Abstract

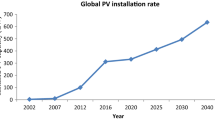

Heat transfer enhancement is challenging area in which different techniques are utilized to dissipate the generated heat during operation. Packed beds are devices which enhance heat transport while being compact and are used in several applications such as energy storage, heat exchange devices, catalysis, food processing etc. In the present study, the behavior of wall heat transfer coefficient with randomized packing of equal aspect ratio cylinders is investigated. In this work, the local wall heat transfer coefficient is calculated from local wall temperature data obtained using infrared (IR) thermography in packed beds with randomized packing of cylinders under steady state conditions with water as the working fluid. The randomized packing of cylinders is done inside a concentric tube heat exchanger and the heat transfer enhancement is studied. Experiments are conducted for bed to equivalent particle diameter ratio 2 using random packing of mono-dispersed glass cylinders (dcyl = 6 mm and lcyl = 6 mm). The local wall temperatures are measured using an infrared (IR) camera while the fluid flow takes place through the packed beds. In literature, it is found that wall region contribution to heat transfer is above 90%. The comparison of enhancement in heat transfer for both packing of spheres and cylinders inside concentric tube heat exchangers is done and it is observed that the random sphere packing is superior to cylinder packing.

Similar content being viewed by others

Abbreviations

- A :

-

Heat transfer area for heat exchanger (mm2)

- C pf :

-

Specific heat capacity of fluid (Jkg−1 K−1)

- D :

-

Bed diameter or Inner diameter of tube (mm)

- D i :

-

Inner diameter of annular side pipe (mm)

- D a :

-

Annulus diameter (mm)

- d eq.p :

-

Equivalent particle diameter (mm)

- d h :

-

Annulus hydraulic diameter (mm)

- d p :

-

Particle diameter (mm)

- d cyl :

-

Diameter of cylinder (mm)

- f :

-

Comparable friction factor (dimensionless)

- f s :

-

Friction factor for open smooth pipe (dimensionless)

- l cyl :

-

Length of cylinder (mm)

- h w :

-

Wall heat transfer coefficient (W m−2 K−1)

- h i :

-

Inner side wall heat transfer coefficient (Tube side) (W m−2 K−1)

- h o :

-

Outer side wall heat transfer coefficient (Annular side) (W m−2 K−1)

- k f :

-

Thermal conductivity of fluid (W m−1 K−1)

- k pipe :

-

Thermal conductivity of tube wall (W m−1 K−1)

- k s :

-

Thermal conductivity of solid (W m−1 K−1)

- L :

-

Length of packed bed (mm)

- L h :

-

Heating length (mm)

- ṁ :

-

Mass flow rate (kg s−1)

- ṁ h :

-

Mass flow rate of hot fluid (kg s−1)

- ṁ c :

-

Mass flow rate of cold fluid (kg s−1)

- Nu a :

-

Nusselt number with augmentation (dimensionless)

- Nu c :

-

Nusselt number for the case of constant pumping power (dimensionless)

- Nu s :

-

Nusselt number for the case of same Reynolds number (Gnieleinski’s correlation) (dimensionless)

- Nu w :

-

Nusselt number at wall based on particle diameter, \( \frac{h_w{d}_p}{k_f} \) (dimensionless)

- Nu i :

-

Nusselt number on inner side (heat exchangers) (dimensionless)

- Nu o :

-

Nusselt number on outer side (heat exchangers) (dimensionless)

- Nu h :

-

Nusselt number based on hydraulic diameter for annular side packing (dimensionless)

- \( {q}_w^{{\prime\prime} } \) :

-

Heat flux (W m−2)

- \( {\overset{.}{q}}_w \) :

-

Heat generation per unit volume (W m−3)

- Re :

-

Reynolds number based on bed diameter, \( \frac{\rho\;U\;D}{\mu } \) (dimensionless)

- Re p :

-

Reynolds number based on particle diameter, \( \frac{\rho\;U\;{d}_p}{\mu } \) (dimensionless)

