Abstract

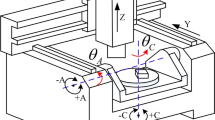

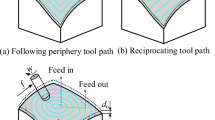

Chatter is one of the challenging topics in the field of metal cutting. The dynamic characteristics of five-axis milling system are complex and variable. Especially in high-speed milling process, the influence of the tool-workpiece interactions and speed effect on milling stability is more obvious. It is necessary to investigate the influence of various interaction effects on milling stability. In this paper, the dynamical model of spindle system was established, and then the model was applied to investigate the influence of gyroscopic effect and centrifugal force on the dynamical characteristics of the tool tip. In order to solve the chatter problem of five-axis flank milling, the extended dynamical model of five-axis flank milling which considers the tool-workpiece interactions and speed effect was established. Based on the established milling dynamical model, the influence mechanism of the spindle system-tool-workpiece interaction effects on five-axis flank milling stability was investigated. The stability lobe diagrams of five-axis flank milling which contains the tool-workpiece interactions and speed effect can be obtained. Experimental results show that the proposed five-axis flank milling dynamical model can predict the milling state more reliable than the traditional ones. The research results are of great significance in preventing five-axis flank milling chatter.

Similar content being viewed by others

Change history

06 June 2020

This original article contained a mistake.

References

Yue CX, Gao HN, Liu XL, Liang SY, Wang LH (2019) A review of chatter vibration research in milling. Chin J Aeronaut 32(2):215–242

Altintas Y, Weck M (2004) Chatter stability of metal cutting and grinding. CIRP Ann-Manuf Technol 53(2):619–642

Sun T, Qin LF, Fu YC, Hong JM (2019) Chatter stability of orthogonal turn-milling analyzed by complete discretization method. Precis Eng 56:87–95

Munoa J, Beudaert X, Dombovari Z, Altintas Y, Budak E, Brecher C, Stepan G (2016) Chatter suppression techniques in metal cutting. CIRP Ann-Manuf Technol 65:785–808

Quintana G, Ciurana J (2011) Chatter in machining processes: a review. Int J Mach Tools Manuf 51(5):363–376

Altintas Y, Budak E (1995) Analytical prediction of stability lobes in milling. CIRP Ann-Manuf Technol 44(1):357–362

Budak E, Altintas Y (1998) Analytical prediction of chatter stability in milling—part I: general formulation. J Dyn Syst Meas Control 120(1):22–30

Merdol SD, Altintas Y (2004) Multi frequency solution of chatter stability for low immersion milling. J Manuf Sci Eng-Trans ASME 126(3):459–466

Zhu LD, Liu BG, Chen HY (2018) Research on chatter stability in milling and parameter optimization based on process damping. J Vib Control 24(12):2642–2655

Ding Y, Zhu LM, Zhang XJ (2010) Ding H (2010) a full-discretization method for prediction of milling stability. Int J Mach Tools Manuf 50(5):502–509

Zhou K, Feng PF, Xu C, Zhang JF, Wu ZJ (2017) High-order full-discretization methods for milling stability prediction by interpolating the delay term of time-delayed differential equations. Int J Adv Manuf Technol 93(5–8):2201–2214

Ding Y, Zhu LM, Zhang XJ, Ding H (2011) Numerical integration method for prediction of milling stability. J Manuf Sci Eng-Trans ASME 133(3):1–9

Zhang Z, Li HG, Meng G, Liu C (2015) A novel approach for the prediction of the milling stability based on the Simpson method. Int J Mach Tools Manuf 99:43–47

Yan BL, Zhu LD (2019) Research on milling stability of thin-walled parts based on improved multi-frequency solution. Int J Adv Manuf Technol 102(1–4):431–441

Ning JS, Zhu LD (2019) Parametric design and surface topography analysis of turbine blade processing by turn-milling based on CAM. Int J Adv Manuf Technol 104(9–12):3977–3990

Dun YC, Zhu LD, Wang SH (2020) Multi-modal method for chatter stability prediction and control in milling of thin-walled workpiece. Appl Math Model 80:602–624

Liu CF, Zhu LD, Ni CB (2018) Chatter detection in milling process based on VMD and energy entropy. Mech Syst Signal Process 105:169–182

