Abstract

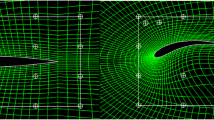

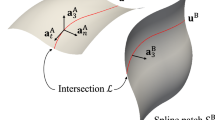

Aerodynamic shape optimization based on computational fluid dynamics (CFD) requires three steps: updating the geometry based on the design variables, updating the CFD surface mesh for the new geometry, and updating the CFD volume mesh based on the new surface mesh. While there are many tools available for the first and third steps, the methods available for the second step are insufficient for geometries that have intersecting components. For these geometries, the CFD surface mesh needs to be updated near component intersections to conform to the component geometries and the updated intersection curves. To address this need, we introduce a method that can deform the CFD surface mesh nodes near component intersections. The method can handle arbitrary design changes for each intersecting component as long as the geometric topology is unchanged. Furthermore, the method is suitable for gradient-based optimization because it smoothly deforms every CFD surface node without introducing topological changes in the CFD surface mesh. In this paper, we detail each step of the proposed method and visualize the range of design changes that can be achieved with this approach. Finally, we use the proposed method in an aerodynamic shape optimization problem to optimize the wing-body intersection of the DLR-F6 configuration. These results demonstrate the effectiveness of the proposed method in a high-fidelity design optimization framework. The method applies to both structured and unstructured CFD meshes and makes it possible to use computer-aided design and conceptual design geometry tools within high-fidelity design optimization.

Similar content being viewed by others

Notes

https://github.com/mdolab/idwarp, Accessed December 2020.

https://github.com/mdolab/MACH-Aero, Accessed December 2020.

https://github.com/mdolab/adflow, Accessed December 2020.

https://github.com/mdolab/pyoptsparse, Accessed December 2020.

References

Jameson A (1988) Aerodynamic design via control theory. J Sci Comput 3(3):233–260. https://doi.org/10.1007/BF01061285

Kenway GKW, Martins JRRA (2014) Multipoint high-fidelity aerostructural optimization of a transport aircraft configuration. J Aircr 51(1):144–160. https://doi.org/10.2514/1.C032150

Carrier G, Destarac D, Dumont A, Méheut M, Din Itham SE, Jacques P, Saloua Ben K, Brezillon J, Pestana M (2014) Gradient-based aerodynamic optimization with the \(els\)A software. In: 52nd Aerospace Sciences Meeting. https://doi.org/10.2514/6.2014-0568

Lyu Z, Kenway GKW, Martins JRRA (2015) Aerodynamic shape optimization investigations of the Common Research Model wing benchmark. AIAA J 53(4):968–985. https://doi.org/10.2514/1.J053318

Kenway GKW, Martins JRRA (2016) Multipoint aerodynamic shape optimization investigations of the Common Research Model wing. AIAA J 54(1):113–128. https://doi.org/10.2514/1.J054154

Kenway GKW, Martins JRRA (2017) Buffet onset constraint formulation for aerodynamic shape optimization. AIAA J 55(6):1930–1947. https://doi.org/10.2514/1.J055172

Bons NP, Mader CA, Martins JRRA, Cuco APC, Odaguil FIK (2018) High-fidelity aerodynamic shape optimization of a full configuration regional jet. In: 2018 AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Kissimmee, FL. https://doi.org/10.2514/6.2018-0106

Reist TA, Koo D, Zingg DW, Bochud P, Castonguay P, Leblond D (2020) Cross validation of aerodynamic shape optimization methodologies for aircraft wing-body optimization. AIAA J. https://doi.org/10.2514/1.J059091

Chan W, Meakin R (1997) Advances towards automatic surface domain decomposition and grid generation for overset grids. In: 13th Computational Fluid Dynamics Conference, fluid dynamics and co-located conferences. american institute of aeronautics and astronautics. https://doi.org/10.2514/6.1997-1979

Chan W, Gomez R, Rogers S, Buning P (2002) Best practices in overset grid generation. In: 32nd AIAA Fluid Dynamics Conference and Exhibit, Fluid Dynamics and Co-located Conferences. American Institute of Aeronautics and Astronautics. https://doi.org/10.2514/6.2002-3191

Kleb WL, Park MA, Wood WA, Bibb KL, Thompson KB, Gomez RJ (2019) Sketch-to-solution: An exploration of viscous CFD with automatic grids. In: AIAA Aviation Forum, AIAA AVIATION Forum. American Institute of Aeronautics and Astronautics. https://doi.org/10.2514/6.2019-2948

