Abstract

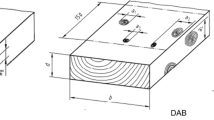

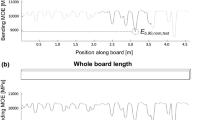

Severe local fiber deviation in timber boards can lead to reduced strength values. As grading machines do traditionally not detect these deviations, such boards are typically assigned to higher strength values than they actually possess. Based on statistics, these cases are taken into account in machine grading. Slope of grain can be measured on the surface by laser diffraction. The aim of this study is to estimate the reducing effect of local slope of grain on tensile strength, which is caused by top ruptures and the impact on the grading results of machine strength grading. This is investigated in full-scale tensile tests. In total, 192 test specimens of Norway spruce (Picea abies) with more or less pronounced local slope of grain were selected, measured and strength-tested to show the influence of local slope of grain on tensile strength. The utilized timber was sawn from relatively small diameter logs. The grain angle was determined on all four longitudinal sides of the boards with the help of a dense matrix. A model is presented for estimation of the grain deviation over the cross section of the sawn timber. These values are converted into a strength-reducing factor taking into account the ratio of tensile strength parallel and perpendicular to the grain. The introduced strength prediction algorithm is tested for the investigated sample. Improvement of the reliability and economy of timber grading using grain angle as an additional parameter will be possible. Furthermore, it is shown that different strength-reducing features such as top ruptures in sawn timber can be located on the specimens, and the strength-reducing effect can be estimated. Local slope of grain around knots is not part of this study.

Similar content being viewed by others

References

Briggert A, Olsson A, Oscarsson J (2015) Three dimensional knot models based on surface laser scanning. In: Proceedings of the 19th international nondestructive testing and evaluation of wood symposium, Rio de Janeiro, Brazil

Denzler JK, Linsenmann P (2014) Utilization of microwave measurement in timber strength grading. In: Proceedings of COST action FP1004 experimental research with timber, Prague, Czech Republic

DIN EN 14081-2:2013 Timber structures—Strength graded structural timber with rectangular cross section—part 2: machine grading; additional requirements for initial type testing; German version DIN EN 14081-2:2010 + A1:2012. DIN Deutsches Institut für Normungen, Beuth, Berlin

DIN EN 1912:2013 Structural timber—Strength classes—assignment of visual grades and species; German version EN 1912:2012 + AC:2013. DIN Deutsches Institut für Normungen, Beuth, Berlin

DIN 4074-1:2012 Strength grading of wood—part 1: coniferous sawn timber; German version DIN 4074-1:2012. DIN Deutsches Institut für Normungen, Beuth, Berlin

DIN EN 384:2010 Structural timber. Determination of characteristic values of mechanical properties and density; German version DIN EN 384:2010. DIN Deutsches Institut für Normungen, Beuth, Berlin

DIN EN 408:2012 Timber structures. Structural timber and glued laminated timber—determination of some physical and mechanical properties; German version DIN EN 408:2012. DIN Deutsches Institut für Normungen, Beuth, Berlin

Glos P, Schleifer A, Linsenmann P (2002) Development of simple grading rules for (visual) strength grading of boards. Report no. 01510, Holzforschung München, Technische Universität München. München

Green DW, Winandy JE, Kretschmann DE (1999) Mechanical properties of wood. Wood handbook: wood as an engineering material. USDA Forest Service, Forest Products Laboratory, Madison

Hankinson R (1921) Investigation of crushing strength of spruce at various angles to the grain. Air Service Information Circular, 3 (259), Materials Section Paper No. 130 (source unavailable)

INSTA 142:2009 Nordic visual strength grading rules for timber; Norwegian version NS-INSTA:2009. NSF Norges Standardiseringsforbund; Oslo

Johansson C-J (2003) Grading of timber with respect to mechanical properties. In: Thelandersson S, Larsen HJ (eds) Timber engineering. Wiley, New York, pp 23–43

Kollmann F (1951) Technology of wood and wood products, vol 1. Springer, Berlin

Olsson A, Oscarsson J, Serrano E, Källsner B, Johansson M, Enquist B (2013) Prediction of timber bending strength and in-member cross-sectional stiffness variation on the basis of local wood fibre orientation. Eur J Wood Prod 71:319–333

Perstopper M, Pellicane PJ, Kliger IR, Johansson G (1995) Quality of timber products from Norway spruce, part 1: quality optimization, key variables and experimental study. Wood Sci Technol 29:157–170

Säll H (2002) Spiral grain in Norway spruce. Ph.D. thesis, Acta Wexionesia 22, Växjö University

Wagenführ R (1999) Anatomie des Holzes (Anatomy of wood), 5th edn. DRW-Verlag Weinbrenner GmbH and Co, Leinfelden-Echterdingen (in German)

Yaitskova N, Van de Kuilen JW (2014) Time-of-flight modeling of transversal ultrasonic scan of wood. J Acoust Soc Am 135(6):3409–3415

Zhou J, Shen J (2003) Ellipse detection and phase demodulation for wood grain orientation measurement based on the tracheid effect. Opt Lasers Eng 39:73–89

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hunger, F., van de Kuilen, JW.G. Slope of grain measurement: a tool to improve machine strength grading by detecting top ruptures. Wood Sci Technol 52, 821–838 (2018). https://doi.org/10.1007/s00226-018-1000-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-018-1000-7