Abstract

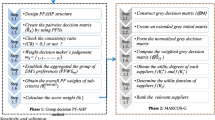

Recently, sustainable warehouse location has been regarded as one of the most critical and significant decision problems for long-term planning in the supply chain. This strategic decision can be effected by different quantitative and qualitative evaluation criteria via three dimensions of the sustainability. Main theme of the paper is to select the most optimal location decision from a number of potential sustainable warehouse candidates. For this purpose, this paper presents a novel multi-criteria decision-making model by a group of supply chain experts or decision makers with interval-valued fuzzy setting and asymmetric uncertainty information. Concepts of mean, variance and skewness are introduced into the proposed group decision model, and their mathematical relations are defined based on a fuzzy possibilistic statistical approach. Then, new relations in this model are presented for obtaining ideal solutions under uncertainty with two high and low values of the possibilistic mean and possibilistic standard deviation, along with the possibilistic cube root of skewness. In addition, novel separation measures and new fuzzy ranking index of hybridized relative closeness coefficients are presented to provide final preference order of warehouse location candidates under uncertain conditions. Finally, a sustainable warehouse location selection problem in a pharmaceutical company is presented and solved by the proposed group decision model to demonstrate its applicability and suitability.

Similar content being viewed by others

References

Amindoust A, Ahmed S, Saghafinia A, Bahreininejad A (2012) Sustainable supplier selection: a ranking model based on fuzzy inference system. Appl Soft Comput 12(6):1668–1677

Ashrafzadeh M, Rafiei FM, Isfahani NM, Zare Z (2012) Application of fuzzy TOPSIS method for the selection of warehouse location: case study. Interdiscip J Contemp Res Bus 3(9):655–671

Ashtiani B, Haghighirad F, Makui A, Ali Montazer G (2009) Extension of fuzzy TOPSIS method based on interval-valued fuzzy sets. Appl Soft Comput 9(2):457–461

Bouchery Y, Corbett CJ, Fransoo JC, Tan T (2017) Sustainable supply chains: introduction. In: Sustainable supply chains, vol 4, 1st edn. Springer, pp. 1–12. ISBN: 978-3-319-29791-0

Büyüközkan G, Çifçi G (2011) A novel fuzzy multi-criteria decision framework for sustainable supplier selection with incomplete information. Comput Ind 62(2):164–174

Büyüközkan G, Göçer F (2017) Application of a new combined intuitionistic fuzzy MCDM approach based on axiomatic design methodology for the supplier selection problem. Appl Soft Comput 52:1222–1238

Carter CR, Rogers DS (2008) A framework of sustainable supply chain management: moving toward new theory. Int J Phys Distrib Logist Manag 38(5):360–387

Chatterjee K, Kar S (2016) Multi-criteria analysis of supply chain risk management using interval valued fuzzy TOPSIS. OPSEARCH 53(3):474–499

Demirel T, Demirel NÇ, Kahraman C (2010) Multi-criteria warehouse location selection using Choquet integral. Expert Syst Appl 37(5):3943–3952

Deng X, Li R (2014) Gradually tolerant constraint method for fuzzy portfolio based on possibility theory. Inf Sci 259:16–24

Dey B, Bairagi B, Sarkar B, Sanyal SK (2013) A hybrid fuzzy technique for the selection of warehouse location in a supply chain under a utopian environment. Int J Manag Sci Eng Manag 8(4):250–261

Dey B, Bairagi B, Sarkar B, Sanyal SK (2016) Warehouse location selection by fuzzy multi-criteria decision making methodologies based on subjective and objective criteria. Int J Manag Sci Eng Manag 11(4):262–278

Dubey R, Gunasekaran A, Papadopoulos T, Childe SJ, Shibin KT, Wamba SF (2017) Sustainable supply chain management: framework and further research directions. J Clean Prod 142(2):1119–1130

Elkington J (1997) Cannibals with forks. In: The triple bottom line of 21st century. Capstone Publishing Ltd. ISBN: 978-1841120843

Ertuğrul İ, Karakaşoğlu N (2008) Comparison of fuzzy AHP and fuzzy TOPSIS methods for facility location selection. Int J Adv Manuf Technol 39(7–8):783–795

Gitinavard H, Mousavi SM, Vahdani B (2016) A new multi-criteria weighting and ranking model for group decision-making analysis based on interval-valued hesitant fuzzy sets to selection problems. Neural Comput Appl 27(6):1593–1605

Gitinavard H, Mousavi SM, Vahdani B, Siadat A (2016) A distance-based decision model in interval-valued hesitant fuzzy setting for industrial selection problems. Sci Iran E 23(4):1928–1940

Gitinavard H, Mousavi SM, Vahdani B (2017) Soft computing based on hierarchical evaluation approach and criteria interdependencies for energy decision-making problems: a case study. Energy 118:556–577

Kahraman C, Ruan D, Doǧan I (2003) Fuzzy group decision-making for facility location selection. Inf Sci 157:135–153

