Abstract

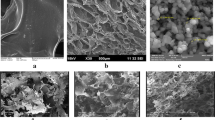

Composite scaffolds were prepared from the mixture of chitosan (C), gelatin (G) and nanodiopside (nDP) in different inorganic/organic weight ratios using the freeze-drying method. The prepared nDP and composite scaffolds were investigated using BET, FT-IR, SEM and XRD techniques. The composite scaffolds had 70–81% porosities with interlinked porous networks. Moreover, investigation of the cell proliferation, adhesion and viability using MTT test and mouse preosteoblast cell proved the cytocompatible nature of the composite scaffolds with improved cell attachment and proliferation. All these results essentially illustrated that this composite could have a potential ability for the tissue engineering applications.

Similar content being viewed by others

References

Youqing S, Yihong Z, Jianbin T (2008) Multifunctioning pH-responsive nanoparticles from hierarchical self-assembly of polymer brush for cancer drug delivery. Am Inst Chem Eng J 54:2979–2989

Vacanti JP, Langer R (1999) Tissue engineering: the design and fabrication of living replacement devices for surgical reconstruction and transplantation. Lancet 354:32–34

Hutmacher DW (2000) Scaffolds in tissue engineering bone and cartilage. Biomaterials 21:2529–2543

Muzzarelli R, Baldassarre V, Conti F (1988) Biological activity of chitosan: ultrastructural study. Biomaterials 9:247–252

Jayakumar R, Prabaharan M, Reis RL (2007) Sulfated chitin and chitosan as novel biomaterials. Int J Biol Macromol 40:175–181

Lifeng Q, Zirong X, Xia J (2004) Preparation and antibacterial activity of chitosan nanoparticles. Carbohydr Res 339:2693–2700

Muzzarelli RAA (2009) Chitins and chitosans for the repair of wounded skin, nerve, cartilage and bone. Carbohydr Polym 76:167–182

Muzzarelli RAA, Giacomelli G (1987) The blood anticoagulant activity of N-carboxymethylchitosan trisulfate. Carbohydr Polym 7:87–96

Muzzarelli RAA, Tarsi R, Filippini O (1990) Antimicrobial properties of N-carboxybutyl chitosan. Antimicrob Agents Chemother 34:2019–2023

Mao JS, Zhao LG, Yin YJ (2003) Structure and properties of bilayer chitosan–gelatin scaffolds. Biomaterials 24:1067–1074

Lien SM, Ko LY, Huang TJ (2009) Effect of pore size on ECM secretion and cell growth in gelatin scaffold for articular cartilage tissue engineering. Acta Biom 5:670–679

Nagahama H, Rani VVD, Shalumon KT (2009) Preparation, characterization, bioactive and cell attachment studies of α-chitin/gelatin composite membranes. Int Biol Macromol 44:333–337

Nagahama H, Maeda H, Kashiki T (2009) Preparation and characterization of novel chitosan/gelatin membranes using chitosan hydrogel. Carbohydr Polym 76(2):255–260

Mohamed KR, Beherei HH, EL-Rashidy ZM (2014) In vitro study of nano-hydroxyapatite/chitosan–gelatin composites for bio-applications. J Ad Res 5:201–208

Kanchan M, Sudip D, Krishna P, Akalabya B (2016) Preparation and evaluation of gelatin–chitosan–nanobioglass 3D porous scaffold for bone tissue engineering. Int J Biomater 2016:1–14

Peter M, Ganesh N, Selvamurugan N, Nair SV, Furuike T, Tamura H, Jayakumar R (2010) Preparation and characterization of chitosan–gelatin/nanohydroxyapatite composite scaffolds for tissue engineering applications. Carbohydr Polym 80:687–694

Yuji Y, Fen Y, Junfeng C, Fujiang Z, Xiulan L, Kangde Y (2003) Preparation and characterization of macroporous chitosan–gelatin/β-tricalcium phosphate composite scaffolds for bone tissue engineering. J Biomed Mater Res A 67:844–855

Huang YC, Chu HW (2013) Using hydroxyapatite from fish scales to prepare chitosan/gelatin/hydroxyapatite membrane: exploring potential for bone tissue engineering. J Mar Sci Tech 21:716–722

Wu C, Chang J (2007) Degradation, bioactivity, and cytocompatibility of diopside, akermanite, and bredigite ceramics. J Biom Mat Res Part B Appl Biom 83:153–160

Ghomi H, Emadi R, Haghjooye Javanmard S (2016) Preparation of nanostructure bioactive diopside scaffolds for bone tissue engineering by two near net shape manufacturing techniques. Mater Lett 167:157–160

Cijun S, Tingting L, Chengde G, Pei F, Shuping P (2014) Mechanical reinforcement of diopside bone scaffolds with carbon nanotubes. Int J Mol Sci 15:19319–19329

Chengtie W, Yogambha R, Hala Z (2010) Porous diopside (CaMgSi2O6) scaffold: a promising bioactive material for bone tissue engineering. Acta Biomater 6:2237–2245

Ishu K, Ashutosh G, Dilshat UT, Maria JP, Hye-Young L, Hae-Won K, Jose MFF (2011) Diopside (CaO·MgO·2SiO2)-fluorapatite (9CaO·3P2O5·CaF2) glassceramics: potential materials for bone tissue engineering. J Mater Chem 21:16247–16256

Hosseini Y, Emadi R, Kharaziha M, Doostmohammadi A (2016) Reinforcement of electrospun poly(ɛ-caprolactone) scaffold using diopside nanopowder to promote biological and physical properties. J Appl Polym Sci 44433:1–9