Secco N (2018) Component-based aerodynamic shape optimization using overset meshes. PhD thesis, University of Michigan, Ann Arbor, MI. https://deepblue.lib.umich.edu/handle/2027.42/146042. Accessed 6 Jan 2021

Samareh JA (2001) Survey of shape parameterization techniques for high-fidelity multidisciplinary shape optimization. AIAA J 39(5):877–884. https://doi.org/10.2514/2.1391

Zhang T-T, Wang Z-G, Huang W, Yan L (2018) A review of parametric approaches specific to aerodynamic design process. Acta Astronaut 145:319–331. https://doi.org/10.1016/j.actaastro.2018.02.011 (ISSN 0094-5765)

Kenway GKW, Kennedy GJ, Martins JRRA (2010) A CAD-free approach to high-fidelity aerostructural optimization. In: Proceedings of the 13th AIAA/ISSMO Multidisciplinary Analysis Optimization Conference, number AIAA 2010-9231, Fort Worth, TX. https://doi.org/10.2514/6.2010-9231

Gagnon H, Zingg DW (2015) Two-level free-form and axial deformation for exploratory aerodynamic shape optimization. AIAA J 53(7):2015–2026. https://doi.org/10.2514/1.J053575 (ISSN 0001-1452)

Taylor NJ (2015) Industrial perspectives on geometry handling for aerodynamics. In: 22nd AIAA Computational Fluid Dynamics Conference, AIAA Aviation Forum. American Institute of Aeronautics and Astronautics. https://doi.org/10.2514/6.2015-3408

Haimes R, Drela M (2012) On the construction of aircraft conceptual geometry for high-fidelity analysis and design. In: 50th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Aerospace Sciences Meetings. American Institute of Aeronautics and Astronautics. https://doi.org/10.2514/6.2012-683

Haimes R, Dannenhoffer J (2013) The Engineering Sketch Pad: A solid-modeling, feature-based, web-enabled system for building parametric geometry. In: 21st AIAA Computational Fluid Dynamics Conference, Fluid Dynamics and Co-located Conferences. American Institute of Aeronautics and Astronautics. https://doi.org/10.2514/6.2013-3073

Mukundakrishnan B, Rajmohan N, Rajnarayan DG, Fugal S (2019) A script-based CAD system for aerodynamic design. In: AIAA Aviation Forum, AIAA AVIATION Forum. American Institute of Aeronautics and Astronautics. https://doi.org/10.2514/6.2019-3069

Hwang JT, Martins JRRA (2012) GeoMACH: Geometry-centric MDAO of aircraft configurations with high fidelity. In: Proceedings of the 14th AIAA/ISSMO Multidisciplinary Analysis Optimization Conference, Indianapolis, IN. https://doi.org/10.2514/6.2012-5605

Hahn A (2010) Vehicle Sketch Pad: A parametric geometry modeler for conceptual aircraft design. In: 48th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Aerospace Sciences Meetings. American Institute of Aeronautics and Astronautics. https://doi.org/10.2514/6.2010-657

McDonald RA (2015) Interactive reconstruction of 3D models in the OpenVSP parametric geometry tool. In: 53rd AIAA Aerospace Sciences Meeting, AIAA SciTech Forum. American Institute of Aeronautics and Astronautics. https://doi.org/10.2514/6.2015-1014

Alonso JJ, Martins JRRA, Reuther JJ, Haimes R (2003) High-fidelity aero-structural design using a parametric CAD-based model. In: Proceedings of the 16th AIAA Computational Fluid Dynamics Conference, Orlando, FL. https://doi.org/10.2514/6.2003-3429

Bobrowski K, Ferrer E, Valero E, Barnewitz H (2017) Aerodynamic shape optimization using geometry surrogates and adjoint method. AIAA J 55(10):3304–3317. https://doi.org/10.2514/1.J055766

Heath C, Slater JW, Rallabhandi SK (2016) Inlet trade study for a low boom aircraft demonstrator. In: 34th AIAA Applied Aerodynamics Conference, AIAA Aviation Forum. American Institute of Aeronautics and Astronautics. https://doi.org/10.2514/6.2016-4050

Dannenhoffer J, Haimes R (2015) Design sensitivity calculations directly on CAD-based geometry. In: 53rd AIAA Aerospace Sciences Meeting, AIAA SciTech Forum. American Institute of Aeronautics and Astronautics. https://doi.org/10.2514/6.2015-1370

