Abstract

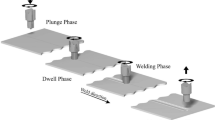

The present work addresses the feasibility of friction stir butt welding of dissimilar Al6063 to polypropylene for cylindrical and threaded tool pin profile at different tool positions like tool offsetting and slotted edge–based base plate design as bridle joint to improve the weld quality. The new slotted edge–based design using threaded tool pin profile was found to be highly efficient. This work was further extended with the interaction effect of tool rotational speed and traverse speed. The major objective was to investigate the variation of axial force and torque due to the parametric variation, especially to find the correlation with weld quality characteristics. The mean and standard deviation of axial force and torque indicated the formability and material mixing capability during welding which in turn found to be highly correlated to weld bead uniformity. The joint behavior due to tensile load and bonding mechanism in weld stirred zone have been studied using stress-strain diagram and scanning electron micrographs, respectively. The weld joint interface was found to be the weakest zone rather than weld stirred zone due to the presence of carbon reach phases as per micro-hardness variation through the weld centerline along with energy dispersive spectroscopy analysis. The maximum joint efficiency was found to be 23.33% at 700-rpm tool rotation and traverse speed of 30 mm/min using threaded pin in slotted edge–based design.

Similar content being viewed by others

References

Katayama S, Kawahito Y (2008) Laser direct joining of metal and plastic. Scr Mater 59:1247–1250. https://doi.org/10.1016/j.scriptamat.2008.08.026

Messler RW (2004) Joining composite materials and structures: some thought-provoking possibilities. J Thermoplast Compos Mater 17:51–75. https://doi.org/10.1177/0892705704033336

Grujicic M, Sellappan V, Omar MA, Seyr N, Obieglo A, Erdmann M, Holzleitner J (2008) An overview of the polymer-to-metal direct-adhesion hybrid technologies for load-bearing automotive components. J Mater Process Technol 197:363–373. https://doi.org/10.1016/j.jmatprotec.2007.06.058

Amancio-Filho ST (2009) Joining of polymers and polymer-metal hybrid structures: recent developments and trends. Polymer Engineering and Science. Dos Santosh JF 47:21–25. https://doi.org/10.1002/pen

Liu FC, Liao J, Nakata K (2014) Joining of metal to plastic using friction lap welding. Mater Des 54:236–244. https://doi.org/10.1016/j.matdes.2013.08.056

Khodabakhshi F, Haghshenas M, Sahraeinejad S, Chen J, Shalchi B, Li J, Gerlich AP (2014) Microstructure-property characterization of a friction-stir welded joint between AA5059 aluminum alloy and high density polyethylene. Mater Charact 98:73–82. https://doi.org/10.1016/j.matchar.2014.10.013

Liu FC, Nakata K, Liao J, Hirota S, Fukui H (2014) Reducing bubbles in friction lap welded joint of magnesium alloy and polyamide. Sci Technol Weld Join 19:578–587. https://doi.org/10.1179/1362171814Y.0000000228

Lambiase F, Ko DC (2016) Feasibility of mechanical clinching for joining aluminum AA6082-T6 and carbon fiber reinforced polymer sheets. Mater Des 107:341–352. https://doi.org/10.1016/j.matdes.2016.06.061

Konchakova N, Balle F, Barth FJ, Mueller R, Eifler D, Steinmann P (2010) Finite element analysis of an inelastic interface in ultrasonic welded metal/fibre-reinforced polymer joints. Comput Mater Sci 50:184–190. https://doi.org/10.1016/j.commatsci.2010.07.024

Lambiase F, Paoletti A, Grossi V, Di Ilio A (2017) Friction assisted joining of aluminum and PVC sheets. J Manuf Process 29:221–231. https://doi.org/10.1016/j.jmapro.2017.07.026

Thomas WM, Nicholas ED, Needham JC, et al (1991) “Friction stir butt welding”. UK Patent GB Patent 9125978