Nonami T, Tsutsumi S (1999) Study of diopside ceramics for biomaterials. J Mater Sci Mater Med 10:475–479

Danilchenko SN, Kalinkevich OV, Pogorelov MV (2009) Chitosan–hydroxyapatite composite biomaterials made by a one step co-precipitation method: preparation, characterization and in vivo tests. J Biol Phys Chem 9:119–126

Peniche C, Yaimara S, Natalia D (2010) Chitosan/hydroxyapatite-based composites. Biotechnol Appl 27:202–210

Yili Q, Danting A, Ping W (2014) Chitosan/nano-hydroxyapatite composite electret membranes enhance cell proliferation and osteoblastic expression in vitro. J Bio Compat Polym 29(1):3–14

Zhang X, Liu C, Li M (2009) Fabrication of hydroxyapatite/diopside/alumina composites by hot-press sintering process. Ceram Int 35:1969–1973

Zhang MF, Zhang XH, Liu CX (2013) Hydroxyapatite/Al2O3/diopside ceramic composites and their behaviour in simulated body fluid. Mater Sci Technol 29:378–382

Ghorbanian L, Emadi R, Razavi SM, Shin H, Teimouri A (2013) Fabrication and characterization of novel diopside/silk fibroin nanocomposite scaffolds for potential application in maxillofacial bone regeneration. Int J Biol Macromol 58:275–280

Teimouri A, Ghorbanian L, Najafi Chermahini A (2014) Fabrication and characterization of silk/forsterite composites for tissue engineering applications. Ceram Int 40:6405–6411

Teimouri A, Ebrahimi R, Emadi R (2015) Nano-composite of silk fibroin-chitosan/nano ZrO2 for tissue engineering applications: fabrication and morphology. Int J Biol Macromol 76:292–302

Teimouri A, Ebrahimi R, Najafi Chermahini A (2015) Fabrication and characterization of silk fibroin/chitosan/nano γ-alumina composite scaffolds for tissue engineering applications. RSC Adv 5:27558–27570

Teimouri A, Azadi M, Emadi R (2015) Preparation, characterization, degradation and biocompatibility of different silk fibroin based composite scaffolds prepared by freeze-drying method for tissue engineering application. Polym Deg Stab 121:18–29

Azadi M, Teimouri A, Mehranzadeh G (2016) Preparation, characterization and biocompatible properties of β-chitin/silk fibroin/nanohydroxyapatite composite scaffolds prepared by freeze-drying method. RSC Adv 6:7048–7060

Ghorbanian L, Emadi R, Teimouri A (2012) Synthesis and characterization of novel nanodiopsidebioceramic powder. JNS 2:357–361

Nazarov R, Jin HJ, Kaplan DL (2004) Porous 3-D scaffolds from regenerated silk fibroin. Biomacromol 5:718–726

Rockwood DN, Preda RC, Yucel T (2011) Materials fabrication from bombyx mori silk fibroin. Nat Prot 10:1612–1631

Li J, Dou Y, Yang J (2009) Surface characterization and biocompatibility of micro- and nano-hydroxyapatite/chitosan–gelatin network films. Mater Sci Eng C 29:1207–1215

Teimouri A, Azadi M (2016) Preparation and characterization of novel chitosan/nanodiopside/nanohydroxyapatite composite scaffolds for tissue engineering applications. Int J Polymer Mater Polymer Biomater 65:917–927

Teimouri A, Azadi M, Shams Ghahfarokhi Z, Razavizadeh R (2016) Preparation and characterization of novel β-chitin/nanodiopside/nanohydroxyapatite composite scaffolds for tissue engineering applications. J Biomater Sci Polym Ed 28:1–14

Teimouri A, Azadi M (2016) β-Chitin/gelatin/nanohydroxyapatite composite scaffold prepared through freeze-drying method for tissue engineering applications. Polym Bull 73:3513–3529

Padilla S, Roman J, Sanchez-Salcedo S (2006) Hydroxyapatite/SiO2–CaO–P2O5 glass materials: in vitro bioactivity and biocompatibility. Acta Biomater 3:331–342

Kokubo T (1991) Bioactive glass ceramics: properties and applications. Biom 2:155–163

Lluch V, Ferrer GG, Pradas MM (2009) Biomimetic apatite coating on P(EMA-co-HEA)/SiO2 hybrid nanocomposites. Polym 50:2874–2884

Tanahashi M, Yao T, Kokubo T (1994) Apatite coating on organic polymers by a biomimetic process. J Am Ceram Soc 77:2805–2808

Blaker J, Gough J, Maquet V (2003) In vitro evaluation of novel bioactive composites based on Bioglass®-filled polylactide foams for bone tissue engineering scaffolds. J Biom Mat Res Part A 67:1401–1411

Lu T, Li Y, Chen T (2013) Techniques for fabrication and construction of three-dimensional scaffolds for tissue engineering. Int J Nanomed 8:337–350

Acknowledgements

The authors are grateful to the Payame Noor University in Isfahan Research council (Grant # 62370). The authors would like to thank Dr. L. Ghorbanian for the critical reading of the manuscript, and Mrs. Hydari for providing cell culture facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Teimouri, A., Roohafza, S., Azadi, M. et al. Fabrication and characterization of chitosan/gelatin/nanodiopside composite scaffolds for tissue engineering application. Polym. Bull. 75, 1487–1504 (2018). https://doi.org/10.1007/s00289-017-2096-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-017-2096-x