Abstract

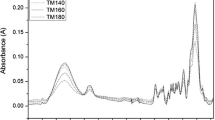

This study focuses on the effects of fiber treatment on the mechanical, morphological, physical and thermal properties of kenaf/jute/polyethylene composites, by using alkaline-treated and raw fibers. The core of jute and kenaf fibers was chopped into shorter lengths and used for composite fabrication. The composites were then subjected to tensile, water absorption, SEM, FTIR, DSC and TGA tests. According to the FTIR spectroscopy results, the alkaline treatment removed a significant amount of lignin and other impurities, especially at lower infrared band. This reduced fibers’ hydrophilicity, making it more compatible with the polymer. This is evident from the SEM results, as it shows improved interfacial bonding. Therefore, the treated fiber composites, especially for 15 wt% composites, have higher tensile strengths, more thermal stability and higher activation energy.

Similar content being viewed by others

References

Elbadry EA, Abdalla GA, Aboraia M, Oraby EA (2012) Notch sensitivity of short and 2D plain woven glass fibres reinforced with different polymer matrix composites. J Reinf Plast Compos 36:1092–1098. https://doi.org/10.1155/2012/354547

Sanjay MR, Madhu P, Jawaid M, Senthamaraikannan P, Senthil S, Pradeep S (2018) Characterization and properties of natural fiber polymer composites: a comprehensive review. J Clean Prod 172:566–581. https://doi.org/10.1016/j.jclepro.2017.10.101

Ramnath BV, Manickavasagam VM, Elanchezhian C, Krishna CV, Karthik S, Saravanan K (2014) Determination of mechanical properties of intra-layer abaca-jute-glass fiber reinforced composite. Mater Des 60:643–652. https://doi.org/10.1016/j.matdes.2014.03.061

Sanjay MR, Arpitha GR, Naik LL, Gopalakrishna K, Yogesha B (2016) Applications of natural fibers and its composites: an overview. Nat Res 7:108–114. https://doi.org/10.4236/nr.2016.73011

Sanjay MR, Arpitha GR, Yogesha B (2015) Study on mechanical properties of natural-glass fibre reinforced polymer hybrid composites: a review. Mater Today Proc 2:2959–2967. https://doi.org/10.1016/j.matpr.2015.07.264

Deng Y, Paraskevas D, Tian Y, Acker KV, Dewulf W, Duflou JR (2016) Life cycle assessment of flax-fibre reinforced epoxidized linseed oil composite with a flame retardant for electronic applications. J Clean Prod 133:427–438. https://doi.org/10.1016/j.jclepro.2016.05.172

Gowda TM, Naidu ACB, Chhaya R (1999) Some mechanical properties of untreated jute fabric-reinforced polyester composites. Compos Part A Appl Sci Manuf 30:277–284. https://doi.org/10.1016/S1359-835X(98)00157-2

Ozturk B (2010) Hybrid effect in the mechanical properties of jute/rockwool hybrid fibers reinforced phenol formaldehyde composites. Fibers Polym 11:464–473. https://doi.org/10.1007/s12221-010-0464-3

Edeerozy AMM, Akil HM, Azhar AB, Ariffin MIZ (2006) Chemical modification of kenaf fibers. Mater Lett 61:2023–2025. https://doi.org/10.1016/j.matlet.2006.08.006

Cherian BM, Leão AL, Souza SF, Costa LMM, Olyveira GM, Kottaisamy M, Nagarajan ER, Thomas S (2011) Cellulose nanocomposites with nanofibers isolated from pineapple leaf fibers for medical applications. Carbohyd Polym 86:1790–1798. https://doi.org/10.1016/j.carbpol.2011.07.009

Nahar S, Khan AR, Dey K, Sarker B, Das KA, Ghoshal S (2011) Comparative studies of mechanical and interfacial properties between jute and bamboo fiber-reinforced polypropylene-based composites. J Thermoplast Compos Mater 25:15–32. https://doi.org/10.1177/0892705711404725

Kabir MA, Huque MM, Islam MR, Bledzki AK (2010) Mechanical properties of jute fiber reinforced polypropylene composite: effect of chemical treatment by benzenediazonium salt in alkaline medium. BioResources 5:1618–1625. https://doi.org/10.15376/biores.5.3.1618-1625

Joseph P, Mathew G, Joseph K, Groeninckx G, Thomas S (2003) Dynamic mechanical properties of short sisal fibre reinforced polypropylene composite. Compos Part A Appl Sci Manuf 34:275–390. https://doi.org/10.1016/S1359-835X(02)00020-9

