Abstract

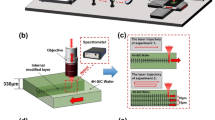

The influence of pulse durations (35fs and 260 fs) and environments (air and vacuum) on the laser-induced damage thresholds (LIDTs) and ablation rates of 304 stainless steel were studied. Two distinct ablation regimes were obtained from the ablation rate curves. At low fluence regime, the ablation rates were similar in spite of the differences of pulse durations and experiment environments. At high fluence regime, the ablation rates of 35 fs pulse duration in vacuum were obviously higher than others. The ablation craters showed smooth edges, moth-eye such as structures, and laser-induced periodic surface structures (LIPSSs). At a fixed fluence, the periods of LIPSSs decreased monotonously in their mean spatial period between ~ 700 nm (5 pulses) and 540 nm (200 pulses) with the increase of pulse numbers in air with 35 fs pulse duration. The formation mechanisms of moth-eye like structures and LIPSSs were also discussed.

Similar content being viewed by others

References

C. Kerse, H. Kalaycıoğlu, P. Elahi, B. Çetin, D.K. Kesim, Ö Akçaalan, S. Yavaş, M.D. Aşık, B. Öktem, H. Hoogland, R. Holzwarth, F. Ilday, Ablation-cooled material removal with ultrafast bursts of pulses. Nature 537, 84–89 (2016)

Z.G. Ou, M. Huang, F.L. Zhao, The fluence threshold of femtosecond laser blackening of metals: the effect of laser-induced ripples. Opt. Laser Technol. 79, 79–87 (2016)

M.E. Shaheen, J.E. Gagnon, B.J. Fryer, Laser ablation of iron: a comparison between femtosecond and picosecond laser pulses. J. Appl. Phys. 114, 083110 (2013)

C.S.R. Nathala, A. Ajami, W. Husinsky, B. Farooq, S.I. Kudryashov, A. Daskalova, I. Bliznakova, A. Assion, Ultrashort laser pulse ablation of copper, silicon and gelatin: effect of the pulse duration on the ablation thresholds and the incubation coefficients. Appl. Phys. A 122, 107 (2016)

C. Liang, B. Li, H. Wang, B. Li, J. Yang, L. Zhou, H. Li, X. Wang, Ch Li, Preparation of hydrophobic and oleophilic surface of 316 L stainless steel by femtosecond laser irradiation in Water. J. Dispers. Sci. Technol. 35, 1345–1350 (2014)

A.E. Wynne, B.C. Stuart, Rate dependence of short-pulse laser ablation of metals in air and vacuum. Appl. Phys. A 76, 373–378 (2003)

M. Pfeiffer, A. Engel, G. Reisse, S. Weissmantel, Microstructuring of fused silica using femtosecond laser pulses of various wavelengths. Appl. Phys. A 121, 689–693 (2015)

S. Amoruso, R. Bruzzese, X. Wang, N.N. Nedialkov, P.A. Atanasov, Femtosecond laser ablation of nickel in vacuum. J. Phys. D: Appl. Phys. 40, 331 (2007)

S. Bruening, G. Hennig, S. Eifel, A. Gillner, Ultrafast scan techniques for 3D-µm structuring of metal surfaces with high repetitive ps-laser pulses. Phys. Procedia 12, 105–115 (2011)

Q. Wang, A. Chen, S. Li, H. Qi, Y. Qi, Z. Hu, M. Jin, Influence of ambient pressure on the ablation hole in femtosecond laser drilling Cu. Appl. Opt. 54, 8235–8240 (2015)

Z.Q. Cui, Y.Q. Li, W.X. Wang, C. Lin, B.S. Xu, Effect of environmental media on ablation rate of stainless steel under femtosecond laser multiple raster scans. Chin. Opt. Lett 13(1), 011402 (2015)

S.Z. Xu, C.Z. Yao, H.Q. Dou, W. Liao, X.Y. Li, R.J. Ding, L.J. Zhang, H. Liu, X.D. Yuan, X.T. Zu, An investigation on 800 nm femtosecond laser ablation of K9 glass in air and vacuum. Appl. Surf. Sci. 4069, 91–98 (2017)

P.T. Mannion, J. Magee, E. Coyne, G.M. O’Connor, T.J. Glynn, The effect of damage accumulation behaviour on ablation thresholds and damage morphology in ultrafast laser micro-machining of common metals in air. Appl. Surf. Sci. 233(1–4), 275–287 (2004)

F. Vidal, T.W. Johnston, S. Laville, O. Barthélemy, M. Chaker, B. Le Drogoff, J. Margot, M. Sabsabi, Critical-point phase separation in laser ablation of conductors. Phys. Rev. Lett. 86(12), 2573–2576 (2001)

J. Cheng, W. Perrie, B. Wu, S. Tao, S.P. Edwardson, G. Dearden, K.G.Watkins, Ablation mechanism study on metallic materials with a 10 ps laser under high fluence. Appl. Surf. Sci. 255, 8171–8175 (2009)

W. Hu, Y. Shin, G. King, Energy transport analysis in ultrashort pulse laser ablation through combined molecular dynamics and Monte Carlo simulation. Phys. Rev. B 82, 094111 (2010)

M.A. Jafarabadi, M.H. Mahdieh, Investigation of phase explosion in aluminum induced by nanosecond double pulse technique. Appl. Surf. Sci. 346, 263–269 (2015)

P. Lorazo, L.J. Lewis, M. Meunier, Short-pulse laser ablation of solids: from phase explosion to fragmentation. Phys. Rev. Lett. 91, 225502 (2003)

