Abstract

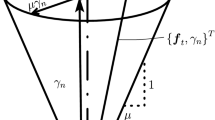

This work presents a concise theoretical and computational framework for the finite element formulation of frictional contact problems with arbitrarily large deformation and sliding. The aim of this work is to extend the contact theory based on surface potentials (Sauer and De Lorenzis in Comput Methods Appl Mech Eng 253:369–395, 2013) to account for friction. Coulomb friction under isothermal conditions is considered here. For a consistent friction formulation, we start with the first and second laws of thermodynamics and derive the governing equations at the contact interface. A so-called interacting gap can then be defined as a kinematic variable unifying both sliding/sticking and normal/tangential contact. A variational principle for the frictional system can then be formulated based on a purely kinematical constraint. The direct elimination approach applied to the tangential part of this constraint leads to the so-called moving friction cone approach of Wriggers and Haraldsson (Commun Numer Methods Eng 19:285–295, 2003). Compared with existing friction formulations, our approach reduces the theoretical and computational complexity. Several numerical examples are presented to demonstrate the accuracy and robustness of the proposed friction formulation.

Similar content being viewed by others

Notes

Computed by averaging the tangential contact traction over the reference surface.

i.e the resultant of the contact force and the surface force due to the volume constraint.

References

Argento C, Jagota A, Carter WC (1997) Surface formulation for molecular interactions of macroscopic bodies. J Mech Phys Solids 45(7):1161–1183

Borden MJ, Scott MA, Evans JA, Hughes TJR (2011) Isogeometric finite element data structures based on bezier extraction of NURBS. Int J Numer Methods Eng 87:15–47

Brivadis E, Buffa A, Wohlmuth B, Wunderlich L (2015) Isogeometric mortar methods. Comput Methods Appl Mech Eng 284(Supplement C):292–319

Corbett CJ, Sauer RA (2014) NURBS-enriched contact finite elements. Comput Methods Appl Mech Eng 275:55–75

Corbett CJ, Sauer RA (2015) Three-dimensional isogeometrically enriched finite elements for mixed-mode contact and debonding. Comput Methods Appl Mech Eng 284:781–806

De Lorenzis L, Wriggers P, Hughes TJR (2014) Isogeometric contact: a review. GAMM Mitteilungen 37:85–123

De Lorenzis L, Temizer I, Wriggers P, Zavarise G (2011) A large deformation frictional contact formulation using NURBS-based isogeometric analysis. Int J Numer Methods Eng 87:1278–1300

De Lorenzis L, Wriggers P, Zavarise G (2012) A mortar formulation for 3D large deformation contact using NURBS-based isogeometric analysis and the augmented Lagrangian method. Comput Mech 49:1–20

Del Piero G, Raous M (2010) A unified model for adhesive interfaces with damage, viscosity, and friction. Eur J Mech A Solid 29:496–507

Dimitri R, Zavarise G (2017) Isogeometric treatment of frictional contact and mixed mode debonding problems. Comput Mech 60(2):315–332

Dittmann M, Franke M, Temizer I, Hesch C (2014) Isogeometric analysis and thermomechanical mortar contact problems. Comput Methods Appl Mech Eng 274:192–212

Duong TX, De Lorenzis L, Sauer RA (2018) A segmentation-free isogeometric extended mortar contact method. Comput Mech. https://doi.org/10.1007/s00466-018-1599-0

Fischer KA, Wriggers P (2006) Mortar based frictional contact formulation for higher order interpolations using the moving friction cone. Comput Methods Appl Mech Eng 195:5020–5036

Gitterle M, Popp A, Gee MW, Wall WA (2010) Finite deformation frictional mortar contact using a semi-smooth Newton method with consistent linearization. Int J Numer Methods Eng 84(5):543–571

Hiermeier M, Wall WA, Popp A (2018) A truly variationally consistent and symmetric mortar-based contact formulation for finite deformation solid mechanics. Comput Methods Appl Mech Eng 342:532–540

Hughes TJR, Cottrell JA, Bazilevs Y (2005) Isogeometric analysis: CAD, finite elements, NURBS, exact geometry and mesh refinement. Comput Methods Appl Mech Eng 194:4135–4195

