Abstract

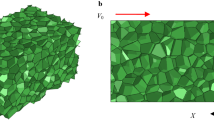

Cellular materials can dissipate a large amount of energy due to their considerable stress plateau, which contributes to their extensive applications in structural design for crashworthiness. However, in some experiments with specimens subjected to intense impact loads, transmitted stress enhancement has been observed, leading to severe damage to the objects protected. Transmitted stress through two-dimensional Voronoi cellular materials as a protective device is qualitatively studied in this paper. Dimensionless parameters of material properties and loading parameters are defined to give critical conditions for shock enhancement and clarify the correlation between the deformations and stress enhancement. The effect of relative density on this amplifying phenomenon is investigated as well. In addition, local strain fields are calculated by using the optimal local deformation gradient, which gives a clear presentation of deformations and possible local non-uniformity in the crushing process. This research provides valuable insight into the reliability of cellular materials as protective structures.

Similar content being viewed by others

References

Zhu, F., Chou, C.C., Yang, K.H.: Shock enhancement effect of lightweight composite structures and materials. Compos. Part B 42, 1202–1211 (2011). doi:10.1016/j.compositesb.2011.02.014

Tan, P.J., Harrigan, J.J., Reid, S.R.: Inertia effect in the uniaxial dynamic compression of a closed-cell aluminium alloy foam. J. Mater. Sci. Technol. 18, 480–488 (2002). doi:10.1179/026708302225002092

Deshpande, V.S., Fleck, N.A.: High strain rate compressive behaviour of aluminium alloy foams. Int. J. Impact Eng. 24, 277–298 (2000). doi:10.1016/S0734-743X(99)00153-0

Dannemann, K.A., Lankford Jr., J.: High strain rate compression of closed-cell aluminium foams. Mater. Sci. Eng. A 293, 157–164 (2000). doi:10.1016/S0921-5093(00)01219-3

Gibson, L.J., Ashby, M.F.: Cellular Solids: Structure and Properties, 2nd edn. Cambridge University Press, Cambridge (1997)

Ashby, M.F., Evans, A., Fleck, N.A., Gibson, L.J., Hutchinson, J.W., Wadley, H.N.G.: Metal Foams: A Design Guide. Butterworth-Heinemann, Boston (2000)

Hanssen, A.G., Enstock, L., Langseth, M.: Close-range blast loading of aluminium foam panels. Int. J. Impact Eng. 27, 593–618 (2002). doi:10.1016/S0734-743X(01)00155-5

Reid, S.R., Peng, C.: Dynamic uniaxial crushing of wood. Int. J. Impact Eng. 19(5–6), 531–570 (1997). doi:10.1016/S0734-743X(97)00016-X

Reid, S.R., Bell, W.W., Barr, R.A.: Structural plastic shock model for one-dimensional ring systems. Int. J. Impact Eng. 1(2), 175–191 (1983). doi:10.1016/0734-743X(83)90005-2

Li, Q.M., Meng, H.: Attenuation or enhancement—a one-dimensional analysis on shock transmission in the solid phase of a cellular material. Int. J. Impact Eng. 27(10), 1049–1065 (2002). doi:10.1016/S0734-743X(02)00016-7

Daxner, T., Böhm, H.J., Rammerstorfer, F.G.: Mesoscopic simulation of inhomogeneous metallic foams with respect to energy absorption. Comput. Mater. Sci. 16(1–4), 61–69 (1999). doi:10.1016/S0927-0256(99)00046-4

Wang, Z.H., Zhang, Y.F., Ren, H.L., Zhao, L.M.: A study on compressive shock wave propagation in metallic foams. Sci. China Phys. Mech. Astron. 53(2), 279–287 (2010). doi:10.1007/s11433-009-0271-2

Karagiozova, D.: Velocity attenuation and force transfer by a single- and double-layer claddings made of foam materials. Int. J. Protect. Struct. 2(4), 417–437 (2011). doi:10.1260/2041-4196.2.4.417

Ma, G.W., Ye, Z.Q., Shao, Z.S.: Modeling loading rate effect on crushing stress of metallic cellular materials. Int. J. Impact Eng. 36, 775–782 (2009). doi:10.1016/j.ijimpeng.2008.11.013