Banović M, Mykhaskiv O, Auriemma S, Walther A, Legrand Herve, Müller Jens-Dominik (2018) Algorithmic differentiation of the Open CASCADE Technology CAD kernel and its coupling with an adjoint CFD solver. Optim Methods Softw 33(4–6):813–828. https://doi.org/10.1080/10556788.2018.1431235 (ISSN 1055-6788)

Agarwal D, Robinson TT, Armstrong CG, Marques S, Vasilopoulos I, Meyer M (2018) Parametric design velocity computation for CAD-based design optimization using adjoint methods. Eng Comput 34(2):225–239. https://doi.org/10.1007/s00366-017-0534-x (ISSN 1435-5663)

Shenren X, Jahn W, Müller J-D (2014) CAD-based shape optimisation with CFD using a discrete adjoint. Int J Numer Methods Fluids 74(3):153–168. https://doi.org/10.1002/fld.3844

Truong AH, Zingg DW, Haimes R (2016) Surface mesh movement algorithm for computer-aided-design-based aerodynamic shape optimization. AIAA J 54(2):542–556. https://doi.org/10.2514/1.J054295 (ISSN 0001-1452)

Sun L, Yao W, Robinson T, Marques S, Armstrong C (2020) A framework of gradient-based shape optimization using feature-based CAD parameterization. In: AIAA Scitech 2020 Forum, Orlando, FL. American Institute of Aeronautics and Astronautics. ISBN 978-1-62410-595-1. https://doi.org/10.2514/6.2020-0889

Kim H-J, Nakahashi K (2007) Surface mesh movement for aerodynamic design of body-installation junction. AIAA J 45(5):1138–1142. https://doi.org/10.2514/1.12947 (ISSN 0001-1452)

Koc S, Kim H-J, Nakahashi K (2006) Aerodynamic design of complex configurations with junctions. J Aircr 43(6):1838–1844. https://doi.org/10.2514/1.20723

Brezillon J, Dwight RP (2012) Applications of a discrete viscous adjoint method for aerodynamic shape optimisation of 3D configurations. CEAS Aeronaut J 3(1):25–34. https://doi.org/10.1007/s13272-011-0038-0 (ISSN 1869-5582)

Xu S, Timme S, Mykhaskiv O, Müller J-D (2017) Wing-body junction optimisation with CAD-based parametrisation including a moving intersection. Aerosp Sci Technol 68:543–551. https://doi.org/10.1016/j.ast.2017.06.014 (ISSN 1270-9638)

Mykhaskiv O, Mohanamuraly P, Mueller J-D, Xu S, Timme S (2017) CAD-based shape optimisation of the NASA CRM wing-body intersection using differentiated CAD-kernel. In: 35th AIAA Applied Aerodynamics Conference, AIAA AVIATION Forum. American Institute of Aeronautics and Astronautics. https://doi.org/10.2514/6.2017-4080

Secco NR, Jasa JP, Kenway GKW, Martins JRRA (2018) Component-based geometry manipulation for aerodynamic shape optimization with overset meshes. AIAA J 56(9):3667–3679. https://doi.org/10.2514/1.J056550

Secco NR, Martins JRRA (2019) RANS-based aerodynamic shape optimization of a strut-braced wing with overset meshes. J Aircr 56(1):217–227. https://doi.org/10.2514/1.C034934

de Boer A, van der Schoot MS, Bijl H (2007) Mesh deformation based on radial basis function interpolation. Comput Struct 85(11):784–795. https://doi.org/10.1016/j.compstruc.2007.01.013 (ISSN 0045-7949)

Coulier P, Darve E (2016) Efficient mesh deformation based on radial basis function interpolation by means of the inverse fast multipole method. Comput Methods Appl Mech Eng 308:286–309. https://doi.org/10.1016/j.cma.2016.05.029 (ISSN 0045-7825)

Witteveen J, Bijl H (2009) Explicit mesh deformation using inverse distance weighting interpolation. In: 19th AIAA Computational Fluid Dynamics, Fluid Dynamics and Co-located Conferences. American Institute of Aeronautics and Astronautics. https://doi.org/10.2514/6.2009-3996

