature ultrasonic bonding method for PMMA microfluidic chips. Microsyst Technol 4:533-541. doi:10.1007/s00542-010-1027-7

Zhang Z, Luo Y, Wang X, He S, Meng F, Wang L (2010) Bonding of planar poly (methyl methacrylate) (PMMA) nanofluidic channels using thermal assisted ultrasonic bonding method. Microsyst Technol 12:2043-2048. doi:10.1007/s00542-010-1140-7

Acknowledgments

This work was supported in part by following foundations: (1) National Natural Science Foundation of China (Grant No. 21105076, Grant No. 81372358, Grant No. 51303140 and Grant No. 51302196), (2) Foundation of Education Bureau of Hubei Province, China (Grant No. D20121705), (3) Science Technology Foundation of Hubei Province, China (Grant No. 2011BAB038), (4) Natural Science Foundation of Hubei Province, China (Grant No. 2014CF029), (5) Colleges of Hubei Province Outstanding Youth Science and Technology Innovation Team (Grant No. T201305).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, K., Xiang, J., Ai, Z. et al. PMMA microfluidic chip fabrication using laser ablation and low temperature bonding with OCA film and LOCA. Microsyst Technol 23, 1937–1942 (2017). https://doi.org/10.1007/s00542-016-2924-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-016-2924-1