Abstract

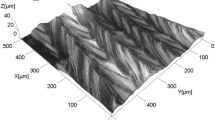

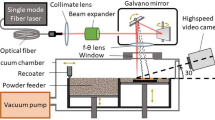

The dynamics of titanium (Ti) melted by laser irradiation was investigated in a synchrotron radiation experiment. As an indicator of wettability, the contact angle between a selective laser melting (SLM) baseplate and the molten Ti was measured by synchrotron X-rays at 30 keV during laser irradiation. As the baseplate temperature increased, the contact angle decreased, down to 28° at a baseplate temperature of 500 °C. Based on this result, the influence of wettability of a Ti plate fabricated by SLM in a vacuum was investigated. It was revealed that the improvement of wettability by preheating suppressed sputtering generation, and a surface having a small surface roughness was fabricated by SLM in a vacuum.

Similar content being viewed by others

References

E.C. Santos, M. Shiomi, K. Osakada, T. Laoui, Int. J. Mach. Tools Manuf. 46, 1459–1468 (2006)

B. Zhang, N.E. Feinech, H.L. Liao, C. Coddet, J. Mater. Sci. Technol. 29(8), 757–760 (2013)

D. Gu, Y. Shen, Z. Lu, Mater. Lett. 63, 1577–1579 (2009)

Z. Wang, K. Guan, M. Gao, X. Li, X. Chen, X. Zeng, J. Alloy Comp. 513, 518–523 (2012)

Q. Jia, D. Gu, J. Alloy Comp. 585, 713–721 (2014)

I. Yadroitsev, P. Krakhmalev, I. Yadroitsava, S. Johansson, I. Smurov, J. Mater. Process. Technol. 213, 606–613 (2013)

S. Merkt, C. Hinke, J. Bultmann, M. Brandt, Y.M. Xie, J. Laser Appl. 27, S17006–1 (2015)

J. Sun, Y. Yang, D. Wang, Mater. Des. 49, 545–552 (2013)

B. Zhang, H. Liao, C. Coddet, Vacuum 95, 25–29 (2013)

A. Agapovichev, V.V. Kokareva, V.G. Smelov, A.V. Stov, Mat. Sci. Eng. 156, 012031 (2016)

Y. Sato, M. Tsukamoto, Y. Yamashita, Appl. Phy. B 119, 545–549 (2015)

Y. Sato, M. Tsukamoto, S. Masuno, Y. Yamashita, D. Tanigawa, N. Abe, Appl. Phys. A 122, 439 (2016)

Y. Sato, M. Tsukamoto, Y. Yamashita, S. Masuno, K. Yamashita, S. Yamagata, R. Higashino, IEEJ Trans. Fundam. Mater. 137(5), 265–270 (2017). (in Japanese).

M.J. Matthews, G. Saad, S.A. Khairallah, A.M. Rubenchil, P.J. Depond, W.E. King, Acta Mater. 114, 33–42 (2016)

I. Egry, E. Rici, R. Novakovic, S. Ozawa, Adv. Colloid Interf. Sci. 159, 198–212 (2010)

N. Eustathopoulos, Metals 5, 350–370 (2015)

S. Nakano, N. Sato, T. Shimizu, Gas Turbine Soc. Jpn. 42, 433–438 (2014). (in Japanese).

Acknowledgements

This work was supported by the Strategic Innovative Promotion Program of the Japan New Energy and Industrial Technology Development Organization (NEDO). The synchrotron radiation experiments were performed at the BL22XU in SPring-8 with the approval of the Japan Synchrotron Radiation Research Institute (Proposal No. 2016B3721, No. 2017A3721).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sato, Y., Tsukamoto, M., Shobu, T. et al. Preheat effect on titanium plate fabricated by sputter-free selective laser melting in vacuum. Appl. Phys. A 124, 288 (2018). https://doi.org/10.1007/s00339-018-1712-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-018-1712-4