Abstract

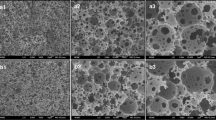

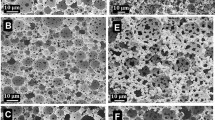

Glycidylmethacrylate (GMA)-based poly(high internal phase emulsion) (polyHIPE) monoliths were prepared using a HIPE template via radiation-induced polymerization at room temperature. The effects of surfactant content, cross-linking degree, water fraction, and porogen content on the surface area, average void diameter, distribution of void diameter, average interconnection diameter, average pore diameter, and epoxy group content of GMA-based polyHIPE monoliths were investigated. The morphology and epoxy group content of GMA-based polyHIPE monoliths may be tailored by tuning each of the factors above according to the requirements of specific applications. Finally, the different morphology and epoxy group content of GMA-based polyHIPE monoliths were applied in phenol removal from cigarette smoke (CS) through a reaction between the epoxy group and phenol. The results showed that GMA-based polyHIPE monoliths with the higher content of epoxy group and bigger surface area showed the higher rate of phenol removal.

Similar content being viewed by others

References

Cameron NR, Sherrington DC (1996) High internal phase emulsions (HIPEs)—Structure, properties and use in polymer preparation. Adv Polym Sci 126:163–214

Hainey P, Huxham IM, Rowatt B, Sherrington DC, Tetley L (1991) Synthesis and ultrastructural studies of styrene-divinylbenzene polyhipe polymers. Macromolecules 24:117–121

Barbetta A, Cameron NR, Cooper SJ (2000) Chem Commun 221–222

Zhang H, Cooper AI (2005) Synthesis and applications of emulsion-templated porous materials. Soft Matter 1:107–113

Menner A, Powell R, Bismarck A (2006) Open porous polymer foams via inverse emulsion polymerization: should the definition of high internal phase (ratio) emulsions be extended? Macromolecules 39:2034–2035

Cameron NR (2005) High internal phase emulsion templating as a route to well-defined porous polymers. Polymer 46:1439–1449

Busby W, Cameron NR, Jahoda CA (2001) Emulsion-derived foams (PolyHIPEs) containing poly(ε-caprolactone) as matrixes for tissue engineering. Biomacromolecules 2:154–164

Christenson EM, Soofi W, Holm J, Cameron NR, Mikos AG (2007) Biodegradable fumarate-based polyHIPEs as tissue engineering scaffolds. Biomacromolecules 8:3806–3814

Akay G, Birchand MA, Bokhari MA (2004) Microcellular polyHIPE polymer supports osteoblast growth and bone formation in vitro. Biomaterials 25:3991–4000

Bokhari M, Carnachan RJ, Przyborski SA, Cameron NR (2007) Emulsion-templated porous polymers as scaffolds for three dimensional cell culture: effect of synthesis parameters on scaffold formation and homogeneity. J Mater Chem 17:4088–4094

Zhao C, Danish E, Cameron NR, Kataky R (2007) Emulsion-templated porous materials (PolyHIPEs) for selective ion and molecular recognition and transport: applications in electrochemical sensing. J Mater Chem 17:2446–2453

Small PW, Sherrington DC (1989). J Chem Soc-Chem Commun 21:1589–1591

Ottens M, Leene G, Beenackers ACCM, Cameron NR, Sherrington DC (2000) PolyHipe: a new polymeric support for heterogeneous catalytic reactions: kinetics of hydration of cyclohexene in two- and three-phase systems over a strongly acidic sulfonated polyHipe. Ind Eng Chem Res 39:259–266

Zhang S, Chen J, Perchyonok VT (2008) PolyHIPEs as novel media for conventional free radical chemistry. Lett Org Chem 5:304–309

Su F, Bray CL, Tan B, Cooper AI (2008) Rapid and reversible hydrogen storage in clathrate hydrates using emulsion-templated polymers. Adv Mater 20:2663–2666

Barbetta A, Cameron NR (2004) Morphology and surface area of emulsion-derived (PolyHIPE) solid foams prepared with oil-phase soluble porogenic solvents: span 80 as surfactant. Macromolecules 37:3188–3201

Barbetta A, Cameron NR (2004) Morphology and surface area of emulsion-derived (PolyHIPE) solid foams prepared with oil-phase soluble porogenic solvents: three-component surfactant system. Macromolecules 37:3202–3213

Carnachan RJ, Bokhari M, Przyborski SA, Cameron NR (2006) Tailoring the morphology of emulsion-templated porous polymers. Soft Matter 2:608–616

