Abstract

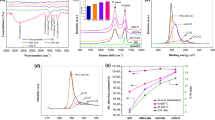

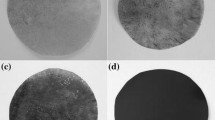

Functionalized graphene nanoplatelets (FGNPs) were synthesized through oxidative chlorophosphorylation (OxCh) reaction of graphite and subsequent hydrolysis of obtained chlorophosphonated graphite. Then FGNPs were used as a nanoscale filler to fabricate FGNPs/modified polybutadiene (MPB) hybrid composite (FGNPs/MPB). Fourier-transform infrared spectroscopy found that FGNPs have phosphonate functional groups and FGNPs/MPB has phosphonate and phosphate functional groups. X-ray diffraction showed that the thickness of FGNPs is 13.53 nm and the number of their layers is equal to 40, which are less than graphite’s thickness (37.08) and layers (111). FGNPs show high conductivity and dielectric permittivity than graphite, while FGNPs/MPB has improved electric properties than MPB without filler. Thermal properties of FGNPs/MPB also improve due to the fact that FGNPs achieve a high degree of dispersion with less agglomeration. As observed in the scanning electron microscope images, FGNPs/MPB displays a two-phase morphology with an MPB continuous phase and a dispersed FGNPs phase.

Graphical abstract

Similar content being viewed by others

References

Novoselov KS, Geim AK, Morozov SV et al (2004) Electric field effect in atomically thin carbon films. Science 306:666–669. https://doi.org/10.1126/science.1102896

Li B, Zhong WH (2011) Review on polymer/graphite nanoplatelet nanocomposites. J Mater Sci 46:5595–5614. https://doi.org/10.1007/s10853-011-5572-y

Pumera M (2010) Graphene-based nanomaterials and their electrochemistry. Chem Soc Rev 39:4146–4157. https://doi.org/10.1039/C002690P

Kotov NA (2006) Carbon sheet solutions. Nature 442:254–255. https://doi.org/10.1038/442254a

Kausar A, Muhammad W-U, Bakhtiar (2015) Processing and characterization of fire-retardant modified polystyrene/functional graphite composites. Compos Interfaces 22:517–530. https://doi.org/10.1080/09276440.2015.1049860

Nam K-H, Cho J, Yeo H (2018) Thermomechanical behavior of polymer composites based on edge-selectively functionalized graphene nanosheets. Polym 10:1–11. https://doi.org/10.3390/polym10010029

Nieto A, Lahiri D, Agarwal A (2012) Synthesis and properties of bulk graphene nanoplatelets consolidated by spark plasma sintering. Carbon 50:4068–4077. https://doi.org/10.1016/j.carbon.2012.04.054

Gatti T, Vicentini N, Mba M, Menna E (2016) Organic functionalized carbon nanostructures for functional polymer-based nanocomposites. Eur J Org Chem 2016:1071–1090. https://doi.org/10.1002/ejoc.201501411

Cunha E, Ren H, Lin F, Kinloch IA, Sun Q, Fan Z, Young RJ (2018) The chemical functionalization of graphene nanoplatelets through solvent-free reaction. RSC Adv 8:33564–33573. https://doi.org/10.1039/C8RA04817G

Aliyeva S, Alosmanov R, Buniyatzadeh I et al (2019) Recent developments in edge-selective functionalization of surface of graphite and derivatives – a review. Soft Mater 17:448–466. https://doi.org/10.1080/1539445X.2019.1600549

Goods JB, Sydlik SA, Walish JJ, Swager TM (2014) Phosphate functionalized graphene with tunable mechanical properties. Adv Mater 26:718–723. https://doi.org/10.1002/adma.201303477

Kim M-J, Jeon I-Y, Seo J-M, Dai L, Baek JB (2014) Graphene phosphonic acid as an efficient flame retardant. ACS Nano 8:2820–2825. https://doi.org/10.1021/nn4066395

Ghafuri H, Talebi M (2016) Water-soluble phosphated graphene: preparation, characterization, catalytic reactivity, and adsorption property. Ind Eng Chem Res 55:2970–2982. https://doi.org/10.1021/acs.iecr.5b02250