Ahmadi K, Altintas Y (2014) Identification of machining process damping using output-only modal analysis. J Manuf Sci Eng-Trans ASME 136(5):1–13

Tunc LT, Budak E (2013) Identification and modeling of process damping in milling. J Manuf Sci Eng-Trans ASME 135(2):1–12

Gurdal O, Ozturk E, Sims ND (2016) Analysis of process damping in milling. Procedia CIRP 55:152–157

Sisson TR, Kegg RL (1969) An explanation of low-speed chatter effects. J Eng Ind 91(4):951–958

Peters J, Vanherck P, Brussel HV (1971) The measurement of the dynamic cutting coefficient. CIRP Ann-Manuf Technol 21(2):129–136

Tlusty J (1978) Analysis of the state of research in cutting dynamics. CIRP Ann-Manuf Technol 27(2):583–589

Tlusty J, Ismail F (1983) Special aspects of chatter in milling. J Vib Acoust Stress Reliab Des-T ASME 105(1):24–32

Wu DW (1989) A new approach of formulating the transfer function for dynamic cutting process. J Eng Ind-Trans ASME 111(1):37–47

Ahmadi K, Ismail F (2012) Stability lobes in milling including process damping and utilizing multi-frequency and semi-discretization methods. Int J Mach Tools Manuf 54-55:46–54

Ahmadi K, Ismail F (2011) Analytical stability lobes including nonlinear process damping effect on machining chatter. Int J Mach Tools Manuf 51(4):296–308

Wang DQ, Löser M, Ihlenfeldt S, Wang XB, Liu ZB (2019) Milling stability analysis with considering process damping and mode shapes of in-process thin-walled workpiece. Int J Mech Sci 159:382–397

Wan M, Feng J, Ma YC, Zhang WH (2017) Identification of milling process damping using operational modal analysis. Int J Mach Tools Manuf 122:120–131

Feng J, Wan M, Gao TQ, Zhang WH (2018) Mechanism of process damping in milling of thin-walled workpiece. Int J Mach Tools Manuf 134:1–19

Zhang XJ, Xiong CH, Ding Y, Feng MJ, Xiong YL (2012) Milling stability analysis with simultaneously considering the structural mode coupling effect and regenerative effect. Int J Mach Tools Manuf 53(1):127–140

Tang XW, Peng FY, Yan R, Gong YH, Li X (2016) An effective time domain model for milling stability prediction simultaneously considering multiple modes and cross-frequency response function effect. Int J Adv Manuf Technol 86(1–4):1037–1054

Li ZY, Jiang SL, Sun YW (2019) Chatter stability and surface location error predictions in milling with mode coupling and process damping. Proc IMechE Part B: J Eng Manuf 233(3):686–698

Ozturk E, Bilkhu R, Turner S (2012) A study on the effects of spindle speed on tool tip dynamics. The 15th International Conference on Machine Design and Production, Denizli

Zorzi ES, Nelson HD (1977) Finite element simulation of rotor-bearing systems with internal damping. J Eng Power 99(1):71–76

Nelson HD (1980) A finite rotating shaft element using Timoshenko beam theory. J Mech Design 102:793–803

Lin CW, Tu JF, Kamman J (2003) An integrated thermo-mechanical-dynamic model to characterize motorized machine tool spindles during very high speed rotation. Int J Mach Tools Manuf 43(10):1035–1050

Wardle FP, Lacey SJ, Poon SY (1983) Dynamic and static characteristics of a wide speed range machine tool spindle. Precis Eng 5(4):175–183

Cao YZ, Altintas Y (2004) A general method for the modeling of spindle-bearing systems. J Mech Design 126(6):1089–1104

Jones AB (1960) A general theory for elastically constrained ball and radial roller bearings under arbitrary load and speed conditions. J Basic Eng 309-320

Cao HR, Li B, He ZJ (2012) Chatter stability of milling with speed-varying dynamics of spindles. Int J Mach Tools Manuf 52(1):50–58

Liu JF, Lai T, Tie GP (2018) Influence of thermo-mechanical coupled behaviors on milling stability of high speed motorized spindles. Precis Eng 52:94–105