Mao DL, Li TT, Liu HR, Li ZC (2013) Colloid polymer. Science 291:1649–1656

Cameron NR, Sherrington DC (1997) Preparation and glass transition temperatures of elastomeric polyHIPE materials. J Mater Chem 7:2209–2212

Edwards JC, Gregory DP, Sharples M, Eur Pat 239360, 1987

Edwards JC, Gregory DP (1988) Sharples M. US Pat 4788225

Bayramoğlu G, Kaya B, Arica MY (2005) Immobilization of lipase onto spacer-arm attached poly(GMA-HEMA-EGDMA) microspheres. Food Chem 92:261–268

Bayramoğlu G, Akgöl S, Bulut A, Denizli A, Arica MY (2003) Covalent immobilisation of invertase onto a reactive film composed of 2-hydroxyethyl methacrylate and glycidyl methacrylate: properties and application in a continuous flow system. Biochem Eng J 14:117–126

Benčina M, Benčina K, Štrancar A, Podgornik A (2005) Immobilization of deoxyribonuclease via epoxy groups of methacrylate monoliths. J Chromat A 1065:83–91

Zhang X, Guan RF, Chan DY (2005) Enzyme immobilization on amino-functionalized mesostructured cellular foam surfaces, characterization and catalytic properties. J Mol Catal B: Enzymatic 33:43–50

Petro M, Svec F, Frèchet JM (1996) Immobilization of trypsin onto “molded” macroporous poly(glycidyl methacrylate-co-ethylene dimethacrylate) rods and use of the conjugates as bioreactors and for affinity chromatography. Biotechnol Bioeng 49:355–363

Godjrvargova T, Kousolov V, Dimov A (1999) Preparation of an ultrafiltration membrane from the copolymer of acrylonitrile–glycidylmethacrylate utilized for immobilization of glucose oxidase. J Membrane Sci 152:235–242

Svec F, Frèchet JM (1995). J Chromat A 705:89–103

Svec F, Frèchet JM (1995) “Molded” rods of macroporous polymer for preparative separations of biological products. Biotechnol Bioeng 48:476–480

Luo Q, Zou H, Xiao X, Guo Z, Kong L, Mao X (2001) Chromatographic separation of proteins on metal immobilized iminodiacetic acid-bound molded monolithic rods of macroporous poly(glycidyl methacrylate–co-ethylene dimethacrylate). J Chromatogr 926:255–264

Majer J, Krajnc P (2010) Amine Functionalisations of Glycidyl methacrylate Based PolyHIPE Monoliths. Macromol Symp 296:5–10

Sprob J, Sinz A (2012). Anal Bioanal Chem 402:2395–2405

Jia M, Qin L, He XW, Li WY (2012) Preparation and application of lysozyme imprinted monolithic column with dopamine as the functional monomer. J Mater Chem 22:707–713

Su RH, Ruan GH, Nie HG, Xie T, Zheng YJ, Du FY, Li JP (2015) Development of high internal phase emulsion polymeric monoliths for highly efficient enrichment of trace polycyclic aromatic hydrocarbons from large-volume water samples. J Chromat A 1405:23–31

Van Berkel PM, Punt M, Koolhaas GJAA, Driessen WL, Reedijk J, Sherrington DC (1997) React Funct Polym 32:139–151, Highly copper(II)-selective chelating ion-exchange resins based ion bis(imidazole)-modified glycidyl methacrylate copolymers

Hainey P, Sherrington DC (2000) Oligoamine-functionalised poly(glycidyl methacrylate-ethyleneglycol dimethacrylate) resins as moderate base extractants for gold from cyanide solutions. React Funct Polym 43:195–210

Bicak N, Sherrington DC, Sungur TS, Nükhet T (2003) A glycidyl methacrylate-based resin with pendant urea groups as a high capacity mercury specific sorbent. React Funct Polym 54:141–147

Beneš MJ, Horák D, Švec F (2005) Methacrylate-based chromatographic media. J Sep Sci 28:1855–1875

Krajnc P, Leber N, Štefanec D, Kontrec S, Podgornik A (2005) Preparation and characterisation of poly(high internal phase emulsion) methacrylate monoliths and their application as separation media. J Chromat A 1065:69–73

Yao CH, Qi L, Jia HY, Xin PY, Yang GL, Chen Y (2009) A novel glycidyl methacrylate-based monolith with sub-micron skeletons and well-defined macropores. J Mater Chem 19:767–772