Elyasi M, Derazkola HA, Hosseinzadeh M (2016) Investigations of tool tilt angle on properties friction stir welding of A441 AISI to AA1100 aluminium. Proc Inst Mech Eng Part B J Eng Manuf 230:1234–1241. https://doi.org/10.1177/0954405416645986

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R Rep 50:1–78. https://doi.org/10.1016/j.mser.2005.07.001

Aghajani Derazkola H, Khodabakhshi F (2018) Intermetallic compounds (IMCs) formation during dissimilar friction-stir welding of AA5005 aluminum alloy to St-52 steel: numerical modeling and experimental study. Int J Adv Manuf Technol 100:2401–2422. https://doi.org/10.1007/s00170-018-2879-8

Rafiei R, Ostovari Moghaddam A, Hatami MR et al (2017) Microstructural characteristics and mechanical properties of the dissimilar friction-stir butt welds between an Al–Mg alloy and A316L stainless steel. Int J Adv Manuf Technol 90:2785–2801. https://doi.org/10.1007/s00170-016-9597-x

Shahmiri H, Movahedi M, Kokabi AH (2016) Friction stir lap joining of aluminium alloy to polypropylene sheets. Sci Technol Weld Join 1718:0–7. https://doi.org/10.1080/13621718.2016.1204171

Ratanathavorn W, Melander A (2015) Dissimilar joining between aluminium alloy (AA 6111) and thermoplastics using friction stir welding. Sci Technol Weld Join 20:222–228. https://doi.org/10.1179/1362171814Y.0000000276

Nagatsuka K, Yoshida S, Tsuchiya A, Nakata K (2015) Direct joining of carbon-fiber–reinforced plastic to an aluminum alloy using friction lap joining. Compos Part B Eng 73:82–88. https://doi.org/10.1016/j.compositesb.2014.12.029

Moshwan R, Rahmat SM, Yusof F, Hassan MA, Hamdi M, Fadzil M (2015) Dissimilar friction stir welding between polycarbonate and AA 7075 aluminum alloy. IJMR 106:258–266. https://doi.org/10.3139/146.111172

Jain R, Pal SK, Singh SB (2017) Finite element simulation of pin shape influence on material flow, forces in friction stir welding. Int J Adv Manuf Technol 94:1–17. https://doi.org/10.1007/s00170-017-0215-3

Roy RB, Ghosh A, Bhattacharyya S, Mahto RP, Kumari K, Pal SK, Pal S (2018) Weld defect identification in friction stir welding through optimized wavelet transformation of signals and validation through X-ray micro-CT scan. Int J Adv Manuf Technol 99:623–633. https://doi.org/10.1007/s00170-018-2519-3

Kumari S, Jain R, Kumar U, Yadav I, Ranjan N, Kumari K, Kesharwani RK, Kumar S, Pal S, Pal SK, Chakravarty D (2016) Defect identification in friction stir welding using continuous wavelet transform. J Intell Manuf 1–12 . doi: https://doi.org/10.1007/s10845-016-1259-1

Ranjan N, Kesharwani RK, Kumar U et al (2015) Defect identification in friction stir welding using discrete wavelet analysis. Adv Eng Softw 85:43–50. https://doi.org/10.1016/j.advengsoft.2015.02.001

Mishra D, Roy RB, Dutta S, Pal SK, Chakravarty D (2018) A review on sensor based monitoring and control of friction stir welding process and a roadmap to Industry 4.0. J Manuf Process 36:373–397. https://doi.org/10.1016/j.jmapro.2018.10.016

ASTM D638 Standard Test method for tensile testing of plastics. In: Annu. B. ASTM Stand

Sahu SK, Panda M, Mahto RP, et al (2017) Experimental investigation to join Al 6063 alloy to polypropylene using friction stir welding. In: 10th international conference on precision, Meso, micro and Nano Engineering (COPEN 10). Indian Institue of Technology Madras, Chennai - 600036 India, pp 727–731