Song, Y.Z., Wang, Z.H., Zhao, L.M., Luo, J.: Dynamic crushing behavior of 3D closed-cell foams based on Voronoi random model. Mater. Des. 31, 4281–4289 (2010). doi:10.1016/j.matdes.2010.04.007

Li, Z., Zhang, J., Fan, J., Wang, Z., Zhao, L.: On crushing response of the three-dimensional closed-cell foam based on Voronoi model. Mech. Mater. 68, 85–94 (2014). doi:10.1016/j.mechmat.2013.08.009

Seitz, M.W., Skews, B.W.: Effect of compressible foam properties on pressure amplification during shock wave impact. Shock Waves 15, 177–197 (2006). doi:10.1007/s00193-006-0033-2

Seitz, M.W., Skews, B.W.: An analytical model for shock wave impact on compressible open-cell foam. Shock Waves 16, 287–298 (2007). doi:10.1007/s00193-007-0073-2

Mazor, G., Ben-Dor, G., Igra, O., Sorek, S.: Shock wave interaction with cellular materials Part I: analytical investigation and governing equations. Shock Waves 3, 159–165 (1994). doi:10.1007/BF01414710

Petel, O.E., Ouellet, S., Higgins, A.J., Frost, D.L.: The elastic–plastic behaviour of foam under shock loading. Shock Waves 23(1), 55–67 (2013). doi:10.1007/s00193-012-0414-7

Zheng, Z., Yu, J., Li, J.: Dynamic crushing of 2D cellular structures: A finite element study. Int. J. Impact Eng 32, 650–664 (2005). doi:10.1016/j.ijimpeng.2005.05.007

Voronoi, G.: Nouvelles applications des paramètres continus à la théorie des formes quadratiques. Deuxième Mémorie: recherches sur les paralléloèdres primitifs. J. für die reine und Angew. Math. 134, 198–287 (1908)

Zhu, H.X., Thorpe, S.M., Windle, A.H.: The geometrical properties of irregular two-dimensional Voronoi tessellations. Philos. Mag. A 81(12), 2765–2783 (2001). doi:10.1080/01418610010032364

Zhu, H.X., Hobdell, J.R., Windle, A.H.: Effects of cell irregularity on the elastic properties of 2D Voronoi honeycombs. J. Mech. Phys. Solids 49(4), 857–870 (2001). doi:10.1016/S0022-5096(00)00046-6

Li, K., Gao, X.L., Wang, J.: Dynamic crushing behavior of honeycomb structures with irregular cell shapes and non-uniform cell wall thickness. Int. J. Solids Struct. 44, 5003–5026 (2007). doi:10.1016/j.ijsolstr.2006.12.017

Schaffner, G., Guo, X.D.E., Silva, M.J., Gibson, L.J.: Modeling fatigue damage accumulation in two-dimensional Voronoi honeycombs. Int. J. Mech. Sci. 42(4), 645–656 (2000). doi:10.1016/S0020-7403(99)00031-4

Tan, P.J., Reid, S.R., Harrigan, J.J., Zou, Z., Li, S.: Dynamic compressive strength properties of aluminium foams. Part I–experimental data and observations. J. Mech. Phys. Solids 53, 2174–2205 (2005). doi:10.1016/j.jmps.2005.05.007

Zou, Z., Reid, S.R., Tan, P.J., Li, S., Harrigan, J.J.: Dynamic crushing of honeycombs and features of shock fronts. Int. J. Impact Eng. 36(1), 165–176 (2009). doi:10.1016/j.ijimpeng.2007.11.008

Tekoglu, C., Gibson, L.J., Pardoen, T., Onck, P.R.: Size effects in foams: experiments and modeling. Prog. Mater. Sci. 56(2), 109–138 (2011). doi:10.1016/j.pmatsci.2010.06.001

Zheng, Z.J., Liu, Y.D., Yu, J.L., Reid, S.R.: Dynamic crushing of cellular materials: Continuum-based wave models for the transitional and shock modes. Int. J. Impact Eng. 42, 66–79 (2012). doi:10.1016/j.ijimpeng.2011.09.009

