Abstract

Tin dioxide (SnO2) behaves excellent properties, but the high recombination rate of photoexcited electron–hole pairs combined with a large band gap restricts its photocatalytic applications. Comparing with pure SnO2 nanospheres, the photocatalytic degradation of rhodamine B (RhB) over polymer/reduced graphene oxide (rGO)/SnO2 composites was enhanced. For the synthesis, graphene oxide (GO) nanosheets were wrapped on the surface of polymer microspheres to form a polymer/GO core–shell structure. Then, SnO2 nanospheres were decorated on polymer/GO microspheres under a hydrothermal condition, meanwhile GO was reduced to rGO. Therefore, polymer/rGO/SnO2 hierarchical structure was obtained. As graphene promote separation of the photoexcited electron–hole pairs and the conduction band potential of SnO2 is more positive than the work function of graphene, electrons can be quickly transferred to the conduction band of SnO2 via graphene leaving over more holes on the surface of catalyst for the de-ethylation of RhB.

Similar content being viewed by others

Introduction

Nanostructured metal oxide semiconductors, such as titanium dioxide (TiO2) and zinc oxide (ZnO) have been considered as the alternative materials for photodegradation of organic pollutants [1–3] because of their unique chemical, electronic, and optical properties, strong oxidizing power and low cost. Among the binary metal oxide, tin dioxide (SnO2) is a well-known large band gap multifunctional material that found widespread applications in the fields of lithium rechargeable batteries [4], gas sensors [5–7], and photovoltaic conversion [8–10]. Because of the more positive conduction band (CB) edge, SnO2 is a better electron acceptor than TiO2 and ZnO [11, 12] that makes it a good potential candidate in the field of photocatalysis. However, the high recombination rate of photoexcited electron–hole pairs combined with a large band gap (3.8 eV) restricts its photocatalytic applications.

Graphene, a monolayer of carbon atoms arranged in two-dimensional nanostructure, has attracted much attention due to its large surface area, high chemical stability, and unique electronic properties. Graphene oxide (GO), a derivative of graphene, has controllable surface chemistry that allows it to be well dispersed in common solvents as individual sheet. Owing to the presence of oxygen-containing groups, such as carboxyl, hydroxyl, and epoxide functional groups [13], GO can interact with cations and provide reactive sites for the nucleation and growth of nanoparticles [14–16]. Therefore, GO has been emerged as a precursor to various graphene-based functional composites. During the functionalization, GO can be reduced to reduced graphene oxide (rGO) with partial restoration of the sp 2-hybridized network. In this way, rGO can partially restore the electrical conductivity of the original graphene and improve the properties and applications of the composites, such as TiO2–graphene [17–19]. As a consequence, combining with rGO will be an efficient way to enhance the photocatalytic property of SnO2.

In this work, a polymer/rGO/SnO2 hierarchical structure composed of SnO2 nanospheres on polymer/rGO core–shell microspheres was synthesized, and its mechanism of photodegradation for rhodamine B (RhB) was proposed. Comparing with pure SnO2 nanospheres, the photocatalytic property of polymer/rGO/SnO2 composites was enhanced mainly due to the interactions between rGO and SnO2.

Experimental

Preparation

GO nanosheets were prepared from natural graphite flakes by a modified Hummers’ method [20]. Poly (styrene-co-glycidyl methacrylate) microspheres were synthesized and then reacted with ethylenediamine to form amino-poly (styrene-co-glycidyl methacrylate) microspheres. The amino-polymer was then wrapped by GO with a weight ratio of 1:0.03 (amino-polymer:GO) to form GO-wrapped polymer/GO core–shell microspheres as previously reported [21]. In this way, the contact area between GO nanosheets was reduced to prevent their re-stacking. Subsequently, 0.155 g polymer/GO microspheres were dispersed in 80 mL sodium stannate trihydrate (Na2SnO3·3H2O) aqueous solution containing Na2SnO3·3H2O (0.267 g), NaOH (0.2 g), and [EMIm] BF4 ionic liquid (1.5 g). The mixture was transferred into 100 mL Teflon-lined stainless steel autoclave and heated at 190 °C in an airflow electric oven for 24 h. Afterwards, the obtained dark-gray polymer/rGO/SnO2 products were washed with deionized water and absolute ethanol several times, collected by centrifugation, followed by drying at room temperature in a vacuum oven prior to the photocatalytic experiments. As a comparison, pure SnO2 nanospheres without polymer/GO microspheres were also synthesized under the same hydrothermal conditions.

