Abstract

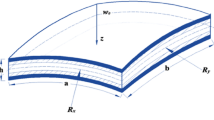

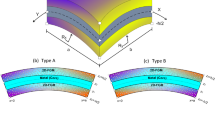

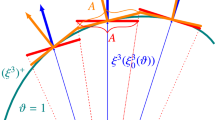

This paper systematically studies the effect of temperature and moisture on bistable anti-symmetric composite cylindrical shells and variable stiffness composite structures in the hygrothermal environment. Based on the classical laminate theory, together with the principle of minimum potential energy, an analytical model is developed to predict the bistable behavior of those bistable anti-symmetric composite cylindrical shells in the hygrothermal environment. Finite element simulates the change of curvature of bistable anti-symmetric composite cylindrical shells. An experiment of temperature and moisture was presented to measure the principal curvatures and twisting curvatures in the hygrothermal environment. The numerical and experimental methods are employed for predicting and verifying the theoretical results. The temperature and moisture have prominent effects on the bistable anti-symmetric composite cylindrical shells. In order to optimize shell’s shape for being used in some particular situations, a novel approach that may control the bistable shell’s curvatures by adjusting the temperature or moisture are presented. For the moisture variation take a long time to affect the structure curvature, the twisting curvature is eliminated by adjusting the temperature to the given value. Finally, the change of variable stiffness composite structures in the process of moisture absorption is discussed, and the load-displacement test of variable stiffness composite structures is carried out at the maximum saturation value.

Similar content being viewed by others

References

Zhang Z, Li Y, Yu X et al (2019) Bistable morphing composite structures: a review[J]. Thin-Walled Struct 142:74–97

Zhang Z, Li Y, Wu H et al (2018) Mechanical analysis of functionally graded graphene oxide-reinforced composite beams based on the first-order shear deformation theory[J]. Mech Adv Mater Struct

Gigliotti M, Minervino M, Grandidier JC et al (2012) Predicting loss of bifurcation behaviour of 0/90 unsymmetric composite plates subjected to environmental loads[J]. Compos Struct 94(9):2793–2808

Pellegrini SP, Tolou N, Schenk M et al (2013) Bistable vibration energy harvesters: a review[J]. J Intell Mater Syst Struct 24(11):1303–1312

Zhang Z, Ye G, Wu H et al (2017) Bistable behaviour and microstructure characterization of carbon fiber/epoxy resin anti-symmetric laminated cylindrical shell after thermal exposure[J]. Compos Sci Technol 138:91–97

Portela P, Camanho P, Weaver P et al (2008) Analysis of morphing, multi stable structures actuated by piezoelectric patches[J]. Comput Struct 86(3):347–356

Gude M, Hufenbach W, Kirvel C (2011) Piezoelectrically driven morphing structures based on bistable unsymmetric laminates[J]. Compos Struct 93(2):377–382

Tawfik SA, Dancila DS, Armanios E (2011) Unsymmetric composite laminates morphing via piezoelectric actuators[J]. Compos A Appl Sci Manuf 42(7):748–756

Zhang Z, Ma W, Wu H, Wu H, Jiang S, Chai G (2018) A rigid thick Miura-Ori structure driven by bistable carbon fibre-reinforced polymer cylindrical shell[J]. Compos Sci Technol 167:411–420

Xiong C, Lei Y, Yao X (2011) Dynamic experimental study of deployable composite structure[J]. Appl Compos Mater 18(5):439–448

Soykasap Ö (2009) Deployment analysis of a self-deployable composite boom[J]. Compos Struct 89(3):374–381

Lei YM, Yao XF (2010) Experimental study of bistable behaviors of deployable composite structure[J]. J Reinf Plast Compos 29(6):865–873

Zhang Z, Wu H, He X et al (2013) The bistable behaviors of carbon-fiber/epoxy anti-symmetric composite shells[J]. Compos Part B 47:190–199

Giddings PF, Kim HA, Salo AIT et al (2011) Modelling of piezoelectrically actuated bistable composites[J]. Mater Lett 65(9):1261–1263

Zhang Z, Li X, Yu X et al (2019) Magnetic actuation bionic robotic gripper with bistable morphing structure[J]. Compos Struct 229:111422

Dai F, Li H, Du S (2013) A multi-stable lattice structure and its snap-through behavior among multiple states[J]. Compos Struct 97:56–63

Daynes S, Nall SJ, Weaver PM, et al (2009) On a bistable flap for an airfoil[J]. AIAA Paper

