Abstract

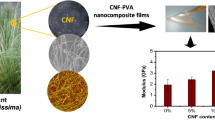

Old corrugated box (OCB) as a raw material was treated using alkali, acetic acid with NaClO and hydrogen peroxide to extract partially purified cellulose microfibers. FTIR and XRD analysis indicates the significant removal of non-cellulosic (lignin and hemicelluloses) content, followed by a notable increase in cellulose purity and crystallinity. Obtained cellulose microfibers (diameter 60–70 µm) were broken down to cellulose nanofibers (diameter up to 80 nm) using high-pressure homogenizer at 1700–1800 bar pressure consisting of 30 cycles and further characterized by SEM and XRD. Later on, nanocomposite films were prepared and optimized for required citric acid concentration for cross-linking with tamarind seed polysaccharide/guar gum blend by polycondensation reaction. And plasticized by glycerol (0.5% w/v) with different concentrations of OCB-CNF (0.1–1% w/v). The cross-link reaction was optimized at 80 °C for 3 h in order to confirm the esterification reaction between citric acid, polysaccharide and nanofiber. Increasing characteristic band intensity at around 1731 cm−1 represents ester bond formation is supported by the FTIR analysis. Rheology reveals the increase in cross-linking density after citric acid cross-link at 0.2% of OCB-CNF. Improvement in interfacial bonding between nanofiber and matrix results in enhanced tensile strength, barrier property and thermal stability as compared to those of control film. In addition, swelling behavior of OCB-CNF composite films was studied at different pH conditions (pH = 3, 7 and 10), where 0.2% and 0.5% OCB-CNFs showed better interaction with the matrix polysaccharide.

Similar content being viewed by others

References

Wu C-S (2003) Physical properties and biodegradability of maleated-polycaprolactone/starch composite. Polym Degrad Stab 80:127–134. https://doi.org/10.1016/S0141-3910(02)00393-2

Aburto J, Alric I, Thiebaud S et al (1999) Synthesis, characterization, and biodegradability of fatty-acid esters of amylose and starch. J Appl Polym Sci 74:1440–1451. https://doi.org/10.1002/(SICI)1097-4628(19991107)74:6%3c1440:AID-APP17%3e3.0.CO;2-V

Cherian BM, Pothan LA, Nguyen-Chung T et al (2008) A novel method for the synthesis of cellulose nanofibril whiskers from banana fibers and characterization. J Agric Food Chem 56:5617–5627. https://doi.org/10.1021/jf8003674

Carpenter AW, de Lannoy C-F, Wiesner MR (2015) Cellulose nanomaterials in water treatment technologies. Environ Sci Technol 49:5277–5287. https://doi.org/10.1021/es506351r

George J, Ramana KV, Bawa AS, Siddaramaiah B (2011) Bacterial cellulose nanocrystals exhibiting high thermal stability and their polymer nanocomposites. Int J Biol Macromol 48:50–57. https://doi.org/10.1016/j.ijbiomac.2010.09.013

Cho B-U, Ryu J-Y, Song B-K (2012) Improvement of ink and heavy metal removal from old corrugated container stock by alkali kneading. J Ind Eng Chem 18:697–701. https://doi.org/10.1016/j.jiec.2011.11.135

Chen YW, Lee HV (2018) Revalorization of selected municipal solid wastes as new precursors of “green” nanocellulose via a novel one-pot isolation system: a source perspective. Int J Biol Macromol 107:78–92. https://doi.org/10.1016/j.ijbiomac.2017.08.143

Guo W-J, Wang Y, Wan J-Q, Ma Y-W (2011) Effects of slushing process on the pore structure and crystallinity in old corrugated container cellulose fibre. Carbohydr Polym 83:1–7. https://doi.org/10.1016/j.carbpol.2010.07.009

Chen Y, Wan J, Ma Y et al (2012) Modification of old corrugated container pulp with laccase and laccase–mediator system. Bioresour Technol 110:297–301. https://doi.org/10.1016/j.biortech.2011.12.120

