Abstract

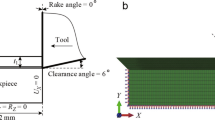

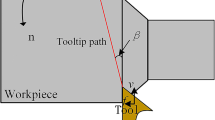

In order to solve the problem of low efficiency and high cost in designing inserts with groove, finite element simulation (FEM) method has been employed to directly simulate the chip breaking condition. However, the current methods tend to involve a large number of cutting experiments and a user subroutine program used for secondary development, causing inconveniency in engineering application. Here, we propose a high-efficient three-dimensional (3D) FEM method to analyze the chip breakage properties of complicate-grooved insert. For the simulation, a three-dimensional cutting simulation model is established by Deform 3D FE package, and the Johnson-Cook (J-C) material constitutive model and Cockcroft-Latham (C-L) ductile fracture criterion are adopted. To verify the validity of the model, the simulations and corresponding turning experiments of AISI 1045 steel are performed with complicate-grooved insert at several combination groups of cutting depth and feed rate. The estimated chip morphology, chip breaking process, and cutting force from the simulation are in good consistency with those from the experiments. Additionally, the comparisons between the simulations and corresponding turning experiments with complicate-grooved insert and flat rake insert are conducted. The results show that the chip breaking groove can significantly change the chip flow angle and the chip geometry and that the complicate-grooved insert can more efficiently promote chip breakage than the flat rake insert. Therefore, the 3D FEM method proposed can be used to effectively investigate the chip formation mechanism and chip breakage properties and has promising application prospects in complicate-grooved insert design and cutting parameter optimization.

Similar content being viewed by others

References

Fang N (1998) Influence of the geometrical parameters of the chip groove on chip breaking performance using new-style chip formers. J Mater Process Technol 74:268–275. https://doi.org/10.1016/S0924-0136(97)00282-3

Buchkremer S, Klocke F, Veselovac D (2016) 3D FEM simulation of chip breakage in metal cutting. Int J Adv Manuf Technol 82(1):645–661. https://doi.org/10.1007/s00170-015-7383-9

Choi JP, Lee SJ (2001) Efficient chip breaker design by predicting the chip breaking performance. Int J Adv Manuf Technol 17(7):489–497. https://doi.org/10.1007/PL00003947

Uhlmann E, Graf von der Schulenburg M, Zettier R (2007) Finite element modeling and cutting simulation of Inconel 718. CIRP Ann-Manuf. Technol. 56(1):61–64. https://doi.org/10.1016/j.cirp.2007.05.017

Klocke F, Lung D, Essig C (2011) 3D FEM model for the prediction of chip breakage. Adv Mater Res 223:142–151. https://doi.org/10.4028/www.scientific.net/AMR.223.142

Zhang X, Wu S, Wang H, Liu CR (2011) Predicting the effects of cutting parameters and tool geometry on hard turning process using finite element method. J Manuf Sci Eng 133(4):1–13. https://doi.org/10.1115/1.4004611

Tang L, Huang J, Xie L (2011) Finite element modeling and simulation in dry hard orthogonal cutting AISI D2 tool steel with CBN cutting tool. Int J Adv Manuf Technol 53:1167–1181. https://doi.org/10.1007/s00170-010-2901-2

Deng WJ, Xia W, Tang Y (2009) Finite element simulation for burr formation near the exit of orthogonal cutting. Int J Adv Manuf Technol 43:1035–1045. https://doi.org/10.1007/s00170-008-1784-y

Arrazola PJ, Özel TR (2010) Investigations on the effects of friction modeling in finite element simulation of machining. Int J Mech Sci 52(1):31–42. https://doi.org/10.1016/j.ijmecsci.2009.10.001

McClain B, Thean W, Maldonado GI, Fang XD (2000) Finite element analysis of chip formation in grooved tool metal cutting. Mach Sci Technol 4(2):305–316. https://doi.org/10.1080/10940340008945712

Ceretti E, Lucchi M, Altan T (1999) FEM simulation of orthogonal cutting: serrated chip formation. J Mater Process Technol 95(1-3):17–26. https://doi.org/10.1016/S0924-0136(99)00261-7