- Re a :

-

Reynolds number based on annulus diameter, \( \frac{\rho\;{V}_c\;{D}_a}{\mu } \) (dimensionless)

- Re h :

-

Reynolds number based on hydraulic diameter, \( \frac{\rho\;{V}_c\;{d}_e}{\mu } \) (dimensionless)

- Re o :

-

Equivalent Reynolds number (defined in Appendix 1) (dimensionless)

- S B :

-

Particle surface area per unit volume of packed bed (m−1)

- T amb :

-

Ambient fluid temperature (surrounding air of test section) (°C)

- T bf :

-

Bulk fluid temperature (°C)

- T fi :

-

Inlet fluid temperature (upstream test section) (°C)

- T fo :

-

Exit fluid temperature (downstream test section) (°C)

- T m :

-

Mixing cup fluid temperature (measuring tank) (°C)

- T wo :

-

Outer wall temperature (test section) (°C)

- T wi :

-

Inner wall temperature (test section) (°C)

- T hi :

-

Inlet fluid temperature in hot line (PBHE) (°C)

- T ho :

-

Exit fluid temperature in hot line (PBHE) (°C)

- T ci :

-

Inlet fluid temperature in cold line (PBHE) (°C)

- T co :

-

Exit fluid temperature in cold line (PBHE) (°C)

- ∆T lm :

-

Logarithmic mean temperature difference (PBHE) (°C)

- U :

-

Superficial velocity (based on bed cross-sectional area) (m s−1)

- U pbhe :

-

Overall heat transfer coefficient for packed bed heat exchanger (PBHE) (W m−2 K−1)

- V h :

-

Hot fluid velocity (PBHE) (m s−1)

- V c :

-

Cold fluid velocity (PBHE) (m s−1)

- V void :

-

Interstitial volume of packed bed (mm3)

- ε :

-

Void fraction (mean) (dimensionless)

- ε paint :

-

Emissivity of paint used for infrared thermography (dimensionless)

- ε t :

-

Void fraction (mean) tube side (dimensionless)

- ε a :

-

Void fraction (mean) annular side (dimensionless)

- μ :

-

Dynamic Viscosity (Pa. s)

- ρ :

-

Density (kg m−3)

- PBHE :

-

Packed Bed Heat Exchanger

References

Allan CP (1931) Heat transfer and pressure drop in empty, baffled, and packed tubes. Ind Eng Chem, ACS publications 23(8):910–913

Max L (1949) Heat transfer to gases through packed tubes. Ind Eng Chem, ACS publications 39(7):857–962

Max L, Milton G (1948) Heat transfer to gases through packed tubes. Ind Eng Chem, ACS publications 40(3):415–419

Gamson BW, Thodos G, Hougen OA (1943) Transactions of American Institute of Chemical Engineers 39

Bunnell DG, Irvin HB, Olson RW, Smith JM (1949) Effective thermal conductivities in gas-solid systems. Ind Eng Chem 41(9):1977–1998

Vortuba J, Hlavacek V, Marek M (1972) Packed bed axial thermal conductivity. Chem Eng Sci 27:1845–1851

Clement K, Jorgensen SB (1983) Experimental investigation of axial and radial thermal dispersion in a packed bed. Chem Eng Sci 38(6):835–842

Borkink JGH, Westerterp KR (1992) Significance of axial heat dispersion for the description of heat transport in wall-cooled packed beds. Chem Eng Technol 15:371–384

Borkink JGH, Westerterp KR (1992) Determination of effective heat transport coefficients for wall-cooled packed beds. Chem Eng Sci 47(9):2337–2342

Smirnov EI, Kuzmin VA, Zolotarskii IA (2004) Radial thermal conductivity in cylindrical beds packed by shaped particles. Chem Eng Res Des 82(A2):293–296

Jorge LMM, Jorge RMM, Giudici R (2010) Experimental and numerical investigation of dynamic heat transfer parameters in packed bed. Heat Mass Transf 46:1355–1365

