Abstract

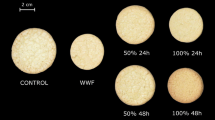

Sourdough (SD), as a natural ingredient, has the highly promising potential to compensate the effect of salt reduction on flavour and the consequent influence on further sensory characteristics in bakery products. The objective of this research was to determine the impact of SD (5, 10 and 20% flour basis) on the structure, flavour and quality characteristics of puff pastry with reduced fat (− 40%) and salt (− 30%) content (RFRS) as well as the rheological properties of the resulting dough. A range of empirical rheological tests was carried out including dough extensibility, dough stickiness and GlutoPeak test. Subsequently, the baked puff pastry quality was investigated using a VolScan, texture analyser, C-Cell and sensory analysis. SD addition significantly changed rheological properties of the basic dough reduced in fat and salt as well as a number of major quality characteristics for the resulting puff pastry. Dough resistance decreased and dough stickiness increased (p < 0.05). Gluten formation was delayed for the higher in salt control and accelerated upon salt reduction as well as increasing levels of SD incorporation. Furthermore, SD addition weakened the gluten network. To some extent, RFRS containing SD were significantly enhanced in texture. Peak firmness of RFRS with SD was significantly decreased when compared to RFRS without SD. Furthermore, the specific volume of RFRS with 5 and 10% SD was significantly higher than for RFRS containing no SD. Finally, supported by a sensory study, the flavour and texture of reduced fat and salt pastry were distinctly improved by 10% SD addition.

Similar content being viewed by others

References

The French Information Center on Food Quality [CIQUAL] (2012) French food composition table. http://www.afssa.fr/TableCIQUAL/. Accessed 4 Jan 2016

Šoronja-Simović D, Šereš Z, Nikolić I et al (2017) Challenges related to the application of high and low trans margarine in puff pastry production. J Food Process Preserv. https://doi.org/10.1111/jfpp.13265

Pajin B, Šoronja-Simović D, Šereš Z et al (2011) Physicochemical and textural properties of puff pastry margarines. Eur J Lipid Sci Technol 113:262–268. https://doi.org/10.1002/ejlt.201000293

Beck M, Jekle M, Becker T (2012) Sodium chloride—sensory, preserving and technological impact on yeast-leavened products. Int J Food Sci Technol 47:1798–1807. https://doi.org/10.1111/j.1365-2621.2012.03048.x

Kaur A, Bala R, Singh B, Rehal J (2011) Effect of replacement of sodium chloride with mineral salts on rheological characteristics of wheat flour. Am J Food Technol 6:674–684. https://doi.org/10.3923/ajft.2011.674.684

Liem DG, Miremadi F, Keast RSJ (2011) Reducing sodium in foods: the effect on flavor. Nutrients 3:694–711. https://doi.org/10.3390/nu3060694

Silow C, Zannini E, Axel C et al (2016) Effect of salt reduction on wheat-dough properties and quality characteristics of puff pastry with full and reduced fat content. Food Res Int 89:330–337. https://doi.org/10.1016/j.foodres.2016.08.031

Arendt EK, Ryan LAM, Dal Bello F (2007) Impact of sourdough on the texture of bread. Food Microbiol 24:165–174. https://doi.org/10.1016/j.fm.2006.07.011

Galle S, Arendt EK (2014) Exopolysaccharides from sourdough lactic acid bacteria. Crit Rev Food Sci Nutr 54:891–901. https://doi.org/10.1080/10408398.2011.617474

Gänzle MG (2014) Enzymatic and bacterial conversions during sourdough fermentation. Food Microbiol 37:2–10. https://doi.org/10.1016/j.fm.2013.04.007

Gobbetti M, Rizzello CG, Di Cagno R, De Angelis M (2014) How the sourdough may affect the functional features of leavened baked goods. Food Microbiol 37:30–40. https://doi.org/10.1016/j.fm.2013.04.012

Thiele C, Gänzle MG, Vogel RF (2002) Contribution of sourdough lactobacilli, yeast, and cereal enzymes to the generation of amino acids in dough relevant for bread flavor. Cereal Chem 79:45–51. https://doi.org/10.1094/CCHEM.2002.79.1.45

Belz MCE, Ryan L, Arendt M EK (2012) The impact of salt reduction in bread: a review. Crit Rev Food Sci Nutr 52:514–524. https://doi.org/10.1080/10408398.2010.502265

Zhao CJ, Kinner M, Wismer W, Gänzle MG (2015) Effect of glutamate accumulation during sourdough fermentation with lactobacillus reuteri on the taste of bread and sodium-reduced bread. Cereal Chem 92:224–230

