Abstract

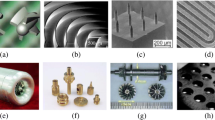

Micro-grinding is a tool based mechanical micromachining process which is mostly applied to create and finish 3D micro-features on hard and brittle materials such as glass, silicon, alumina, etc. Miniature-sized abrasive tool comes in physical contact with the workpiece and removes the unwanted material with mostly nanometric undeformed chip thickness and hence can achieve ductile mode cutting. Electroplated and metal bonded sintered abrasive tools are the most researched micro-grinding tools in terms of their fabrication techniques evolution, design modification, and processing of different materials. In the last decade, researchers have thoroughly investigated the micro-grinding process mechanics and identified different issues along with controlling strategies to improve the process performance. Through experimental and analytical studies, it was shown that process performance could be improved through proper tool modifications, optimum selection of process parameters, proper lubrication media, and most importantly by the development of dedicated machine tools. This paper describes the micro-grinding process mechanism considering tool-workpiece interaction. Thereafter, a comprehensive review on micro-grinding tool manufacturing technologies, issues and controlling strategies, proper machining parameter selection, modeling techniques, and micro-feature generation in various materials is presented. After critical examination of the state of the art of this process, challenges, and limitations in the process establishment and applications are derived. Future research scopes in different aspects of the said process are suggested so as to multiply the process utility.

Similar content being viewed by others

References

Dornfeld D, Min S, Takeuchi Y (2006) Recent advances in mechanical micromachining. CIRP Ann - Manuf Technol 55:745–768. https://doi.org/10.1016/j.cirp.2006.10.006

Baehr-Jones T, Pinguet T, Lo Guo-Qiang P, Danziger S, Prather D, Hochberg M (2012) Myths and rumours of silicon photonics. Nat Photonics 6:206–208. https://doi.org/10.1038/nphoton.2012.66

Chidambaram PR, Bowen C, Chakravarthi S, Machala C, Wise R (2006) Fundamentals of silicon material properties for successful exploitation of strain engineering in modern CMOS manufacturing. IEEE Trans Electron Devices 53:944–964. https://doi.org/10.1109/TED.2006.872912

Gottmann J, Hermans M, Ortmann J (2013) Digital photonic production of 3D micro fluidics in glass by high speed micro scanner. MATEC Web Conf 8:05003. https://doi.org/10.1051/matecconf/20130805003

Rigamonti G, Merlo S, Carpignano F (2015) Rectangular glass micro-capillaries for biophotonic Applications. 6–8. doi: https://doi.org/10.1049/cp.2015.0185

Jackson MJ (2007) Microgrinding. In: Jackson MJ (ed) micro and nanomanufacturing. Springer, Printed in USA, pp 255–315

Perveen A, San WY, Rahman M (2012) Fabrication of different geometry cutting tools and their effect on the vertical micro-grinding of BK7 glass. Int J Adv Manuf Technol 61:101–115. https://doi.org/10.1007/s00170-011-3688-5

Sano S, Pan W, Suzuki K, et al (2007) Development of a fine grade PCD wheel for precision and micro grinding using an ED-truing. In: Asia Electr. Mach. Symp. Nagoya, Japan, pp 3–8

Gäbler J, Pleger S (2010) Precision and micro CVD diamond-coated grinding tools. Int J Mach Tools Manuf 50:420–424. https://doi.org/10.1016/j.ijmachtools.2009.10.008

Kuppuswamy R, Airey KA, Sardikmen H (2014) Micro-grinding characteristics of polycrystalline diamond tool. Int J Adv Manuf Technol 76:161–171. https://doi.org/10.1007/s00170-014-6204-x

Chen ST, Tsai MY, Lai YC, Liu CC (2009) Development of a micro diamond grinding tool by compound process. J Mater Process Technol 209:4698–4703. https://doi.org/10.1016/j.jmatprotec.2008.10.055

Aurich JC, Engmann J, Schueler GM, Haberland R (2009) Micro grinding tool for manufacture of complex structures in brittle materials. CIRP Ann - Manuf Technol 58:311–314. https://doi.org/10.1016/j.cirp.2009.03.049

