Abstract

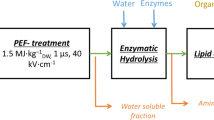

Microalgae are regarded as a promising source of biofuels, and the concept of a microalgae-based biorefinery has attracted increasing attention in recent years. From an economic perspective, however, the process remains far from competitive with fossil fuels. This is particularly true of lipid extraction, due in part to the energy-intensive drying step. As a result, wet extraction methods have been studied as an economic alternative. In the present study, a novel extraction approach which utilizes high shear stress mixing was adopted and demonstrated for simultaneous lipid extraction and cell disruption to enable the retrieval of lipids directly from concentrated wet biomass. When a high shear mixer (HSM) was used to extract lipid from a dense biomass (> 350 g/L) of the oleaginous algae Aurantiochytrium sp., it exhibited a yield of esterifiable lipids which exceeded 80% in 10 min at 15,000 rpm with various solvent types. The HSM was found to improve the lipid yields substantially with solvents less miscible with either lipids or water, such that the range of Hansen solubility parameters for the usable solvents became 3.3 times wider (14.9–26.5 MPa1/2). The HSM, which appeared effectively to loosen the water barrier that prevents solvent molecules from penetrating through the cell envelope, was found to be more efficient with hexane, hexane/isopropanol, and ethanol, all of which showed nearly identical lipid yields compared to the dry extraction process. The HSM can, indeed, offer a powerful mechanical means of lipid extraction with non-polar and less toxic solvents from wet biomass.

Similar content being viewed by others

References

Liang YN, Sarkany N, Cui Y (2009) Biomass and lipid productivities of Chlorella vulgaris under autotrophic, heterotrophic and mixotrophic growth conditions. Biotechnol Lett 31(7):1043–1049. https://doi.org/10.1007/s10529-009-9975-7

Li Q, Chen GQ, Fan KW, Lu FP, Aki T, Jiang Y (2009) Screening and characterization of squalene-producing thraustochytrids from Hong Kong Mangroves. J Agr Food Chem 57(10):4267–4272. https://doi.org/10.1021/Jf9003972

Suen YL, Tang H, Huang J, Chen F (2014) Enhanced production of fatty acids and astaxanthin in Aurantiochytrium sp. by the expression of vitreoscilla hemoglobin. J Agric Food Chem 62(51):12392–12398. https://doi.org/10.1021/jf5048578

Lardon L, Helias A, Sialve B, Steyer JP, Bernard O (2009) Life-cycle assessment of biodiesel production from microalgae. Environ Sci Technol 43(17):6475–6481. https://doi.org/10.1021/es900705j

Kim J, Yoo G, Lee H, Lim J, Kim K, Kim CW, Park MS, Yang JW (2013) Methods of downstream processing for the production of biodiesel from microalgae. Biotechnol Adv 31(6):862–876. https://doi.org/10.1016/j.biotechadv.2013.04.006

Halim R, Danquah MK, Webley PA (2012) Extraction of oil from microalgae for biodiesel production: a review. Biotechnol Adv 30(3):709–732. https://doi.org/10.1016/j.biotechadv.2012.01.001

Samarasinghe N, Fernando S, Lacey R, Faulkner WB (2012) Algal cell rupture using high pressure homogenization as a prelude to oil extraction. Renew Energ 48:300–308. https://doi.org/10.1016/j.renene.2012.04.039

Ma YA, Cheng YM, Huang JW, Jen JF, Huang YS, Yu CC (2014) Effects of ultrasonic and microwave pretreatments on lipid extraction of microalgae. Bioproc Biosyst Eng 37(8):1543–1549. https://doi.org/10.1007/s00449-014-1126-4

Byreddy AR, Barrow CJ, Puri M (2016) Bead milling for lipid recovery from thraustochytrid cells and selective hydrolysis of Schizochytrium DT3 oil using lipase. Bioresour Technol 200:464–469. https://doi.org/10.1016/j.biortech.2015.10.019

Lohman EJ, Gardner RD, Halverson L, Macur RE, Peyton BM, Gerlach R (2013) An efficient and scalable extraction and quantification method for algal derived biofuel. J Microbiol Meth 94(3):235–244. https://doi.org/10.1016/j.mimet.2013.06.007

Kim YH, Park S, Kim MH, Choi YK, Yang YH, Kim HJ, Kim H, Kim HS, Song KG, Lee SH (2013) Ultrasound-assisted extraction of lipids from Chlorella vulgaris using [Bmim][MeSO4]. Biomass Bioenerg 56:99–103. https://doi.org/10.1016/j.biombioe.2013.04.022

Piasecka A, Krzemiñska I, Tys J (2014) Physical methods of microalgal biomass pretreatment. Int Agrophys 28(3):341

Lee I, Han JI (2015) Simultaneous treatment (cell disruption and lipid extraction) of wet microalgae using hydrodynamic cavitation for enhancing the lipid yield. Bioresour Technol 186:246–251. doi:https://doi.org/10.1016/j.biortech.2015.03.045

Zhang JL, Xu SQ, Li W (2012) High shear mixers: a review of typical applications and studies on power draw, flow pattern, energy dissipation and transfer properties. Chem Eng Process 57–58:25–41. https://doi.org/10.1016/j.cep.2012.04.004

Shirgaonkar IZ, Lothe RR, Pandit AB (1998) Comments on the mechanism of microbial cell disruption in high-pressure and high-speed devices. Biotechnol Progr 14(4):657–660. doi:https://doi.org/10.1021/bp980052g