Belz MCE, Mairinger R, Zannini E et al (2012) The effect of sourdough and calcium propionate on the microbial shelf-life of salt reduced bread. Appl Microbiol Biotechnol 96:493–501. https://doi.org/10.1007/s00253-012-4052-x

Silow C, Zannini E, Arendt EK (2016) Impact of low-trans fat compositions on the quality of conventional and fat-reduced puff pastry. J Food Sci Technol 53:2117–2126. https://doi.org/10.1007/s13197-016-2186-z

Axel C, Brosnan B, Zannini E et al (2016) Antifungal activities of three different Lactobacillus species and their production of antifungal carboxylic acids in wheat sourdough. Appl Microbiol Biotechnol 100:1701–1711. https://doi.org/10.1007/s00253-015-7051-x

Oliveira PM, Brosnan B, Furey A et al (2015) Lactic acid bacteria bioprotection applied to the malting process. Part I: Strain characterization and identification of antifungal compounds. Food Control 51:433–443. https://doi.org/10.1016/j.foodcont.2014.07.004

Oliveira PM, Brosnan B, Furey A et al (2015) Lactic acid bacteria bioprotection applied to the malting process. Part II: substrate impact and mycotoxin reduction. Food Control 51:444–452. https://doi.org/10.1016/j.foodcont.2014.11.011

Axel C, Zannini E, Arendt EK (2016) Mould spoilage of bread and its biopreservation: a review of current strategies for bread shelf life extension. Crit Rev Food Sci Nutr. https://doi.org/10.1080/10408398.2016.1147417

Wolter A, Hager AS, Zannini E et al (2014) Impact of sourdough fermented with Lactobacillus plantarum FST 1.7 on baking and sensory properties of gluten-free breads. Eur Food Res Technol 1–12. https://doi.org/10.1007/s00217-014-2184-1

Arbeitsgemeinschaft Getreideforschung e.V (1994) Standard-Methoden für Getreide, Mehl und Brot, vol 7.Verlag Moritz Schäfer, Detmold

Wolter A, Hager A-S, Zannini E et al (2014) Evaluation of exopolysaccharide producing Weissella cibaria MG1 strain for the production of sourdough from various flours. Food Microbiol 37:44–50. https://doi.org/10.1016/j.fm.2013.06.009

Axel C, Roecker B, Brosnan B et al (2015) Application of Lactobacillus amylovorus DSM19280 in gluten-free sourdough bread to improve the microbial shelf life. Food Microbiol. https://doi.org/10.1016/j.fm.2014.10.005

Silow C, Zannini E, Axel C et al (2017) Optimization of fat-reduced puff pastry using response surface methodology. Foods. https://doi.org/10.3390/foods6020015

Dunnewind B, Sliwinski EL, Grolle K (2004) The Kieffer dough and gluten extensibility rig—an experimental evaluation. J Texture Stud 34:537–560

Kieffer R, Wieser H, Henderson MH, Graveland A (1998) Correlations of the breadmaking performance of wheat flour with rheological measurements on a micro-scale. J Cereal Sci 27:53–60. https://doi.org/10.1006/jcrs.1997.0136

Grausgruber H, Hatzenbichler E, Ruckenbauer P (2003) Analysis of repeated stickiness measures of wheat dough using a texture analyzer. J Texture Stud 34:69–82. https://doi.org/10.1111/j.1745-4603.2003.tb01056.x

Melnyk JP, Dreisoerner J, Bonomi F et al (2011) Effect of the Hofmeister series on gluten aggregation measured using a high shear-based technique. Food Res Int 44:893–896. https://doi.org/10.1016/j.foodres.2011.01.053

Marti A, Augst E, Cox S, Koehler P (2015) Correlations between gluten aggregation properties defined by the GlutoPeak test and content of quality-related protein fractions of winter wheat flour. J Cereal Sci 66:89–95. https://doi.org/10.1016/j.jcs.2015.10.010

Rakita S, Dokić L, Dapčević Hadnadev T et al (2017) Predicting rheological behavior and baking quality of wheat flour using a GlutoPeak test. J Texture Stud 1–9. https://doi.org/10.1111/jtxs.12308

FSAI (Food Safety Authority of Ireland) (2014) Validation of Product Shelf-life (Revision 2)

Beck M, Jekle M, Becker T (2012) Impact of sodium chloride on wheat flour dough for yeast-leavened products. I. Rheological attributes. J Sci Food Agric 92:585–592. https://doi.org/10.1002/jsfa.4612

Lynch EJ, Dal Bello F, Sheehan EM et al (2009) Fundamental studies on the reduction of salt on dough and bread characteristics. Food Res Int 42:885–891. https://doi.org/10.1016/j.foodres.2009.03.014