Characterization

X-ray diffraction (XRD) was performed on a D/MAX-2550 diffractometer (CuKα, 5° ≤ 2θ ≤ 80°, Δ2θ = 0.02°). The microstructure and morphology were examined on a Hitachi S-4800 microscope. The Raman spectra were recorded using an Iuvia Reflex Raman microscope from 100 to 3000 cm−1 at an excitation wavelength of 514.5 nm. Thermogravimetric analysis (TGA) was performed on a Netzsch STA 409PC instrument, heated under N2 from room temperature to 900 °C with a rate of 5 K/min. The ultraviolet and visible (UV–Vis) absorption spectra were measured by a Varian Cary 500 UV spectrophotometer with the scanning range from 200 to 800 nm. X-ray photoelectron spectroscopy (XPS) was measured at room temperature on an ESCALAB 250 using Al Kα as the exciting source.

Photodegradation experiments

For the photodegradation experiments, RhB was an analytical reagent and was used as supplied. Catalyst of 20 mg was dispersed in 60 mL RhB solution (10 ppm). First, the suspension was stirred for 30 min under dark to reach adsorption/desorption equilibrium. Subsequently, the suspension was irradiated by a CEL-TCH 150-W halogen lamp under a visible light region (380–780 nm). Every a given time, a 4-mL suspension was collected and centrifuged (8000 rpm, 15 min) to separate the catalyst, then the supernatant fluid was examined by a UV–Vis (TU-1810) spectrophotometer. The degree of photodegradation was calculated by measuring the maximum absorbance of RhB at 554 nm.

Results and discussion

The XRD pattern of GO nanosheets shows a strong diffraction peak at 2θ = 9.1° (Fig. 1), indicating the presence of a layered structure with d-spacing of 0.97 nm for GO [22].

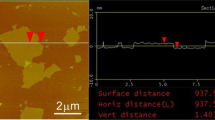

The morphology of amino-polymer and polymer/GO is similar to that observed previously [21]. They have a spherical shape and the size is about 2.5 μm as shown in Fig. 2a, b. Comparing with amino-polymer, owing to the folded and tiled features of GO layers, the surface of polymer/GO microspheres becomes rough with wrinkled structures (inset, Fig. 2b) which can provide effective sites for the nucleation and growth of nanoparticles. For the morphology of polymer/rGO/SnO2 hierarchical structures, a large number of SnO2 nanospheres with a uniform size of about 100 nm are located on the surface of polymer/rGO microspheres but not completely covered (Fig. 2c). In addition, another combing way is indicated that SnO2 nanospheres are wrapped by rGO as the layered structures over the composites are observed (Fig. 2d). Figure 2e shows that the decorated SnO2 nanospheres are built by a great many small-sized nanoparticles leading to a rough surface which helps to adsorb organic molecules. Moreover, pure SnO2 nanospheres for contrast photocatalytic degradation experiments were obtained as shown in Fig. 2f.

Further evidence of the polymer/rGO/SnO2 composites is from XRD pattern and Raman spectra. The XRD pattern of polymer/rGO/SnO2 is displayed in Fig. 3a; all the diffraction peaks are well indexed to rutile SnO2 indicating the formation of SnO2 crystalline phase. The mean crystallite size of SnO2 nanoparticles is 6.9, 8.5, and 7.3 nm by applying the Scherrer’s formula to three characteristic diffraction peaks at 2θ = 26.41°, 33.89°, and 51.68°, respectively. The results consist with FE-SEM images that the SnO2 nanospheres are formed by numerous small-sized nanoparticles. Raman spectra of polymer/GO and polymer/rGO/SnO2 (Fig. 3b) display two signals at 1350 and 1600 cm−1 corresponding to the typical D and G bands of graphene. The D band is due to the covalently attached functional groups, resulting in the formation of sp 3 bonds in the carbon network. The G band is derived from the stretching of the sp 2-hybridized carbon–carbon bonds [23]. The intensity ratio of G band to D band for polymer/rGO/SnO2 (G/D = 1.52) is larger than that for polymer/GO (G/D = 1.41), suggesting an increase in the average size of the sp 2 carbon domains. The results suggest that GO can be reduced during the process of SnO2 decoration under hydrothermal conditions.

To gain a better insight into the surface composition and the band alignment in the polymer/rGO/SnO2 composites, XPS studies were performed. As shown in XPS spectrum (Fig. 4a), the signals of C, Sn, and O elements are clearly observed. In addition, the weak peak corresponding to F element is due to the residual ionic liquid in the final products. C 1s XPS spectrum (Fig. 4b) shows binding energies at 284.6 eV (C–C, sp 2), 285.6 eV (C–OH/C–NH), 286.7 eV (C–O), and 289.1 eV (O–C=O) [24, 25]. XPS spectrum for Sn 3d (Fig. 4c) displays two signals at 486.8 and 495.2 eV which are assigned to Sn 3d5/2 and Sn 3d3/2, respectively [26]. The measured emission lines of Sn 3d correspond to a binding energy of Sn4+ ion in SnO2 [12].