Lee AK, Lewis DM, Ashman PJ (2012) Disruption of microalgal cells for the extraction of lipids for biofuels: processes and specific energy requirements. Biomass Bioenerg 46:89–101. doi:https://doi.org/10.1016/j.biombioe.2012.06.034

Balasubramanian RK, Doan TTY, Obbard JP (2013) Factors affecting cellular lipid extraction from marine microalgae. Chem Eng J 215:929–936. doi:https://doi.org/10.1016/j.cej.2012.11.063

Hong WK, Rairakhwada D, Seo PS, Park SY, Hur BK, Kim CH, Seo JW (2011) Production of lipids containing high levels of docosahexaenoic acid by a newly isolated microalga, Aurantiochytrium sp KRS101. Appl Biochem Biotech 164(8):1468–1480. doi:https://doi.org/10.1007/s12010-011-9227-x

Choi SA, Jung JY, Kim K, Kwon JH, Lee JS, Kim SW, Park JY, Yang JW (2014) Effects of molten-salt/ionic-liquid mixture on extraction of docosahexaenoic acid (DHA)-rich lipids from Aurantiochytrium sp KRS101. Bioproc Biosyst Eng 37(11):2199–2204. https://doi.org/10.1007/s00449-014-1197-2

Kwak M, Park W-K, Shin S-E, Koh H-G, Lee B, Jeong B-r, Chang YK (2017) Improvement of biomass and lipid yield under stress conditions by using diploid strains of Chlamydomonas reinhardtii. Algal Res 26:180–189

Yoo G, Yoo Y, Kwon JH, Darpito C, Mishra SK, Pak K, Park MS, Im SG, Yang JW (2014) An effective, cost-efficient extraction method of biomass from wet microalgae with a functional polymeric membrane. Green Chem 16(1):312–319. https://doi.org/10.1039/c3gc41695j

Li Y, Naghdi FG, Garg S, Adarme-Vega TC, Thurecht KJ, Ghafor WA, Tannock S, Schenk PM (2014) A comparative study: the impact of different lipid extraction methods on current microalgal lipid research. Microb Cell Fact 13:14. https://doi.org/10.1186/1475-2859-13-14

Willis RM, McCurdy AT, Ogborn MK, Wahlen BD, Quinn JC, Pease LF, Seefeldt LC (2014) Improving energetics of triacylglyceride extraction from wet oleaginous microbes. Bioresource Technol 167:416–424. https://doi.org/10.1016/j.biortech.2014.06.013

Hara A, Radin NS (1978) Lipid extraction of tissues with a low-toxicity solvent. Anal Biochem 90(1):420–426

Dong T, Knoshaug EP, Pienkos PT, Laurens LM (2016) Lipid recovery from wet oleaginous microbial biomass for biofuel production: a critical review. Appl Energ 177:879–895

Moradi-Kheibari N, Ahmadzadeh H, Hosseini M (2017) Use of solvent mixtures for total lipid extraction of Chlorella vulgaris and gas chromatography FAME analysis. Bioproc Biosyst Eng 40(9):1363–1373. https://doi.org/10.1007/s00449-017-1794-y

Olmstead ILD, Kentish SE, Scales PJ, Martin GJO (2013) Low solvent, low temperature method for extracting biodiesel lipids from concentrated microalgal biomass. Bioresource Technol 148:615–619. https://doi.org/10.1016/j.biortech.2013.09.022

Byreddy AR, Gupta A, Barrow CJ, Puri M (2015) Comparison of cell disruption methods for improving lipid extraction from thraustochytrid strains. Mar Drugs 13(8):5111–5127. https://doi.org/10.3390/md13085111

Ranjan A, Patil C, Moholkar VS (2010) Mechanistic assessment of microalgal lipid extraction. Ind Eng Chem Res 49(6):2979–2985. https://doi.org/10.1021/ie9016557

Angles E, Jaouen P, Pruvost J, Marchal L (2017) Wet lipid extraction from the microalga Nannochloropsis sp.: disruption, physiological effects and solvent screening. Algal Res 21:27–34

Grima EM, González MJI, Giménez AG (2013) Solvent extraction for microalgae lipids. In: Borowitzka M, Moheimani N (eds) Algae for biofuels and energy. Developments in applied phycology, vol 5. Springer, Dordrecht, pp 187–205

Ramluckan K, Moodley KG, Bux F (2014) An evaluation of the efficacy of using selected solvents for the extraction of lipids from algal biomass by the soxhlet extraction method. Fuel 116:103–108. https://doi.org/10.1016/j.fuel.2013.07.118

Im H, Lee H, Park MS, Yang JW, Lee JW (2014) Concurrent extraction and reaction for the production of biodiesel from wet microalgae. Bioresour Technol 152:534–537. https://doi.org/10.1016/j.biortech.2013.11.023

Halim R, Rupasinghe TWT, Tull DL, Webley PA (2014) Modelling the kinetics of lipid extraction from wet microalgal concentrate: a novel perspective on a classical process. Chem Eng J 242:234–253. https://doi.org/10.1016/j.cej.2013.12.070

Acknowledgements

This work was supported by the Advanced Biomass R&D Center (ABC) of the Global Frontier Project funded by the Ministry of Science and ICT (ABC-2010-0029728). We thank Dr. Chul-Ho Kim at the Korea Research Institute of Bioscience and Biotechnology (KRIBB) for providing Aurantiochytrium sp. KRS101.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interests.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kwak, M., Kang, S.G., Hong, WK. et al. Simultaneous cell disruption and lipid extraction of wet aurantiochytrium sp. KRS101 using a high shear mixer. Bioprocess Biosyst Eng 41, 671–678 (2018). https://doi.org/10.1007/s00449-018-1901-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-018-1901-8