Gnielinski V (2010) Fluid-particle heat transfer in flow through packed beds of solids. VDI Heat Atlas 2nd Ed, Springer, Heidelberg, Vol G9, p 743–744

Bird R, Stewart W, Lightfoot E (2002) Transport phenomena, 2nd edn. Wiley, New York

Bogdan IP, Mohamad AA (2004) An experimental and numerical study on heat transfer enhancement for gas heat exchangers fitted with porous media. IJHMT 47:4939–4952

Huang ZE, Nakayam A, Yang K, Yang C, Liu W (2010) Enhancing heat transfer in the core flow by using porous medium insert in a tube. IJHMT 53:1167–1174

Noh J, Lee KB, Lee CG (2006) Pressure loss and forced convective heat transfer in an annulus filled with aluminum foam. ICHMT 33:434–444

Dekhthyar RA, Sikovsky D, Gorin AV, Mukhin VA (2002) Heat transfer in a packed bed at moderate values of the Reynolds number. High Temperature Translated from TeplofizikaVysokikhTemperatur-Russian copyright, Vol. 40, No. 5, p 693–700

Hardik BK, Baburajan PK, Prabhu SV (2015) Local heat transfer coefficient in helical coils with single phase flow. Int J Heat Mass Transf 89:522–538

Moffat RJ (1985) Using uncertainty analysis in the planning of an experiment. Am Soc Mech Eng 107:173–178

Halkarni SS, Sridharan A, Prabhu SV (2017) Measurement of local wall heat transfer coefficient in randomly packed beds of uniform sized spheres using infrared thermography (IR) and water as working medium. Appl Therm Eng 126:358–378

Dixon AG (1988) Correlations for wall and particle shape effects on fixed bed bulk Voidage. Can J Chem Eng 66:705–708

Mueller GE (2002) Narrow annular packed-bed RadialVoid fraction correlation”, R&D note. Am Inst Chem Eng J 48(3):644–647

Eisfeld B, Schnitzlein K (2001) The influence of confining walls on the pressure drop in packed beds. Chem Eng Sci 56:4321–4329

Incropera FP, Dewitt DP (2007) Fundamentals of heat and mass transfer. Wiley, New York

Halkarni SS, Sridharan A, Prabhu SV (2016) Estimation of volumetric heat transfer coefficient in randomly packed beds of uniform sized spheres with water as working medium. Int J Therm Sci 110:340–355

Mueller GE (1992) Radial void fraction distributions in randomly packed fixed beds of uniformly sized spheres in cylindrical containers. Powder Technol 72:269–275

Gorin A (2010) Asymptotic law for turbulent forced convection from wall surface in packed beds, 7th International conference on Heat Transfer, Fluid Mechanics and Thermodynamics, Anatalya, Turkey

Halkarni SS, Sridharan A, Prabhu SV (2018) Experimental investigation on effect of random packing with uniform sized spheres inside concentric tube heat exchangers on heat transfer coefficient and using water as working medium. Int J Therm Sci 133:341–356

Halkarni SS, Sridharan A, Prabhu SV (2016) Influence of inserts on the pressure drop distribution in randomly packed beds with uniform sized spheres in the end-shield model of AHWR. Exp Thermal Fluid Sci 74:181–194

Acknowledgements

Authors would like to thank Mr. Rahul Shirsat for his assistance in building the experimental setup.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

*Appendix 1

Relations used to calculate for the case of constant pumping power analogy are:

Average performance ratio (Nua/ Nuc) is a factor used to estimate the amount of augmentation in heat transfer (Nua) due to packing in comparison to the case without any packing. It is also popularly known as Constant pumping power analogy. If the value (Nua/ Nuc) is above 1 then it is economically feasible for operation.

