Abstract

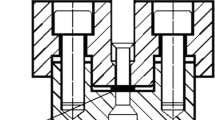

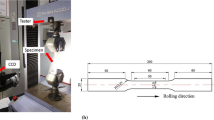

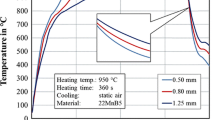

The research mainly focused on the forming limit curves (FLC) of the 6061 Al alloy subjected to heat treatments with various (1 mm, 1.6 mm, 2 mm, and 2.5 mm) sheet metal thicknesses. Five peculiar heat treatments, including natural aging temper (T4) and highest-strength (T6) temper, were devised to study the influence of heat treatments on the formability of 6061 Al alloy sheets. Tensile tests were executed to determine the plastic behavior of the alloy under specific heat treatments. Laser marked FLC specimens were deep-drawn with the proposed spring-attached Nakajima deep drawing test setup. A finite element model (FEM) of the deep drawing experiment was constructed to investigate the nucleation and growth mechanism of the voids. The developed model was compared and verified with the experimental FLC, fracture locations, and dome height. The FEM results were differed from the experimental FLC by less than 5% considering all heat treatments and sheet thicknesses. The results declared that sheet metal thickness has a positive effect on the effective strain up to failure. On the other hand, the duration of artificial aging time reduced effective strain to failure controlled by nucleation and growth of voids.

Similar content being viewed by others

Data availability

Not applicable

Code availability

Not applicable

References

Wang N, Zhou Z, Lu G (2011) Microstructural evolution of 6061 alloy during ısothermal heat treatment. J Mater Sci Technol 27:8–14. https://doi.org/10.1016/S1005-0302(11)60018-2

Benedyk JC (2010) 3 - Aluminum alloys for lightweight automotive structures. Woodhead Publishing Limited. https://doi.org/10.1533/9781845697822.1.79

Demir H, Gündüz S (2009) The effects of aging on machinability of 6061 aluminium alloy. Mater Des 30:1480–1483. https://doi.org/10.1016/j.matdes.2008.08.007

ASM Handbook Committe C (1991) ASM Metals Handbook Volume 4, 10 th Edit. ASM International

Braun R (2010) On the stress corrosion cracking behaviour of 6XXX series aluminium alloys. Int J Mater Res 101:657–668. https://doi.org/10.3139/146.110314

Buha J, Lumley RN, Crosky AG (2006) Microstructural development and mechanical properties of interrupted aged Al-Mg-Si-Cu alloy. Metall Mater Trans A 37:3119–3130. https://doi.org/10.1007/s11661-006-0192-x

Buha J, Lumley RN, Crosky AG, Hono K (2007) Secondary precipitation in an Al-Mg-Si-Cu alloy. Acta Mater 55:3015–3024. https://doi.org/10.1016/j.actamat.2007.01.006

Marioara CD, Nordmark H, Andersen SJ, Holmestad R (2006) Post-β″ phases and their influence on microstructure and hardness in 6xxx Al-Mg-Si alloys. J Mater Sci 41:471–478. https://doi.org/10.1007/s10853-005-2470-1

Yassar RS, Field DP, Weiland H (2005) Transmission electron microscopy and differential scanning calorimetry studies on the precipitation sequence in an Al-Mg-Si alloy: AA6022. J Mater Res 20:2705–2711. https://doi.org/10.1557/Jmr.2005.0330

Pogatscher S, Antrekowitsch H, Ebner T, Leoben M (2012) The role of co-clusters in the artificial aging of AA 6061 and AA 6060. 415–420. https://doi.org/10.1007/978-3-319-48179-1_70

Dutta I, Allen SM (1991) A calorimetric study of precipitation in aluminum alloy 6061. J Mater Sci Lett 10:323–326. https://doi.org/10.1007/BF00719697

Edwards GA, Stiller K, Dunlop GL, Couper MJ (1998) The precipitation sequence in Al–Mg–Si alloys. Acta Mater 46:3893–3904. https://doi.org/10.1016/S1359-6454(98)00059-7