Abdulsamad A, Oyi AR, Isah AB, Odidi I (2015) Derivatisation of cashew gum via cross-linking with citric acid: characterisation and preliminary evaluation of tableting properties. Br J Pharm Res 6:22–34

Gupta AP, Arora G (2011) Preparation and characterization of guar-gum/polyvinylalcohol blend films. J Mater Sci Eng B 1:28–33

Azeredo HMC, Waldron KW (2016) Crosslinking in polysaccharide and protein films and coatings for food contact: a review. Trends Food Sci Technol 52:109–122. https://doi.org/10.1016/j.tifs.2016.04.008

Reddy N, Yang Y (2010) Citric acid cross-linking of starch films. Food Chem 118:702–711. https://doi.org/10.1016/j.foodchem.2009.05.050

Chabrat E, Abdillahi H, Rouilly A, Rigal L (2012) Influence of citric acid and water on thermoplastic wheat flour/poly(lactic acid) blends. I: thermal, mechanical and morphological properties. Ind Crops Prod 37:238–246. https://doi.org/10.1016/j.indcrop.2011.11.034

Da Róz AL, Zambon MD, Curvelo AAS, Carvalho AJF (2011) Thermoplastic starch modified during melt processing with organic acids: the effect of molar mass on thermal and mechanical properties. Ind Crops Prod 33:152–157. https://doi.org/10.1016/j.indcrop.2010.09.015

Coma V, Sebti I, Pardon P et al (2003) Film properties from crosslinking of cellulosic derivatives with a polyfunctional carboxylic acid. Carbohydr Polym 51:265–271. https://doi.org/10.1016/S0144-8617(02)00191-1

Jiugao Y, Ning W, Xiaofei M (2005) The effects of citric acid on the properties of thermoplastic starch plasticized by glycerol. Starch-Stärke 57:494–504. https://doi.org/10.1002/star.200500423

Park H-R, Chough S-H, Yun Y-H, Yoon S-D (2005) Properties of starch/PVA blend films containing citric acid as additive. J Polym Environ 13:375–382. https://doi.org/10.1007/s10924-005-5532-1

Tibolla H, Pelissari FM, Martins JT et al (2018) Cellulose nanofibers produced from banana peel by chemical and mechanical treatments: characterization and cytotoxicity assessment. Food Hydrocoll 75:192–201. https://doi.org/10.1016/j.foodhyd.2017.08.027

Yoon S-D, Chough S-H, Park H-R (2006) Properties of starch-based blend films using citric acid as additive II. J Appl Polym Sci 100:2554–2560. https://doi.org/10.1002/app.23783

Sun XF, Xu F, Sun RC et al (2005) Characteristics of degraded cellulose obtained from steam-exploded wheat straw. Carbohydr Res 340:97–106. https://doi.org/10.1016/j.carres.2004.10.022

Wang Y, Wei X, Li J et al (2013) Homogeneous isolation of nanocellulose from cotton cellulose by high pressure homogenization. J Mater Sci Chem Eng 01:49–52. https://doi.org/10.4236/msce.2013.15010

Wang Y, Wei X, Li J et al (2015) Study on nanocellulose by high pressure homogenization in homogeneous isolation. Fibers Polym 16:572–578. https://doi.org/10.1007/s12221-015-0572-1

de Cuadro P, Belt T, Kontturi KS et al (2015) Cross-linking of cellulose and poly(ethylene glycol) with citric acid. React Funct Polym 90:21–24. https://doi.org/10.1016/j.reactfunctpolym.2015.03.007

Kolmas J, Oledzka E, Sobczak M, Nałęcz-Jawecki G (2014) Nanocrystalline hydroxyapatite doped with selenium oxyanions: a new material for potential biomedical applications. Mater Sci Eng C 39:134–142. https://doi.org/10.1016/j.msec.2014.02.018

Mansouri NEE, Qiaolong Yuan FH (2011) Characterization of alkaline lignins for use in penol-formaldehyde and epoxy resins. BioResources 6:2647–2662

