Abstract

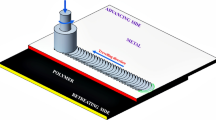

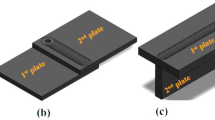

Newly, linear friction-stir welding (FSW) was introduced and implemented as a very effective and emerging solid-state technology for the dissimilar joining of metals and non-metals such as polymers. This kind of joint design is very interesting for structural applications especially in the case of the automotive industry. In this regard, several combinations of materials in terms of metals (mainly focused on aluminum) and polymers (mostly thermoplastic compounds) were assessed in two joint designs as butt and lap in terms of processing parameters optimization, microstructural features, interfacial bonding, and mechanical behavior. This systematic review article deals with overviewing the previous studies on this specific object to categorize the existing knowledge and open some new windows for future developments.

Similar content being viewed by others

References

Cho JH, Jae Kim W, Gil Lee C (2014) Texture and microstructure evolution and mechanical properties during friction stir welding of extruded aluminum billets. Mater Sci Eng A 597:314–323

Garcés JM, Moll DJ, Bicerano J, Fibiger R, McLeod DG (2000) Polymeric nanocomposites for automotive applications. Adv Mater 12(23):1835–1839

Oliveira PHF, Amancio-Filho ST, dos Santos JF, Hage E Jr (2010) Preliminary study on the feasibility of friction spot welding in PMMA. Mater Lett 64(19):2098–2101

Bilici MK, Yükler Aİ, Kurtulmuş M (2011) The optimization of welding parameters for friction stir spot welding of high density polyethylene sheets. Mater Des 32(7):4074–4079

Cole GS, Sherman AM (1995) Light weight materials for automotive applications. Mater Charact 35(1):3–9

Amancio-Filho ST, dos Santos JF (2009) Joining of polymers and polymer–metal hybrid structures: recent developments and trends. Polym Eng Sci 49(8):1461–1476

David E, Lazar A (2003) Adhesive bonding between aluminium and polytetrafluoroethylene. J Mater Process Technol 143(144):191–194

Yusof F, Yukio M, Yoshiharu M, Abdul Shukor MH (2012) Effect of anodizing on pulsed Nd:YAG laser joining of polyethylene terephthalate (PET) and aluminium alloy (A5052). Mater Des 37:410–415

Grujicic M, Sellappan V, Omar MA, Seyr N, Obieglo A, Erdmann M, Holzleitner J (2008) An overview of the polymer-to-metal direct-adhesion hybrid technologies for load-bearing automotive components. J Mater Process Technol 197(1–3):363–373

Wahba M, Kawahito Y, Katayama S (2011) Laser direct joining of AZ91D thixomolded mg alloy and amorphous polyethylene terephthalate. J Mater Process Technol 211(6):1166–1174

Goushegir SM, dos Santos JF, Amancio-Filho ST (2014) Friction spot joining of aluminum AA2024/carbon-fiber reinforced poly(phenylene sulfide) composite single lap joints: microstructure and mechanical performance. Mater Des 54:196–206

Arici A, Sinmazçelýk T (2005) Effects of double passes of the tool on friction stir welding of polyethylene. J Mater Sci 40(12):3313–3316

Liu FC, Liao J, Nakata K (2014) Joining of metal to plastic using friction lap welding. Mater Des 54:236–244

Tres PA (2014) 5 - welding techniques for plastics. In: Tres PA (ed) Designing plastic parts for assembly (seventh edition). Hanser, pp 83–166

Jones I (2013) 10 - Laser welding of plastics*. In: Katayama S (ed) Handbook of laser welding technologies. Woodhead Publishing, pp 280–301e

Bergmann JP, Stambke M (2012) Potential of laser-manufactured polymer-metal hybrid joints. Phys Procedia 39:84–91

Berry DH, Namkanisorn A (2005) Fracture toughness of a Silane coupled polymer-metal Interface: Silane concentration effects. J Adhes 81(3–4):347–370

Matheny MP, Graff KF (2015) 11 - ultrasonic welding of metals. In: Gallego-Juárez JA, Graff KF (eds) Power ultrasonics. Woodhead Publishing, Oxford, pp 259–293

Yan P, Güngör ÖE, Thibaux P, Liebeherr M, Bhadeshia HKDH (2011) Tackling the toughness of steel pipes produced by high frequency induction welding and heat-treatment. Mater Sci Eng A 528(29–30):8492–8499