Aziz M, Ohnishi O, Onikura H (2012) Advanced burr-free hole machining using newly developed micro compound tool. Int J Precis Eng Manuf 13:947–953. https://doi.org/10.1007/s12541-012-0123-2

Gong YD, Wen XL, Cheng J, Yin GQ, Wang C (2014) Experimental study on fabrication and evaluation of a micro-scale shaft grinding tool. J Mech Sci Technol 28:1027–1037. https://doi.org/10.1007/s12206-013-1176-6

Butler-Smith PW, Axinte DA, Daine M (2012) Solid diamond micro-grinding tools: from innovative design and fabrication to preliminary performance evaluation in Ti-6Al-4V. Int J Mach Tools Manuf 59:55–64. https://doi.org/10.1016/j.ijmachtools.2012.03.003

Aurich JC, Carrella M, Walk M (2015) Micro grinding with ultra small micro pencil grinding tools using an integrated machine tool. CIRP Ann - Manuf Technol 64:325–328. https://doi.org/10.1016/j.cirp.2015.04.011

Chen ST, Jiang ZH (2015) A force controlled grinding-milling technique for quartz-glass micromachining. J Mater Process Technol 216:206–215. https://doi.org/10.1016/j.jmatprotec.2014.09.017

Mizutani K, Kawano T, Tanaka Y (1990) A piezoelectric-drive table and its application to micro-grinding of ceramic materials. Precis Eng 12:219–226. doi: https://doi.org/10.1016/0141-6359(90)90064–6

Bifano TG, Yi Y (1992) Acoustic emission as an indicator of material-removal regime in glass micro-machining. Precis Eng 14:219–228

Ohmori H, Ebizuka N, Morita S, Yamagata Y, Kudo H (2001) Ultraprecision micro-grinding of germanium immersion grating element for mid-infrared super dispersion spectrograph. CIRP Ann - Manuf Technol 50:221–224. https://doi.org/10.1016/S0007-8506(07)62109-X

Wada T, Masaki T, Davis DW (2002) Development of micro grinding process using micro EDM trued diamond tools. In: Proc ASPE 2002 Annu meet, pp 7–10

Onikura H, Inoue R, Okuno K, Ohnishi O (2003) Fabrication of electroplated micro grinding wheels and manufacturing of microstructures with ultrasonic vibration. Key Eng Mater 238–239:9–14. https://doi.org/10.4028/www.scientific.net/KEM.238-239.9

Arrabiyeh PA, Raval V, Kirsch B, Bohley M, Aurich JC (2016) Electroless plating of micro pencil grinding tools with 5-10 μm sized cBN grits. Adv Mater Res 1140:133–140. https://doi.org/10.4028/www.scientific.net/AMR.1140.133

Park HW (2008) Development of micro-grinding mechanics and machine tools. ProQuest Diss. Theses

Perveen A (2012) Study of micro-grinding of glass using on-machine fabrication polycrystalline diamond by micro-EDM. PhD Thesis Mech Eng Natl Univ SINGAPORE 180

Hou ZB, Komanduri R (2003) On the mechanics of the grinding process–part I . Stochastic nature of the grinding process. Int J Mach Tools Manuf 43:1579–1593. https://doi.org/10.1016/S0890-6955(03)00186-X

Graham D, Baul RM (1972) An investigation into the mode of metal removal in the grinding process. Wear 19:301–314. https://doi.org/10.1016/0043-1648(72)90122-6

Ya-dong G, Yin L, Yao S et al (2018) Experimental and emulational investigations into grinding characteristics of Zr-based bulk metallic glass ( BMG ) using microgrinding. Int J Adv Manuf Technol 97:3431–3451

Setti D, Kirsch B, Aurich JC (2017) An analytical method for prediction of material deformation behavior in grinding using single grit analogy. Procedia CIRP 58:263–268. https://doi.org/10.1016/j.procir.2017.03.193

Pratap A, Patra K, Dyakonov AA (2016) Manufacturing miniature products by micro-grinding: a review. Procedia Eng 150:969–974. https://doi.org/10.1016/j.proeng.2016.07.072

Cheng J, Gong YD (2014) Experimental study of surface generation and force modeling in micro-grinding of single crystal silicon considering crystallographic effects. Int J Mach Tools Manuf 77:1–15. https://doi.org/10.1016/j.ijmachtools.2013.10.003