Ferry WB, Altintas Y (2008) Virtual five-axis flank milling of jet engine impellers—part I: mechanics of five-axis flank milling. J Manuf Sci Eng-Trans ASME 130(1):1–11

Ahmadi K, Ismail F (2012) Modeling chatter in peripheral milling using the semi discretization method. CIRP J Manuf Sci Technol 5(2):77–86

Ji YJ, Wang XB, Liu ZB, Wang HJ, Wang KJ, Wang DQ (2019) Stability prediction of five-axis ball-end finishing milling by considering multiple interaction effects between the tool and workpiece. Mech Syst Signal Process 131:261–287

Cao YZ, Altintas Y (2007) Modeling of spindle-bearing and machine tool systems for virtual simulation of milling operations. Int J Mach Tools Manuf 47:1342–1350

Ertürk A, Ozguven HN, Budak E (2006) Analytical modeling of spindle–tool dynamics on machine tools using Timoshenko beam model and receptance coupling for the prediction of tool point FRF. Int J Mach Tools Manuf 46(15):1901–1912

Liu ZF, Ma SM, Cai LG, Guo TN, Zhao YS (2012) Timoshenko beam-based stability and natural frequency analysis for heavy load mechanical spindles. J Mech Sci Technol 26(11):3375–3388

Cao YZ (2006) Modeling of high-speed machine-tool spindle systems. The University of British Columbia, Vancouver

Feng W, Liu BG, Yao B, Cui ZM, He QS, Wang X (2018) An integrated prediction model for the dynamics of machine tool spindles. Mach Sci Technol 22(6):968–988

Hu T, Yin GF, Sun MN (2014) Model based research of dynamic performance of shaft-bearing system in high-speed field. Shock Vib 1-12

Ozturk E, Tunc LT, Budak E (2009) Investigation of lead and tilt angle effects in 5-axis ball-end milling processes. Int J Mach Tools Manuf 49(14):1053–1062

Ozturk E, Budak E (2007) Modeling of 5-axis milling processes. Mach Sci Technol 11(3):287–311

Wang SB (2015) Automated five-axis tool path generation based on dynamic analysis. National University of Singapore, Singapore

Wang SB, Geng L, Zhang YF, Liu K, Ng TE (2016) Chatter-free cutter postures in five-axis machining. Proc Inst Mech Eng Part B-J Eng Manuf 230(8):1428–1439

Schmitz TL, Smith KS (2008) Machine dynamics—frequency response to improved productivity. Springer, Berlin

Ji YJ, Wang XB, Liu ZB, Wang HJ, Jiao L, Lu Z, Huang T (2018) Milling stability prediction with simultaneously considering the multiple factors coupling effects—regenerative effect, mode coupling, and process damping. Int J Adv Manuf Technol 97(5–8):2509–2527

Lu YA, Ding Y, Zhu LM (2017) Dynamics and stability prediction of five-Axis flat-end milling. J Manuf Sci Eng-Trans ASME 139(6):1–11

Sadeghipour K, Cowley A (1988) The effect of viscous damping and mass distribution on the dynamic behaviour of a spindle-bearing system. Int J Mach Tools Manuf 28(1):69–77

Elbestawi MA, Ismail F, Du R, Ullagaddi BC (1994) Modelling machining dynamics including damping in the tool-workpiece interface. J Eng Ind 116(4):435–439

Funding

This work is supported by the National Natural Science Foundation of China (Grant Nos. 51375055 and 51575055).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original version of this article was revised: Equation 39 is missing in the original published paper.

Appendices

Appendix 1. Details of Tx1(90°),Tx2(90°),Ty(θB), Tz(θC),(TF‐ to ‐W)−1in Eq.(17)

Appendix 2. Details of p1, p2, p3, p4, e1, e2, e3, e4, o1, o2, o3, o4, f1, f2, f3, f4 in Eq. (47)

Rights and permissions

About this article

Cite this article

Ji, Y., Wang, X., Liu, Z. et al. Five-axis flank milling stability prediction by considering the tool-workpiece interactions and speed effect. Int J Adv Manuf Technol 108, 2037–2060 (2020). https://doi.org/10.1007/s00170-020-05251-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05251-8