Abibe AB, Amancio-Filho ST, dos Santos JF, Hage E Jr (2013) Mechanical and failure behaviour of hybrid polymer–metal staked joints. Mater Des 46:338–347

Blaga L, Bancilă R, dos Santos JF, Amancio-Filho ST (2013) Friction riveting of glass–fibre-reinforced polyetherimide composite and titanium grade 2 hybrid joints. Mater Des 50:825–829

Balle F, Wagner G, Eifler D (2007) Ultrasonic spot welding of aluminum sheet/carbon fiber reinforced polymer – joints. Mater Werkst 38(11):934–938

Balle F, Wagner G, Eifler D (2009) Ultrasonic metal welding of Aluminium sheets to carbon fibre reinforced thermoplastic composites. Adv Eng Mater 11(1–2):35–39

Balle F, Eifler D (2012) Statistical test planning for ultrasonic welding of dissimilar materials using the example of aluminum-carbon fiber reinforced polymers (CFRP) joints, Statistische Versuchsplanung zum Ultraschallschweißen artfremder Werkstoffe am Beispiel von Aluminium-Kohlefaser-Kunststoff-Verbunden (CFK). Mater Werkst 43(4):286–292

Goushegir SM, dos Santos JF, Amancio-Filho ST (2015) Influence of process parameters on mechanical performance and bonding area of AA2024/carbon-fiber-reinforced poly(phenylene sulfide) friction spot single lap joints. Mater Des 83:431–442

Mitschang P, Velthuis R, Didi M (2013) Induction spot welding of metal/CFRPC hybrid joints. Adv Eng Mater 15(9):804–813

He X, Gu F, Ball A (2014) A review of numerical analysis of friction stir welding. Prog Mater Sci 65:1–66

Nandan R, DebRoy T, Bhadeshia HKDH (2008) Recent advances in friction-stir welding – process, weldment structure and properties. Prog Mater Sci 53(6):980–1023

Khodabakhshi F, Arab SM, Švec P, Gerlich AP (2017) Fabrication of a new Al-mg/graphene nanocomposite by multi-pass friction-stir processing: dispersion, microstructure, stability, and strengthening. Mater Charact 132:92–107

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R 50(1–2):1–78

Khodabakhshi F, Gerlich AP, Švec P (2017) Fabrication of a high strength ultra-fine grained Al-mg-SiC nanocomposite by multi-step friction-stir processing. Mater Sci Eng A 698:313–325

Khodabakhshi F, Gerlich AP (2018) Potentials and strategies of solid-state additive friction-stir manufacturing technology: a critical review. J Manuf Process 36:77–92

Simar A, Bréchet Y, de Meester B, Denquin A, Gallais C, Pardoen T (2012) Integrated modeling of friction stir welding of 6xxx series Al alloys: process, microstructure and properties. Prog Mater Sci 57(1):95–183

Khodabakhshi F, Gerlich AP, Švec P (2017) Reactive friction-stir processing of an Al-Mg alloy with introducing multi-walled carbon nano-tubes (MW-CNTs): microstructural characteristics and mechanical properties. Mater Charact 131:359–373

Rafiei R, Moghaddam AO, Hatami M, Khodabakhshi F, Abdolahzadeh A, Shokuhfar A (2017) Microstructural characteristics and mechanical properties of the dissimilar friction-stir butt welds between an Al–mg alloy and A316L stainless steel. Int J Adv Manuf Technol 90(9–12):2785–2801

Rafiei R, Shamanian M, Fathi MH, Khodabakhshi F (2018) Dissimilar friction-stir lap-welding of aluminum-magnesium (AA5052) and aluminum-copper (AA2024) alloys: microstructural evolution and mechanical properties. Int J Adv Manuf Technol 94(9):3713–3730

Khodabakhshi F, Ghasemi Yazdabadi H, Kokabi AH, Simchi A (2013) Friction stir welding of a P/M Al–Al2O3 nanocomposite: microstructure and mechanical properties. Mater Sci Eng A 585:222–232

Khodabakhshi F, Marzbanrad B, Shah L, Jahed H, Gerlich A (2017) Friction-stir processing of a cold sprayed AA7075 coating layer on the AZ31B substrate: structural homogeneity, microstructures and hardness. Surf Coat Technol 331:116–128

Khodabakhshi F, Simchi A, Kokabi AH, Gerlich AP (2016) Similar and dissimilar friction-stir welding of an PM aluminum-matrix hybrid nanocomposite and commercial pure aluminum: microstructure and mechanical properties. Mater Sci Eng A 666:225–237