Cheng J, Gong YD (2013) Experimental study on ductile-regime micro-grinding character of soda-lime glass with diamond tool. Int J Adv Manuf Technol 69:147–160. https://doi.org/10.1007/s00170-013-5000-3

Perveen A, Molardi C (2017) Machining of glass materials: an overview. Adv. Manuf. Technol. Springer, Cham, In, pp 23–47

Inasaki I (1987) Grinding of hard and brittle materials. CIRP Ann - Manuf Technol 36:463–471. https://doi.org/10.1016/S0007-8506(07)60748-3

Malkin S, Hwang TW (1996) Grinding mechanisms for ceramics. CIRP Ann - Manuf Technol 45:569–580. https://doi.org/10.1016/S0007-8506(07)60511-3

Bifano TG, Dow TA, Scattergood RO (1991) Ductile-regime grinding: a new technology for machining brittle materials. J Eng Ind 113:184. https://doi.org/10.1115/1.2899676

Lawn BR, Evans A (1977) A model for crack initiation in elastic/plastic indentation fields. J Mater Sci 12:2195–2199

Cheng J, Wu J, Gong YD, Wen XL, Wen Q (2017) Experimental study on the single grit interaction behaviour and brittle–ductile transition of grinding with a diamond micro-grinding tool. Int J Adv Manuf Technol 91:1209–1226. https://doi.org/10.1007/s00170-016-9816-5

Li Z, Zhang F, Luo X, Guo X, Cai Y, Chang W, Sun J (2018) A new grinding force model for micro grinding RB-SiC ceramic with grinding wheel topography as an input. Micromachines 9:368. https://doi.org/10.3390/mi9080368

Luo JK, Chu DP, Flewitt AJ, Spearing SM, Fleck NA, Milne WI (2005) Uniformity control of Ni thin-film microstructures deposited by through-mask plating. J Electrochem Soc 152:C36–C41. https://doi.org/10.1149/1.1833320

Cheng J, Wu J (2018) Experimental study on the fabrication method of diamond ultra-small micro-grinding tool. Int J Adv Manuf Technol 97:1431–1444

Kanani N (2004) Electroplating: properties, application, process, 1st edn. Published by Elsevier Ltd., Great Britain

Park HK, Onikura H, Ohnishi O, Sharifuddin A (2010) Development of micro-diamond tools through electroless composite plating and investigation into micro-machining characteristics. Precis Eng 34:376–386. https://doi.org/10.1016/j.precisioneng.2009.09.001

Arrabiyeh PA, Kirsch B, Aurich JC (2016) Development of micro pencil grinding tools via an electroless plating process. J Micro Nano-Manufacturing 5:011002. https://doi.org/10.1115/1.4034645

Moridi A, Hassani-Gangaraj SM, Guagliano M, Dao M (2014) Cold spray coating: review of material systems and future perspectives. Surf Eng 30:369–395. https://doi.org/10.1179/1743294414Y.0000000270

Asad ABMA, Masaki T, Rahman M, Lim HS, Wong YS (2007) Tool-based micro-machining. J Mater Process Technol 192–193:204–211. https://doi.org/10.1016/j.jmatprotec.2007.04.038

Morgan CJ (2004) Micro electro-discharge machining: techniques and procedures for micro fabrication. MS thesis Univ Kentucky 327

Perveen A, Jahan MP, Rahman M, Wong YS (2012) A study on microgrinding of brittle and difficult-to-cut glasses using on-machine fabricated poly crystalline diamond ( PCD ) tool. J Mater Process Tech 212:580–593. https://doi.org/10.1016/j.jmatprotec.2011.05.021

Brinksmeier E, Riemer O, Kirchberg S, Brandao C (2013) Injection molded spherical grinding tools: manufacture and application of a novel tool concept for micro grinding. Prod Eng 7:383–389. https://doi.org/10.1007/s11740-013-0468-0

Brinksmeier E, Orlik B, Groll R, Brandao C, Norbach A, Leach K (2013) GrindBall: an advanced micro-grinding tool. Prod Eng 7:469–476. https://doi.org/10.1007/s11740-013-0469-z

