Abstract

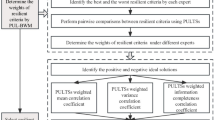

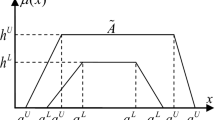

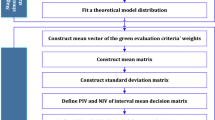

Since resilient supplier selection problems (RSSPs) are regarded vague, uncertain and complex, interval-valued fuzzy sets (IVFSs) and possibilistic statistical theories can assist to deal with preferences and experience of group of experts into meaningful results to appraise the potential suppliers. This research presents a novel comprehensive possibilistic statistical group decision approach with IVFSs and asymmetric information to solve RSSPs in the supply chain networks (SCNs). Possibilistic statistical concepts, including mean, variance, skewness and kurtosis, are proposed for the first time in the literature of SCNs for the group decision process. Also, asymmetric information with IVFSs is provided in the presented approach along with introducing two new extensions of weighting methods for experts as well as evaluation criteria. In addition, new relations, new separation measures and novel distinguish indices are introduced regarding to the preference by similarity to ideal solutions with mean–variance–skewness–kurtosis modeling. Then, the proposed comprehensive decision approach is implemented to an application in automobile industry for the RSSPs to assess the resilience strategy in the SCNs under uncertain conditions.

Similar content being viewed by others

References

Azadfallah M (2016) Improving preference assessment in TOPSIS method for multi-criteria supplier selection problem. Int J Supply Chain Oper Resil 2(3):233–245

Baležentis T, Baležentis A (2014) A survey on development and applications of the multi-criteria decision making method multimoora. J Multi-Criteria Decision Anal 21(3–4):209–222

Chai J, Liu JN, Ngai EW (2013) Application of decision-making techniques in supplier selection: a systematic review of literature. Expert Syst Appl 40(10):3872–3885

Chang KH (2017) A novel supplier selection method that integrates the intuitionistic fuzzy weighted averaging method and a soft set with imprecise data. Ann Oper Res. https://doi.org/10.1007/s10479-017-2718-6

Deng Y, Chan FT, Wu Y, Wang D (2011) A new linguistic MCDM method based on multiple-criterion data fusion. Expert Syst Appl 38(6):6985–6993

Deng Y, Sadiq R, Jiang W, Tesfamariam S (2011) Risk analysis in a linguistic environment: a fuzzy evidential reasoning-based approach. Expert Syst Appl 38(12):15438–15446

Ebrahimnejad S, Mousavi SM, Tavakkoli-Moghaddam R, Heydar M (2014) Risk ranking in mega projects by fuzzy compromise approach: a comparative analysis. J Intell Fuzzy Syst 26:949–959

Foroozesh N, Tavakkoli-Moghaddam R, Mousavi SM (2017) Resilient supplier selection in a supply chain by a new interval-valued fuzzy group decision model based on possibilistic statistical concepts. J Ind Syst Eng 10(2):113–133

Gitinavard H, Mousavi SM, Vahdani B (2017) Soft computing-based new interval-valued hesitant fuzzy multi-criteria group assessment method with last aggregation to industrial decision problems. Soft Comput 21(12):3247–3265

Gitinavard H, Mousavi SM, Vahdani B (2017) Soft computing based on hierarchical evaluation approach and criteria interdependencies for energy decision-making problems: a case study. Energy 118:556–577

Haldar A, Ray A, Banerjee D, Ghosh S (2012) A hybrid MCDM model for resilient supplier selection. Int J Manag Sci Eng Manag 7(4):284–292

Haldar A, Ray A, Banerjee D, Ghosh S (2014) Resilient supplier selection under a fuzzy environment. Int J Manag Sci Eng Manag 9(2):147–156

Hosseini S (2016) Modeling and measuring resilience: applications in supplier selection and critical infrastructure. https://shareok.org/handle/11244/44886. Accessed 1 Aug 2016

Hosseini S, Al Khaled A (2016) A hybrid ensemble and AHP approach for resilient supplier selection. J Intell Manuf. https://doi.org/10.1007/s10845-016-1241-y

Hosseini S, Barker K (2016) A Bayesian network model for resilience-based supplier selection. Int J Prod Econ 180:68–87