Khodabakhshi F, Simchi A, Kokabi AH, Gerlich AP, Nosko M, Švec P (2017) Influence of hard inclusions on microstructural characteristics and textural components during dissimilar friction-stir welding of an PM Al–Al2O3–SiC hybrid nanocomposite with AA1050 alloy. Sci Technol Weld Join 22(5):412–427

Ratanathavorn W, Melander A (2015) Dissimilar joining between aluminium alloy (AA 6111) and thermoplastics using friction stir welding. Sci Technol Weld Join 20(3):222–228

Khodabakhshi F, Haghshenas M, Sahraeinejad S, Chen J, Shalchi B, Li J, Gerlich AP (2014) Microstructure-property characterization of a friction-stir welded joint between AA5059 aluminum alloy and high density polyethylene. Mater Charact 98:73–82

Aghajani Derazkola H, Khodabakhshi F (2019) Intermetallic compounds (IMCs) formation during dissimilar friction-stir welding of AA5005 aluminum alloy to St-52 steel: numerical modeling and experimental study. Int J Adv Manuf Technol 100:2401–2422

Derazkola HA, Elyasi M (2018) The influence of process parameters in friction stir welding of Al-mg alloy and polycarbonate. J Manuf Process 35:88–98

Huang Y, Meng X, Wang Y, Xie Y, Zhou L (2018) Joining of aluminum alloy and polymer via friction stir lap welding. J Mater Process Technol 257:148–154

Huang Y, Meng X, Xie Y, Wan L, Lv Z, Cao J, Feng J (2018) Friction stir welding/processing of polymers and polymer matrix composites. Compos Part A 105:235–257

Moshwan R, Rahmat SM, Yusof F, Hassan MA, Hamdi M, Fadzil M (2014) Dissimilar friction stir welding between polycarbonate and AA 7075 aluminum alloy. Int J Mater Res 106(3):258–266

Patel AR, Dalwadi CG, Rana HG (2016) A review: dissimilar material joining of metal to polymer using friction stir welding (FSW), IJSTE. Int J Sci Tech Eng 2(10):702–706

Rahmat SM, Hamdi M, Yusof F, Moshwan R (2014) Preliminary study on the feasibility of friction stir welding in 7075 aluminium alloy and polycarbonate sheet. Mater Res Innov 18(sup6):S6–515-S6-519

Derazkola HA, Kashiry Fard R, Khodabakhshi F (2018) Effects of processing parameters on the characteristics of dissimilar friction-stir-welded joints between AA5058 aluminum alloy and PMMA polymer. Weld World 62(1):117–130

Derazkola HA, Khodabakhshi F, Simchi A (2018) Friction-stir lap-joining of aluminium-magnesium/poly-methyl-methacrylate hybrid structures: thermo-mechanical modelling and experimental feasibility study. Sci Technol Weld Join 23(1):35–49

Shahmiri H, Movahedi M, Kokabi AH (2017) Friction stir lap joining of aluminium alloy to polypropylene sheets. Sci Technol Weld Join 22(2):120–126

H.C M, Kailas SV (2018) Fabrication of localised aluminium foam by a novel polymeric blowing agent. Mater Charact 142:340–351

Aghajani Derazkola H, Simchi A (2018) Effects of alumina nanoparticles on the microstructure, strength and wear resistance of poly(methyl methacrylate)-based nanocomposites prepared by friction stir processing. J Mech Behav Biomed Mater 79:246–253

Ali AA, El-Meniawi MAH, Khafagi SM (2015) A novel Bi-processing technique for metal matrix nanocomposites. Int J Adv Manuf Technol 78(5):907–915

Barmouz M, Shahi P, Asadi P (2014) 14 - friction stir welding/processing of polymeric materials. In: Givi MKB, Asadi P (eds) Advances in friction-stir welding and processing. Woodhead Publishing, pp 601–670

Okada T, Uchida S, Nakata K (2014) Direct joining of aluminum alloy and plastic sheets by friction lap processing. Mater Sci Forum 794-796:395–400

Khodabakhshi F, Haghshenas M, Chen J, Shalchi Amirkhiz B, Li J, Gerlich AP (2017) Bonding mechanism and interface characterisation during dissimilar friction stir welding of an aluminium/polymer bi-material joint. Sci Technol Weld Join 22(3):182–190

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Haghshenas, M., Khodabakhshi, F. Dissimilar friction-stir welding of aluminum and polymer: a review. Int J Adv Manuf Technol 104, 333–358 (2019). https://doi.org/10.1007/s00170-019-03880-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03880-2