Butler-smith PW, Axinte DA, Daine M et al (2015) A study of an improved cutting mechanism of composite materials using novel design of diamond micro-core drills. Int J Mach Tools Manuf 88:175–183. https://doi.org/10.1016/j.ijmachtools.2014.10.002

Pratap A, Patra K, Dyakonov AA (2017) Enhancing performances of micro-grinding of BK-7 glass through modification of PCD micro-tool. Procedia Eng 206:1365–1370. https://doi.org/10.1016/j.proeng.2017.10.646

Pratap A, Sahoo P, Patra K, Dyakonov AA (2017) Experimental study of tool wear and grinding forces during BK-7 glass micro-grinding with modified PCD tool. IOP Conf Ser Mater Sci Eng 229:012033

Pratap A, Patra K, Dyakonov AA (2019) On-machine texturing of PCD micro-tools for dry micro-slot grinding of BK7 glass. Precis Eng 55:491–502. https://doi.org/10.1016/j.precisioneng.2018.11.004

Cheng J, Wang C, Wen X, Gong Y (2014) Modeling and experimental study on micro-fracture behavior and restraining technology in micro-grinding of glass. Int J Mach Tools Manuf 85:36–48. https://doi.org/10.1016/j.ijmachtools.2014.05.002

Cheng J, Wu J, Zhou YG, Gong YD, Wen XL, Wen Q (2017) Characterization of fracture toughness and micro-grinding properties of monocrystal sapphire with a multi-layer toughening micro-structure (MTM). J Mater Process Technol 239:258–272. https://doi.org/10.1016/j.jmatprotec.2016.08.028

Cao XD, Kim BH, Chu CN (2013) Hybrid micromachining of glass using ECDM and micro grinding. Int J Precis Eng Manuf 14:5–10. https://doi.org/10.1007/s12541-013-0001-6

Singh RK, Melkote SN (2008) Laser-assisted mechanical micromachining. Smart Devices Mach Adv Manuf:337–365. https://doi.org/10.1007/978-1-84800-147-3_14

Chang WL, Luo XC, Zhao QL, Sun JN, Zhao Y (2011) Laser assisted micro grinding of high strength materials. Key Eng Mater 496:44–49. https://doi.org/10.4028/www.scientific.net/KEM.496.44

Kumar M, Melkote S, Lahoti G (2011) Laser-assisted microgrinding of ceramics. CIRP Ann - Manuf Technol 60:367–370. https://doi.org/10.1016/j.cirp.2011.03.121

Chen ST, Lin SJ (2011) Development of an extremely thin grinding-tool for grinding microgrooves in optical glass. J Mater Process Technol 211:1581–1589. https://doi.org/10.1016/j.jmatprotec.2011.04.012

Walk M, Aurich JC (2014) Integrated desktop machine tool for manufacturing and application of ultra-small micro pencil grinding tools. Procedia CIRP 14:333–338. https://doi.org/10.1016/j.procir.2014.06.003

Jiang X, Guo M, Li B (2018) Active control of high-frequency tool-workpiece vibration in micro-grinding. Int J Adv Manuf Technol 94:1429–1439. https://doi.org/10.1007/s00170-017-1015-5

Mikrotools (2017) Hybrid μEDM: technical specifications. http://mikrotools.com/hybriduedm/hybrid-μedm-technical-specifications/. Accessed 20 Jul 2018

Microtechnik K (2017) Kern Evo. https://www.kern-microtechnik.com/en/machine-tool-manufacture/products/kern-evo/. Accessed 20 Jul 2018

Jagannadh VK, Mackenzie MD, Pal P, Kar AK, Gorthi SS (2014) Imaging flow cytometry with femtosecond laser micromachined glass microfluidic channels. IEEE J Sel Top QUANTUM Electron 21:1–6. https://doi.org/10.1109/JSTQE.2014.2382978

Bhupathiraju S (2012) The art of microchannel molding in microscope glass slides. Thesis Dr Philos Univ Texas Arlingt 111

Chen M, Zhao Q, Dong S, Li D (2005) The critical conditions of brittle-ductile transition and the factors influencing the surface quality of brittle materials in ultra-precision grinding. J Mater Process Technol 168:75–82. https://doi.org/10.1016/j.jmatprotec.2004.11.002