Monteiro SN, Calado V, Rodriguez RJS, Margem FM (2012) Thermogravimetric behavior of natural fibers reinforced polymer composites—an overview. Mater Sci Eng, A 557:17–28. https://doi.org/10.1016/j.msea.2012.05.109

Shubhra QTH, Alam AKMM (2011) Effect of gamma radiation on the mechanical properties of natural silk fiber and synthetic E-glass fiber reinforced polypropylene composites: a comparative study. Radiat Phys Chem 80:1228–1232. https://doi.org/10.1016/j.radphyschem.2011.04.010

Bledzki AK, Faruk O (2005) Microcellular wood fiber reinforced PP composites: cell morphology, surface roughness, impact, and odor properties. J Cell Plast 41:539–550. https://doi.org/10.1177/0021955X05059033

Pan M, Zhang SY, Zhou D (2009) Preparation and properties of wheat straw fiber-polypropylene composites. Part II. Investigation of surface treatments on the thermo-mechanical and rheological properties of the composites. J Compos Mater 44:1061–1073. https://doi.org/10.1177/0021998309349549

Bachtiar D, Sapuan SM, Hamdan MM (2008) The effect of alkaline treatment on tensile properties of sugar palm fibre reinforced epoxy composites. Mater Des 29:1285–1290. https://doi.org/10.1016/j.matdes.2007.09.006

Vilaseca F, Mendez JA, Pelach A, Llop M, Canigueral N, Girones J (2007) Composite materials derived from biodegradable starch polymer and jute strands. Process Biochem 42:329–334. https://doi.org/10.1016/j.procbio.2006.09.004

ASTM E168-16 (2016) Standard practices for general techniques of infrared quantitative analysis. ASTM International, West Conshohocken. https://doi.org/10.1520/E0168-16

ASTM E1252-98 (2013) Standard practice for general techniques for obtaining infrared spectra for qualitative analysis. ASTM International, West Conshohocken. https://doi.org/10.1520/E1252-98R13E01

ASTM E2015-04 (2014) Standard guide for preparation of plastics and polymeric specimens for microstructural examination. ASTM International, West Conshohocken. https://doi.org/10.1520/E2015-04R14

ASTM D638-14 (2014) Standard test method for tensile properties of plastics. ASTM International, West Conshohocken. https://doi.org/10.1520/D0638-14

ASTM D570-98 (2010) Standard test method for water absorption of plastics. ASTM International, West Conshohocken. https://doi.org/10.1520/D0570-98R10E01

ASTM E1868-10 (2015) Standard test methods for loss-on-drying by thermogravimetry. ASTM International, West Conshohocken. https://doi.org/10.1520/E1868-10R15

ASTM E1131-08 (2014) Standard test method for compositional analysis by thermogravimetry. ASTM International, West Conshohocken. https://doi.org/10.1520/E1131

ASTM D3418-15 (2015) Standard test method for transition temperatures and enthalpies of fusion and crystallization of polymers by differential scanning calorimetry. ASTM International, West Conshohocken. https://doi.org/10.1520/D3418-15

ASTM E1269-11 (2011) Standard test method for determining specific heat capacity by differential scanning calorimetry. ASTM International, West Conshohocken. https://doi.org/10.1520/E1269-11

Li X, Tabil LG, Panigrahi S (2007) Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J Polym Environ 15:25–33. https://doi.org/10.1007/s10924-006-0042-3

Agrawal R, Saxena NS, Sharma KB, Thomas S, Sreekala MS (2000) Activation energy and crystallization kinetics of untreated and treated oil palm fibre reinforced phenol formaldehyde composites. Mater Sci Eng Part A 277:77–82. https://doi.org/10.1016/S0921-5093(99)00556-0

Khan RA, Khan MA, Zaman HU, Khan MN, Sultana S (2010) Comparative studies of mechanical and interfacial properties between jute and E-glass fibers reinforced polypropylene composites. J Reinf Plast Compos 29:1078–1088. https://doi.org/10.1177/0731684409103148

Ganan P, Zulunga R, Restrepo A, Labidi J, Mondragon I (2008) Plantain fibre bundles isolated from Colombian agro-industrial restudies. Biores Technol 99:486–491. https://doi.org/10.1016/j.biortech.2007.01.012