Luke E, Collins E, Blades E (2012) A fast mesh deformation method using explicit interpolation. J Comput Phys 231(2):586–601. https://doi.org/10.1016/j.jcp.2011.09.021 (ISSN 0021-9991)

Secco N, Kenway GKW, He P, Mader CA, Martins JRRA (2020) Efficient mesh generation and deformation for aerodynamic shape optimization. AIAA J (In press)

He X, Li J, Mader CA, Yildirim A, Martins JRRA (2019) Robust aerodynamic shape optimization–from a circle to an airfoil. Aerosp Sci Technol 87:48–61. https://doi.org/10.1016/j.ast.2019.01.051

Brodersen O (2002) Drag prediction of engine-airframe interference effects using unstructured Navier-Stokes calculations. J Aircr 39(6):927–935. https://doi.org/10.2514/2.3037

Secco NR, Jasa JP, Kenway GKW, Martins JRRA (2017) Component-based geometry manipulation for aerodynamic shape optimization with overset meshes. In: 18th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference. American Institute of Aeronautics and Astronautics. https://doi.org/10.2514/6.2017-3327

Patrikalakis NM (1993) Surface-to-surface intersections. IEEE Comput Graph Appl 13(1):89–95. https://doi.org/10.1109/38.180122 (ISSN 0272-1716)

Kenway GKW, Secco N, Martins JRRA, Mishra A, Duraisamy K (2017) An efficient parallel overset method for aerodynamic shape optimization. In: Proceedings of the 58th AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, AIAA SciTech Forum, Grapevine, TX. https://doi.org/10.2514/6.2017-0357

Shepard D (1968) A two-dimensional interpolation function for irregularly-spaced data. In: Proceedings of the 1968 23rd ACM National Conference, ACM ’68, pages 517–524, New York, NY, USA. ACM. https://doi.org/10.1145/800186.810616

Mark A (2013) Finlayson. ANSYS ICEM CFD User’s Manual. ANSYS Inc, Canonsburg

Liao Y, Yildirim A, Lu YY, Martins JRRA (2020) Hydrodynamic optimization of a T-foil. In: SNAME Maritime Convention. The Society of Naval Architects and Marine Engineers. https://www.onepetro.org/conference-paper/SNAME-SMC-2020-084. Accessed 6 Jan 2021

Binns JR, Brandner PA, Plouhinec J (2008) The effect of heel angle and free-surface proximity on the performance and strut wake of a moth sailing dinghy rudder T-foil. Auckland, NZ. https://eprints.utas.edu.au/8987/. Accessed 6 Jan 2021

Sacher M, Durand M, Élisa B, Hauville F, Duvigneau R, Le Maître O, Astolfi J-A (2018) Flexible hydrofoil optimization for the 35th America’s Cup with constrained EGO method. Ocean Eng 157:62–72. https://doi.org/10.1016/j.oceaneng.2018.03.047 (ISSN 0029-8018)

Wackers J, Guilmineau E, Palmieri A, Queutey P (2014) Hessian-based grid refinement for the simulation of surface-piercing hydrofoils. In: 17th Numerical Towing Tank Symposium (NuTTS 2014), Marstrand, Sweden. https://hal.archives-ouvertes.fr/hal-01202486. Accessed 6 Jan 2021

Barden TA, Binns JR (2012) On the road to establishing ventilation probability for Moth sailing dinghies. Australasian Fluid Mechanics Society. https://trove.nla.gov.au/version/191926247. Accessed 6 Jan 2021

Laflin KR, Klausmeyer SM, Zickuhr T, Vassberg JC, Wahls RA, Morrison JH, Brodersen OP, Rakowitz ME, Tinoco EN, Godard J-L (2005) Data summary from second AIAA computational fluid dynamics drag prediction workshop. J Aircr 42(5):1165–1178. https://doi.org/10.2514/1.10771

Vassberg J, Tinoco E, Mani M, Brodersen O, Eisfeld B, Wahls R, Morrison J, Zickuhr T, Laflin K, Mavriplis D (2007) Summary of the third AIAA CFD drag prediction workshop. In: 45th AIAA Aerospace Sciences Meeting and Exhibit, Aerospace Sciences Meetings. American Institute of Aeronautics and Astronautics. https://doi.org/10.2514/6.2007-260

Vassberg J, Sclafani A, DeHaan M (2005) A wing-body fairing design for the DLR-F6 model: A DPW-III case study. In: 23rd AIAA Applied Aerodynamics Conference, Fluid Dynamics and Co-located Conferences. American Institute of Aeronautics and Astronautics. https://doi.org/10.2514/6.2005-4730