Mandal A, Chakrabarty D (2011) Isolation of nanocellulose from waste sugarcane bagasse (SCB) and its characterization. Carbohydr Polym 86:1291–1299. https://doi.org/10.1016/j.carbpol.2011.06.030

Sun FJM, Goodwin A et al (1998) Isolation and characterization of polysaccharides from abaca fiber. J Agric Food Chem 46:2817–2822. https://doi.org/10.1021/jf9710894

Bourtoom T (2008) Plasticizer effect on the properties of biodegradable blend film from rice starch-chitosan. Songklanakarin J Sci Techno 30:149–165

Lee J-A, Yoon M-J, Lee E-S et al (2014) Preparation and characterization of cellulose nanofibers (CNFs) from microcrystalline cellulose (MCC) and CNF/polyamide 6 composites. Macromol Res 22:738–745. https://doi.org/10.1007/s13233-014-2121-y

Li J, Wei X, Wang Q et al (2012) Homogeneous isolation of nanocellulose from sugarcane bagasse by high pressure homogenization. Carbohydr Polym 90:1609–1613. https://doi.org/10.1016/j.carbpol.2012.07.038

Tang Y, Shen X, Zhang J et al (2015) Extraction of cellulose nano-crystals from old corrugated container fiber using phosphoric acid and enzymatic hydrolysis followed by sonication. Carbohydr Polym 125:360–366. https://doi.org/10.1016/j.carbpol.2015.02.063〹

Donsì F, Wang Y, Li J, Huang Q (2010) Preparation of curcumin sub-micrometer dispersions by high-pressure homogenization. J Agric Food Chem 58:2848–2853. https://doi.org/10.1021/jf903968x

Floury J, Desrumaux A, Axelos MAV, Legrand J (2002) Degradation of methylcellulose during ultra-high pressure homogenisation. Food Hydrocoll 16:47–53. https://doi.org/10.1016/S0268-005X(01)00039-X

Amarasekara AS, Owereh OS (2009) Hydrolysis and decomposition of cellulose in Brönsted acidic ionic liquids under mild conditions. Ind Eng Chem Res 48:10152–10155. https://doi.org/10.1021/ie901047u

Li M, Wang L, Li D et al (2014) Preparation and characterization of cellulose nanofibers from de-pectinated sugar beet pulp. Carbohydr Polym 102:136–143. https://doi.org/10.1016/j.carbpol.2013.11.021

Nasri-Nasrabadi B, Behzad T, Bagheri R (2014) Preparation and characterization of cellulose nanofiber reinforced thermoplastic starch composites. Fibers Polym 15:347–354. https://doi.org/10.1007/s12221-014-0347-0

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794. https://doi.org/10.1177/004051755902901003

Alemdar A, Sain M (2008) Isolation and characterization of nanofibers from agricultural residues—wheat straw and soy hulls. Bioresour Technol 99:1664–1671. https://doi.org/10.1016/j.biortech.2007.04.029

Tang L-C, Hon DNS, Pan S-H, Zhu Y-Q, Wang Z, Wang Z-Z (1996) Evaluation of microcrystalline cellulose. 1. Changes in ultrastructural characteristics during preliminary acid hydrolysis. J Appl Polym Sci 59:483–488

Bhatnagar A (2004) Isolation of cellulose nanofibres from renewable feed stocks and root crops. University of Toronto, Scarborough

Sakurada I, Nukushina Y, Ito T (1962) Experimental determination of the elastic modulus of crystalline regions in oriented polymers. J Polym Sci 57:651–660. https://doi.org/10.1002/pol.1962.1205716551

Stelte W, Sanadi AR (2009) Preparation and characterization of cellulose nanofibers from two commercial hardwood and softwood pulps. Ind Eng Chem Res 48:11211–11219. https://doi.org/10.1021/ie9011672

Romainor ANB, Chin SF, Pang SC, Bilung LM (2014) Preparation and characterization of chitosan nanoparticles-doped cellulose films with antimicrobial property. J Nanomater 2014:1–10. https://doi.org/10.1155/2014/710459

