Abstract

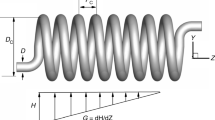

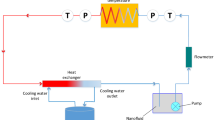

In this paper, the effects of the variations of the coil pitch and coil diameter on ferrofluid flow boiling characteristics inside helical tubes have been investigated using two-fluid model and control volume technique. The effects of the non-uniform magnetic field on the ferrofluid flow boiling inside helical tubes have also been studied. The results indicated showed that decreasing the coil diameter enhances the heat transfer coefficient. This is due to the effect of centrifugal force which is increased by decreasing the coil diameter. Also, the results confirmed the dual role of the centrifugal force on heat transfer (increase) and vapor volume fraction (decrease) and at the same time remarkable increasing of locally void fraction on heated wall and raising possibility of occurrence of CHF. In addition, the improvement of surface wettability which is induced by nanoparticles sedimentation during the boiling process has been considered. Results showed the reduction of the void fraction. The application of a magnetic field at critical regions resulted in the bubble departure diameter and vapor volume fraction generation reduction. Consequently, the critical heat flux is increased.

Similar content being viewed by others

Abbreviations

- A lv :

-

Interphase contact area(m−1.)

- PCD:

-

Pitch circle diameter(m)

- A Q :

-

Wall fraction influenced by nucleating bubbles

- c p :

-

Specific heat capacity(J kg−1K−1)

- d b :

-

Bubble mean diameter(m)

- d bW :

-

Bubble departure diameter (m)

- f :

-

Frequency (S−1)

- \( \overrightarrow{f_D} \) :

-

Drag force (N)

- \( \overrightarrow{f_L} \) :

-

Lift force (N)

- \( \overrightarrow{f_W} \) :

-

Wall lubrication force (N)

- \( \overrightarrow{f_{TD}} \) :

-

Turbulent dispersion force(N)

- \( \overrightarrow{f_{VM}} \) :

-

Virtual mass force (N)

- H lv :

-

Difference between specific enthalpies (J kg−1)

- h C :

-

Liquid single-phase heat transfer coefficient (W m−2 K−1)

- \( \overrightarrow{H} \) :

-

Magnetic field vector (A m−1)

- H x :

-

Magnetic field intensity component in x direction (A m−1)

- H y :

-

Magnetic field intensity component in y direction (A m−1)

- I:

-

Electric intensity(=200 A)

- k l :

-

Liquid thermal conductivity (W m−1 K−1)

- k B :

-

Boltzmann constant(=1.3806503 × 10−23 J K−1)

- L:

-

Langevin function

- M:

-

Magnetization (A m−1)

- m p :

-

Particle magnetic moment (A m2)

- N a :

-

Active nucleation site density(m−2)

- P:

-

Coil Pitch(m)

- q T :

-

Total heat flux (W m−2)

- q Q :

-

Quenching heat flux (W m−2)

- q C :

-

Single-phase convection heat flux (W m−2)

- q E :

-

Evaporation heat flux (W m−2)

- D :

-

Inner Diameter(m)

- T :

-

Temperature(K)

- u :

-

Velocity (m s−1)

- α :

-

Void fraction

- ρ :

-

Density (kg m−3)

- μ l :

-

Liquid dynamic viscosity (kg m−1s−1)

- μ 0 :

-

Magnetic permeability in vacuum (=4π × 10−7 T m A−1)

- μ B :

-

Bohr magneton(=9.27 × 10−24 A m−2)

- ξ :

-

Langevin parameter

- b :

-

Bubble

- l :

-

Liquid

- m :

-

Mean

- v :

-

Vapor

- p:

-

Particle

References

Owhadi A, Bell KJ, Crain B Jr (1968) Forced convection boiling inside helically coiled tubes. Int J Heat Mass Transf 11:1179–1793

Chen JC (1966) A correlation for boiling heat transfer to saturated fluids in convective flow. Ind Eng Chem Process Des Dev 5(3):322–329