To investigate the weight percent of different components, TGA measurement was performed on polymer/rGO/SnO2 composites. As shown in TGA curve (Fig. 5), three steps of mass loss can be observed. The first step from 20 to 60 °C is attributed to the evaporation of absorbed water. The second step observed from 340 to 390 °C shows a significant mass loss of about 39.39 % due to the decomposition of polymer microspheres and the removal of residual oxygen-containing groups of rGO [27]. The third step from 445 to 482 °C with about 5.87 % mass loss relates to an unstable carbon remaining in the main structure to yield CO and CO2 [27]. At 900 °C, the residual mass of polymer/rGO/SnO2 is about 51.92 % due to the presence of SnO2 and a little percent of rGO.

The UV–Vis absorption spectrum of polymer/rGO/SnO2 composites presents two peaks in the range of 200–300 nm (Fig. 6) owing to the presence of polymer microspheres [21]. The optical absorption of polymer/rGO/SnO2 near the band edge is assumed to follow the formula αhν = A (hν − Eg)0.5, where α, ν, Eg, and A are the absorption coefficient, light frequency, band gap energy, and a constant, respectively. The band gap energy (Eg) of polymer/rGO/SnO2 estimated from a plot of (αhν)2 versus photon energy (hν) is 3.8 eV.

To evaluate the photocatalytic activity of polymer/rGO/SnO2 composites, the photocatalytic degradation of RhB was performed as a test reaction. As displayed in Fig. 7, the main absorbance of the solution shifts gradually from the initial 554 nm to a shorter wavelength and finally reaches at 498 nm. It agrees well with the report of Zhao et al. about the SiW12O40 4− ions/RhB process [28]. The blue shift of absorbance peak corresponds to a step-by-step de-ethylation of RhB, and the peak centered at 498 nm is assigned to the absorbance of rhodamine (R), which is the completely de-ethylated product of RhB. Furthermore, blank experiments in the presence of irradiation without photocatalyst or in the absence of irradiation with the photocatalyst as well as similar experiments with polymer/rGO and SnO2 nanospheres were carried out to rationalize the photocatalytic activity of the polymer/rGO/SnO2 composites. The degradation efficiency of the samples was defined as C/C0, where C0 is initial concentration of RhB (λ = 554 nm), after equilibrium adsorption, and C is concentration during the degradation. As shown in Fig. 8, both the results of blank experiments indicate that RhB could not be de-ethylated or decomposed without polymer/rGO/SnO2 or light irradiation. In addition, the comparing experiments suggest that polymer/rGO or pure SnO2 nanospheres have no photocatalytic property for de-ethylation or decomposition of RhB. During the studies, pH value (≈4.7) of the solution used for the photocatalytic experiments is found to be independent of the photocatalysts. Concluded from the results, the photocatalytic performance of polymer/rGO/SnO2 composites is mainly attributed to the interactions between graphene and SnO2 nanospheres.

The mechanism of photocatalytic performance of polymer/rGO/SnO2 for de-ethylation of RhB can be proposed as Fig. 9. RhB molecules are excited to produce electron–hole pairs under visible light irradiation [29]. The conduction band potential of SnO2 is 0.4 V [8], which is more positive than the work function of graphene (−0.08 V vs SHE) [30]. Therefore, the photoexcited electrons are effectively transferred from RhB* to the CB of SnO2 via graphene and to produce O2 to active oxygen species [28]. The direct hole oxidation leads to the de-ethylation of RhB [28, 31].

Conclusions

In summary, polymer/rGO/SnO2 composites composed of SnO2 nanospheres loaded onto polymer/rGO core–shell microspheres were synthesized. The enhanced photodegradation of RhB over polymer/rGO/SnO2 is mainly due to the interactions between rGO and SnO2. Graphene promote transportation of photoexcited electrons to CB of SnO2, leaving more holes for the de-ethylation of RhB. This study further opens the possibility to enhance the photocatalytic property of metal oxide semiconductors by composing with graphene.