Yen Y, Jain A, Altan T (2004) A finite element analysis of orthogonal machining using different tool edge geometries. J Mater Process Technol 146(1):72–81. https://doi.org/10.1016/S0924-0136(03)00846-X

Özel T (2009) Computational modelling of 3D turning: influence of edge micro-geometry on forces, stresses, friction and tool wear in PCBN tooling. J Mater Process Technol 209(11):5167–5177. https://doi.org/10.1016/j.jmatprotec.2009.03.002

Aurich JC, Bil H (2006) 3D finite element modelling of segmented chip formation [J]. CIRP Ann-Manuf. Technol. 55(1):47–50. https://doi.org/10.1016/S0007-8506(07)60363-1

Guo YB, Liu CR (2002) 3D FEA modeling of hard turning. J Manuf Sci Eng 124(2):189–199. https://doi.org/10.1115/1.1430678

Ceretti E, Lazzaroni C, Menegardo L, Altan T (2000) Turning simulations using a three-dimensional FEM code. J Mater Process Technol 98(1):99–103. https://doi.org/10.1016/S0924-0136(99)00310-6

Haddag B, Makich H, Nouari M, Dhers J (2014) Tribological behaviour and tool wear analyses in rough turning of large-scale parts of nuclear power plants using grooved coated insert. Tribol Int 80:58–70. https://doi.org/10.1016/j.triboint.2014.06.017

Puls H, Klocke F, Lung D (2012) A new experimental methodology to analyse the friction behaviour at the tool-chip interface in metal cutting. Prod Eng Res 6(4):349–354. https://doi.org/10.1007/s11740-012-0386-6

Buchkremer S, Klocke F, Lung D (2014) Analytical study on the relationship between chip geometry and equivalent strain distribution on the free surface of chips in metal cutting. Int J Mech Sci 85:88–103. https://doi.org/10.1016/j.ijmecsci.2014.05.005

Klocke F, Lung D, Veselovac D, Buchkremer S (2015) An analytical model of the temperature distribution in the chip breakage location of metal cutting operations. Procedia CIRP 31:240–245. https://doi.org/10.1016/j.procir.2015.03.090

Puls H, Klocke F, Veselovac D (2016) FEM-based prediction of heat partition in dry metal cutting of AISI 1045. Int J Adv Manuf Technol 86(1):737–745. https://doi.org/10.1007/s00170-015-8190-z

Zhang YC, Mabrouki T, Nelias D, Gong YD (2011) Chip formation in orthogonal cutting considering interface limiting shear stress and damage evolution based on fracture energy approach. Finite Elem Anal Des 47(7):850–863. https://doi.org/10.1016/j.finel.2011.02.016

Klocke F, Lung D, Buchkremer S (2013) Inverse identification of the constitutive equation of Inconel 718 and AISI 1045 from FE machining simulations. Procedia CIRP 8:212–217. https://doi.org/10.1016/j.procir.2013.06.091

Arrazola PJ, Özel T, Umbrello D, Davies M, Jawahir IS (2013) Recent advances in modelling of metal machining processes. CIRP Ann-Manuf Technol. 62(2):695–718. https://doi.org/10.1016/j.cirp.2013.05.006

Zhou L, Huang ST, Wang D, Yu XL (2011) Finite element and experimental studies of the cutting process of SiCp/Al composites with PCD tools. Int J Adv Manuf Technol 52(5):619–626. https://doi.org/10.1007/s00170-010-2776-2

Funding

This work was financially supported by the National Basic Research Program of China (Grant No. 2015CB057304), National Natural Science Foundation of China (Grant No. 51305060), and National Natural Science Foundation of China (Grant No. 51275072).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, L., Liu, J., Ren, Y. et al. 3D FEM simulation of chip breakage in turning AISI1045 with complicate-grooved insert. Int J Adv Manuf Technol 108, 1331–1341 (2020). https://doi.org/10.1007/s00170-020-05460-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05460-1