Jensen MK, Bergles AE (1982) Critical heat flux in helical coils with a circumferential heat flux tilt toward the outside surface. Int J Heat Mass Transf 25(9):1383–1395

Chen C, Han J, Jen T, Shaho L (2011) Thermo-chemical characteristics of R134a flow boiling in helically coiled tubes at low mass fluxes and low pressure. Thermochim Acta 512:163–169

Hwang KW, Kim DE, Yang KH, Kim JM, Kim MH, Park HS (2014) Experimental study of flow boiling heat transfer and dryout characteristics at low mass flux in helically-coiled tubes. Nucl Eng Des 273:529–541

Steiner D, Taborek J (1992) Flow boiling heat transfer in vertical tubes correlated by an asymptotic model. Heat Transfer Eng 13(2):43–69

Zhao L, Guo L, Bai B, Hou Y, Zhang K (2003) Convective boiling heat transfer and two-phase flow characteristics inside a small horizontal helically coiled tubing once-through steam generator. Int J Heat Mass Transf 46:4779–4688

Wang M, Han J, Ji C, Shaho L, Guo Z (2014) Fluid-to-fluid modeling study on critical heat flux of R134a flow boiling in helically-coiled horizontal tubes, 17th International Conference on Electrical Machines and Systems (ICEMS), Oct. 22–25, Hangzhou, China

Elsayed A, AL-Dadah R, Mahmoud S, Rezk A (2012) Investigation of flow boiling heat transfer inside small diameter helically coiled tubes. Int J Refrig 35:2179–2187

Santini L, Cioncolini A, Butel M, Ricotti M (2016) Flow boiling heat transfer in a helically coiled steam generator for nuclear power applications. Int J Heat Mass Transf 92:91–99

Jayanti S, Hewitt GE (1991) Prediction of onset of nucleate boiling, net vapour generation and subcooled CHF in coiled tubes. Wärme- und Stoffübertragung 26:301–305

Aminfar H, Mohammadpourfard M, Sahraro M (2014) Numerical simulation of nucleate pool boiling on the horizontal surface for ferrofluid the effect of non-uniform magnetic field. Heat Mass Transf 50:1167–1176

Mohammadpourfard M, Aminfar H, Sahraro M (2014) S., numerical simulation of nucleate pool boiling on the horizontal surface for ferrofluid under the effect of non-uniform magnetic field. Heat Mass Transf 50(8):1167–1176

Aminfar H, Mohammadpourfard M, Maroofiazar R (2014) Numerical study of non-uniform magnetic fields effects on subcooled nanofluid flow boiling. Prog Nucl Energy 74:232–241

Osamu T, Masaaki N, Nobuyuki T, Itaru M (1980) Pool boiling heat transfer from horizontal plane heater to mercury under magnetic field. Int J Heat Mass Transf 23:27–36

Aminfar H, Mohammadpourfard M, Maroofiazar R (2014) Experimental study on the effect of magnetic field on critical heat flux of ferrofluid flow boiling in a vertical annulus. Exp Thermal Fluid Sci 58:156–169

Mohammadpourfard M, Aminfar H, Karimi M (2016) Numerical investigation of non-uniform transverse magnetic field effects on the swirling flow boiling of magnetic nanofluid in annuli. Int Commun Heat Mass Tranfer 75:240–252

Roy RP, Kang S, Zarate JA, Laporta A (2002) Turbulent subcooled boiling flow-experiments and simulations. J Heat Transf 124:73–93

Yamaguchi H (2008) Engineering fluid mechanics. Springer science, Dordrecht

Kittel C (1967) Introduction to solid state physics. Wiley, New York

Tzirtzilakis EE, Kafoussias NG (2010) Three-dimensional magnetic fluid boundary layer flow over a linearly stretching sheet. J Heat Tranf 132

Rosensweig RE (1985) Ferrohydrodynamics. Cambridge University Press, London

Hamilton RL, Crosser OK (1962) Thermal conductivity of heterogeneous two-component system. Ind Eng Chem 1:187–191

