Abstract

The aim of the present work is to develop a flow model which can be used to determine the paths of the polyurethane foam in the mold filling process of a refrigerator cabinet so that improvements in the distribution and the size of the venting holes can be achieved without the expensive prototyping and experiments. For this purpose, the multi-component, two-phase chemically reacting flow is described by Navier Stokes and 12 scalar transport equations. The air and the multi-component foam zones are separated by an interface, which moves only with advection since the mass diffusion of species are set zero in the air zone. The inverse density, viscosity and other diffusion coefficients are calculated by a mass fraction weighted average of the corresponding temperature-dependent values of all species. Simulations are performed in a real refrigerator geometry, are able to reveal the problematical zones where air bubbles and voids trapped in the solidified foam are expected to occur. Furthermore, the approach proves itself as a reliable design tool to use in deciding the locations of air vents and sizing the channel dimensions.

Similar content being viewed by others

References

Klempner D, Sendijarevic V (2004) Handbook of polymeric foams and foam technology, 2nd edn. Hanser Publications, Cincinnatti

Federation of European Rigid Polyurethane Foam Associations. Report No: 1, Thermal insulation materials made of rigid polyurethane foam (PUR/PIR): Properties – Manufacture, October 2006

Wu J-W, Sung W-F, Chu H-S (1999) Thermal conductivity of polyurethane foams. Int J Heat Mass Transf 42:2211–2217

Morris DB, Fogg B (1979) Rigid polyurethane foam: refrigerator cabinet design and construction. Int J Refrig 2:105–112

Hammond EC, Evans JA (2014) Application of vacuum insulation panels in the cold chain – analysis of viability. Int J Refrig 47:58–65

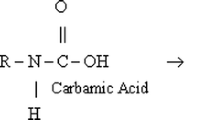

Ozdemir IB, Akar F (2017) Effects of composition and temperature of initial mixture on the formation and properties of polyurethane foam. Adv Polym Technol

Goods SH, Neuschwanger CL, Henderson C, Skala DM (1997) Mechanical properties and energy absorption characteristics of a polyurethane foam. Technical Paper SAND97–8490

Maier U, Wirtz H-G, Fietz J, Frahm A, Rüb T (2005) Polyurethane Processing Systems, Bayer Material Science, (24)19:1–12

Ashida K (2007) Polyurethane and related foams – chemistry and technology. Taylor and Francis, Abingdon

Everitt SL, Harlen OG, Wilson HJ, Read DJ (2003) Bubble dynamics in viscoelastic fluids with application to reacting and non-reacting polymer foams. J Non-Newton Fluid 114:83–107

Khazabi M (2015) Investigation of biopolyol spray foam insulation modified with natural fibers. PhD Thesis, Faculty of Forestry, University of Toronto

Hobbs ML, Erickson KL, Chu TY (2000) Modeling decomposition of unconfined rigid polyurethane foam. Polym Degrad Stab 69:47–66

Schwartz LW, Roy RV (2003) A mathematical model for an expanding foam. J Colloid Interface Sci 264:237–249

Geier S, Winkler C, Piesche M (2009) Numerical simulation of mold filling processes with polyurethane foams. Chem Eng Technol 32:1438–1447

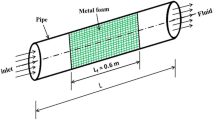

Xu W, Zhang H, Yang Z, Zhang J (2008) Numerical investigation on the flow characteristics and permeability of three-dimensional reticulated foam materials. Chem Eng J 140:562–569

Kim YB, Kim KD, Hong SE, Kim JG, Park MH, Kim JH, Kweon JK (2005) Numerical simulation of PU foaming flow in a refrigerator cabinet. J Cell Plast 41:252–266

Gopala VR, van Wachem BGM (2008) Volume of fluid methods for immiscible-fluid and free-surface flows. Chem Eng J 141:204–221

Sussman M, Smereka P, Osher S (1994) A level set approach for computing solutions to incompressible two-phase flow. J Comput Phys 114:146–159

Osher S, Fedkiw RP (2001) Level set methods: an overview and some recent results. J Comput Phys 169:463–502

Unverdi SO, Tryggvason G (1992) A front-tracking method for viscous, incompressible multi-fluid flows. J Comput Phys 100:25–37

Prosperetti A, Tryggvason G (2007) Computational methods for multiphase flow. Cambridge University Press, Cambridge

Seo D, Youn JR, Tucker CL (2003) Numerical simulation of mold filling in foam reaction injection molding. Int J Numer Methods Fluids 42:1105–1134

Mitani T, Hamada H (2003) Prediction of flow patterns in the polyurethane foaming process by numerical simulation considering foam expansion. Polym Eng Sci 43:1603–1612

Seo D, Youn JR (2005) Numerical analysis on reaction injection molding of polyurethane foam by using a finite volume method. Polymer 46:6482–6493

Dodd AB, Lautenberger C, Fernandez-Pello AC (2009) Numerical examination of two-dimensional smolder structure in polyurethane foam. P Combust Inst 32:2497–2504

Bikard J, Bruchon J, Coupez T, Silva L (2007) Numerical simulation of 3D polyurethane expansion during manufacturing process. Colloid Surface A 309:49–63

Kee RJ, Coltrin ME, Glarborg P (2005) Chemically reacting flow: theory and practice. John Wiley and Sons, Hoboken

Warnatz J (2002) HOMREA user guide, Steinbeis-Transferzentrum, Simulation Reaktiver Strömungen, Heidelberg

Maier RS, Petzold LR, Rath W (1995) Parallel solution of large differential-algebraic systems. Concurrency: Practice and Experience 7:795–822

Ferziger JH, Peric M (2002) Computational methods for fluid dynamics. Springer, Berlin

ANSYS FLUENT, Release 6.3, Analysis guide, ANSYS, Inc.

Acknowledgments

This study has been funded by the Turkish Ministry of Industry (SANTEZ 01213.STZ-2012-1). The partial support by Arcelik Inc. is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Özdemir, İ.B., Akar, F. 3D simulation of polyurethane foam injection and reacting mold flow in a complex geometry. Heat Mass Transfer 54, 1281–1288 (2018). https://doi.org/10.1007/s00231-017-2232-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-017-2232-z