Abstract

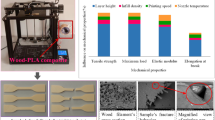

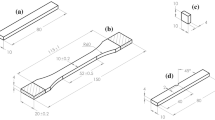

The present study evaluates the effects of manufacturing parameters on the tensile properties of a commercial composite material based upon polylactic acid (PLA) with wood fibers known as Timberfill. The specimens are built through fused filament fabrication (FFF), and the influence of four printing parameters (layer height, fill density, printing velocity, and orientation) is considered through a L27 Taguchi orthogonal array. Tensile tests are applied to obtain the response variable used as output results to perform the ANOVA calculations. Results show that fill density is the most influential parameter on the tensile strength, followed by building orientation and layer height, whereas the printing velocity shows no significant influence. The optimal set of parameters and levels is found, being 75% fill density, 0○Z-axis orientation, 0.4 mm layer height, and 40 mm/s velocity as the best combination. Applying this combination, a 9.37-MPa maximum strength is the highest value obtained for the material. Additionally, five solid injection molded Timberfill specimens were tested as well and the results compared with the FFF samples. The values of the elastic modulus, elastic limit, and maximum strength of the injected samples were almost twofold of those were obtained for the FFF samples, but the maximum elongation of the injected specimens fell sharply.

Similar content being viewed by others

Abbreviations

- AM:

-

Additive manufacturing

- FFF:

-

Fused filament fabrication

- DOE:

-

Design of experiments

- ANOVA:

-

Analysis of variance

References

Jerez-Mesa R, Travieso-Rodriguez JA, Llumà-Fuentes J, Gomez-Gras G, Puig D (2017) Fatigue lifespan study of PLA parts obtained by additive manufacturing. Procedia Manuf 13:872–879

Domingo-Espin M, Travieso-Rodriguez JA, Jerez-Mesa R, Lluma-Fuentes J (2018) Fatigue performance of ABS specimens obtained by fused filament fabrication. Materials. 11:2521

Fayazbakhsh K, Movahedi M, Kalman J (2019) The impact of defects on tensile properties of 3D printed parts manufactured by fused filament fabrication. Mater Today Commun 18:140–148

Morales-Planas S, Minguella-Canela J, Lluma-Fuentes J, Travieso-Rodriguez JA, García-Granada AA (2018) Multi jet fusion PA12 manufacturing parameters for watertightness, strength and tolerances. Materials. 11:1472

Es-Said OS, Foyos J, Noorani R, Mendelson M, Marloth R, Pregger BA (2000) Effect of layer orientation on mechanical properties of rapid prototyped samples. Mater Manuf Process 1:107–122

Sood AK, Ohdar RK, Mahapatra SS (2010) Parametric appraisal of mechanical property of fused deposition modelling processed parts. Mater Des 31:287–295

Fernandez-Vicente M, Calle W, Ferrandiz S, Conejero A (2006) Effect of infill parameters on tensile mechanical behavior in desktop 3D printing. 3D Print Addit Manuf 3:183–192

Laureto JJ, Pearce JM (2018) Anisotropic mechanical property variance between ASTM D638-14 type I and type IV fused filament fabricated specimens. Polym Test 68:294–301

Cwikla G, Grabowik C, Kalinowski K, Paprocka I, Ociepka P (2017) The influence of printing parameters on selected mechanical properties of FDM/FFF 3D-printed parts. IOP Conf Ser Mater Sci Eng 227(no. 1):012033

Marat-Mendes, Rosa M, Guedes M, Leite Baptista R (2018) Effect of fused filament fabrication processing parameters on the mechanical properties of PLA components. XVI PCF

El Magri A, El Mabrouk K, Vaudreuil S, Ebn Touhami M (2019) Mechanical properties of CF-Reinforced PLA Parts Manufactured by Fused Deposition Modeling. J Thermoplast Compos Mater:0892705719847244

Tymrak BM, Kreiger M, Pearce JM (2014) Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater Des 58:242–246

Mazzanti V, Pariante R, Bonanno A, de Ballesteros OR, Mollica F, Filippone G (2019) Reinforcing mechanisms of natural fibers in green composites: role of fibers morphology in a PLA/hemp model system. Compos Sci Technol 180:51–59

Ochi S (2008) Mechanical properties of kenaf fibers and kenaf/PLA composites. Mech Mater 40:446–452

Oksman K, Skrifvars M, Selin JF (2003) Natural fibres as reinforcement in polylactic acid (PLA) composites. Compos Sci Technol 63:1317–1324

Huber T, Müssig J (2008) Fibre matrix adhesion of natural fibres cotton, flax and hemp in polymeric matrices analyzed with the single fibre fragmentation test. Compos Interfaces 15:335–349

Tisserat B, Liu Z, Finkenstadt V, Lewandowski B, Ott S, Reifschneider L (2015) 3D printing biocomposites. J Plast Res [Online early access] Feb 23