References

Wu HB, Hng HH, Lou XW (2012) Adv Mater 24:2567

Xiang GL, Wang YG, Wu D, Li TY, He J, Li J, Wang X (2012) Chem Eur J 18:4759

Harish S, Navaneethan M, Archana J, Silambarasan A, Ponnusamy S, Muthamizhchelvan C, Hayakawa Y (2015) Dalton Trans 44:10490

Zhao XY, Liu B, Hu CW, Cao MH (2014) Chem Eur J 20:467

Yeow SC, Ong WL, Wong ASW, Ho GW (2009) Sens Actuator B 143:295

Renard L, Brötz J, Fuess H, Gurlo A, Riedel R, Toupance T (2014) ACS Appl Mater Interfaces 6:17093

Renard L, Babot O, Saadaoui H, Fuess H, Brötz J, Gurlo A, Arveux E, Klein A, Toupance T (2012) Nanoscale 4:6806

Gubbala S, Chakrapani V, Kumar V, Sunkara MK (2008) Adv Funct Mater 18:2411

Birkel A, Lee Y-G, Koll D, Meerbeek XV, Frank S, Choi MJ, Kang YS, Char K, Tremel W (2012) Energy Environ Sci 5:5392

Cojocaru L, Olivier C, Toupance T, Sellier E, Hirsch L (2013) J Mater Chem A 1:13789

Dong Z, Wu M, Wu J, Ma Y, Ma Z (2015) Dalton Trans 44:11901

Uddin MT, Nicolas Y, Olivier C, Toupance T, Servant L, Müller MM, Kleebe HJ, Ziegler J, Jaegermann W (2012) Inorg Chem 51:7764

Dreyer DR, Park S, Bielawski CW, Ruoff RS (2010) Chem Soc Rev 39:228

Faria AF, Martinez DST, Moraes ACM, Da Costa MEH M, Barros EB, Souza Filho AG, Paula AJ, Alves OL (2012) Chem Mater 24:4080

Li W, Wang F, Feng SS, Wang JX, Sun ZK, Li B, Li YH, Yang JP, Elzatahry AA, Xia YY, Zhao DY (2013) J Am Chem Soc 135:18300

Li Q, Guo BD, Yu JG, Ran JR, Zhang BH, Yan HJ, Gong JR (2011) J Am Chem Soc 133:10878

Lee JS, You KH, Park CB (2012) Adv Mater 24:1084

Zhang H, Lv XJ, Li YM, Wang Y, Li JH (2010) ACS Nano 4:380

Fang R, Liang Y, Ge XP, Du M, Li SB, Li TY, Li Z (2015) Colloid Polym Sci 293:1151

Marcano DC, Kosynkin DV, Berlin JM, Sinitskii A, Sun ZZ, Slesarev A, Alemany LB, Lu W, Tour JM (2010) ACS Nano 4:4806

Fang R, Ge XP, Du M, Li Z, Yang CZ, Fang B, Liang Y (2014) Colloid Polym Sci 292:985

Stankovich S, Dikin DA, Piner RD, Kohlhaas KA, Kleinhammes A, Jia Y, Wu Y, Nguyen SBT, Ruoff RS (2007) Carbon 45:1558

Schwab MG, Narita A, Hernandez Y, Balandina T, Mali KS, Feyter SD, Feng XL, Müllen K (2012) J Am Chem Soc 134:18169

Yang YF, Wang J, Zhang J, Liu JC, Yang XL, Zhao HY (2009) Langmuir 25:11808

Wang SJ, Zhang YW, Ma HL, Zhang QL, Xu WG, Peng J, Li JQ, Yu ZZ, Zhai ML (2013) Carbon 55:245

Ahn HJ, Choi HC, Park KW, Kim SB, Sung YE (2004) J Phys Chem B 108:9815

Loryuenyong V, Totepvimarn K, Eimburanapravat P, Boonchompoo W, Buasri A (2013) Adv Mater Sci Eng 2013:923403

Chen CC, Zhao W, Lei PX, Zhao JC, Serpone N (2004) Chem Eur J 10:1956

Li WJ, Li DZ, Meng SG, Chen W, Fu XZ, Shao Y (2011) Environ Sci Technol 45:2987

Tao WG, Chang JL, Wu DP, Gao ZY, Duan XL, Xu F, Jiang K (2013) Mater Res Bull 48:538

Hu SW, Zhu J, Wu L, Wang XX, Liu P, Zhang YF, Li ZH (2011) J Phys Chem C 115:460

Acknowledgments

This work was supported by the Project Sponsored by the Scientific Research Foundation for the Returned Overseas Chinese Scholars, State Education Ministry, the Fundamental Research Funds for the Central Universities (No. 222201314059), and the Training Programs of Innovation and Entrepreneurship for Undergraduates (No. S13052).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liang, Y., Li, S. & Du, M. Synthesis of polymer/rGO/SnO2 hierarchical structure and its photodegradation of organic pollutants. Colloid Polym Sci 293, 3499–3504 (2015). https://doi.org/10.1007/s00396-015-3723-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-015-3723-4