Packed bed friction factor: \( {f}_{Eisfeld}=\left(\frac{190}{\left(\frac{R{e}_p}{1-\varepsilon}\right)}{A}_w^2+\frac{A_w}{B_w}\right)\frac{1-\varepsilon }{\varepsilon^3} \)

Comparable friction factor: \( f=2\times \left(\frac{D}{d_p}\right)\times {f}_{Eisfeld} \)

Equivalent Reynolds number (Reo): \( {\operatorname{Re}}_o={\left(\frac{f{\operatorname{Re}}^3}{0.3164}\right)}^{1/2.75} \)

Smooth pipe friction factor (fo): fo = [1.58 ln (Reo) − 3.28]−2

Packed bed Nusselt number to comparable form: \( N{u}_a= Nu\left(\frac{D}{d_p}\right)=\frac{h_w{d}_p}{k_f}\left(\frac{D}{d_p}\right) \)

Nusselt number based on Constant pumping power analogy (Gnieleinski correlation):

Relations used to calculate for the case of same Reynolds number analogy are:

The other comparative basis is the Same Reynolds number analogy (Nua/Nus;f/fs). Under this analogy the enhancement in heat transfer (Average Nusselt number ratio = Nua/ Nus) and ratio of friction factors (f / fs) are compared for tubes with and without packing.

Packed bed friction factor: \( {f}_{Eisfeld}=\left(\frac{190}{\left(\frac{R{e}_p}{1-\varepsilon}\right)}{A}_w^2+\frac{A_w}{B_w}\right)\frac{1-\varepsilon }{\varepsilon^3} \)

Comparable friction factor: \( f=2\times \left(\frac{D}{d_p}\right)\times {f}_{Eisfeld} \)

Smooth pipe friction factor correlation (fs): fs = [1.58 ln (Re) − 3.28]−2

Packed bed Nusselt number to comparable form: \( N{u}_a= Nu\left(\frac{D}{d_p}\right)=\frac{h_w{d}_p}{k_f}\left(\frac{D}{d_p}\right) \)

Nusselt number based on Same Reynolds number analogy (Gnieleinski correlation):

Appendix 2

Heat loss calculations

The heat loss to surroundings from the external walls of test section is possible through natural convection and radiation. The inlet fluid temperature (Tfi), exit fluid temperature (Tfo), outer wall temperature of test sect ion (Two), surrounding ambient air temperature (Tamb) and mass flow rate of flowing fluid are measured. The heat loss by natural convection is calculated assuming value of convective heat transfer coefficient to be 10 (Wm−2 K−1) for surrounding air of the test section as per standardized norm.

For the case of lowest flow rate

\( \overset{.}{m} \) = 19.8 gs−1and packing with 6 mm particles; h = 10 Wm−2 K−1, Do = 14 mm, Lh = 500 mm, Outer wall temperature (Two) = 75.84 °C, ambient air temperature surrounding test section (Tamb) = 28.03 °C.

The heat loss by radiation is calculated using Stefan- Boltzmann law given by:

Hence the total heat loss to the surroundings is:

Total heat input to system of packed bed is given by:

For the case of highest flow rate

\( \overset{.}{m} \) = 44 gs−1 and packing with 6 mm particles; h = 10 Wm−2 K−1, Do = 14 mm, Lh = 500 mm, Outer wall temperature (Two) = 52.43 °C, ambient air temperature surrounding test section (Tamb) = 27.85 °C.

Hence the total heat loss to the surroundings is:

Total heat input to system of packed bed:

Hence the percentage of heat loss to surroundings is 0.46% and 0.19% and similar approach is followed for all particle size packing and higher flow rate. Table 9 shows the calculations of heat loss to surroundings for all packing sizes and range of highest and lowest flow rates. It is evident that the amount of heat loss occurring with surrounding is less than 1%.

Rights and permissions

About this article

Cite this article

Halkarni, S.S., Sridharan, A. & Prabhu, S.V. Local wall heat transfer coefficient measurement in a packed bed of cylinders using infrared (IR) thermography technique and application of random packing of cylindrical particles inside concentric tube heat exchangers with water as working medium. Heat Mass Transfer 55, 2305–2328 (2019). https://doi.org/10.1007/s00231-019-02569-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-019-02569-2