Paoletti A, Lambiase F, Di Ilio A (2016) Analysis of forces and temperatures in friction spot stir welding of thermoplastic polymers. Int J Adv Manuf Technol 83:1395–1407. https://doi.org/10.1007/s00170-015-7669-y

Sahu Santosh Kumar, Mishra Debasish, Mahto Raju P, Shrama Vyas M, Pal Surjya K, Pal Kamal, Banerjee Susanta, Dash Padmanav (2018) Friction stir welding of polypropylene sheet. Eng Sci Technol an Int J 21:245–254. https://doi.org/10.1016/j.jestch.2018.03.002

Mishra D, Sahu SK, Mahto RP, Pal SK (2019) Strengthening and joining by plastic deformation. Springer, Singapore

Lambiase F, Paoletti A, Di Ilio A (2017) Effect of tool geometry on mechanical behavior of friction stir spot welds of polycarbonate sheets. Int J Adv Manuf Technol 88:3005–3016. https://doi.org/10.1007/s00170-016-9017-2

Khodabakhshi F, Haghshenas M, Chen J, Shalchi Amirkhiz B, Li J, Gerlich AP (2017) Bonding mechanism and interface characterisation during dissimilar friction stir welding of an aluminium/polymer bi-material joint. Sci Technol Weld Join 22:182–190. https://doi.org/10.1080/13621718.2016.1211583

Derazkola HA, Kashiry Fard R, Khodabakhshi F (2018) Effects of processing parameters on the characteristics of dissimilar friction-stir-welded joints between AA5058 aluminum alloy and PMMA polymer. Weld World 62:117–130. https://doi.org/10.1007/s40194-017-0517-y

Khodabakhshi F, Simchi A, Kokabi AH, Gerlich AP, Nosko M, Švec P (2017) Influence of hard inclusions on microstructural characteristics and textural components during dissimilar friction-stir welding of an PM Al–Al2O3–SiC hybrid nanocomposite with AA1050 alloy. Sci Technol Weld Join 22:412–427. https://doi.org/10.1080/13621718.2016.1251714

Panneerselvam K, Lenin K (2014) Joining of nylon 6 plate by friction stir welding process using threaded pin profile. Mater Des 53:302–307. https://doi.org/10.1016/j.matdes.2013.07.017

Ahmadi H, Arab NBM, Ghasemi FA, Farsani RE (2012) Influence of pin profile on quality of friction stir lap welds in carbon fiber reinforced polypropylene composite. Int J Mech Appl 2:24–28. https://doi.org/10.5923/j.mechanics.20120203.01

Gao J, Li C, Shilpakar U, Shen Y (2016) Microstructure and tensile properties of dissimilar submerged friction stir welds between HDPE and ABS sheets. Int J Adv Manuf Technol 87:919–927. https://doi.org/10.1007/s00170-016-8539-y

Aghajani Derazkola H, Simchi A (2018) Experimental and thermomechanical analysis of friction stir welding of poly(methyl methacrylate) sheets. Sci Technol Weld Join 34:209–218. https://doi.org/10.1016/j.jmapro.2018.06.015

Sahu SK, Pal K, Routara BC (2015) Effects of pin geometry on friction stir Cuto Alalloy lap joint. Mater Today Proc 2:3356–3362. https://doi.org/10.1016/j.matpr.2015.07.309

Rafiei R, Shamanian M, Fathi MH, Khodabakhshi F (2018) Dissimilar friction-stir lap-welding of aluminum-magnesium (AA5052) and aluminum-copper (AA2024) alloys: microstructural evolution and mechanical properties. Int J Adv Manuf Technol 94:3713–3730. https://doi.org/10.1007/s00170-017-0964-z