Gu W, Yao Z, Li H (2011) Investigation of grinding modes in horizontal surface grinding of optical glass BK7. J Mater Process Technol 211:1629–1636. https://doi.org/10.1016/j.jmatprotec.2011.05.006

Gu W, Yao Z, Liang X (2011) Material removal of optical glass BK7 during single and double scratch tests. Wear 270:241–246. https://doi.org/10.1016/j.wear.2010.10.064

Qiu Y, Gu ML, Zhang FG, Wei Z (2014) Influence of tool inclination on micro-ball-end milling of quartz glass. Mater Manuf Process 29:1436–1440. https://doi.org/10.1080/10426914.2014.921693

Morgan CJ, Vallance RR, Marsh ER (2004) Micro machining glass with polycrystalline diamond tools shaped by micro electro discharge machining. J Micromechanics Microengineering 14:1687–1692. https://doi.org/10.1088/0960-1317/14/12/013

Perveen A, Wong YS, Rahman M (2010) Fabrication of PCD micro tools using block edm method and their application to different microstructures in brittle and hard materials. In: Int. Manuf. Sci. Eng. Conf. Proc. 2010 ASME Erie, Pennsylvania, USA. pp 1–7

Egashira K, Kumagai R, Okina R, Yamaguchi K, Ota M (2014) Drilling of microholes down to 10 μm in diameter using ultrasonic grinding. Precis Eng 38:605–610. https://doi.org/10.1016/j.precisioneng.2014.02.010

Pratap A, Patra K, Dyakonov AA (2019) Experimental analysis of ductile-brittle transitions for parallel and intersecting micro-slot grinding in BK-7 glass. Ceram Int 45:11013–11026. https://doi.org/10.1016/j.ceramint.2019.02.185

Hochberg M, Harris N, Ding R et al (2013) Silicon photonics: the next fabless semiconductor industry. IEEE Solid-State Circuits Mag 5:48–58. https://doi.org/10.1109/MSSC.2012.2232791

Nakaya H, Nishida M, Takeda Y, Moriuchi S, Tonegawa T, Machida T, Nunoi T (1994) Polycrystalline silicon solar cells with V-grooved surface. Sol Energy Mater Sol Cells 34:219–225. https://doi.org/10.1016/0927-0248(94)90043-4

Inomata Y, Fukui K, Shirasawa K (1997) Surface texturing of large area multicrystalline silicon solar cells using reactive ion etching method. Sol Energy Mater Sol Cells 48:237–242. https://doi.org/10.1016/S0927-0248(97)00106-2

Wang L, Iyengar VV, Gupta MC (2012) Electric-arc micro-texturing of silicon surfaces for photovoltaic applications. In: Conf rec IEEE Photovolt spec Conf 2274–2277. https://doi.org/10.1109/PVSC.2012.6318051

Xie J, Xie HF, Liu XR, Tan TW (2012) Dry micro-grooving on Si wafer using a coarse diamond grinding. Int J Mach Tools Manuf 61:1–8. https://doi.org/10.1016/j.ijmachtools.2012.05.004

Zhong ZW (2003) Ductile or partial ductile mode machining of brittle materials. Int J Adv Manuf Technol 21:579–585. https://doi.org/10.1007/s00170-002-1364-5

Tanaka H, Shimada S, Anthony L (2007) Requirements for ductile-mode machining based on deformation analysis of mono-crystalline silicon by molecular dynamics simulation. Ann CIRP 56:53–56. https://doi.org/10.1016/j.cirp.2007.05.015

Wen X, Cheng J (2019) Experimental study of a specially designed diamond micro discontinuous grinding tool. Int J Adv Manuf Technol:1–16

Lee PH, Lee SW (2011) Experimental characterization of micro-grinding process using compressed chilly air. Int J Mach Tools Manuf 51:201–209. https://doi.org/10.1016/j.ijmachtools.2010.11.010

Lee PH, Nam JS, Li C, Lee SW (2012) An experimental study on micro-grinding process with nanofluid minimum quantity lubrication (MQL). Int J Precis Eng Manuf 13:331–338. https://doi.org/10.1007/s12541-012-0042-2