Koceva Komlenić D, Ugarčić-Hardi Ž, Jukić M et al (2010) Wheat dough rheology and bread quality effected by Lactobacillus brevis preferment, dry sourdough and lactic acid addition. Int J Food Sci Technol 45:1417–1425. https://doi.org/10.1111/j.1365-2621.2010.02282.x

Clarke CI, Schober TJ, Arendt EK (2002) Effect of single strain and traditional mixed strain starter cultures on rheological properties of wheat dough and on bread quality. Cereal Chem 79:640–647

Tamani RJ, Goh KKT, Brennan CS (2013) Physico-chemical properties of sourdough bread production using selected lactobacilli starter cultures. J Food Qual 36:245–252. https://doi.org/10.1111/jfq.12037

Armero E, Collar C (1997) Texture properties of formulated wheat doughs relationships with dough and bread technological quality. Zeitschrift für Leb Und-forsch 204:136–145

Hoseney RC, Smewing J (1999) Instrumental measurement of stickiness of doughs and other foods. J Texture Stud 30:123–136. https://doi.org/10.1111/j.1745-4603.1999.tb00206.x

Wang SM, Watts BM, Lukow OM et al (1996) Dough profiling: an instrumental method for dough stickiness measurement. Cereal Chem 73:445–451

Bouachra S, Begemann J, Aarab L, Hüsken A (2017) Prediction of bread wheat baking quality using an optimized GlutoPeak®-Test method. J Cereal Sci 76:8–16. https://doi.org/10.1016/j.jcs.2017.05.006

McCann TH, Day L (2013) Effect of sodium chloride on gluten network formation, dough microstructure and rheology in relation to breadmaking. J Cereal Sci 57:444–452. https://doi.org/10.1016/j.jcs.2013.01.011

Danno G, Hoseney RC (1982) Effect of sodium chloride and sodium dodecyl sulfate on mixograph properties. Cereal Chem 59:202–204

Wehrle K, Grau H, Arendt EK (1997) Effects of lactic acid, acetic acid, and table salt on fundamental rheological properties of wheat dough. Cereal Chem 74:739–744. https://doi.org/10.1094/CCHEM.1997.74.6.739

Galal A, Varriano-Marston E, Johnson J (1978) Rheological dough properties as affected by organic acids and salt. Cereal Chem 55:683–691

Wehrle K, Arendt EK (1998) Rheological changes in wheat sourdough during controlled and spontaneous fermentation. Cereal Chem 75:882–886. https://doi.org/10.1094/CCHEM.1998.75.6.882

Simovic DS, Pajin B, Seres Z, Filipovic N (2009) Effect of low-trans margarine on physicochemical and sensory properties of puff pastry. Int J Food Sci Technol 44:1235–1244

Baardseth P, Næs T, Vogt G (1995) Roll-in shortenings effects on Danish pastries sensory properties studied by principal component analysis. LWT - Food Sci Technol 28:72–77

Telloke GW (1991) Puff pastry I: process and dough ingredient variables. Flour Milling and Baking Research Association, Chipping Campden

Anonymus (2000) Technologie gezogener Teige Teil II. brot und backwaren, 5, 48

Dörr R (1982) Dänisch-Gebäck - eine internationale Spezialität: Gebäckcharakteristik - Rohstoffe - Herstellung. Getreide Mehl Brot 36:154–158

Ghotra BS, Dyal SD, Narine SS (2002) Lipid shortenings: a review. Food Res Int 35:1015–1048

Salmon SE (2004) Wheat functionality for puff pastry. In: Cauvain SP, Salmon SS, Young LS (eds) Using Cereal Sci. Technol. Benefit Consum. Proc. 12th Int. ICC Cereal Bread Congr. 24–26 May, 2004. CRC, pp 445–450

Noll B, Gräber S, Kitta M et al (1997) Neue Erkenntnisse zur Herstellung von Blätterteiggebäcken. Getreide Mehl Brot 51:363–368

Thiele C, Grassl S, Gänzle M (2004) Gluten hydrolysis and depolymerization during sourdough fermentation. J Agric Food Chem 52:1307–1314. https://doi.org/10.1021/jf034470z

Acknowledgements

This study was carried out with financial support from the European Commission, FP7, Thematic Area KBBE, Project “PLEASURE” (Grant agreement no: 289536).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Rights and permissions

About this article

Cite this article

Silow, C., Axel, C., Zannini, E. et al. Application of sourdough in the production of fat- and salt-reduced puff pastry. Eur Food Res Technol 244, 1581–1593 (2018). https://doi.org/10.1007/s00217-018-3071-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-018-3071-y