Kamdem JS, Deffo CT, Fono LA (2012) Moments and semi-moments for fuzzy portfolio selection. Insur Math Econ 51(3):517–530

Kleindorfer PR, Singhal K, Wassenhove LN (2005) Sustainable operations management. Prod Oper Manag 14(4):482–492

Li X, Qin Z, Kar S (2010) Mean–variance–skewness model for portfolio selection with fuzzy returns. Eur J Oper Res 202(1):239–247

Lin YH, Tseng ML (2016) Assessing the competitive priorities within sustainable supply chain management under uncertainty. J Clean Prod 112:2133–2144

Luthra S, Govindan K, Kannan D, Mangla SK, Garg CP (2017) An integrated framework for sustainable supplier selection and evaluation in supply chains. J Clean Prod 140:1686–1698

Mokhtarian MN, Sadi-nezhad S, Makui A (2014) A new flexible and reliable interval valued fuzzy VIKOR method based on uncertainty risk reduction in decision making process: an application for determining a suitable location for digging some pits for municipal wet waste landfill. Comput Ind Eng 78:213–233

Mousavi SM, Vahdani B (2016) Cross-docking location selection in distribution systems: a new intuitionistic fuzzy hierarchical decision model. Int J Comput Intell Syst 9(1):91–109

Mousavi SM, Tavakkoli-Moghaddam R, Heydar M, Ebrahimnejad S (2013) Multi-criteria decision making for plant location selection: an integrated Delphi–AHP–PROMETHEE methodology. Arab J Sci Eng 38(5):1255–1268

Mousavi SM, Vahdani B, Tavakkoli-Moghaddam R, Ebrahimnejad S, Amiri M (2013) A multi-stage decision-making process for multiple attributes analysis under an interval-valued fuzzy environment. Int J Adv Manuf Technol 64(9–12):1263–1273

Neumüller C, Kellner F, Gupta JN, Lasch R (2015) Integrating three-dimensional sustainability in distribution centre selection: the process analysis method-based analytic network process. Int J Prod Res 53(2):409–434

Özcan T, Çelebi N, Esnaf Ş (2011) Comparative analysis of multi-criteria decision making methodologies and implementation of a warehouse location selection problem. Expert Syst Appl 38(8):9773–9779

Özkir VÇ, Demirel T (2016) An effective extension of fuzzy TOPSIS method for hierarchically structured group decision making problems. J Multiple-Valued Logic Soft Comput 26(3–5):295–314

Peters S (ed) (2005) KPMG international survey of corporate responsibility reporting 2005. KPMG Global Sustainability Services

Scholten K, Fynes B (2017) Risk and uncertainty management for sustainable supply chains. In: Sustainable supply chains, vol 4. Springer, pp 413–436. ISBN: 978-3-319-29791-0

Sezer F, Özkan BALİ, Gürol P (2016) Hazardous materials warehouse selection as a multiple criteria decision making problem. J Econ Bibliogr 3(1):63–73

Shrivastava P (1995) The role of corporations in achieving ecological sustainability. Acad Manag Rev 20(4):936–960

Simchi-Levi D, Kaminsky P (2003) Designing and managing the supply chain: concepts, strategies and case studies. McGraw-Hill/Irwin. ISBN-13: 978-0072357561

Tavakkoli-Moghaddam R, Mousavi SM, Heydar M (2011) An integrated AHP-VIKOR methodology for plant location selection. Int J Eng Trans B Appl 24(2):127–137

Tosun Ö, Uysal F (2016) Physical distribution flexibility in logistics systems and its impact on productivity. J Adv Manag Sci 4(1):53–56

Uysal F, Tosun Ö (2014) Selection of sustainable warehouse location in supply chain using the grey approach. Int J Inf Decis Sci 6(4):338–353

Vahdani B, Mousavi SM, Ebrahimnejad S (2014) Soft computing-based preference selection index method for human resource management. J Intell Fuzzy Syst 26(1):393–403

Wang Chen HM, Chou SY, Luu QD, Yu THK (2016) A fuzzy MCDM approach for green supplier selection from the economic and environmental aspects. Math Probl Eng. doi:10.1155/2016/8097386

Wu KJ, Liao CJ, Tseng M, Chiu KKS (2016) Multi-attribute approach to sustainable supply chain management under uncertainty. Ind Manag Data Syst 116(4):777–800

Zhang WG, Wang YL, Chen ZP, Nie ZK (2007) Possibilistic mean–variance models and efficient frontiers for portfolio selection problem. Inf Sci 177(13):2787–2801

Acknowledgements

The authors thank the anonymous referees for the valuable comments and recommendations that improved the primary version of the study.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Foroozesh, N., Tavakkoli-Moghaddam, R. & Mousavi, S.M. A novel group decision model based on mean–variance–skewness concepts and interval-valued fuzzy sets for a selection problem of the sustainable warehouse location under uncertainty. Neural Comput & Applic 30, 3277–3293 (2018). https://doi.org/10.1007/s00521-017-2885-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-017-2885-z