Abstract

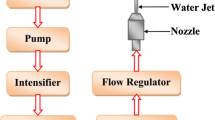

Waterjet machining has attracted great attention in the conditions of hard-to-machine materials, microstructures, or complicated industrial components, and it has become well-established in all major areas of theoretical researches and already been found across the broad spectrum of technical application areas especially in the specific sectors of scientific frontiers, including the mechanical precision component, advanced functional material, intelligent automotive engineering, aerospace equipment, renewable energy science, leading medical instruments, etc. This paper reviews the historical and latest research developments and integrated applications of waterjet machining in the domains of mechanism and performances, which covers a lot of key aspects such as waterjet machining optimization, dynamic simulation and process monitoring of machining process, and the influence mechanism of waterjet machining as well. Its machining mechanism, performance capability, functional advantages, and inherent disadvantages are characterized and assessed in detail, so that the integrated applications of multifield-assisted waterjet machining can be introduced and focused thereafter. Finally, various future development prospects in all the abovementioned aspects of waterjet machining are discussed systematically and explored subsequently, which contribute to the acquirement of a series of comprehensive conclusions. This review can be used as suitable and effective tools to study and summarize the complicated correlations between waterjet machining mechanism and its actual working performances in different environmental conditions; therefore, this proposed investigation facilitates the precision manufacture or characteristic improvements of industrial product with higher efficiency and better quality in return.

Similar content being viewed by others

Change history

23 March 2019

The original version of this article contained several mistakes. 1. The origin of Fig. 1 was provided from the following literature.

References

Pang KL, Nguyen T, Fan JM, Wang J (2012) Modelling of the micro-channeling process on glasses using an abrasive slurry jet. Int J Mach Tools Manuf 53:118–126

Escobar-Palafox GA, Gault R, Ridgway K (2012) Characterisation of abrasive waterjet process for pocket milling in Inconel. Procedia CIRP 718:404–408

Fowler G, Pashby IR, Shipway PH (2005) Abrasive waterjet controlled depth milling of Ti6Al4V alloy—an investigation of the role of jet–workpiece traverse speed and abrasive particle size on the characteristics of the milled material. J Mater Processing Technol 161:407–414

Kong MC, Axinte D, Voice W (2011) An innovative method to perform mask less plain waterjet milling for pocket generation: a case study in Ti-based superalloys. Int J Mach Tools Manuf 51:642–648

Hlavac LM, Hlavacova IM, Gembalova L, Kalicinsky J, Fabian S, Mestanek J, Kmec J, Madr V (2009) Experimental method for the investigation of the abrasive water jet cutting quality. J Mater Processing Technol 209:6190–6195

Hloch S, Valıcek J (2012) Topographical anomaly on surfaces created by abrasive waterjet. Int J Adv Manuf Technol 59:593–604

Selvan C, Raju M (2012) Abrasive waterjet cutting surfaces of ceramics—an experimental investigation. Int J Adv Sci Eng Technol Res 1:52–59

Brient A, Brissot M, Rouxel T, Sangleboeuf J-C (2011) Influence of grinding parameters on glass workpieces surface finish using response surface methodology. J Manuf Sci Eng 133:445011–445016

Brient A., Laniel R., Miroir M., Le Goic G., Samper S., Sangleboeuf J.-C. (2015) Multi-scale topography analysis of waterjet pocketing of silica glass surfaces. Int Conf on Metrology and Properties of Engineering Surfaces, Charlotte (USA)

Hsu CY, Liang CC, Teng TL, Nguyen AT (2013) A numerical study on high-speed water jet impact. Ocean Eng 72:98–106

Junkar M, Jurisevic B, Fajdiga M, Grah M (2006) Finite element analysis of single-particle impact in abrasive water jet machining. Int J Impact Eng 32:1095–1112

El Tobgy MS, Ng E, Elbestawi MA (2005) Finite element modeling of erosion wear. Int J Mach Tools Manuf 45:1337–1346

Kumar N, Shukla M (2012) Finite element analysis of multi-particle impact on erosion in abrasive water jet machining of titanium alloy. J Comput Appl Math 236:4600–4610

Anwar S, Axinte DA, Becker AA (2013) Finite element modelling of abrasive waterjet milled footprints. J Mater Processing Technol 213:180–193

Mabrouki T, Raissi K, Cornier A (2000) A numerical simulation and experimental study of the interaction between a pure high velocity waterjet and targets: contribution to investigate the decoating process. Wear 239:260–273

Zaki M. (2009) Modelisation et simulation numerique du procede de per¸cage non debouchant par jet d’eau abrasif, PhD thesis, Ecole Nationale Supérieure d'Arts et Métiers

Srinivasu DS, Axinte DA, Shipway PH, Folkes J (2009) Influence of kinematic operation parameters on kerf geometry in abrasive waterjet machining of silicon carbide ceramics. Int J Mach Tools Manuf 49:1077–1088

Cook BK, Noble DR, Williams JR (2004) A direct simulation method for particle-fluid system. Eng Comput 21:151–168

Haghbin N, Spelt JK, