Abstract

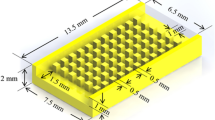

The experimental investigation of heat transfer of water flowing in a rifled tube was explored at different pressures and at various operating conditions in a rifled tube heat exchanger. The specifications for the inner and outer diameters of the inner tube are 25.8 and 50.6 mm, respectively. The working fluids used in shell side and tube side are cold and hot water. The rifled tube was made of the stainless steel with 4 ribs, 50.6 mm outer diameter, 0.775 mm rib height, 58o helix angle and the length 1500 mm. The effect of pressure, wall heat flux and friction factor were discussed. The results confirm that even at low pressures the rifled tubes has an obvious enhancement in heat transfer compared with smooth tube. Results depicts that the Nusselt number increases with Reynolds number and the friction factor decreases with increase in Reynolds number and the heat transfer rate is higher for the rifled tube when compared to smooth tube, because of strong swirl flow due to centrifugal action. It also confirms that, the friction factor obtained from the rifled tube is significantly higher than that of smooth tube.

Similar content being viewed by others

Abbreviations

- D :

-

Tube diameter,m

- f :

-

Friction factor

- h :

-

Heat transfer coefficient,W/m2 K

- L :

-

Tube length,m

- Nu :

-

Nusselt number

- Pr :

-

Prandtl number

- Re :

-

Reynolds Number

- Q :

-

Heat transfer rate,W

- T :

-

Temperature,OC

- M :

-

Mass flow rate,kg/s

- μ:

-

Dynamic viscosity,kg/m-s

- ave:

-

Average

- c:

-

Cold

- h:

-

Hot

- i:

-

Inside

- in:

-

Inlet

- m:

-

Logarithmic mean temperature

- o:

-

Outside

- out:

-

Outlet

- w:

-

Water

References

Smith JW et al (1968) Turbulent heat transfer and temperature profiles in a rifled pipe. Chem Eng Sci 23:751–758

Blaszczuk A, Nowak W (2016) The impact of bed temperature on heat transfer characteristic between fluidized bed and vertical rifled tubes. J Therm Sci 25(5):476–483

Iwabuchi, M. et al (1982) Heat transfer characteristic of rifled tubes in the near critical pressure region. Proceeding of 7th International Heat Transfer Conference 5: 313–318

Köhler, W. and Kastner, W. (1986) Heat transfer and pressure loss in rifled tube. Proceeding of 8th International Heat Transfer Conference 5: 2861–2865

Almeida JA, Souza Mendes PR (1992) Local and average transport coefficients for the turbulent flow in internally ribbed tubes. Exp Thermal Fluid Sci 5:513–523

Cheng LX, Chen TK (2001) Flow boiling heat transfer in a vertical spirally internally ribbed tube. Heat Mass Transf 37:229–236

Kim CH et al (2005) Critical heat flux performance for flow boiling of R-134a in vertical uniformly heated smooth tube and rifled tubes. Int J Heat Mass Transf 48:2868–2877

Cheng LX, Chen TK (2006) Study of single-phase flow heat transfer and friction pressure drop in a spiral internally ribbed tube. Chem Eng Technol 29:588–595

Cheng LX, Chen TK (2007) Study of vapour liquid two-phase frictional pressure drop in a vertical heated spirally internally ribbed tube. Chem Eng Sci 62:783–792

Pan J, Yang D, Dong Z, Zhu T, Bi Q (2011) Experimental investigation on heat transfer characteristics of low mass flux rifled tube with upward flow. Int J Heat Mass Transf 54:2952–2961

Taklifi A, Hanafizadeh P, Akhavan Behabadi MA, Aliabadi A (2016) Experimental investigation on heat transfer and pressure drop of supercritical water flows in an inclined rifled tube. J Supercrit Fluids 107:209–218

Majewski K, Grądziel S (2016) CFD simulations of heat transfer in internally helically ribbed tubes. Chem Process Eng 37(2):251–260

Sławomir G, Karol M (2016) Simulation of temperature distribution and heat transfer coefficient in internally ribbed tubes. Procedia Eng 157:44–49

Zhao Z, Wang X, Che D (2014) Numerical study on heat transfer and resistance characteristics of supercritical water inside internally ribbed tube. Heat Mass Transf 50(4):559–572

Wang S, Yang D, Xie B, Wang L, Wang Y (2015) Experimental investigation on heat transfer characteristics of water in inclined downward tube of a supercritical pressure CFB boiler. J Therm Sci 24(5):478–487

Lee SK, Chang SH (2008) Experimental study of post-dryout with R-134a upward flow in smooth tube and rifled tubes. Int J Heat Mass Transf 51:3153–3163

Gnielinski V (1976) New equations for heat and mass transfer in turbulent pipe and channel flows. NASA STI/ReconTech Rep A 75:8–16

Nikuradse J (1932) Laws of turbulent flow in smooth pipes (English translation). NASA,TT F-10: 359

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Jegan, C.D., Azhagesan, N. A novel investigation of heat transfer characteristics in rifled tubes. Heat Mass Transfer 54, 1503–1509 (2018). https://doi.org/10.1007/s00231-017-2247-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-017-2247-5