Abstract

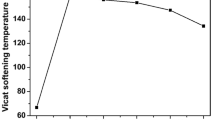

Polystyrene (PS) has low impact strength and also shows poor strain hardening. In this work, poly(styrene–butadiene–styrene) triblock copolymer (SBS) was solution- and melt-blended with PS in the presence of a free-radical polymerization initiator, dicumyl peroxide (DCP), to enhance PS’s thermal stability, mechanical properties, impact resistance, and strain hardening. The solution-blended PS/SBS containing 0.1% DCP annealed at 180 °C showed strong strain hardening, but the melt-blended PS/SBS annealed at the same temperature and time showed poor strain hardening. The change in the blending temperature, DCP concentration, and PS-to-SBS ratio had minimal effect on the strain hardening of melt-blended PS/SBS. The tensile strength increased with an increase in the concentration of DCP up to 0.1%, and beyond that level, the tensile strength started decreasing. The impact resistance considerably improved with an increase in the SBS loading in the PS matrix, and the enhancement was more than double of the impact resistance shown by the neat PS.

Similar content being viewed by others

References

Hassan MM, Koyama K (2015) Thermal, physicomechanical, and morphological properties of HDPE graft-copolymerized with polystyrene. Polym Adv Technol 26:1285–1293

Sukhareva LA, Legonkova OA, Yakovlev VS (2008) Polymers for packaging and containers in food industry. CRC Press, Boca Raton, pp 455–490

Piorkowska E, Argon AS, Cohen RE (1993) Izod impact strength of polystyrene-based blends containing low molecular weight polybutadiene. Polymer 34:4435–4444

Zhou C, Wu S, Yang B, Gao Y-X, Wu G-F, Zhang H-X (2015) Toughening polystyrene by core-shell rubber particles: analysis of the internal structure and properties. Polym Polym Compos 23:317–324

Guo TY, Tang GL, Hao GJ, Song MD, Zhang BH (2003) Toughening modification of PS with n-BA/MMA/styrene core–shell structured copolymer from emulsifier-free emulsion polymerization. J Appl Polym Sci 90:1290–1297

Wu DY, Svazas Y (2006) Micro- and nano-sized calcium carbonate toughened polystyrene. J Nanosci Nanotechnol 6:3919–3922

Yang H, Zhang X, Qu C, Li B, Zhang L, Zhang Q, Fu Q (2007) Largely improved toughness of PP/EPDM blends by adding nano-SiO2 particles. Polymer 48:860–869

Han J-J, Huang H-X (2011) Preparation and characterization of biodegradable polylactide/thermoplastic polyurethane elastomer blends. J Appl Polym Sci 120:3217–3223

Feng F, Zhao X-W, Ye L (2011) Structure and properties of ultradrawn polylactide/thermoplastic polyurethane elastomer blends. J Macromol Sci B 50:1500–1507

Sugimoto M, Masubuchi M, Takimoto J, Koyama K (2001) Melt rheology of polypropylene containing small amounts of high-molecular-weight chain. 2. Uniaxial and biaxial extensional flow. Macromolecules 34:6056–6063

Fowler MW, Baker WE (1988) Rubber toughening of polystyrene through reactive blending. Polym Eng Sci 28:1427–1433

Schneider M, Pith T, Lambla M (1997) Toughening of polystyrene by natural rubber-based composite particles: Part I Impact reinforcement by PMMA and PS grafted core-shell particles. J Mater Sci 32:6331–6342

Michler GH (1990) Formation of crazes in polymer blends. Macromol Chem: Macromol Sympos 38:195–204

Doufas AK, Rice L, Thurston W (2011) Shear and extensional rheology of polypropylene melts: experimental and modeling studies. J Rheol 55:95–126

Wang J, James DF, Park CB (2010) Planar extensional flow resistance of a foaming plastic. J Rheol 54:95–116

Takahashi M, Isaki T, Takigawa T, Masuda T (1993) Measurement of biaxial and uniaxial extensional flow behavior of polymer melts at constant strain rates. J Rheol 37:827–846

Lentzakis H, Vlassopoulos V, Read DJ, Lee H, Chang T, Driva P, Hadjichristidis N (2013) Uniaxial extensional rheology of well-characterized comb polymers. J Rheol 57:605–625

Ahirwal D, Filipe S, Neuhaus I, Busch M, Schlatter G, Wilhelm M (2014) Large amplitude oscillatory shear and uniaxial extensional rheology of blends from linear and long-chain branched polyethylene and polypropylene. J Rheol 58:635–658

Huang Q, Magnus M, Alvarez NJ, Koopmans R, Hassager O (2016) A new look at extensional rheology of low-density polyethylene. Rheol Acta 55:343–350

Sugimoto M, Suzuki Y, Hyun K, Ahn KH, Ushioda T, Nishioka A, Taniguchi T, Koyama K (2006) Melt rheology of long-chain-branched polypropylenes. Rheol Acta 46:33–46

Stange J, Munstedt H (2006) Rheological properties and foaming behavior of polypropylenes with different molecular structures. J Rheol 50:907–927

Minegishi A, Nishioka A, Takahashi T, Masubuchi Y, Takimoto J, Koyama K (2001) Uniaxial elongational viscosity of PS/a small amount of UHMW-PS blends. Rheol Acta 40:329–338