Liu X, Li J, Wang X, Chen C, Wang X (2015) High performance of phosphate-functionalized graphene oxide for the selective adsorption of U(VI) from acidic solution. J Nucl Mater 466:56–64. https://doi.org/10.1016/j.jnucmat.2015.07.027

Dehghani F, Sardarian AR, Doroodmand MM (2014) Preparation and characterization of multi-walled carbon nanotubes (MWCNTs), functionalized with phosphonic acid (MWCNTs–C–PO3H2) and its application as a novel, efficient, heterogeneous, highly selective and reusable catalyst for acetylation of alcohols, phenols, aromatic amines, and thiols. J Iran Chem Soc 11:673684–673684. https://doi.org/10.1007/s13738-013-0339-9

Ensafi AA, Golbon Haghighi M, Jafari-Asl M (2018) Phosphine-functionalized graphene oxide, a high-performance electrocatalyst for oxygen reduction reaction. Appl Surf Sci 427:722–729. https://doi.org/10.1016/j.apsusc.2017.08.011

Holt B, Arnold AM, Sydlik SA (2016) Phosphate functionalized graphene oxide as a bone graft substitute material. Front Bioeng Biotechnol Conference Abstract: 10th World Biomaterials Congress. https://doi.org/10.3389/conf.FBIOE.2016.01.00175

Kannan R, Bipinlal U, Kurungot S, Pillai VK (2011) Enhanced electrocatalytic performance of functionalized carbon nanotube electrodes for oxygen reduction in proton exchange membrane fuel cells. Phys Chem Chem Phys 13:10312–10317. https://doi.org/10.1039/C0CP02853C

Bai H, Li Y, Zhang H, Chen H, Wu W, Wang J, Liu J (2015) Anhydrous proton exchange membranes comprising of chitosan and phosphorylated graphene oxide for elevated temperature fuel cells. J Membr Sci 495:48–60. https://doi.org/10.1016/j.memsci.2015.08.012

Żelechowska K, Prześniak-Welenc M, Łapiński M, Kondratowicz I, Miruszewski T (2017) Fully scalable one-pot method for the production of phosphonic graphene derivatives. Beilstein J Nanotechnol 8:1094–1103 10.3762%2Fbjnano.8.111

Shukla G, Pandey RP, Shahi VK (2016) Temperature resistant phosphorylated graphene oxide-sulphonated polyimide composite cation exchange membrane for water desalination with improved performance. J Membr Sci 520:972–982. https://doi.org/10.1016/j.memsci.2016.08.050

Cai Y, Wu C, Liu Z, Zhang L, Chen L, Wang J, Wang X, Yang S, Wang S (2017) Fabrication of a phosphorylated graphene oxide–chitosan composite for highly effective and selective capture of U(VI). Environ Sci Nano 4:1876–1886. https://doi.org/10.1039/C7EN00412E

Li J, Li X, Zhu K, Wang H, Fei G (2018) Reinforcement of phosphorylated graphene oxide on the anticorrosive properties of waterborne acrylate-epoxy resin coatings. J Macromol Sci Part A 55:649–657. https://doi.org/10.1080/10601325.2018.1504611

Alosmanov R, Wolski K, Matuschek G, Magerramov A, Azizov A, Zimmermann R, Aliyev E, Zapotoczny S (2017) Effect of functional groups on the thermal degradation of phosphorus- and phosphorus/nitrogen-containing functional polymers. J Therm Anal Calorim 130:799–812. https://doi.org/10.1007/s10973-017-6464-4

Boehm HP (1994) Some aspects of the surface chemistry of carbon blacks and other carbons. Carbon 32:759–769. https://doi.org/10.1016/0008-6223(94)90031-0

Crompton TR (1993) Practical polymer analysis. Plenum Press, New York

Socrates G (2004) Long DA (2004) Infrared and Raman characteristic group frequencies. Tables and ChartsThird edn. John Wiley and Sons, Chichester

Bragg WH, Bragg WL (1913) The reflection of X-rays by crystals. Proc R Soc London Ser A 88:428–438

Patterson AL (1939) The Scherrer formula for X-ray particle size determination. Phys Rev 56:978–982. https://doi.org/10.1103/PhysRev.56.978