Junior FRL, Osiro L, Carpinetti LCR (2014) A comparison between fuzzy AHP and fuzzy TOPSIS methods to supplier selection. Appl Soft Comput 21:194–209

Kamdem JS, Deffo CT, Fono LA (2012) Moments and semi-moments for fuzzy portfolio selection. Insur Math Econ 51(3):517–530

Kuo MS, Liang GS (2012) A soft computing method of performance evaluation with MCDM based on interval-valued fuzzy numbers. Appl Soft Comput 12(1):476–485

Mohagheghi V, Mousavi SM, Vahdani B (2015) A new optimization model for project portfolio selection under interval-valued fuzzy environment. Arab J Sci Eng 40:3351–3361

Mohagheghi V, Mousavi SM, Vahdani B (2016) A new multi-objective optimization approach for sustainable project portfolio selection: a real-world application under interval-valued fuzzy environment. Iran J Fuzzy Syst 13(6):41–68

Parkouhi SV, Ghadikolaei AS (2017) A resilience approach for supplier selection: using fuzzy analytic network process and grey VIKOR techniques. J Clean Prod 161:431–451

Pettit TJ, Fiksel J, Croxton KL (2010) Ensuring supply chain resilience: development of a conceptual framework. J Bus Logist 31(1):1–21

Ponomarov SY, Holcomb MC (2009) Understanding the concept of supply chain resilience. Int J Logist Manag 20(1):124–143

Pramanik D, Haldar A, Mondal SC, Naskar SK, Ray A (2017) Resilient supplier selection using AHP-TOPSIS-QFD under a fuzzy environment. Int J Manag Sci Eng Manag 12(1):45–54

Rajagopal V, Venkatesan SP, Goh M (2017) Decision-making models for supply chain risk mitigation: a review. Comput Ind Eng 113:646–682

Rajesh R, Ravi V (2015) Supplier selection in resilient supply chains: a grey relational analysis approach. J Clean Prod 86:343–359

Sahu AK, Datta S, Mahapatra SS (2016) Evaluation and selection of resilient suppliers in fuzzy environment: exploration of fuzzy-VIKOR. Benchmark Int J 23(3):651–673

Sanayei A, Mousavi SF, Yazdankhah A (2010) Group decision making process for supplier selection with VIKOR under fuzzy environment. Expert Syst Appl 37(1):24–30

Sheffi Y (2006) Resilience reduces risk. Logist Q 12(1):12–14

Shemshadi A, Shirazi H, Toreihi M, Tarokh MJ (2011) A fuzzy VIKOR method for supplier selection based on entropy measure for objective weighting. Expert Syst Appl 38(10):12160–12167

Vahdani B, Mousavi SM, Ebrahimnejad S (2014) Soft computing-based preference selection index method for human resource management. J Intell Fuzzy Syst 26(1):393–403

Vahdani B, Mousavi SM, Tavakkoli-Moghaddam R, Ghodratnama A, Mohammadi M (2014) Robot selection by a multiple criteria complex proportional assessment method under an interval-valued fuzzy environment. Int J Adv Manuf Technol 73(5–8):687–697

Wang JW, Cheng CH, Huang KC (2009) Fuzzy hierarchical TOPSIS for supplier selection. Appl Soft Comput 9(1):377–386

Wang X, Herty M, Zhao L (2016) Contingent rerouting for enhancing supply chain resilience from supplier behavior perspective. Int Trans Oper Res 23(4):775–796

Yeh Tsu-Ming, Pai Fan-Yun, Liao Cheng-Wei (2014) Using a hybrid MCDM methodology to identify critical factors in new product development. Neural Comput Appl 24(3–4):957–971

Zimmermann HJ (2001) Fuzzy set theory and its applications, 4th edn. Springer, Dordrecht

Acknowledgements

The authors are grateful to four anonymous referees for their valuable suggestions and comments that improved the quality of the primary version.

Author information

Authors and Affiliations

Contributions

The authors of this research confirm their names’ arrangement based on their contributions in the revised version.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Foroozesh, N., Tavakkoli-Moghaddam, R., Mousavi, S.M. et al. A new comprehensive possibilistic group decision approach for resilient supplier selection with mean–variance–skewness–kurtosis and asymmetric information under interval-valued fuzzy uncertainty. Neural Comput & Applic 31, 6959–6979 (2019). https://doi.org/10.1007/s00521-018-3506-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-018-3506-1