Abstract

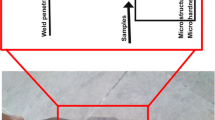

L8 (27) orthogonal test table is applied to design eight kinds of flux, and arranged with SiO2, ZrO2 and TiO2 as three factors. The microstructure, morphology and mechanical properties of low carbon bainitic steels are investigated by means of optical microscope, scanning electron microscope, transmission electron microscope, tensile testing machine and instrumented drop weight impact tester with oscilloscope. The results indicate that the optimum composition rate is as follows: 20% SiO2, 10% ZrO2, and 6% TiO2, and the interaction between ZrO2 and TiO2 is obvious. The microstructure of deposited metal of low carbon bainitic steel is mainly formed by acicular ferrite and granular bainite. The acicular ferrite is paralleled distribution, and plenty of fine sheet Martensitic–Austenitic constituents are dispersing, which can hinder crack propagation and improve strength and toughness. The impact energy is up to 109.7 J at − 20 °C, and the ratio of brittle fracture termination load to maximum impact load is 0.378, ensuring excellent crack arrest toughness.

Similar content being viewed by others

References

R. Pourazizi, M.A. Mohtadi-Bonab, J.A. Szpunar, Investigation of different failure modes in oil and natural gas pipeline steels. Eng. Fail. Anal. 109, 104400 (2020)

M. Zhang, L. Yang, J.H. Li, Submerged arc welding X100 pipeline steels. Mater. Manuf. Process 29, 64–68 (2014)

Y. Niu, S. Jia, Q. Liu, S. Tong, B. Li, Y. Ren, B. Wang, Influence of effective grain size on low temperature toughness of high-strength pipeline steel. Materials 12, 3672 (2019)

H. Chen, Y.S. Yu, B.B. Wu, C.J. Shang, Metallurgical design and high strength-toughness mechanism of ultrahigh strength-toughness oil pipeline steel. Kang T’ieh/Iron Steel 54, 96–103 (2020)

L. Fan, G. Wang, P. Liang, J. Ma, Q. Bao, H. Zhang, High-temperature ductile damage behavior and modeling of X100 pipeline steel. J. Eng. Sci. Technol. Rev. 12, 161–169 (2019)

M.B. Sk, D. Chakrabarti, S. Chatterjee, Microstructural engineering and strength-impact toughness prediction in ultra-low carbon bainitic steel. Mater. Sci. Tech. 34, 1910–1918 (2018)

S. Dhua, P. Sarkar, A. Saxena, B. Jha, Development of fine-grained, low-carbon bainitic steels with high strength and toughness produced through the conventional hot-rolling and air-cooling. Metall. Mater. Trans. A 47, 6224 (2016)

M. Zhang, L. Yang, Microstructure and mechanical properties of joints of X100 line pipe by submerged arc welding. Appl. Mech. Mater. 310, 139–144 (2013)

D.V. Kiran, B. Basu, A. De, Influence of process variables on weld bead quality in two wire tandem submerged arc welding of HSLA steel. J. Mater. Proc. Technol. 212, 2041–2050 (2012)

S.Q. Moinuddin, A. Kapil, K. Kohama, A. Sharma, K. Ito, M. Tanaka, On process-structure-property interconnection in anti-phase synchronised twin-wire GMAW of low carbon steel. Sci. Technol. Weld. Joi. 21, 452–459 (2016)

Y. Zhong, F.R. Xiao, J.W. Zhang, Y.Y. Shan, W. Wang, K. Yang, In situ TEM study of the effect of M/A films at grain boundaries on crack propagation in an ultra-fine acicular ferrite pipeline steel. Acta. Mater. 54, 435–443 (2006)

H.H. Sayyed, Apportion of Charpy energy in API 5L grade X70 pipeline steel. Int. J. Pres. Ves. Pip. 85, 879–884 (2008)

Acknowledgements

The author of the present article would like to express profound gratitude to Professor M. Zhang for the valuable comments and helpful cooperation during the course of this research. The author also appreciates valuable services made by all personnel of Xi’an University of Technology, China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, L., Wang, H. Orthogonal optimum design of parameters of flux used for low carbon bainitic steel. Appl. Phys. A 126, 538 (2020). https://doi.org/10.1007/s00339-020-03730-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-020-03730-z