Khodabakhshi F, Ghasemi Yazdabadi H, Kokabi AH, Simchi A (2013) Friction stir welding of a P/M Al–Al2O3 nanocomposite: microstructure and mechanical properties. Mater Sci Eng A 585:222–232. https://doi.org/10.1016/j.msea.2015.07.093

Oliveira PHF, Amancio-Filho ST, dos Santos JF, Hage E (2010) Preliminary study on the feasibility of friction spot welding in PMMA. Mater Lett 64:2098–2101. https://doi.org/10.1016/j.matlet.2010.06.050

Khodabakhshi F, Simchi A, Kokabi AH, Gerlich AP (2016) Similar and dissimilar friction-stir welding of an PM aluminum-matrix hybrid nanocomposite and commercial pure aluminum: microstructure and mechanical properties. Mater Sci Eng A 666:225–237. https://doi.org/10.1016/j.msea.2016.04.078

Min J, Li Y, Li J, Carlson BE, Lin J (2014) Friction stir blind riveting of carbon fiber-reinforced polymer composite and aluminum alloy sheets. Int J Adv Manuf Technol 76:1403–1410. https://doi.org/10.1007/s00170-014-6364-8

Simar A, Bréchet Y, De MB et al (2012) Integrated modeling of friction stir welding of 6xxx series Al alloys : process , microstructure and properties. Prog Mater Sci 57:95–183. https://doi.org/10.1016/j.pmatsci.2011.05.003

NANDAN R, DEBROY T, BHADESHIA H (2008) Recent advances in friction-stir welding – process, weldment structure and properties. Prog Mater Sci 53:980–1023. https://doi.org/10.1016/j.pmatsci.2008.05.001

Eskandari H, Taheri RKF (2016) Friction- stir processing of an AA8026-TiB2-Al2O3 hybrid nanocomposite: microstructural developments and mechanical properties. Mater Sci Eng A 662:84–96. https://doi.org/10.1016/j.radphyschem.2016.09.019

Khodabakhshi F, Simchi A, Kokabi AH et al (2015) Effects of stored strain energy on restoration mechanisms and texture components in an aluminum-magnesium alloy prepared by friction stir processing. Mater Sci Eng A 642:204–214. https://doi.org/10.1016/j.radphyschem.2016.09.019

Sahu SK, Mishra D, Mahto RP, et al (2016) Friction stir welding of HDPE sheets : a study on the effect of rotational speed. In: 6th international & 27th all India manufacturing technology, design and research conference (AIMTDR-2016). College of Engineering, Pune, Maharashtra, India, pp 1065–1068

Nateghi E, Hosseinzadeh M (2016) Experimental investigation into effect of cooling of traversed weld nugget on quality of high-density polyethylene joints. Int J Adv Manuf Technol 84:581–594. https://doi.org/10.1007/s00170-015-7663-4

Derazkola HA, Khodabakhshi F, Simchi A (2018) Friction-stir lap-joining of aluminium-magnesium/poly-methyl-methacrylate hybrid structures: thermo-mechanical modelling and experimental feasibility study. Sci Technol Weld Join 23:35–49. https://doi.org/10.1080/13621718.2017.1323441

Aghajani Derazkola H, Simchi A (2018) Experimental and thermomechanical analysis of the effect of tool pin profile on the friction stir welding of poly(methyl methacrylate) sheets. J Manuf Process 23:412–423. https://doi.org/10.1080/13621718.2017.1364896

Acknowledgments

The authors are immensely grateful to Steel Technology Centre, IIT Kharagpur, for carrying out the sample preparation and measurement of weld joint quality characteristics. They also wish to acknowledge the assistance and support provided by the Friction stir welding Laboratory of the Department of Mechanical Engineering, IIT Kharagpur.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sahu, S.K., Pal, K., Mahto, R.P. et al. Monitoring of friction stir welding for dissimilar Al 6063 alloy to polypropylene using sensor signals. Int J Adv Manuf Technol 104, 159–177 (2019). https://doi.org/10.1007/s00170-019-03855-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03855-3