Zhang Z, Chen D, Wu H et al (2016) Non-contact magnetic driving bioinspired Venus flytrap robot based on bistable anti-symmetric CFRP structure[J]. Compos Struct 135:17–22

Daynes S, Weaver PM, Trevarthen JA (2011) A morphing composite air inlet with multiple stable shapes[J]. J Intell Mater Syst Struct 22(9):961–973

Daton-Lovett A (1996) An extendible member, patent cooperation treaty application [P]. Patent No. PCT/GB97/00839

Dano ML, Hyer MW (1998) Thermally-induced deformation behavior of unsymmetric laminates[J]. Int J Solids Struct 35(17):2101–2120

Kebadze E, Guest SD, Pellegrino S (2004) Bistable prestressed shell structures[J]. Int J Solids Struct 41(11–12):2801–2820

Galletly DA, Guest SD (2004) Bistable composite slit tubes. I. A beam model[J]. Int J Solids Struct 41(16):4517–4533

Galletly DA, Guest SD (2004) Bistable composite slit tubes. II. A shell model[J]. Int J Solids Struct 41(16):4503–4516

Zhang Z, Ye G, Wu H et al (2015) Prediction and control of the bi-stable functionally graded composites by temperature gradient field[J]. Mater Sci 21(4):543–548

Pirrera A, Avitabile D, Weaver PM (2012) On the thermally induced bistability of composite cylindrical shells for morphing structures[J]. Int J Solids Struct 49(5):685–700

Zhang Z, Li Y, Wu H et al (2018) Viscoelastic bistable behaviour of antisymmetric laminated composite shells with time-temperature dependent properties[J]. Thin-Walled Struct 122:403–415

Norman A, Guest S, Seffen K (2007) Novel multistable corrugated structures [C]. Collect Tech Pap AIAA/ASME/ASCE/AHS/ASC Struct Struct Dyn Mater Conf 6:6379–6390

Zhang Z, Wu H, Ye G et al (2016) Experimental study on bistable behaviour of anti-symmetric laminated cylindrical shells in thermal environments[J]. Compos Struct 144:24–32

Zhang Z, Ye D, Li F et al (2018) Experimental study of the influence levels of different vehicle seat adjustments on the fore-and-aft modal characteristics using the orthogonal array method [J]. P I Mech Eng D-J Aut 232(2):212–219

Zhang Z, Wu H, Ye G et al (2014) Systematic experimental and numerical study of bistable snap processes for anti-symmetric cylindrical shells[J]. Compos Struct 112:368–377

Zhang Z, Chen B, Lu C et al (2017) A novel thermo-mechanical anti-icing/de-icing system using bi-stable laminate composite structures with superhydrophobic surface[J]. Compos Struct 180:933–943

Dong YH, Zhang YF, Li YH (2017) An analytical formulation for postbuckling and buckling vibration of micro-scale laminated composite beams considering hygrothermal effect[J]. Compos Struct 170:11–25

Cantera MA, Romera JM, Adarraga I et al (2012) Hygrothermal effects in composites: influence of geometry and determination of transverse coefficient of thermal expansion[J]. J Reinf Plast Compos 31(19):1270–1281

Zhang Z, Ye G, Wu H et al (2015) Thermal effect and active control on bistable behaviour of anti-symmetric composite shells with temperature-dependent properties[J]. Compos Struct 124:263–271

Qin Y, Li YH (2017) Influences of hygrothermal environment and installation mode on vibration characteristics of a rotating laminated composite beam[J]. Mech Syst Signal Process 91:23–40

Qin Y, Li X, Yang EC et al (2016) Flapwise free vibration characteristics of a rotating composite thin-walled beam under aerodynamic force and hygrothermal environment[J]. Compos Struct 153:490–503

Suh DW, Ku MK, Nam JD et al (2001) Equilibrium water uptake of epoxy/carbon fiber composites in hygrothermal environmental conditions[J]. J Compos Mater 35(3):264–278

Jiang BK, Xu J, Li YH (2014) Flapwise vibration analysis of a rotating composite beam under hygrothermal environment[J]. Compos Struct 117:201–211

Shen CH, Springer GS (1976) Moisture absorption and desorption of composite materials[J]. J Compos Mater 10(1):2–20

Li X, Li YH, Qin Y (2016) Free vibration characteristics of a spinning composite thin-walled beam under hygrothermal environment[J]. Int J Mech Sci 119:253–265

Moore M, Ziaei-Rad S, Salehi H (2013) Thermal response and stability characteristics of bistable composite laminates by considering temperature dependent material properties and resin layers[J]. Appl Compos Mater 20(1):87–106