Massardier V, Epicier T, Merle P (2000) Correlation between the microstructural evolution of A 6061 aluminium alloy and the evolution of its thermoelectric power. Acta Mater 48:2911–2924. https://doi.org/10.1016/S1359-6454(00)00085-9

Ozturk F, Sisman A, Toros S, Kilic S, Picu RC (2010) Influence of aging treatment on mechanical properties of 6061 aluminum alloy. Mater Des 31:972–975. https://doi.org/10.1016/j.matdes.2009.08.017

Giuliano G, Bellini C, Sorrentino L, Turchetta S (2018) Forming process analysis of an AA6060 aluminum vessel. Frat ed Integrita Strutt 12:164–172. https://doi.org/10.3221/IGF-ESIS.45.14

Keeler SP, Backofen WA (1963) Plastic instability and fracture in sheet stretched over rigid punches. ASM Trans Q 56:25–48

Goodwin GM (1968) Application of strain analysis to sheet metal forming problems in the press shop. Soc Automot Eng 380–387

El-Domiaty AA, Shabara MAN, Al-Ansary MD (1996) Determination of stretch-bendability of sheet metals. Int J Adv Manuf Technol 12:207–220. https://doi.org/10.1007/BF01351200

ISO (2006) ISO 12004-2:2008 Metallic materials-sheet and strip-determination of plastic strain ratio. BSI Stand Publ 3:10

Mohammed B, Park T, Pourboghrat F, Hu J, Esmaeilpour R, Abu-Farha F (2018) Multiscale crystal plasticity modeling of multiphase advanced high strength steel. Int J Solids Struct 151:57–75. https://doi.org/10.1016/j.ijsolstr.2017.05.007

Mohammed B, Park T, Kim H, Pourboghrat F, Esmaeilpour R (2018) The forming limit curve for multiphase advanced high strength steels based on crystal plasticity finite element modeling. Mater Sci Eng A 725:250–266. https://doi.org/10.1016/j.msea.2018.04.029

Panich S, Barlat F, Uthaisangsuk V, Suranuntchai S, Jirathearanat S (2013) Experimental and theoretical formability analysis using strain and stress based forming limit diagram for advanced high strength steels. Mater Des 51:756–766. https://doi.org/10.1016/j.matdes.2013.04.080

Bong HJ, Barlat F, Lee M-G, Ahn DC (2012) The forming limit diagram of ferritic stainless steel sheets: experiments and modeling. Int J Mech Sci 64:1–10. https://doi.org/10.1016/j.ijmecsci.2012.08.009

Saxena KK, Das IM, Mukhopadhyay J (2015) Evaluation of bending limit curves of aluminium alloy AA6014-T4 and dual phase steel DP600 at ambient temperature. Int J Mater Form 10:221–231. https://doi.org/10.1007/s12289-015-1271-6

Paul SK (2015) Path independent limiting criteria in sheet metal forming. J Manuf Process 20:291–303. https://doi.org/10.1016/j.jmapro.2015.06.025

Yang TS (2007) The strain path and forming limit analysis of the lubricated sheet metal forming process. Int J Mach Tools Manuf 47:1311–1321. https://doi.org/10.1016/j.ijmachtools.2006.08.019

Assempour A, Hashemi R, Abrinia K, Ganjiani M, Masoumi E (2009) A methodology for prediction of forming limit stress diagrams considering the strain path effect. Comput Mater Sci 45:195–204. https://doi.org/10.1016/j.commatsci.2008.09.025

Uppaluri R, Venkata Reddy N, Dixit PM (2011) An analytical approach for the prediction of forming limit curves subjected to combined strain paths. Int J Mech Sci 53:365–373. https://doi.org/10.1016/j.ijmecsci.2011.02.006

Nurcheshmeh M, Green DE (2011) Investigation on the strain-path dependency of stress-based forming limit curves. Int J Mater Form 4:25–37. https://doi.org/10.1007/s12289-010-0989-4