Girgis BS, Temerk YM, Gadelrab MM, Abdullah ID (2007) X-ray diffraction patterns of activated carbons prepared under various conditions. Carbon Lett 8:95–100. https://doi.org/10.5714/CL.2007.8.2.095

Jeon I-Y, Choi H-J, Jung S-M, Seo JM, Kim MJ, Dai L, Baek JB (2013) Large-scale production of edge-selectively functionalized graphene nanoplatelets via ball milling and their use as metal-free electrocatalysts for oxygen reduction reaction. J Am Chem Soc 135:1386–1393. https://doi.org/10.1021/ja3091643

Liu C, Hu G (2014) Effect of nitric acid treatment on the preparation of graphene sheets by supercritical N,N-dimethylformamide exfoliation. Ind Eng Chem Res 53:14310–14314. https://doi.org/10.1021/ie5019707

Hatui G, Malas A, Bhattacharya P et al (2015) Effect of expanded graphite and PEI-co-silicon rubber on the thermo mechanical, morphological as well as rheological properties of in situ composites based on poly (ether imide) and liquid crystalline polymer. J Alloys Compd 619:709–718. https://doi.org/10.1016/j.jallcom.2014.08.144

Jeon I-Y, Shin Y-R, Sohn G-J et al (2012) Edge-carboxylated graphene nanosheets via ball milling. Proc Natl Acad Sci 109:5588 LP – 5593. https://doi.org/10.1073/pnas.1116897109

Antunes M, Gedler G, Abbasi H, Velasco JI (2016) Graphene nanoplatelets as a multifunctional filler for polymer foams. Mater Today Proc 3:S233–S239. https://doi.org/10.1016/j.matpr.2016.02.039

Ben Difallah B, Kharrat M, Dammak M, Monteil G (2012) Microstructure, friction and wear analysis of thermoplastic based composites with solid lubricant. Mech Ind 13:337–346. https://doi.org/10.1051/meca/2012041

Hong X, Yu W, Chung DDL (2017) Electric permittivity of reduced graphite oxide. Carbon 111:182–190. https://doi.org/10.1016/j.carbon.2016.09.071

Galindo B, Alcolea SG, Gómez J (2014) Effect of the number of layers of graphene on the electrical properties of TPU polymers. IOP Conf Ser: Mater Sci Eng 64:12008. https://doi.org/10.1088/1757-899X/64/1/012008

Fang X-Y, Yu X-X, Zheng H-M, Jin HB, Wang L, Cao MS (2015) Temperature- and thickness-dependent electrical conductivity of few-layer graphene and graphene nanosheets. Phys Lett A 379:2245–2251. https://doi.org/10.1016/j.physleta.2015.06.063

Grove TT, Masters MF, Miers RE (2005) Determining dielectric constants using a parallel plate capacitor. Am J Phys 73:52–56. https://doi.org/10.1119/1.1794757

Wang A, Chung DDL (2014) Dielectric and electrical conduction behavior of carbon paste electrochemical electrodes, with decoupling of carbon, electrolyte and interface contributions. Carbon 72:135–151. https://doi.org/10.1016/j.carbon.2014.01.066

Fang X, Liu X, Cui Z-K, Qian J, Pan J, Li X, Zhuang Q (2015) Preparation and properties of thermostable well-functionalized graphene oxide/polyimide composite films with high dielectric constant, low dielectric loss and high strength via in situ polymerization. J Mater Chem A 3:10005–10012. https://doi.org/10.1039/C5TA00943J

Güler Ö, Güler SH, Selen V, Albayrak MG, Evin E (2016) Production of graphene layer by liquid-phase exfoliation with low sonication power and sonication time from synthesized expanded graphite. Fullerenes Nanotubes Carbon Nanostruct 24:123–127. https://doi.org/10.1080/1536383X.2015.1114472

Kong B-S, Geng J, Jung H-T (2009) Layer-by-layer assembly of graphene and gold nanoparticles by vacuum filtration and spontaneous reduction of gold ions. Chem Commun:2174–2176. https://doi.org/10.1039/B821920F

Bhattacharya P, Dhibar S, Hatui G, Mandal A, Das T, Das CK (2014) Graphene decorated with hexagonal shaped M-type ferrite and polyaniline wrapper: a potential candidate for electromagnetic wave absorbing and energy storage device applications. RSC Adv 4:17039–17053. https://doi.org/10.1039/C4RA00448E