Lee PH, Nam TS, Li C, Lee SW (2010) Environmentally-friendly nano-fluid minimum quantity lubrication (MQL) meso-scale grinding process using nano-diamond particles. Proc Int Conf Manuf Autom:44–49

Singh H, Jain PK (2015) A comparative study of precision finishing of rebuild engine valve faces using micro-grinding and ECH. J Remanufacturing 5:6. https://doi.org/10.1186/s13243-015-0016-5

Ota M, Nakayama T, Nanbu T, Yasuda Y (2008) Novel microsurface machining techniques for improving the traction coefficient methods. SAE Int J Mater Manuf 1:174–181

Özkurt Z, Kazazoğlu E (2011) Zirconia dental implants: a literature review. J Oral Implantol 37:367–376. https://doi.org/10.1563/AAID-JOI-D-09-00079

Roy T, Choudhury D, Ghosh S, Bin Mamat A, Pingguan-Murphy B (2014) Improved friction and wear performance of micro dimpled ceramic-on-ceramic interface for hip joint arthroplasty. Ceram Int 41:681–690. https://doi.org/10.1016/j.ceramint.2014.08.123

Fujiki K, Sasaki R (2013) Lens barrel part, lens assembly, imaging device, and lens barrel part manufacturing method

Zhou Y, Gong Y, Zhu Z, Gao Q, Wen X (2016) Modelling and optimisation of surface roughness from microgrinding of nickel-based single crystal superalloy using the response surface methodology and genetic algorithm. Int J Adv Manuf Technol 85:2607–2622. https://doi.org/10.1007/s00170-015-8121-z

Zhou Y, Gong Y, Cai M, Zhu Z, Gao Q, Wen X (2017) Study on surface quality and subsurface recrystallization of nickel-based single-crystal superalloy in micro-grinding. Int J Adv Manuf Technol 90:1749–1768. https://doi.org/10.1007/s00170-016-9401-y

Gong Y, Zhou Y, Wen X, et al (2017) Experimental study on micro-grinding force and subsurface microstructure of nickel-based single crystal superalloy in micro grinding . 31:3397–3410. doi: https://doi.org/10.1007/s12206-017-0629-8

Jin Y, Cheng J (2017) Experimental investigation on surface generation mechanism of micro-grinding of hard brittle crystal materials. Int J Adv Manuf Technol 91:3953–3965. https://doi.org/10.1007/s00170-017-0075-x

Siegel SC, Fraunhofer JAVON (1998) Practice dental cutting: the historical development of diamond burs. J Am Dent Assoc 129:740–745. https://doi.org/10.14219/jada.archive.1998.0316

Blue DS, Griggs JA, Woody RD, Miller BH (2003) Effects of bur abrasive particle size and abutment composition on preparation of ceramic implant abutments. J Prosthet Dent 90:247–254

Yin L, Ives LK, Jahanmir S, Rekow ED, Romberg E (2001) Abrasive machining of glass-infiltrated alumina with diamond burs. Mach Sci Technol 5:43–61. https://doi.org/10.1081/MST-100103177

Dong X, Yin L, Jahanmir S, Ives LK, Rekow ED (2000) Abrasive machining of glass-ceramics with a dental handpiece. Mach Sci Technol ISSN 4:209–233. https://doi.org/10.1080/10940340008945707

Jackson MJ, Sein H, Ahmed W (2004) Diamond coated dental bur machining of natural and synthetic dental materials. J Mater Sci Mater Med 5:1323–1331

Dyakonov A, Gorodkova A (2018) Experimental research of cutting forces during microgrinding. MATEC Web Conf 224:1049–1053

Park HW, Liang SY (2008) Force modeling of micro-grinding incorporating crystallographic effects. Int J Mach Tools Manuf 48:1658–1667. https://doi.org/10.1016/j.ijmachtools.2008.07.004

Cheng J, Wu J, Gong YD, Wen XL, Wen Q (2017) Grinding forces in micro slot-grinding (MSG) of single crystal sapphire. Int J Mach Tools Manuf 112:7–20. https://doi.org/10.1016/j.ijmachtools.2016.10.004

Perveen A, Rahman M, Wong YS (2012) Analysis of surface and subsurface damage of micro-ground BK7 glass using on machine fabricated PCD micro-tool. Int J Abras Technol 5:72–92. https://doi.org/10.1504/IJAT.2012.046829