D. Perez, L.J. Lewis, Molecular-dynamics study of ablation of solids under femtosecond laser pulses. Phys. Rev. B 67, 184102 (2003)

N.N. Nedialkov, S.E. Imamova, P.A. Atanasov, P. Berger, F. Dausinger, Mechanism of ultrashort laser ablation of metals: molecular dynamics simulation. Appl. Surf. Sci. 247, 243–248 (2005)

S. Höhm, A. Rosenfeld, J. Krüger, J. Bonse, Femtosecond laser-induced periodic surface structures on silica. J. Appl. Phys. 112, 014901 (2012)

F. Liang, R. Vallée, S.L. Chin, Mechanism of nanograting formation on the surface of fused silica. Opt. Express 20(4), 4389–4396 (2012)

J. Bonse, J. Krüger, Pulse number dependence of laser-induced periodic surface structures for femtosecond laser irradiation of silicon. J. Appl. Phys. 108, 034903 (2010)

M. Huang, F.L. Zhao, Y. Cheng, N.S. Xu, Z.Z. Xu, Origin of laser-induced near-subwavelength ripples: interference between surface plasmons and incident laser. ACS Nano 3, 4062–4070 (2009)

A.A. Ionin, Y.M. Klimachev, A.Y. Kozlov, S.I. Kudryashov, A.E. Ligachev, S.V. Makarov, L.V. Seleznev, D.V. Sinitsyn, A.A. Rudenko, R.A. Khmelnitsky, Direct femtosecond laser fabrication of antireflective layer on GaAs surface. Appl. Phys. B111(3), 419–423 (2013)

M.H. Dar, R. Kuladeep, V. Saikiran, N. Rao, D., Femtosecond laser nanostructuring of titanium metal towards fabrication of low-reflective surfaces over broad wavelength range. Appl. Surf. Sci. 371, 479–487 (2016)

F.T. Meng, J. Hu, W.N. Han, P.J. Liu, Q.S. Wang, Morphology control of laser-induced periodic surface structure on the surface of nickel by femtosecond laser. Chin. Opt. Lett. 13(6), 062201 (2015)

C.Z. Yao, S.Z. Xu, Y.Y. Ye, Y. Jiang, R.J. Ding, W. Gao, X.D. Yuan, The influence of femtosecond laser repetition rates and pulse numbers on the formation of micro/nano structures on stainless steel. J. Alloy. Compd. 722, 235–241 (2017)

C.Z. Yao, Y.Y. Ye, B.S. Jia, Y. Li, R.J. Ding, Y. Jiang, Y.X. Wang, X.D. Yuan, Polarization and fluence effects in femtosecond laser induced micro/nano structures on stainless steel with antireflection property. Appl. Surf. Sci. 425, 1118–1124 (2017)

R. Le Harzic, D. Dorr, D. Sauer, M. Neumeier, M. Epple, H. Zimmermann, F. Stracke, Large-area uniform, high-spatial-frequency ripples generated on silicon using a nanojoule-femtosecond laser at high repetition rate. Opt. Lett. 36, 229–231 (2011)

M. Henyk, N. Vogel, D. Wolfframm, A. Tempel, J. Reif, Femtosecond laser ablation from dielectric materials: comparison to arc discharge erosion. Appl. Phys. A 69, S355–S358 (1999)

D.S. Milovanović, B. Gaković, C. Radu, M. Zamfirescu, B. Radak, S. Petrović, Z. Rogić Miladinović, I.N. Mihailescu, Femtosecond laser surface patterning of steel and titanium alloy. Phys. Scr. T162, 014017 (2014)

G.D. Tsibidis, E. Skoulas, E. Stratakis, Ripple formation on nickel irradiated with radially polarized femtosecond beams. Opt. Lett. 40(22), 5172–5175 (2015)

O. Armbruster, A. Naghilou, M. Kitzler, W. Kautek, Spot size and pulse number dependence of femtosecond laser ablation thresholds of silicon and stainless steel. Appl. Surf. Sci. 396, 1736–1740 (2017)

J.J.J. Nivas, Z.M. Song, R. Fittipaldi, A. Vecchione, R. Bruzzese, S. Amoruso, Direct ultrashort laser surface structuring of silicon in air and vacuum at 1055 nm. Appl. Surf. Sci. 417, 149–154 (2017)

J.J.J. Nivas, F. Gesuele, E. Allahyari, S.L. Oscurato, R. Fittipaldi, A. Vecchione, R. Bruzzese, S. Amoruso Effects of ambient air pressure on surface structures produced by ultrashort laser pulse irradiation. Opt. Lett. 42, 2710–2713 (2017)

T.Q. Jia, Z.Z. Xu, R.X. Li, D.H. Feng, X.X. Li, C.F. Cheng, H.Y. Sun, N.S. Xu, H.Z. Wang, Mechanisms in fs-laser ablation in fused silica. J. Appl. Phys. 95, 5166 (2004)

Acknowledgements

This work was supported by National Natural Science Foundation of China (NSFC) (Grant no: 51535003, 51701087); China Postdoctoral Science Foundation (Grant no: 2016M592709) and Sichuan Postdoctoral Science Foundation.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Xu, S., Ding, R., Yao, C. et al. Effects of pulse durations and environments on femtosecond laser ablation of stainless steel. Appl. Phys. A 124, 310 (2018). https://doi.org/10.1007/s00339-018-1714-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-018-1714-2