Zhao DX, Cai X, Shou GZ, Gu YQ, Wang PX (2016) Study on the preparation of bamboo plastic composite intend for additive manufacturing. Key Eng Mater 667:250–258

Daver F, Lee KP, Brandt M, Shanks R (2018) Cork–PLA composite filaments for fused deposition modelling. Compos Sci Technol 168:230–237

Tao Y, Wang H, Li Z, Li P, Shi S, Q. (2017) Development and application of wood flour-filled polylactic acid composite filament for 3D printing. Materials. 10:339

Xie G, Zhang Y, Lin W (2017) Plasticizer combinations and performance of wood flour–poly (lactic acid) 3D printing filaments. BioResources. 12:6736–6748

Gkartzou E, Koumoulos EP, Charitidis CA (2017) Production and 3D printing processing of bio-based thermoplastic filament. Manuf Rev 4:1

Filgueira D, Holmen S, Melbø JK, Moldes D, Echtermeyer AT, Chinga-Carrasco G (2017) Enzymatic-assisted modification of thermomechanical pulp fibers to improve the interfacial adhesion with poly (lactic acid) for 3D printing. ACS Sustain Chem Eng 5:9338–9346

Stoof D, Pickering K, Zhang Y (2017) Fused deposition Modelling of natural fibre/polylactic acid composites. J Compos Sci 1:8

Kariz M, Sernek M, Obućina M, Kuzman MK (2017) Effect of wood content in FDM filament on properties of 3D printed parts. Mater Today Commun 14:135–140

Guo R, Ren Z, Bi H, Song Y, Xu M (2018) Effect of toughening agents on the properties of poplar wood flour/poly (lactic acid) composites fabricated with fused deposition modeling. Eur Polym J 107:34–45

Depuydt D, Balthazar M, Hendrickx K, Six W, Ferraris E, Desplentere F, Ivens J, Van Vuure AW (2019) Production and characterization of bamboo and flax fiber reinforced polylactic acid filaments for fused deposition modeling (FDM). Polym Compos 2019(40):1951–1963

Ozcelik B, Ozbay A, Demirbas E (2010) Influence of injection parameters and mold materials on mechanical properties of ABS in plastic injection molding. Int Commun Heat Mass Transf 37:1359–1365

Casavola C, Cazzato A, Moramarco V, Pappalettere C (2016) Orthotropic mechanical properties of fused deposition modelling parts described by classical laminate theory. Mater Des 90:453–458

Quintana R, Choi JW, Puebla K, Wicker R (2010) Effects of build orientation on tensile strength for stereolithography-manufactured ASTM D-638 type I specimens. Int J Adv Manuf Technol 46:201–215

Galantucci LM, Lavecchia F, Percoco G (2010) Quantitative analysis of a chemical treatment to reduce roughness of parts fabricated using fused deposition modeling. CIRP Ann 59:247–250

Maidin S, Mohamed AS, Akmal S, Mohamed SB, Wong JHU (2018) Feasibility study of vacuum technology integrated fused deposition modeling to reduce staircase effect. J Fundam Appl Sci 10:633–645

Lederle F, Meyer F, Brunotte GP, Kaldun C, Hübner EG (2016) Improved mechanical properties of 3D-printed parts by fused deposition modeling processed under the exclusion of oxygen. Addit Manuf 1:3–7

Malinauskas M, Rekštytė S, Lukoševičius L, Butkus S, Balčiūnas E, Pečiukaitytė M, Baltriukienė D, Bukelskienė V, Butkevičius A, Kucevičius P, Rutkūnas V (2014) 3D microporous scaffolds manufactured via combination of fused filament fabrication and direct laser writing ablation. Micromachines. 5:839–858

Mazzanti V, Malagutti L, Mollica F (2019) FDM 3D printing of polymers containing natural fillers: a review of their mechanical properties. Polymers. 11:1094

Mohamed OA, Masood SH, Bhowmik JL (2015) Optimization of fused deposition modeling process parameters: a review of current research and future prospects. Adv Manuf 3:42–53

Zandi MD, Jerez-Mesa R, Lluma-Fuentes J, Roa JJ, Travieso-Rodriguez JA (2020) Experimental analysis of manufacturing parameters’ effect on the flexural properties of wood-PLA composite parts built through FFF. Int J Adv Manuf Technol 10:1–4

Endruweit A, Gommer F, Long A, C. (2013) Stochastic analysis of fibre volume fraction and permeability in fibre bundles with random filament arrangement. Compos A: Appl Sci Manuf 49:109–118

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zandi, M.D., Jerez-Mesa, R., Lluma-Fuentes, J. et al. Study of the manufacturing process effects of fused filament fabrication and injection molding on tensile properties of composite PLA-wood parts. Int J Adv Manuf Technol 108, 1725–1735 (2020). https://doi.org/10.1007/s00170-020-05522-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05522-4