Khiêm VN, Itskov M (2017) An averaging based tube model for deformation induced anisotropic stress softening of filled elastomers. Int J Plast 90:96–115

Kiliç K, Temizer I (2016) Tuning macroscopic sliding friction at soft contact interfaces: interaction of bulk and surface heterogeneities. Tribol Int 104:83–97

Kim J-Y, Youn S-K (2012) Isogeometric contact analysis using mortar method. Int J Numer Methods Eng 89(12):1559–1581

Krstulovic-Opara L, Wriggers P, Korelc J (2002) A \(C^1\)-continuous formulation for 3D finite deformation friction contact. Comput Mech 29:27–42

Laursen TA (2002) Computational contact and impact mechanics: fundamentals of modeling interfacial phenomena in nonlinear finite element analysis. Springer, Berlin

Laursen TA, Simo JC (1993) A continuum-based finite element formulation for the implicit solution of multibody, large deformation frictional contact problems. Int J Numer Methods Eng 36:3451–3485

Lu J (2011) Isogeometric contact analysis: geometric basis and formulation for frictionless contact. Comput Methods Appl Mech Eng 200:726–741

Mergel JC, Sahli R, Scheibert J, Sauer RA (2018) Continuum contact models for coupled adhesion and friction. J Adhes 94:1–33

Neto D, Oliveira M, Menezes L, Alves J (2016) A contact smoothing method for arbitrary surface meshes using Nagata patches. Comput Methods Appl Mech Eng 299:283–315

Ogden RW (1987) Non-linear elastic deformations. Dover Edition, Mineola

Persson BNJ (2000) Sliding friction: physical principles and application, 2nd edn. Springer, Berlin

Popp A, Wohlmuth BI, Gee MW, Wall WA (2012) Dual quadratic mortar finite element methods for 3D finite deformation contact. SIAM J Sci Comput 34:B421–B446

Puso MA, Laursen TA (2004) A mortar segment-to-segment contact method for large deformation solid mechanics. Comput Methods Appl Mech Eng 193:601–629

Raous M, Cangémi L, Cocu M (1999) A consistent model coupling adhesion, friction, and unilateral contact. Comput Methods Appl Mech Eng 177:383–399

Sauer RA (2006) An atomic interaction based continuum model for computational multiscale contact mechanics. Ph.D. thesis, University of California, Berkeley, USA

Sauer RA (2011) Enriched contact finite elements for stable peeling computations. Int J Numer Methods Eng 87:593–616

Sauer RA (2013) Local finite element enrichment strategies for 2D contact computations and a corresponding postprocessing scheme. Comput Mech 52(2):301–319

Sauer RA, De Lorenzis L (2013) A computational contact formulation based on surface potentials. Comput Methods Appl Mech Eng 253:369–395

Sauer RA, De Lorenzis L (2015) An unbiased computational contact formulation for 3D friction. Int J Numer Methods Eng 101:251–280

Sauer RA, Duong TX, Corbett CJ (2014) A computational formulation for constrained solid and liquid membranes considering isogeometric finite elements. Comput Methods Appl Mech Eng 271:48–68

Sauer RA, Li S (2007) An atomic interaction-based continuum model for adhesive contact mechanics. Finite Elem Anal Des 43(5):384–396

Sauer RA, Li S (2008) An atomistically enriched continuum model for nanoscale contact mechanics and its application to contact scaling. J Nanosci Nanotech 8(7):3757–3773

Seitz A, Farah P, Kremheller J, Wohlmuth BI, Wall WA, Popp A (2016) Isogeometric dual mortar methods for computational contact mechanics. Comput Methods Appl Mech Eng 301:259–280

Shadowitz A (1988) The electromagnetic field. Dover Publications, New York

Simo J, Ju J (1987) Strain- and stress-based continuum damage models-I. Formulation. Int J Solids Struct 23(7):821–840

Temizer I (2013) A mixed formulation of mortar-based contact with friction. Comput Methods Appl Mech Eng 255:183–195

Temizer I (2016) Sliding friction across the scales: thermomechanical interactions and dissipation partitioning. J Mech Phys Solids 89:126–148