Eckstein E, Pirrera A, Weaver PM (2013) Morphing high-temperature composite plates utilizing thermal gradients[J]. Compos Struct 100:363–372

Zhang Z, Pan H, Wu H et al (2018) Hygroscopic influence on bistable characteristics of antisymmetric composite cylindrical shells: an experimental study[J]. J Compos Mater 52(26):3565–3577

Choi HS, Ahn KJ, Nam JD et al (2001) Hygroscopic aspects of epoxy/carbon fiber composite laminates in aircraft environments[J]. Compos A Appl Sci Manuf 32(5):709–720

Abdel-Magid B, Ziaee S, Gass K et al (2005) The combined effects of load, moisture and temperature on the properties of E-glass/epoxy composites[J]. Compos Struct 71(3):320–326

Jana RN, Bhunia H (2008) Hygrothermal degradation of the composite laminates from woven carbon/SC-15 epoxy resin and woven glass/SC-15 epoxy resin[J]. Polym Compos 29(6):664–669

Hufenbach W, Gude M, Czulak A (2006) Actor-initiated snap-through of unsymmetric composites with multiple deformation states[J]. J Mater Process Technol 175(1):225–230

Hyer MW (1982) The room-temperature shapes of four-layer unsymmetric cross-ply laminates[J]. J Compos Mater 16(4):318–340

Barker AJ, Vangerko H (1983) Temperature dependence of elastic constants of CFRP[J]. Composites 14(1):52–56

Rahman T, Ijsselmuiden ST, Abdalla MM et al (2011) Postbuckling analysis of variable stiffness composite plates using a finite element-based perturbation method[J]. Int J Struct Stab Dyn 11(04):735–753

Mattioni F, Weaver P M, Potter K D, et al (2008) The application of thermally induced multistable composites to morphing a ircraft structures[C]. Proc. SPIE 6930:693012

Arrieta AF, Kuder IK, Rist M et al (2014) Passive load alleviation aerofoil concept with variable stiffness multi-stable composites[J]. Compos Struct 116:235–242

Kuder IK, Arrieta AF, Rist M et al (2016) Aeroelastic response of a selectively compliant morphing aerofoil featuring integrated variable stiffness bi-stable laminates[J]. J Intell Mater Syst Struct 27(14):1949–1966

Diaconu CG, Weaver PM, Mattioni F (2008) Concepts for morphing airfoil sections using bi-stable laminated composite structures[J]. Thin-Walled Struct 46(6):689–701

Arrieta AF, Kuder IK, Waeber T et al (2014) Variable stiffness characteristics of embeddable multi-stable composites[J]. Compos Sci Technol 97:12–18

Daynes S, Nall SJ, Weaver PM et al (2010) Bistable composite flap for an airfoil[J]. J Aircr 47(1):334–338

Zhang Z, Wu H, Wu H et al (2013) Bistable characteristics of irregular anti-symmetric lay-up composite cylindrical shells[J]. Int J Struct Stab Dyn 13(6):1350029

Mansfield EH (2005) The bending and stretching of plates[M]. Cambridge university press

Liu J, Qiao W, Liu J et al (2015) High temperature indentation behaviors of carbon fiber composite pyramidal truss structures[J]. Compos Struct 131:266–272

Ma W, Zheng Z, Zhang H, Yang L, Wu H, Jiang S, Chai G (2019) An origami-inspired cube pipe structure with bistable anti-symmetric CFRP shells driven by magnetic field. Smart Mater Struct 28(2):025028

Liu J, Zhou Z, Wu L et al (2013) Mechanical behavior and failure mechanisms of carbon fiber composite pyramidal core sandwich panel after thermal exposure[J]. J Mater Sci Technol 29(9):846–854

Iqbal K, Pellegrino S, Daton-Lovett A (2000) Bi-stable composite slit tubes[C]//IUTAM-IASS symposium on deployable structures: theory and applications. Springer Netherlands: 153–162

Funding

This research was supported by the National Natural Science Foundation of China (Grant Nos. 51675485, 11672269, 51775510) and the Zhejiang Provincial Natural Science Foundation of China (Grant No. LR18E050002).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chai, H., Li, Y., Zhang, Z. et al. Systematic analysis of bistable anti-symmetric composite cylindrical shells and variable stiffness composite structures in hygrothermal environment. Int J Adv Manuf Technol 108, 1091–1107 (2020). https://doi.org/10.1007/s00170-019-04887-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04887-5