Abstract

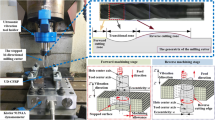

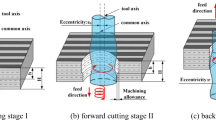

During CFRP hole-making, exit damages such as burrs and delamination frequently occur. To adequately eliminate the influence of the axial force on the damages, a new combined drill-milling process was proposed. But the details of the cutting forces and the undeformed chip geometry in the helical milling phase for special drill-milling tool have not yet been comprehensively described and analyzed. Theoretical and experimental analyses of the drill-milling cutting forces and the performance of the novel drill-milling tool are investigated. The results indicate that the helical milling parameters significantly affect the undeformed chip transverse areas as well as the cutting forces. During the drilling phase, the exit tears and delamination can be observed, but few exit burrs can be left. During the helical milling phase, the drilling-induced damages can be further reduced even removed completely. The cutting forces Fx and Fy increase up to 15.9% and 22.6%, respectively, when ng increases from 60 to 180 rpm. When e increases from 0.1 to 1.3 mm, Fx and Fy increase up to 69.9% and 44.4%, respectively. Fx and Fy increase up to 40.3% and 35.2% respectively, when vf increases from 6 to 24 mm/min. But Fx and Fy decrease up to 18.0% and 10.4% respectively, when nz increases from 2000 to 5000 rpm.

Similar content being viewed by others

References

Li M, Soo SL, Aspinwall DK, Pearson D, Leahy W (2018) Study on tool wear and workpiece surface integrity following drilling of CFRP laminates with variable feed rate strategy. Procedia CIRP 71:407–412

Chen T, Xiang JP, Gao F, Liu XL, Liu GJ (2019) Study on cutting performance of diamond-coated rhombic milling cutter in machining carbon fiber composites. Int J Mach Tools Manuf 103:4731–4737

Heberger L, Kirsch B, Donhauser T, Nissle S, Gurka M, Schmeer S, Aurich JC (2016) Influence of the quality of rivet holes in carbon-fiber-reinforced-polymer (CFRP) on the connection stability. Procedia Manuf 6:140–147

Caggiano A, Improta I, Nele L (2018) Characterization of a new dry drill-milling process of carbon fibre reinforced polymer laminates. Mater 11(8):1–15

Wang GD, Melly SK, Li N, Peng T, Li YC (2018) Research on milling strategies to reduce delamination damage during machining of holes in CFRP/Ti stack. Compos Struct 200:679–688

Wang GD, Suntoo D, Li N, Peng T, Li YC (2018) Experimental research in CFRP/Ti stack through different helical milling strategies. Int J Mach Tools Manuf 98:3251–3267

Ahmad N, Khan SA, Raza SF (2019) Influence of hole diameter, workpiece thickness, and tool surface condition on machinability of CFRP composites in orbital drilling: a case of workpiece rotation. Int J Mach Tools Manuf 103:2007–2015

Amini S, Baraheni M, Hakimi E (2019) Enhancing dimensional accuracy and surface integrity by helical milling of carbon fiber reinforced polymers. Int J Lightweight Mater Manuf 2:362–372. https://doi.org/10.1016/j.ijlmm.2019.03.001

Rahim EA, Mohid Z, Hamzah MR, Yusuf AF, Rahman NA (2014) Performance of tools design when helical milling on carbon fiber reinforced plastics (CFRP) aluminum (Al) stack. Appl Mech Mater 465-466:1075–1079

Li SP, Qin XD, Jin Y, Sun D, Li YH (2018) A comparative study of hole-making performance by coated and uncoated WC/Co cutters in helical milling of Ti/CFRP stacks. Int J Adv Manuf Technol 94:2645–2658

Wang GD, Kirwa MS, Li N (2018) Experimental studies on a two-step technique to reduce delamination damage during milling of large diameter holes in CFRP/Al stack. Compos Struct 188:330–339

Tanaka H, Kitamura M, Sai T (2015) An evaluation of cutting edge and machinability of inclined planetary motion milling for difficult-to-cut materials. Procedia CIRP 35:96–100

Wang Q, Wu Y, Li Y, Lu D, Bitoh T (2019) Proposal of a tilted helical milling technique for high-quality hole drilling of CFRP: analysis of hole surface finish. Int J Adv Manuf Technol 101(1-4):1041–1049

Wang Q, Wu Y, Bitou T, Nomura M, Fujii T (2017) Proposal of a tilted helical milling technique for high quality hole drilling of CFRP: kinetic analysis of hole formation and material removal. Int J Adv Manuf Technol 3–4:1–15

Boccarusso L, Fazio DD, Durante M, Langella A, Minutolo FMC (2019) CFRPs drilling: comparison among holes produced by different drilling strategies. Procedia CIRP 79:325–330

Durante M, Boccarusso L, De Fazio D, Dario Langella A (2019) Circular cutting strategy for drilling of carbon fiber-reinforced plastics (CFRPs). Mater Manuf Process 34(5):554–566

Liu C, Wang G, Dargusch MS (2012) Modelling, simulation and experimental investigation of cutting forces during helical milling operations. Int J Adv Manuf Technol 63(9-12):839–850

Shang S, Qin XD, Li JH, Li SP, Li H, Huang T, Jin Y, Sun D (2018) Modelling of cutting forces and researching calibration method in helical milling. Int J Adv Manuf Technol 94:2949–2960

Brinksmeier E, Fangmann S, Meyer I (2008) Orbital drilling kinematics. Prod Eng 2(3):277–283

Tian YL, Liu YP, Wang FJ, Jing XB, Zhang DW, Liu XP (2017) Modeling and analyses of helical milling process. Int J Adv Manuf Technol 90:1003–1022

Zhou L, Dong HY, Ke YL, Chen GL (2017) Analysis of the chip-splitting performance of a dedicated cutting tool in dry orbital drilling process. Int J Adv Manuf Technol 90:1809–1823

Zhou L, Dong H, Ke Y, Chen GL (2018) Modeling of non-linear cutting forces for dry orbital drilling process based on undeformed chip geometry. Int J Adv Manuf Technol 94:203–216

Su F, Zheng L, Sun FJ, Wang ZH, Deng ZH, Qiu XY (2018) Novel drill bit based on the step-control scheme for reducing the CFRP delamination. J Mater Process Technol 262:157–167

Su F, Deng ZH, Sun FJ, Li SC, Wu QP, Jiang XJ (2019) Comparative analyses of damages formation mechanisms for novel drills based on a new drill-induced damages analytical model. J Mater Process Technol 271:111–125

Chegdani F, Mansori ME (2019) Tribo-functional effects of double-crossed helix on surface finish, cutting friction and tool wear mechanisms during the milling process of natural fiber composites. Wear 426-427:1507–1514

Funding

Special thanks to the National Science Foundation of China (No. 51805164) for funding this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This is an original paper which has neither previously nor simultaneously in whole or in part been submitted anywhere else.

Rights and permissions

About this article

Cite this article

Su, F., Li, C., Li, W. et al. Cutting forces and correlation with the damages during CFRP drill-milling by using novel drill-milling tool. Int J Adv Manuf Technol 108, 2661–2674 (2020). https://doi.org/10.1007/s00170-020-05580-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05580-8