Cheng J, Wu J (2017) Experimental investigation of fracture behaviors and subsurface cracks in micro-slot-grinding of monocrystalline sapphire. J Mater Process Technol 242:160–181. https://doi.org/10.1016/j.jmatprotec.2016.11.030

Zhou Y, Ma L, Gong Y, Zhang L, Yin G, Sun Y (2019) Study on the mechanism of chip forming and the microhardness of micro-grinding nickel-based single-crystal superalloy. Int J Adv Manuf Technol

Cai R, Rowe WB (2004) Assessment of vitrified CBN wheels for precision grinding. Int J Mach Tools Manuf 44:1391–1402. https://doi.org/10.1016/j.ijmachtools.2004.04.004

Wen X, Gong Y (2017) Modeling and prediction research on wear of electroplated diamond micro-grinding tool in soda lime glass grinding. Int J Adv Manuf Technol 91:3467–3479. https://doi.org/10.1007/s00170-017-9992-y

Feng J, Kim BS, Shih A, Ni J (2009) Tool wear monitoring for micro-end grinding of ceramic materials. J Mater Process Technol 209:5110–5116. https://doi.org/10.1016/j.jmatprotec.2009.02.009

Perveen A, Wong YS, Rahman M (2011) Characterisation and online monitoring of wear behaviour of on-machine fabricated PCD micro-tool while vertical micro-grinding of BK7 glass. Int J Abras Technol 4:304–324

Feng J (2010) Microgrinding of ceramic materials. PhD Diss Mech Eng Univ Michigan 147

Lee P-H, Kim DH, Baek DS, Nam JS, Lee SW (2014) A study on tool condition monitoring and diagnosis of micro-grinding process based on feature extraction from force data. Proc Inst Mech Eng Part B J Eng Manuf 229:1472–1478. https://doi.org/10.1177/0954405414539497

Park HW, Liang SY (2009) Force modeling of microscale grinding process incorporating thermal effects. 476–486. doi: https://doi.org/10.1007/s00170-008-1852-3

Gong YD, Wen XL, Yin GQ, Wang C, Cheng J, Li BP (2013) Experiment research on grinding temperature of micro-grinding H62. Adv Mater Res 797:615–621. https://doi.org/10.4028/www.scientific.net/AMR.797.615

Yin L, Ya-dong G, Huan Z, Yao S, Ming C (2018) Experimental investigations into grinding characteristics of high entropy alloys ( HEAs ) using micro grinding. Int J Adv Manuf Technol 96:4477–4499

Lee PH, Chung H, Lee SW (2011) Optimization of micro-grinding process with compressed air using response surface methodology. Proc Inst Mech Eng Part B-Journal Eng Manuf 225:2040–2050. https://doi.org/10.1177/0954405411398808

Li KM, Liang SY (2007) Performance profiling of minimum quantity lubrication in machining. Int J Adv Manuf Technol 35:226–233. https://doi.org/10.1007/s00170-006-0713-1

Tasdelen B, Thordenberg H, Olofsson D (2008) An experimental investigation on contact length during minimum quantity lubrication (MQL) machining. J Mater Process Technol 203:221–231. https://doi.org/10.1016/j.jmatprotec.2007.10.027

Li KM, Lin CP (2012) Study on minimum quantity lubrication in micro-grinding. Int J Adv Manuf Technol 62:99–105. https://doi.org/10.1007/s00170-011-3789-1

Lee P-H, Lee SW, Lim S-H, Lee SH, Ko HS, Shin SW (2015) A study on thermal characteristics of micro-scale grinding process using nanofluid minimum quantity lubrication (MQL). Int J Precis Eng Manuf 16:1899–1909. https://doi.org/10.1007/s12541-015-0247-2

Arrabiyeh P, Bohley M, Ströer F, Kirsch B, Seewig J, Aurich J (2017) Experimental analysis for the use of sodium dodecyl sulfate as a soluble metal cutting fluid for micromachining with electroless-plated micropencil grinding tools. Inventions 2:29. https://doi.org/10.3390/inventions2040029

Dyakonov AA, Ardashev D V (2018) Prediction of blunting area of abrasive grains on a grinding wheel. ASME J Manuf Sci Eng 139:1–5. doi: https://doi.org/10.1115/1.4038055