Barbetta A, Dentini M, Leandri L, Ferraris G, Coletta A (2009) Synthesis and characterization of porous glycidylmethacrylate–divinylbenzene monoliths using the high internal phase emulsion approach. React Funct Polym 69:724–736

Yang S, Zeng L, Wang YP, Sun XH, Sun PJ, Liu HM, Nie C, Liu HR (2014) Facile approach to glycidyl methacrylate-based polyHIPE monoliths with high epoxy-group content. Colloid Polym Sci 292:2563–2570

Wang XB, Zhang ZC, Chen J, Wang SJ (2007) Preparation of charged polystyrene microlatexes by emulsion polymerization induced by gamma rays. Mater Lett 61:2662–2666

Wu DZ, Ge XW, Zhang ZC, Wang MZ, Zhang SL (2004) Novel one-step route for synthesizing CdS/polystyrene nanocomposite hollow spheres. Langmuir 20:5192–5195

Yang S, Liu HR (2006) A novel approach to hollow superparamagnetic magnetite/polystyrene nanocomposite microspheres via interfacial polymerization. J Mater Chem 16:4480–4487

Yang S, Liu HR, Zhang ZC (2008) A facile route to hollow superparamagnetic magnetite/polystyrene nanocomposite microspheres via inverse miniemulsion polymerization. J Polym Sci Pol Chem 46:3900–3910

Yang S, Liu HR, Huang HF, Zhang ZC (2009) Fabrication of superparamagnetic magnetite/poly(styrene-co-12-acryloxy-9-octadecenoic acid) nanocomposite microspheres with controllable structure. J Colloid Interf Sci 338:584–590

Li TT, Liu HR, Zeng L, Yang S, Li ZC, Zhang JD, Zhou XT (2011) Macroporous magnetic poly(styrene–divinylbenzene) nanocomposites prepared via magnetite nanoparticles-stabilized high internal phase emulsions. J Mater Chem 21:12865–12872

Mao DL, Li TT, Liu HR, Liu ZC, Shao H, Li Min (2013) Colloid Poly Sci 291:1649–1656

Wang SF, Zhang ZC, Liu HR, Zhang W, Qian Z, Wang BB (2010) One-step synthesis of manganese dioxide/polystyrene nanocomposite foams via high internal phase emulsion and study of their catalytic activity. Colloid Poly Sci 288:1031–1039

Atawodi SE, Preussmann R, Spiegelhalder B (1995) Tobacco-specific nitrosamines in some Nigerian cigarettes. Cancer Lett 97:1–6

Health Canada Test Method T-1140-Determination of Phenolic Compounds in Mainstream Tobacco Smoke, 1999

Williams JM, Wrobleski DA (1988) Spatial distribution of the phases in water-in-oil emulsions. Open and closed microcellular foams from cross-linked polystyrene. Langmuir 4:656–662

Williams JM, Gray AJ, Wilkerson MH (1990) Emulsion stability and rigid foams from styrene or divinylbenzene water-in-oil emulsions. Langmuir 6:437–444

Cameron NR (2005). Polymer 1:107–113

Barbetta A, Cameron NR (2004) Morphology and surface area of emulsion-derived (polyHIPE) solid foams prepared with oil-phase soluble porogenic solvents: span 80 as surfactant. Macromolecules 37:3188–3201

Barbetta A, Cameron NR (2004) Morphology and surface area of emulsion-derived (polyHIPE) solid foams prepared with oil-phase soluble porogenic solvents: three-component surfactant system. Macromolecules 37:3202–3213

Cameron NR, Barbetta A (2000) The influence of porogen type on the porosity, surface area and morphology of poly(divinylbenzene) polyHIPE foams. J Mater Chem 10:2466–2471

Xie JP (2008) CORESTA congress. Shanghai, China

Acknowledgements

The authors thank the National Natural Science Foundation of China (no. 51003122), the Dean Science and Technology Development Fund Project of Zhengzhou Tobacco Research Institute (no. 332016CA0210), the Key Science and Technology Projects of CNTC (no. 312010AA0040), and the National Science and Technology Project of China (no. 322012AK0030) for their financial support.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Yang, S., Wang, Y., Jia, Y. et al. Tailoring the morphology and epoxy group content of glycidyl methacrylate-based polyHIPE monoliths via radiation-induced polymerization at room temperature. Colloid Polym Sci 296, 1005–1016 (2018). https://doi.org/10.1007/s00396-018-4307-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-018-4307-x