Ishii M, Zuber N (1979) Drag coefficient and relative velocity in bubbly, droplet or particulate flows. AICHE J 25(5):843–855

Tomiyama A (1998) Struggle with computational bubble dynamics 10(4):369–405

Lopez de Bertodano M (1991) Turbulent bubbly flow in a triangular duct, Ph.D. Thesis, Rensselaer Polytechnic Institute, Troy New York

Kurul N, Podowski MZ (1990) Multidimensional effects in forced convection subcooled boiling. In: Proceedings of the Ninth International Heat Transfer Conference, Jerusalem, Israel, 2 pp 21–26

Antal SP, Lahey RT, Flaherty JE (1991) Analysis of phase distribution in fully developed laminar bubbly two-phase flow. Int J Multiphase Flow 7:635e652

Zuber N (1964) On the dispersed two-phase flow in the laminar flow regime. Chem Eng Sci 19(11):897–917

Kurul N, Podowski MZ (1991) “On the modeling of multidimensional effects in boiling channels,” ANS Proc. 27th National Heat Transfer Conference, July 28–31, Minneapolis

Tolubinski VI, Kostanchuk DM (1970) Vapour bubbles growth rate and heat transfer intensity at subcooled water boiling, 4th. International Heat Transfer Conference, Paris, France

Lemmert MC, Chawla JM (1977) Influence of flow velocity on surface boiling heat transfer coefficient. In: Hahne E, Grigull U (eds) Heat transfer and boiling. Cambridge: Academic Press

Del Valle VH, Kenning DBR (1985) Subcooled flow boiling at high heat flux. Int J Heat Mass Transf 28(10):1907–1920

Egorov Y, Menter F (2004) Experimental implementation of the RPI wall boiling model in CFX-5.6, Technical Report ANSYS / TR-04-10

Sato Y, Sadatomi M, Sekoguchi K (1981) Momentum and heat transfer in two-phase bubble flow—I. Theory. Int J Multiphase Flow 7(2):167–177

Kreper E, Rezhak R (2011) CFD for subcooled flow boilimg:simulation of DEBORA experiments. Nucl Eng Des 241:3851–3866

Faulkner D, Khotan M, Shekarriz R (2003) Practical design of a 1000W/cm2 cooling system [high power electronics]. Semiconductor ThermalU"__137 _Measurement and Management Symposium, 2003 Ninteenth Annual IEEE. p 223–230

Das SK, Prakash Narayan G, Baby AK (2008) Survey on nucleate pool boiling of nanofluids: the effect of particle size relative to roughness. J Nanopart Res 10:1099–1108

Peng H, Ding G, Jiang W, Hu H, Gao Y (2009) Heat transfer characteristics of refrigerant-based nanofluid flow boiling inside a horizontal smooth tube. Int J Refrig 32:1259–1270

Wu Z, Wang L, Suden B (2013) Pressure drop and convective heat transfer of water and nanofluid in a double-pipe helical heat exchanger. Appl Therm Eng 60:266–274

Fritz W (1935) Maximum volume of vapour bubbles. Phys Z 36:379–384

Kocamustafaogullari G, Ishii M (1995) Foundation of the interfacial area transport equation and its closure relations. Int J Heat Mass Transf 38(3):481–493

Junhong L, Jianming G, Zhiwei L, Hui L (2004) Experiments and mechanism analysis of pool boiling heat transfer enhancement with water-based magnetic fluid. Heat Mass Transf 41(2):170–175

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original version of this article was revised: The family name of the fourth author should be Maroofiazar instead of Maroofi.

Rights and permissions

About this article

Cite this article

Saedi, M., Aminfar, H., Mohammadpourfard, M. et al. Simulation of ferrofluid flow boiling in helical tubes using two-fluid model. Heat Mass Transfer 55, 133–148 (2019). https://doi.org/10.1007/s00231-018-2400-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-018-2400-9