Rahman MR, Islam MN, Haque MM, Hamdan S, Ahmed AS (2010) Effect of chemical treatment on rice husk (RH) reinforced polyethylene (PE) composites. BioResources 5:854–869. https://doi.org/10.15376/biores.5.2.854-869

Bulut Y, Aksit A (2013) A comparative study on chemical treatment of jute fiber: potassium dichromate, potassium permanganate and sodium perborate trihydrate. Cellulose 20:3155–3164. https://doi.org/10.1007/s10570-013-0049-6

Sinha E, Rout SK (2009) Influence of fibre-surface treatment on structural, thermal and mechanical properties of jute fibre and its composite. Bull Mater Sci 32:65–76. https://doi.org/10.1007/s12034-009-0010-3

Wang B (2004) Pre-treatment of flax fibers for use in rotationally molded bio-composites. Master thesis, University of Saskatchewan, Canada. http://hdl.handle.net/10388/etd-08132004-114954

Ray D, Sarkara BK, Rana AK, Bose NR (2001) The mechanical properties of vinyl ester resin matrix composites reinforced with alkali-treated jute fibres. Compos Part A Appl Sci Manuf 32:119–127. https://doi.org/10.1016/S1359-835X(00)00101-9

Hossen MF, Hamdan S, Rahman MR, Rahman MM, Liew FK, Lai JC (2015) Effect of fiber treatment and nanoclay on the tensile properties of jute fiber reinforced polyethylene/clay nanocomposites. Fibers Polym 16:479–485. https://doi.org/10.1007/s12221-015-0479-x

Sever K (2010) The improvement of mechanical properties of jute fiber/LDPE composites by fiber surface treatment. J Reinf Plast Compos 29(13):1921–1929. https://doi.org/10.1177/0731684409339078

Ray D, Sengupta S, Sengupta SP, Mohanty AK, Misra M (2007) A study of the mechanical and fracture behavior of jute fabric reinforced clay modified thermoplastic starch-matrix composites. Macromol Mater Eng 292:1075–1084. https://doi.org/10.1002/mame.200700111

Kokabi M, Sirousazar M, Hassan ZM (2007) PVA-clay nanocomposite hydrogels for wound dressing. Eur Polym J 43:773–781. https://doi.org/10.1016/j.eurpolymj.2006.11.030

Freire CSR, Silvestre AJD, Neto CP, Gandini A, Martin L, Mondragon I (2008) Composites based on acylated cellulose fibers and low-density polyethylene: effect of the fiber content, degree of substitution and fatty acid chain length on final properties. Compos Sci Technol 68:3358–3364. https://doi.org/10.1016/j.compscitech.2008.09.008

Hossain MK, Dewan MW, Hosur M, Jeelani S (2011) Mechanical performances of surface modified jute fiber reinforced biopol nanophased green composites. Compos Part B Eng 42:1701–1707. https://doi.org/10.1016/j.compositesb.2011.03.010

Morshed MM, Alam MM, Deniels SM (2012) Moisture removal from natural jute fiber by plasma drying process. Plasma Chem Plasma Process 32:249–258. https://doi.org/10.1177/0021998313499955

Raghavendra G, Ojha S, Acharya SK, Pal SK (2014) Jute fiber reinforced epoxy composites and comparison with the glass and neat epoxy composites. J Compos Mater 48:2537–2547. https://doi.org/10.1177/0021998313499955

Bozkurt E, Kaya E, Tanoglu M (2007) Mechanical and thermal behavior of non-crimp glass fiber reinforced layered clay/epoxy nanocomposites. Compos Sci Technol 67:3394–3403. https://doi.org/10.1016/j.compscitech.2007.03.021

Wang X, Cui Y, Xu Q, Xie B, Li W (2010) Effect of alkali and silane treatment on the mechanical properties of jute-fiber-reinforced recycled polypropylene composites. J Vinyl Addit Technol 16:183–188. https://doi.org/10.1002/vnl.20230

Acknowledgements

The authors are grateful for the support of Faculty of Engineering, Universiti Malaysia Sarawak (UNIMAS). The authors are grateful to the Ministry of Education Malaysia (MOE) for providing financial assistance under the FGRS Grant scheme (FRGS/SG01(01)/1085/2013(31)).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rahman, M.R., Hamdan, S., Jayamani, E. et al. Tert-butyl catechol/alkaline-treated kenaf/jute polyethylene hybrid composites: impact on physico-mechanical, thermal and morphological properties. Polym. Bull. 76, 763–784 (2019). https://doi.org/10.1007/s00289-018-2404-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-018-2404-0