Abstract

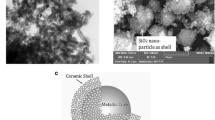

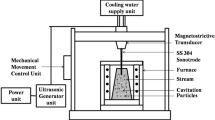

This study has been presented with mechanical properties of aluminum matrix composites, reinforced by SiO2 nano-particles. The stir casting method was employed to produce various aluminum matrix composites. Different composites by varying the SiO2 nano-particle content (including 0.5 and 1 weight percents) and two dispersion methods (including ball-milling and pre-heating) were made. Then, the density, the hardness, the compression strength, the wear resistance and the microstructure of nano-composites have been studied in this research. Besides, the distribution of nano-particles in the aluminum matrix for all composites has been also evaluated by the field emission scanning electron microscopy (FESEM). Obtained results showed that the density, the elongation and the ultimate compressive strength of various nano-composites decreased by the presence of SiO2 nano-particles; however, the hardness, the wear resistance, the yield strength and the elastic modulus of composites increased by auditioning of nano-particles to the aluminum alloy. FESEM images indicated better wetting of the SiO2 reinforcement in the aluminum matrix, prepared by the pre-heating dispersion method, comparing to ball-milling. When SiO2 nano-particles were added to the aluminum alloy, the morphology of the Si phase and intermetallic phases changed, which enhanced mechanical properties. In addition, the wear mechanism plus the friction coefficient value were changed for various nano-composites with respect to the aluminum alloy.

Similar content being viewed by others

References

R. Khorshidi, R. Mahmudi, A. Honarbakhsh-Raouf, Compressive creep behavior of a cast Al-15Mg2Si in situ composite. Mater. Sci. Eng. A 668, 112–119 (2016)

M. Azadi, S. Safarloo, F. Loghman, R. Rasouli, Microstructural and thermal properties of piston aluminum alloy reinforced by nano-particles, AIP Conference Proceedings, 1920, 020027 (2018)

M.K. Akbari, O. Mirzaee, H.R. Baharvandi, Fabrication and study on mechanical properties and fracture behavior of nano-metric Al2O3 particle-reinforced A356 composites focusing on the parameters of vortex method. Mater. Des. 46, 199–205 (2013)

M. Zeren, The effect of heat-treatment on aluminum-based piston alloys. Mater. Des. 28, 2511–2517 (2007)

P.R.M. Raju, S. Rajesh, K.S.R. Raju, V.R. Raju, Evaluation of fatigue life of Al2024/Al2O3 particulate nano composite fabricated using stir casting technique, Materials Today: Proceedings 4, 3188–3196 (2017)

M.K. Akbari, H.R. Baharvandi, O. Mirzaee, Nano-sized aluminum oxide reinforced commercial casting A356 alloy matrix: evaluation of hardness, wear resistance and compressive strength focusing on particle distribution in aluminum matrix. Compos. B 52, 262–268 (2013)

R. Singh, D. Podder, S. Singh, Effect of single, double and triple particle size SiC and Al2O3 reinforcement on wear properties of AMC prepared by stir casting in vacuum mould. Trans. Indian Inst. Met. 68, 791–797 (2015)

Y. Chen, D.D.L. Chung, In situ AI–TiB composite obtained by stir casting. J. Mater. Sci. 31, 311–315 (1996)

S. Soltani, R.A. Khosroshahi, R.T. Mousavian, Z.Y. Jiang, A.F. Boostani, D. Brabazon, Stir casting process for manufacture of Al–SiC composites. Rare Met. 36, 581–590 (2015)

A.O. Inegbenebor, C.A. Bolu, P.O. Babalola, A.I. Inegbenebor, O.S.I. Fayomi, Aluminum silicon carbide particulate metal matrix composite development via stir casting processing. Silicon 8, 1–5 (2016)

M. Raei, M. Panjepour, M. Meratian, Effect of stirring speed and time on microstructure and mechanical properties of cast Al-Ti-Zr-B4C composite produced by stir casting. Russ. J. Non-Ferr. Met. 57(4), 347–360 (2016)

M.K. Sahu, R.K. Sahu, Optimization of stirring parameters using CFD simulations for HAMCs Synthesis by stir casting process. Trans. Indian Inst. Met. 70, 2573–2570 (2017)

M. Khademian, A. Alizadeh, A. Abdollahi, Fabrication and characterization of hot rolled and hot extruded boron carbide (B4C) reinforced A356 aluminum alloy matrix composites produced by stir casting method. Trans. Indian Inst. Met. 70, 1635–1646 (2016)

J.J. Moses, S.J. Sekhar, Investigation on the tensile strength and micro-hardness of AA6061/TiC composites by stir casting. Trans. Indian Inst. Met. 70, 1035–1046 (2016)

S.H. Juang, L.J. Fan, H.P.O. Yang, Influence of preheating temperatures and adding rates on distributions of fly ash in aluminium matrix composites prepared by stir casting. Int. J. Precis. Eng. Manuf. 16(7), 1321–1327 (2015)

A. Salehi, A. Babakhani, S.M. Zebarjad, Microstructural and mechanical properties of Al–SiO2 nano composite foams produced by an ultrasonic technique. Mater. Sci. Eng. A 638, 54–59 (2015)