Ma B, Diao K, Wu X, Li X, Wan M, Cai Z (2016) The effect of the through-thickness normal stress on sheet formability. J Manuf Process 21:134–140. https://doi.org/10.1016/j.jmapro.2015.12.006

Tseng HC, Hung C, Huang CC (2010) An analysis of the formability of aluminum/copper clad metals with different thicknesses by the finite element method and experiment. Int J Adv Manuf Technol 49:1029–1036. https://doi.org/10.1007/s00170-009-2446-4

Dilmec M, Halkaci HS, Ozturk F (2013) Effects of sheet thickness and anisotropy on forming limit curves of AA2024-T4. Int J Adv Manuf Technol 67:2689–2700. https://doi.org/10.1007/s00170-012-4684-0

Dehghani F, Salimi M (2016) Analytical and experimental analysis of the formability of copper-stainless-steel 304L clad metal sheets in deep drawing. Int J Adv Manuf Technol 82:163–177. https://doi.org/10.1007/s00170-015-7359-9

Mahabunphachai S, Koç M (2010) Investigations on forming of aluminum 5052 and 6061 sheet alloys at warm temperatures. Mater Des 31:2422–2434. https://doi.org/10.1016/j.matdes.2009.11.053

Wang L, Strangwood M, Balint D, Lin J, Dean TA (2011) Formability and failure mechanisms of AA2024 under hot forming conditions. Mater Sci Eng A 528:2648–2656. https://doi.org/10.1016/j.msea.2010.11.084

Wang L, Lee TC (2006) The effect of yield criteria on the forming limit curve prediction and the deep drawing process simulation. Int J Mach Tools Manuf 46:988–995. https://doi.org/10.1016/j.ijmachtools.2005.07.050

Nurcheshmeh M, Green DE (2012) Influence of out-of-plane compression stress on limit strains in sheet metals. Int J Mater Form 5:213–226. https://doi.org/10.1007/s12289-011-1044-9

Hashemi R, Abrinia K (2014) Analysis of the extended stress-based forming limit curve considering the effects of strain path and through-thickness normal stress. Mater Des 54:670–677. https://doi.org/10.1016/j.matdes.2013.08.023

Assempour A, Nejadkhaki HK, Hashemi R (2010) Forming limit diagrams with the existence of through-thickness normal stress. Comput Mater Sci 48:504–508. https://doi.org/10.1016/j.commatsci.2010.02.013

Dhara S, Basak S, Panda SK, Hazra S, Shollock B, Dashwood R (2016) Formability analysis of pre-strained AA5754-O sheet metal using Yld96 plasticity theory: role of amount and direction of uni-axial pre-strain. J Manuf Process 24:270–282. https://doi.org/10.1016/j.jmapro.2016.09.014

Zhang L, Lin J, Min J, Ye Y, Kang L (2016) Formability evaluation of sheet metals based on global strain distribution. J Mater Eng Perform 25:2296–2306. https://doi.org/10.1007/s11665-016-2054-z

Prasad KS, Panda SK, Kar SK, Murty SVSN, Sharma SC (2018) Prediction of fracture and deep drawing behavior of solution treated Inconel-718 sheets: numerical modeling and experimental validation. Mater Sci Eng A 733:393–407. https://doi.org/10.1016/j.msea.2018.07.007

Atkins AG (1996) Fracture in forming. J Mater Process Technol 56:609–618. https://doi.org/10.1016/0924-0136(95)01875-1

Isik K, Silva MB, Tekkaya AE, Martins PAF (2014) Formability limits by fracture in sheet metal forming. J Mater Process Technol 214:1557–1565. https://doi.org/10.1016/j.jmatprotec.2014.02.026

Lumelskyj D, Rojek J, Tkocz M (2018) Detection of strain localization in numerical simulation of sheet metal forming. Arch Civ Mech Eng 18:490–499. https://doi.org/10.1016/j.acme.2017.08.004

Amaral R, Teixeira P, Azinpour E, et al (2016) Evaluation of ductile failure models in sheet metal forming. MATEC Web Conf 80:1–6. https://doi.org/10.1051/matecconf/20168003004