Temizer I, Wriggers P, Hughes T (2011) Contact treatment in isogeometric analysis with NURBS. Comput Methods Appl Mech Eng 200:1100–1112

Temizer I, Wriggers P, Hughes TJR (2012) Three-dimensional mortar-based frictional contact treatment in isogeometric analysis with NURBS. Comput Methods Appl Mech Eng 209–212:115–128

Weeger O, Narayanan B, Dunn ML (2018) Isogeometric collocation for nonlinear dynamic analysis of Cosserat rods with frictional contact. Nonlinear Dyn 91(2):1213–1227

Wriggers P (2006) Computational contact mechanics, 2nd edn. Springer, Berlin

Wriggers P, Haraldsson A (2003) A simple formulation for two-dimensional contact problems using a moving friction cone. Commun Numer Methods Eng 19:285–295

Wriggers P, Krstulovic-Opara L (2004) The moving friction cone approach for three-dimensional contact simulations. Int J Comput Methods 01(01):105–119

Yang B, Laursen TA, Meng X (2005) Two dimensional mortar contact methods for large deformation frictional sliding. Int J Numer Methods Eng 62:1183–1225

Acknowledgements

The authors are grateful to the German Research Foundation (DFG) for supporting this research under Grants GSC 111 and SA1822/8-1.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

A Linearization of the kinematical constraint

Given the current position of \(\varvec{x}_k\) and \(\varvec{x}_{\ell }({\hat{\varvec{\xi }}}^n)\), the sliding point \(\varvec{\xi }_\mathrm {m}\) is determined by solving nonlinear Eq. (43) with the Newton–Raphson method. Accordingly, the Taylor series of \(f_\alpha (\xi ^\beta )\) about the point \(\xi ^\beta + \Delta \xi ^\beta \) is given by

With this, the increment \(\Delta \xi ^\beta \) for the iterative procedure is determined from setting \(f_\alpha (\xi ^\beta + \Delta \xi ^\beta )=0\), giving

where \(c^{\alpha \beta }\) are the components of the matrix

Here, following from Eq. (43), we have

where we have denoted

with \(g_\mathrm {n}:=\varvec{g}_\mathrm {e}\cdot \varvec{n}\), \(g^\alpha :=\varvec{g}_\mathrm {e}\cdot \varvec{a}^\alpha \), \(\tau _\alpha :=\varvec{\tau }\cdot \varvec{a}_\alpha \), \(\tau _{\alpha \beta }:=\tau _\alpha \,\tau _\beta \), and \(\tau _{\alpha }^{\beta }:=\tau _{\alpha \gamma }\,a^{\gamma \beta }\).

B Tangent matrices

The tangent matrices for the full-pass algorithm follow from the linearization of Eq. (49). In general, we have

which includes both sticking and sliding. However, when sticking occurs, \(\hat{\varvec{g}}\) becomes \(\hat{\varvec{g}}{^n}\) since \(\omega =0\) in Eq. (35). Equation (70) then reduces to

where \(\bar{e}\in \mathcal {E}_\ell \) denotes the master elements that contain the previous interacting point \(\hat{\varvec{\xi }}{^n}\), and

denote the tangent matrices. When sliding occurs, i.e. \(\omega =1\), Eq. (70) becomes

where \(\hat{e}\in \mathcal {E}_\ell \) denotes the master elements that contain the current interacting point \(\hat{\varvec{\xi }}{^{n+1}}\), and the tangent matrices are defined by

with

where

For the two-half-pass algorithm, all the tangent matrices associated with the variation of the master surface, i.e. \(\mathbf {k}_{\bar{\ell }k}\) and \(\mathbf {k}_{\bar{\ell }\bar{\ell }}\) in Eq. (71); \(\mathbf {k}_{\hat{\ell }k}\), \(\mathbf {k}_{\hat{\ell }\hat{\ell }}\), and \(\mathbf {k}_{\hat{\ell }\bar{\ell }}\) in Eq. (73), are not needed.

Rights and permissions

About this article

Cite this article

Duong, T.X., Sauer, R.A. A concise frictional contact formulation based on surface potentials and isogeometric discretization. Comput Mech 64, 951–970 (2019). https://doi.org/10.1007/s00466-019-01689-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-019-01689-0