A.E. Nassar, E.E. Nassar, Properties of aluminum matrix Nano composites prepared by powder metallurgy processing. J. King Saud Univ. Eng. Sci. 29, 295–299 (2017)

A.V. Nomoev, S.P. Bardakhanov, M. Schreiber, D.G. Bazarova, N.A. Romanov, B.B. Baldanov, B.R. Radnaev, V.V. Syzrantsev, Structure and mechanism of the formation of core–shell nanoparticles obtained through a one-step gas-phase synthesis by electron beam evaporation. Beilstein J. Nano Technol. 6, 874–880 (2015)

F. Zainon, K.R. Ahmad, R. Daud, Effect of heat treatment on microstructure, hardness and wear of aluminum alloy 332. Appl. Mech. Mater. 786, 18–22 (2015)

L. Han, Y. Sui, Q. Wang, K. Wang, Y. Jiang, Effects of Nd on microstructure and mechanical properties of cast Al–Si–Cu–Ni–Mg piston alloys. J. Alloy. Compd. 695, 1566–1572 (2017)

J.A. Taylor, Iron-containing intermetallic phases in Al-Si based casting alloys. Proc. Mater. Sci. 1, 19–33 (2012)

M. Paramsothya, S.F. Hassan, N. Srikanth, M. Gupta, Enhancing tensile/compressive response of magnesium alloy AZ31 by integrating with Al2O3 nanoparticles. Mater. Sci. Eng., A 527, 162–168 (2009)

C. Weigelt, G. Schmidt, C.G. Aneziris, R. Eckner, D. Ehinger, L. Krüger, C. Ullrich, D. Rafaja, Compressive and tensile deformation behavior of TRIP steel-matrix composite materials with reinforcing additions of zirconia and/or aluminum titanate. J. Alloy. Compd. 695, 9–20 (2017)

Y. Afkham, R.A. Khosroshahi, S. Rahimpour, C. Aavani, D. Brabazon, R.T. Mousavian, Enhanced mechanical properties of in situ aluminum matrix composites reinforced by alumina nanoparticles. Arch. Civ. Mech. Eng. 18, 215–226 (2018)

K.S. Reddy, D. Sreedhar, K.D. Kumar, G.P. Kumar, Role of reduced graphene oxide on mechanical-thermal properties of aluminum metal matrix nano composites, Materials Today: Proceedings 2, 1270–1275 (2015)

J. Wang, L. Li, W. Tao, Crack initiation and propagation behavior of WC particles reinforced Fe-based metal matrix composite produced by laser melting deposition. Opt. Laser Technol. 82, 170–182 (2016)

K.K. Singh, S. Singh, A.K. Shrivastava, Comparison of wear and friction behavior of aluminum silicon carbide based aluminum metal matrix composite under dry condition at different sliding distance, Materials Today: Proceedings 4, 8960–8970, (2017)

S. Ma, E. Xu, Z. Zhu, Q. Liu, S. Yu, J. Liu, H. Zhong, Y. Jiang, Mechanical and wear performances of aluminum/sintered-carbon composites produced by pressure infiltration for pantograph sliders. Powder Technol. 326, 54–61 (2018)

A. Nieto, H. Yang, L. Jiang, J.M. Schoenung, Reinforcement size effects on the abrasive wear of boron carbide reinforced aluminum composites. Wear 390–391 228–235 (2017)

S.K. Ghosh, P. Saha, Crack and wear behavior of SiC particulate reinforced aluminum based metal matrix composite fabricated by direct metal laser sintering process. Mater. Des. 32, 139–145 (2011)

A. Pramanik, Effects of reinforcement on wear resistance of aluminum matrix composites. Trans. Nonferr. Met. Soc. China 26, 348–358 (2016)

Q.B. Nguyen, M. Gupta, Enhancing compressive response of AZ31B using nano-Al2O3 and copper additions. J. Alloy. Compd. 490, 382–387 (2010)

K. Ravikumar, K. Kiran, V.S. Sreebalaji, Characterization of mechanical properties of aluminum/tungsten carbide composites. Measurement 102, 142–149 (2017)

H.Y. Yue, B. Wang, X. Gao, S.L. Zhang, X.Y. Lin, L.H. Yao, E.J. Guo, Effect of interfacial modifying on the microstructures, mechanical properties and abrasive wear properties of aluminum borate whiskers reinforced 6061Al composite. J. Alloy. Compd. 692, 395–402 (2017)

A.P. Reddy, P.V. Krishna, R.N. Rao, N.V. Murthy, Silicon carbide reinforced aluminum metal matrix nano composites—a review, Materials Today: Proceedings 4, 3959–3971 (2017)

M.N. Hegde, P. Hegde, S. Bhandary, K. Deepika, An evaluation of compressive strength of newer nano-composite: an in vitro study. J. Conser. Dent. 14(1), 36–39 (2011)

M. Azadi, A.S. Rouhaghdam, Nano-mechanical properties of TiN/TiC multilayer coatings. Strength Mater. 46(1), 121–131 (2014)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Azadi, M., Zolfaghari, M., Rezanezhad, S. et al. Effects of SiO2 nano-particles on tribological and mechanical properties of aluminum matrix composites by different dispersion methods. Appl. Phys. A 124, 377 (2018). https://doi.org/10.1007/s00339-018-1797-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-018-1797-9