Kenway GKW, Kennedy GJ, Martins JRRA (2014) Scalable parallel approach for high-fidelity steady-state aeroelastic analysis and derivative computations. AIAA J 52(5):935–951. https://doi.org/10.2514/1.J052255

Lyu Z, Martins JRRA (2015) Aerodynamic shape optimization of an adaptive morphing trailing edge wing. J Aircr 52(6):1951–1970. https://doi.org/10.2514/1.C033116

Chen S, Lyu Z, Kenway GKW, Martins JRRA (2016) Aerodynamic shape optimization of the Common Research Model wing-body-tail configuration. J Aircr 53(1):276–293. https://doi.org/10.2514/1.C033328

Mader CA, Kenway GKW, Yildirim A, Martins JRRA (2020) ADflow: An open-source computational fluid dynamics solver for aerodynamic and multidisciplinary optimization. J Aerosp Inf Syst. https://doi.org/10.2514/1.I010796

Kenway GKW, Mader CA, He P, Martins JRRA (2019) Effective adjoint approaches for computational fluid dynamics. Progress Aerosp Sci 110:100542. https://doi.org/10.1016/j.paerosci.2019.05.002

Gill PE, Murray W, Saunders MA (2002) SNOPT: an SQP algorithm for large-scale constrained optimization. SIAM J Optim 12(4):979–1006. https://doi.org/10.1137/S1052623499350013

Neil W, Kenway G, Mader CA, Jasa J, Martins JRRA (2020) pyOptSparse: A Python framework for large-scale constrained nonlinear optimization of sparse systems. J Open Source Softw 5(54):2564. https://doi.org/10.21105/joss.02564

Spalart P, Allmaras S (1994) A one-equation turbulence model for aerodynamic flows. La Recherche Aerosp 1:5–21

Dacles-Mariani J, Zilliac GG, Chow JS, Bradshaw P (1995) Numerical/experimental study of a wingtip vortex in the near field. AIAA J 33(9):1561–1568. https://doi.org/10.2514/3.12826

Spalart PR (2000) Strategies for turbulence modelling and simulations. Int J Heat Fluid Flow 21(3):252–263. https://doi.org/10.1016/S0142-727X(00)00007-2 (ISSN 0142-727X)

Yildirim A, Kenway GKW, Mader CA, Martins JRRA (2019) A Jacobian-free approximate Newton-Krylov startup strategy for RANS simulations. J Comput Phys 397:108741. https://doi.org/10.1016/j.jcp.2019.06.018 (ISSN 0021-9991)

Acknowledgements

This work was funded by the NASA Advanced Air Transport Technology (AATT) and Transformational Tools and Technologies (TTT) projects. Computational resources were provided by the NASA High-End Computing (HEC) Program through the NASA Advanced Supercomputing (NAS) Division at Ames Research Center, and the Extreme Science and Engineering Discovery Environment (XSEDE), which is supported by the National Science Foundation grant number ACI-1548562. We are especially grateful to Justin Gray for his guidance and support. Thanks to Ney Secco for developing the pySurf framework, Yingqian Liao for providing the T-shaped hydrofoil geometry, Benjamin Brelje for reviewing an early version of this paper, and Gaetan Kenway for developing an earlier version of the surface-mesh deformation method that led to this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A: Computation of the curve-based deformation

Appendix A: Computation of the curve-based deformation

The curve-based deformation step introduced in Sect. 2.5 relies on the computation of two integrals in the nominator and denominator in Eq. (6). The equation can be written again using a simplified notation for a general case as

where \({\mathcal {C}}\) represents the original location of the curve and \(\varDelta {\mathcal {C}}\) is the displacement defined on this curve, such that \({\mathcal {C}} + \varDelta {\mathcal {C}}\) yields the updated coordinates of the curve. Using these displacements, the method computes the displacement of a given point \(\mathbf{x}\), using a weighted averaging based on the inverse distance of the point to the curve. The parameter \(t \in [0,1]\) is used to traverse the curve \({\mathcal {C}}\) with length L and the weight w can be written as

where m is an exponent, which set to 3 in this work. In the next two sections, we inspect the behavior of this approach for the special case when the evaluation point \(\mathbf{x}\) is located on the curve \({\mathcal {C}}\) and detail the computation of the terms for this method when the curve \({\mathcal {C}}\) is defined using line elements.