Li, J., Shimizu, F.: Least-square atomic strain. http://li.mit.edu/A/Archive/Graphics/A/annotate_atomic_strain/Doc/main.pdf (2005). Accessed 24 May 2017

Gullett, P.M., Horstemeyer, M.F., Baskes, M.I., Fang, H.: A deformation gradient tensor and strain tensors for atomistic simulations. Model Simul. Mater. Sci. Eng. 16(1), 015001 (2008). doi:10.1088/0965-0393/16/1/015001. (17pp)

Zimmerman, J.A., Bammann, D.J., Gao, H.: Deformation gradients for continuum mechanical analysis of atomistic simulations. Int. J. Solids Struct. 46(2), 238–253 (2009). doi:10.1016/j.ijsolstr.2008.08.036

Liao, S.F., Zheng, Z.J., Yu, J.L.: Dynamic crushing of 2D cellular structures: Local strain field and shock wave velocity. Int. J. Impact Eng. 57, 7–16 (2013). doi:10.1016/j.ijimpeng.2013.01.008

Reddy, J.N.: An Introduction to Continuum Mechanics. Cambridge University Press, New York (2007)

Song, Y.Z., Zhang, X.H., Li, Z.Q., Zhao, L.M.: In-plane dynamic crushing of 2D cellular structures with the edges deleted. In: Advances in Heterogeneous Material Mechanics, 2nd International Conference on Heterogeneous Material Mechanics (ICHMM-2008), Huangshan, pp. 829–832 (2008)

Zhao, L.M., Song, Y.Z., Li, Z.Q.: Study of the dynamic crushing behavior of cellular materials by using the Voronoi random models. J. Mech. Strength 31(6), 932–938 (2009). (in Chinese)

Zheng, Z.J., Yu, J.L.: Effect of random defects on dynamic response of honeycomb structures. Mater. Sci. Forum. 706–709, 805–810 (2012). doi:10.4028/www.scientific.net/MSF.706-709.805

Liu, Y.D., Yu, J.L., Zheng, Z.J., Li, J.R.: A numerical study on the rate sensitivity of cellular metals. Int. J. Solids Struct. 46(22–23), 3988–3998 (2009). doi:10.1016/j.ijsolstr.2009.07.024

Pattofatto, S., Elnasri, I., Zhao, H., Tsitsiris, H., Hild, F., Girard, Y.: Shock enhancement of cellular structures under impact loading: Part II analysis. J. Mech. Phys. Solids 55(12), 2672–2686 (2007). doi:10.1016/j.jmps.2007.04.004

Lopatnikov, S.L., Gama, B.A., Haque, M.J., Krauthauser, C., Gillespie Jr., J.W., Guden, M., Hall, I.W.: Dynamics of metal foam deformation during Taylor cylinder–Hopkinson bar impact experiment. Compos. Struct. 61, 61–71 (2003). doi:10.1016/S0263-8223(03)00039-4

Skews, B.W., Atkins, M.D., Seitz, M.W.: The impact of a shock wave on porous compressible foams. Fluid Mech. 253, 245–265 (1993). doi:10.1017/S0022112093001788

Cooper, G.J., Townend, D.J., Cater, S.R., Pearce, B.P.: The role of stress waves in thoracic visceral injury from blast loading: Modification of stress transmission by foams and high-density materials. J. Biomech. 24(5), 273–285 (1991). doi:10.1016/0021-9290(91)90346-O

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Grant Nos. 11572214, 11402163, 11672199 and 11602161), Shanxi Scholarship Council of China (2013-046), Natural Science Foundation of Shanxi Province (No. 201601D021025), State Key Laboratory of Advanced Design and Manufacturing for Vehicle Body (No. 31615008) and the Top Young Academic Leaders of Shanxi, Opening Foundation for State Key Laboratory for Strength and Vibration of Mechanical Structures and Opening Foundation for State Key Laboratory of Explosion Science and Technology (Grant No. KFJJ16-07M). The financial contributions are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by W. Proud.

Rights and permissions

About this article

Cite this article

Zhang, J., Fan, J., Wang, Z. et al. Shock enhancement of cellular materials subjected to intensive pulse loading. Shock Waves 28, 175–189 (2018). https://doi.org/10.1007/s00193-017-0730-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00193-017-0730-z