Yang CQ, Andrews BAK (1991) Infrared spectroscopic studies of the nonformaldehyde durable press finishing of cotton fabrics by use of polycarboxylic acids. J Appl Polym Sci 43:1609–1616. https://doi.org/10.1002/app.1991.070430904

Azeredo HMC, Kontou-Vrettou C, Moates GK et al (2015) Wheat straw hemicellulose films as affected by citric acid. Food Hydrocoll 50:1–6. https://doi.org/10.1016/j.foodhyd.2015.04.005

Savadekar NR, Karande VS, Vigneshwaran N et al (2015) Preparation of cotton linter nanowhiskers by high-pressure homogenization process and its application in thermoplastic starch. Appl Nanosci 5:281–290. https://doi.org/10.1007/s13204-014-0316-3

Zhao J, He X, Wang Y et al (2014) Reinforcement of all-cellulose nanocomposite films using native cellulose nanofibrils. Carbohydr Polym 104:143–150. https://doi.org/10.1016/j.carbpol.2014.01.007

Mtibe A, Linganiso LZ, Mathew AP et al (2015) A comparative study on properties of micro and nanopapers produced from cellulose and cellulose nanofibres. Carbohydr Polym 118:1–8. https://doi.org/10.1016/j.carbpol.2014.10.007

Karande VS, Bharimalla AK, Vigneshwaran N et al (2014) Cotton linter nano-fibers as the potential reinforcing agent for guar gum. Iran Polym J 23:869–879. https://doi.org/10.1007/s13726-014-0283-2

Shao L, Ji Z-Y, Ma J-Z et al (2016) The synergy of double cross-linking agents on the properties of styrene butadiene rubber foams. Sci Rep 6:36931. https://doi.org/10.1038/srep36931

Kaushik A, Singh M, Verma G (2010) Green nanocomposites based on thermoplastic starch and steam exploded cellulose nanofibrils from wheat straw. Carbohydr Polym 82:337–345. https://doi.org/10.1016/j.carbpol.2010.04.063

Zhang B, Luo Y, Wang Q (2011) Effect of acid and base treatments on structural, rheological, and antioxidant properties of α-zein. Food Chem 124:210–220. https://doi.org/10.1016/j.foodchem.2010.06.019

Mitra T, Sailakshmi G, Gnanamani A et al (2011) Preparation and characterization of a thermostable and biodegradable biopolymers using natural cross-linker. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2010.11.011

Patel PK, Pandya SS (2013) Preparation and characterization of crosslinked gum acacia microspheres by single step emulsion in-situ polymer crosslinking method: a potential vehicle for controlled drug delivery. Res Rev J Pharm Pharm Sci 2:40–48

Dharela R, Raj L, Chauhan GS (2012) Synthesis, characterization, and swelling studies of guar gum-based pH, temperature, and salt responsive hydrogels. J Appl Polym Sci 126:E260–E265. https://doi.org/10.1002/app.36983

Ferreira L, Vidal MM, Gil MH (2000) Evaluation of poly(2-hydroxyethyl methacrylate) gels as drug delivery systems at different pH values. Int J Pharm 194:169–180

Rizwan M, Yahya R, Hassan A et al (2017) pH sensitive hydrogels in drug delivery: Brief history, properties, swelling, and release mechanism, material selection and applications. Polymers Basel 9:34–54

Ifebajo AO (2014) Synthesis and characterisation of chemically crosslinked chitosan citrate gel. Eastern Mediterranean University, Famagusta

Acknowledgements

The author is thankful to University grant commission Basic scientific research (UGC BSR), New Delhi, India, for the financial assistance provided in the form of fellowship in vide sanction no. F.4-1/2006 (BSR)/8-10/2007(BSR).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lal, S.S., Mhaske, S.T. Old corrugated box (OCB)-based cellulose nanofiber-reinforced and citric acid-cross-linked TSP–guar gum composite film. Polym. Bull. 78, 885–915 (2021). https://doi.org/10.1007/s00289-020-03138-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-020-03138-y