Li J, Li S, Xie Z, Wang W (2015) Numerical simulation of incremental sheet forming based on GTN damage model. Int J Adv Manuf Technol 81:2053–2065. https://doi.org/10.1007/s00170-015-7333-6

Kami A, Dariani BM, Sadough Vanini A, Comsa DS, Banabic D (2014) Numerical determination of the forming limit curves of anisotropic sheet metals using GTN damage model. J Mater Process Technol 216:472–483. https://doi.org/10.1016/j.jmatprotec.2014.10.017

Nguyen HH, Nguyen TN, Vu HC (2018) Ductile fracture prediction and forming assessment of AA6061-T6 aluminum alloy sheets. Int J Fract 209:143–162. https://doi.org/10.1007/s10704-017-0249-4

Haltom SS, Kyriakides S, Ravi-Chandar K (2013) Ductile failure under combined shear and tension. Int J Solids Struct 50:1507–1522. https://doi.org/10.1016/j.ijsolstr.2012.12.009

Sari Sarraf I, Green DE, Vasilescu DM, Song Y (2018) Numerical analysis of damage evolution and formability of DP600 sheet with an extended Rousselier damage model. Int J Solids Struct 134:70–88. https://doi.org/10.1016/j.ijsolstr.2017.10.030

Jenab A, Green DE, Alpas AT, Golovashchenko SF (2018) Experimental and numerical analyses of formability improvement of AA5182-O sheet during electro-hydraulic forming. J Mater Process Technol 255:914–926. https://doi.org/10.1016/j.jmatprotec.2017.12.037

Banhart J, Chang CST, Liang Z, Wanderka N, Lay MDH, Hill AJ (2010) Natural aging in Al-Mg-Si alloys—a process of unexpected complexity. Adv Eng Mater 12:559–571. https://doi.org/10.1002/adem.201000041

Mohammadtaheri M (2012) A new metallographic technique for revealing grain boundaries in aluminum alloys. Metallogr Microstruct Anal 1:224–226. https://doi.org/10.1007/s13632-012-0033-9

ASTM (2009) Standard test methods for tension testing of metallic materials. ASTM International. https://doi.org/10.1520/E0008_E0008M-16AE01

Yildiz RA, Yilmaz S (2020) Stress–strain properties of artificially aged 6061 Al alloy: experiments and modeling. J Mater Eng Perform 29:5764–5775. https://doi.org/10.1007/s11665-020-05080-6

Barnwal VK, Raghavan R, Tewari A, Narasimhan K, Mishra SK (2017) Effect of microstructure and texture on forming behaviour of AA-6061 aluminium alloy sheet. Mater Sci Eng A 679:56–65. https://doi.org/10.1016/j.msea.2016.10.027

Barnwal VK, Tewari A, Narasimhan K, Mishra SK (2016) Effect of plastic anisotropy on forming behavior of AA-6061 aluminum alloy sheet. J Strain Anal Eng Des 51:507–517. https://doi.org/10.1177/0309324716655727

ASTM (2010) Standard test method for plastic strain ratio ‘r’ for sheet metal 1. ASTM International. https://doi.org/10.1520/E0517-00R10.2

ASTM (2014) Standard test method for determining forming limit curves. ASTM International. https://doi.org/10.1520/E2218-15

Yildiz RA, Yilmaz S (2017) The verification of strains obtained by grid measurements using digital image processing for sheet metal formability. J Strain Anal Eng Des 52:506–514. https://doi.org/10.1177/0309324717734669

Gurson AL (1977) Continuum theory of ductile rupture by void nucleation and growth: part I—yield criteria and flow rules for porous ductile media. J Eng Mater Technol 99:2–15. https://doi.org/10.1115/1.3443401

Tvergaard V (1981) Influence of voids on shear band instabilities under plane strain conditions. Int J Fract 17:389–407. https://doi.org/10.1007/BF00036191

Tvergaard V, Needleman A (1984) Analysis of the cup-cone fracture in a round tensile bar. Acta Metall 32:157–169. https://doi.org/10.1016/0001-6160(84)90213-X