Doyle CD (1961) Estimating thermal stability of experimental polymers by empirical thermogravimetric analysis. Anal Chem 33:77–79. https://doi.org/10.1021/ac60169a022

Yasmin A, Daniel IM (2004) Mechanical and thermal properties of graphite platelet/epoxy composites. Polymer 45:8211–8219. https://doi.org/10.1016/j.polymer.2004.09.054

Ma W, Wu L, Zhang D, Wang S (2013) Preparation and properties of 3-aminopropyltriethoxysilane functionalized graphene/polyurethane nanocomposite coatings. Colloid Polym Sci 291:2765–2773. https://doi.org/10.1007/s00396-013-3014-x

Macan J, Brnardić I, Orlić S, Ivanković H, Ivanković M (2006) Thermal degradation of epoxy–silica organic–inorganic hybrid materials. Polym Degrad Stab 91:122–127. https://doi.org/10.1016/j.polymdegradstab.2005.04.024

Bajaj P, Jha NK, Kumar RA (2018) Effect of mica on the curing behavior of an amine-cured epoxy system: differential scanning calorimetric studies. J Appl Polym Sci 40:203–212. https://doi.org/10.1002/app.1990.070400116

Tuteja A, Mackay ME, Hawker CJ, Van Horn B (2005) Effect of ideal, organic nanoparticles on the flow properties of linear polymers: non-Einstein-like behavior. Macromolecules 38:8000–8011. https://doi.org/10.1021/ma050974h

Abot JL, Yasmin A, Daniel IM (2002) Mechanical and thermoviscoelastic behavior of clay/epoxy nanocomposites. MRS Proc 740:I6.5. https://doi.org/10.1557/PROC-740-I6.5

Liu K, Chen S, Luo Y, Jia D, Gao H, Hu G, Liu L (2013) Edge-functionalized graphene as reinforcement of epoxy-based conductive composite for electrical interconnects. Compos Sci Technol 88:84–91. https://doi.org/10.1016/j.compscitech.2013.08.032

Pandit JA, Sudarshan K, Athawale AA (2016) Electrically conductive epoxy-polyester-graphite nanocomposites modified with aromatic amines. Polymer 104:49–60. https://doi.org/10.1016/j.polymer.2016.09.084

Sarkar S, Bekyarova E, Niyogi S, Haddon RC (2011) Diels−Alder chemistry of graphite and graphene: graphene as diene and dienophile. J Am Chem Soc 133:3324–3327. https://doi.org/10.1021/ja200118b

Jeon I-Y, Choi E-K, Bae S-Y, Baek J-B (2010) Edge-functionalization of pyrene as a miniature graphene via Friedel–crafts acylation reaction in poly(phosphoric acid). Nanoscale Res Lett 5:1686–1691. https://doi.org/10.1007/s11671-010-9697-8

Dogadina AV, Ionin BI, Petrov AA (1990) 1,3-Alkadiene-phosphonates. Sov Sci Rev B Chem 15:1–55

Schroeder JP, Sopchak WP (1960) The reaction of phosphorus trichloride and oxygen with polymers. J Polym Sci 47:417–433. https://doi.org/10.1002/pol.1960.1204714937

Boyce CBC, Webb SB, Phillips L (1974) The phosphorus trichloride–oxigen–olefin reaction: scope and mechanism. J Chem Soc Perkin Trans 1:1650–1658. https://doi.org/10.1039/P19740001650

Acknowledgments

The authors thank Melytec LLC for providing help in SEM-EDS analysis of samples. The authors also thank Emin Aliyev, MA for providing language help.

Funding

This work was supported by the Science Development Foundation under the President of the Republic of Azerbaijan – Grant № EİF/MQM/Elm-Tehsil-1-2016-1(26)-71/02/4.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Aliyeva, S., Alosmanov, R., Buniyatzadeh, I. et al. Functionalized graphene nanoplatelets/modified polybutadiene hybrid composite. Colloid Polym Sci 297, 1529–1540 (2019). https://doi.org/10.1007/s00396-019-04565-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-019-04565-8