1.1 A.1: Special case for points located on curves

The weighting function has a finite value as long as the evaluation point \(\mathbf{x}\) is not on the curve \({\mathcal {C}}\). For the special case where the evaluation point is on the curve and \(m > 0\), the weighing function tends to infinity as the parameter \(t \rightarrow t_*\), where the evaluation point \(\mathbf{x}\) is co-located with the point \({\mathcal {C}}(t_*)\). This can be written as

As a result, the two integrands we define also tend to infinity as \(t\rightarrow t_*\), which results in two improper integrals.

The integrations over the curve \({\mathcal {C}}\), which is defined in \(t=[0,1]\), can be split into two at \(t = T\), which results in

Then, we substitute \(t = -s\) for the two integrals that go from T to 1, and reverse the integration limits, which yields

For the special case where \(\mathbf{x}\) is co-located with \({\mathcal {C}}(t_*)\) and \(m\ge 1\), these integrals do not converge; however, \(\varDelta \mathbf{x}\) can be computed using the L’Hôpital’s rule as

This result means that when \(\mathbf{x}\) is initially co-located with \({\mathcal {C}}(t_*)\), the displacement \(\varDelta \mathbf{x}\) computed using Eq. (16) results in the displacement of the curve at \(t=t_*\), which is the desired behavior demonstrated in Fig. 10. With this approach, the surface mesh nodes that are initially located on the intersection and feature curves directly follow the displacements of these curves.

1.2 A.2: Computation of the integrals over piecewise linear curves

In our application, the curve \({\mathcal {C}}\) is defined using a union of line elements. Using this definition, the two integrals introduced in Eq. (16) can be computed as a sum over every line element, where we compute the integral for each line element separately.

Without loss of generality, we consider the case where the curve \({\mathcal {C}}\) is defined using a single line element, with endpoints \(\mathbf{x} _A\) and \(\mathbf{x} _B\). In this case, we use the parameter \(t \in [0,1]\) to traverse this line element, and the coordinate along this line element can be written as

such that \({\mathcal {C}}(0) = \mathbf{x} _A = (x_A, y_A, z_A)\) and \({\mathcal {C}}(1) = \mathbf{x} _B = (x_B, y_B, z_B)\) in Cartesian coordinates. Similarly, we can write the displacement of the curve as

where \(\varDelta \mathbf{x} _A\) and \(\varDelta \mathbf{x} _B\) are the displacements of the points that define the line element.

Using these definitions, we can re-write \(\varDelta \mathbf{x}\) as

The terms \(\varDelta \mathbf{x} _A\) and \(\varDelta \mathbf{x} _B\) correspond to the displacements defined at the two endpoints of the line and can be taken out of the integrals because they do not depend on the parameter t. This expression can be evaluated by evaluating the two integrals that appear, which can be defined as

In this work, \(m=3\) in the definition of w (17); therefore, we specialize the exact integration of these terms for this value. In this case, we can write the two integrals as

By expressing the evaluation point \(\mathbf{x}\) as (x, y, z) in Cartesian coordinates, the 2-norm that appears in the denominator of both integrals can be written as

where

With these definitions, the two integrals can be analytically computed as

In this formulation, the terms \(a+b+c\) and c can have small negative values because of machine precision errors. Therefore, when computing the square roots of these terms, we set them to zero if they are less than zero to prevent results with nonzero imaginary parts. Finally, the terms \((b^2 - 4ac) \sqrt{a+b+c}\) and \((b^2 - 4ac) \sqrt{c}\) can have a value of zero. This is problematic because these terms appear in the denominators. Therefore, we subtract a small number \(\epsilon = 10^{-50}\) from the denominators. We subtract \(\epsilon\) instead of adding it, because the result of \(\sqrt{a+b+c}\) and \(\sqrt{c}\) are guaranteed to be non-negative, while the term \(b^2 - 4ac \le 0\). With these considerations, we can robustly compute the terms required for the curve-based displacement approach introduced in Eq. (6).

Rights and permissions

About this article

Cite this article

Yildirim, A., Mader, C.A. & Martins, J.R.R.A. A surface mesh deformation method near component intersections for high-fidelity design optimization. Engineering with Computers 38 (Suppl 2), 1393–1425 (2022). https://doi.org/10.1007/s00366-020-01247-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00366-020-01247-w