Kurose T, Takahashi T, Sugimoto M, Koyama K (2005) Uniaxial elongational viscosity of PC/a small amount of PTFE blend. Nihon Reoroji Gakkaishi 33:173–182

Liu J, Lou L, Yu W, Liao R, Li R, Zhou C (2010) Long chain branching polylactide: structures and properties. Polymer 51:5186–5197

Li S, He G, Liao X, Park CB, Yang Q, Li G (2017) Introduction of a long-chain branching structure by ultraviolet-induced reactive extrusion to improve cell morphology and processing properties of polylactide foam. RSC Adv 7:6266–6277

Sugimoto M, Tanaka T, Masubuchi Y, Takimoto J, Koyama K (1999) Effect of chain structure on the melt rheology of modified polypropylene. J Appl Polym Sci 73:1493–1500

Kurzbeck S, Oster F, Munstedt H (1999) Rheological properties of two polypropylenes with different molecular structure. J Rheol 43:359–374

Auhl D, Stange J, Münstedt H, Krause B, Voigt D, Lederer A, Lappan U, Lunkwitz K (2004) Long-chain branched polypropylenes by electron beam irradiation and their rheological properties. Macromolecules 37:9465–9472

Li S, Xiao M, Wei D, Xiao H, Hu F, Zheng A (2009) The melt grafting preparation and rheological characterization of long chain branching polypropylene. Polymer 50:6121–6128

Takahashi T, Takimoto J-I, Koyama K (1999) Elongational viscosity for miscible and immiscible polymer blends. II. Blends with a small amount of UHMW polymer. J Appl Polym Sci 72:961–969

Wagner MH, Bastian H, Hachmann P, Meissner J, Kurzbeck S, Munstedt H, Langouche F (2000) The strain-hardening behavior of linear and long-chain-branched polyolefin melts in extensional flows. Rheol Acta 39:97–109

Yang L, Huang J, Lu X, Jia S, Zhang H, Jin G, Qu J (2015) Influences of dicumyl peroxide on morphology and mechanical properties of polypropylene/poly(styrene-b-butadiene-b-styrene) blends via vane-extruder. J Appl Polym Sci 132:41543

Ghosh P, Ray P (1991) Studies on polybutadiene rubber (PBR)-polystyrene (PS) interpenetrating polymer network. J Mater Sci 26:6004–6012

Jehani Y, Ghetmiri M, Vaseghi MR (2015) Polypropylene and chain extension of poly(ethylene terephthalate) on the thermal behavior, rheology and morphology of their blends. RSC Adv 5:21620–21628

Su F-H, Huang H-X (2010) Rheology and melt strength of long chain branching polypropylene prepared by reactive extrusion with various peroxides. Polym Eng Sci 50:342–351

Münstedt H (1980) Dependence of elongational behavior of polystyrene melts on molecular weight and molecular weight distribution. J Rheol 24:847

Krupa I, Luyt AS (2001) Mechanical properties of uncrosslinked and crosslinked linear low-density polyethylene/wax blends. J Appl Polym Sci 81:973–980

Ha CS, Kim SC (1989) Tensile properties and morphology of the dynamically cured EPDM and PP/HDPE ternary blends. J Appl Polym Sci 37:317–334

Lungulescu EM, Zaharescu T (2016) Stabilization of polymers against photodegradation. In: Dan R, Visakh PM (eds) Photochemical behavior of multicomponent polymeric-based materials. Springer, Basel, p 187

Munteanu SB, Brebu M, Vasile C (2005) Thermal and thermo-oxidative behavior of butadiene-styrene copolymers with different architectures. Polym Degrad Stab 89:501–512

Zhou J, Du X-H, Yue W (2017) Study on the blend of SBS and polystyrene, and properties of their mixture. Adv Eng Res 112:27–30

Thomann Y, Thomann R, Hasenhindl A, Mülhaupt R (2009) Gradient interfaces in SBS and SBS/PS blends and their influence on morphology development and material properties. Macromolecules 42:5684–5699

Chung Y-C, Lee BH, Jo SH, Chun BC (2015) Preparation and characterization of polyurethane copolymer grafted with polystyrene side chains. Polym Plast Technol Eng 54:1066–1076

Andreopoulos AG, Tarantili PA, Anastassakis P (2007) Compatibilizers for low-density polyethylene/polypropylene blends, Novel determination of the crystallinity of syndiotactic polystyrene using FTIR spectrum. J Macromol Sci A 36:1113–1122

Masson J-F, Pelletier L, Collins P (2001) Rapid FTIR method for quantification of styrene-butadiene type copolymers in bitumen. J Appl Polym Sci 79:1034–1041

Wang S-M, Chang J-R, Tsiang RC-C (1996) Infrared studies of thermal oxidative degradation of polystyrene-block polybutadiene-block polystyrene thermoplastic elastomers. Polym Degrad Stab 52:51–57

Acknowledgements

We would like to thank the Ministry of Education of the Japanese Government for sponsoring Dr. Hassan through a ‘visiting professorship.’ I would like to thank Ken Miyata for helping in the measurement of uniaxial extensional rheology.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hassan, M.M., Takahashi, T. & Koyama, K. Thermal stability, mechanical properties, impact strength, and uniaxial extensional rheology of reactive blends of PS and SBS polymers. Polym. Bull. 76, 5537–5557 (2019). https://doi.org/10.1007/s00289-018-02674-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-018-02674-y