Zhao PJ, Chen ZH, Dong CF (2016) Failure analysis based on microvoids damage model for DP600 steel on in-situ tensile tests. Eng Fract Mech 154:152–168. https://doi.org/10.1016/j.engfracmech.2015.11.017

Chu CC, Needleman A (1980) Void nucleation effects in biaxially stretched sheets. J Eng Mater Technol 102:249–256. https://doi.org/10.1115/1.3224807

Yildiz RA (2019) Investigation of the effect of heat treatments on the formability of the 6061 Al alloy. Istanbul Technical University

Yildiz RA, Yilmaz S (2020) European Journal of Mechanics/A Solids Experimental Investigation of GTN model parameters of 6061 Al alloy. Eur J Mech/A Solids 83:104040. https://doi.org/10.1016/j.euromechsol.2020.104040

He M, Li F, Wang Z (2011) Forming limit stress diagram prediction of aluminum alloy 5052 based on GTN model parameters determined by in situ tensile test. Chin J Aeronaut 24:378–386. https://doi.org/10.1016/S1000-9361(11)60045-9

Nahshon K, Hutchinson JW (2008) Modification of the Gurson model for shear failure. Eur J Mech - A/Solids 27:1–17. https://doi.org/10.1016/j.euromechsol.2007.08.002

Xue L (2008) Constitutive modeling of void shearing effect in ductile fracture of porous materials. Eng Fract Mech 75:3343–3366. https://doi.org/10.1016/j.engfracmech.2007.07.022

Jackiewicz J (2011) Use of a modified Gurson model approach for the simulation of ductile fracture by growth and coalescence of microvoids under low, medium and high stress triaxiality loadings. Eng Fract Mech 78:487–502. https://doi.org/10.1016/j.engfracmech.2010.03.027

Sen H, Yilmaz S, Yildiz RA (2020) Springback behavior of DP600 steel: an implicit finite element simulation. J Eng Res 8:252–264

Wang C, Ma R, Zhao J, Zhao J (2017) Calculation method and experimental study of coulomb friction coefficient in sheet metal forming. J Manuf Process 27:126–137. https://doi.org/10.1016/j.jmapro.2017.02.016

Oliveira MC, Alves JL, Menezes LF (2008) Algorithms and strategies for treatment of large deformation frictional contact in the numerical simulation of deep drawing process. Arch Comput Methods Eng 15:113–162. https://doi.org/10.1007/s11831-008-9018-x

Duncan JL, Shabel BS, Filho JG (2010) A tensile strip test for evaluating friction in sheet metal forming. SAE Tech Pap Ser 1. https://doi.org/10.4271/780391

Luo M, Wierzbicki T (2010) Numerical failure analysis of a stretch-bending test on dual-phase steel sheets using a phenomenological fracture model. Int J Solids Struct 47:3084–3102. https://doi.org/10.1016/j.ijsolstr.2010.07.010

Ramazani A, Abbasi M, Prahl U, Bleck W (2012) Failure analysis of DP600 steel during the cross-die test. Comput Mater Sci 64:101–105. https://doi.org/10.1016/j.commatsci.2012.01.031

Keeler S, Brazier WG (1975) Relationship between laboratory material characterization and press-shop formability. In: Proceedings of the Micro alloying Conference. pp 21–32

Materials availability

Not applicable

Funding

This study was funded by Istanbul Technical University (Project Number: 38489).

Author information

Authors and Affiliations

Contributions

The corresponding author is responsible for ensuring that the descriptions are accurate and agreed upon by all authors. The roles of all authors listed below:

Rasid Ahmed YILDIZ: Methodology, Software, Validation, Investigation, Resources, Writing – Original Draft,

Safak YILMAZ: Conceptualization, Writing – Review & Editing, Supervision, Project Administration, Funding Acquisition

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yildiz, R.A., Yilmaz, S. Influence of heat treatments on the formability of the 6061 Al alloy sheets: experiments and GTN damage model. Int J Adv Manuf Technol 113, 2277–2299 (2021). https://doi.org/10.1007/s00170-021-06792-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-06792-2