Park HW, Liang SY, Chen R (2007) Microgrinding force predictive modelling based on microscale single grain interaction analysis. Int J Manuf Technol Manag 12:25–38. https://doi.org/10.1504/IJMTM.2007.014141

Komanduri R, Chandrasekaran N, Raff LM (1999) Some aspects of machining with negative-rake tools simulating grinding: a molecular dynamics simulation approach. Philos Mag Part B 79:955–968. https://doi.org/10.1080/13642819908214852

Hecker RL, Ramoneda IM, Liang SY (2003) Analysis of wheel topography and grit force for grinding process modeling. J Manuf Process 5:13–23. https://doi.org/10.1016/S1526-6125(03)70036-X

Perveen A, Rahman M, Wong YS (2014) Modeling and simulation of cutting forces generated during vertical micro-grinding. Int J Adv Manuf Technol 71:1539–1548. https://doi.org/10.1007/s00170-013-5572-y

Koshy P, Iwasald A, Elbestawl MA (2003) Surface generation with engineered diamond grinding wheels: insights from simulation. CIRP Ann - Manuf Technol 52:271–274. https://doi.org/10.1016/S0007-8506(07)60582-4

Cheng J, Gong Y, Wang J (2013) Modeling and evaluating of surface roughness prediction in micro-grinding on soda-lime glass considering tool characterization. Chinese J Mech Eng 26:1091–1100. https://doi.org/10.3901/CJME.2013.06.1091

Griffith AA (1920) The phenomena of rupture and flow in solids. Philos Trans R Soc A 221:163–198

Gorodkova AE, Dyakonov AA, Herreinstein AV (2017) Thermophysical modeling of microgrinding. Russ Eng Res 37:647–650. https://doi.org/10.3103/S1068798X17070139

Feng J, Chen P, Ni J (2012) Prediction of surface generation in microgrinding of ceramic materials by coupled trajectory and finite element analysis. Finite Elem Anal Des 57:67–80. https://doi.org/10.1016/j.finel.2012.03.002

Feng J, Chen P, Ni J (2013) Prediction of grinding force in microgrinding of ceramic materials by cohesive zone-based finite element method. Int J Adv Manuf Technol 68:1039–1053. https://doi.org/10.1007/s00170-013-4895-z

Ji S, Liu L, Zhao J, Sun C (2015) Finite Element Analysis and Simulation about Microgrinding of SiC. J Nanomater 2015:9. https://doi.org/10.1155/2015/575398

Sopeltzev AV, Dyakonov AA, Patra K (2015) Dynamic model of material deforming under microgrinding. In: Proceedia Eng Elsevier BV, pp 127–133

Pashnyov VA, Pimenov DY, Erdakov IN, Koltsova MS, Mikolajczyk T, Patra K (2017) Modeling and analysis of temperature distribution in the multilayer metal composite structures in grinding. Int J Adv Manuf Technol 91:4055–4068. https://doi.org/10.1007/s00170-017-0036-4

Anandita S, Mote RG, Singh R (2018) Stochastic analysis of microgrinding tool topography and its role in surface generation. ASME J Manuf Sci Eng 139:121013: 1–121013:14. https://doi.org/10.1115/1.4038056

Cheng J, Wu J, Gong Y (2018) Ductile to brittle transition in ultra-micro-grinding ( UMG ) of hard brittle crystal material. Int J Adv Manuf Technol 97:1971–1994

Jaeger JC (1942) Moving sources of heat and the temperature at sliding contacts. Proc R Soc NSW 76:203–224

Acknowledgements

This article is a part of the bilateral research project “Modeling and analysis of high speed hybrid micromachining”:

1. The reported study was partially supported by DST, Govt. of India, research project No. INT/RUS/RFBR/P-226.

2. The reported study was partially supported by RFBR, research project No. 15-58-45017 ИНД_a.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pratap, A., Patra, K. & Dyakonov, A.A. A comprehensive review of micro-grinding: emphasis on toolings, performance analysis, modeling techniques, and future research directions. Int J Adv Manuf Technol 104, 63–102 (2019). https://doi.org/10.1007/s00170-019-03831-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03831-x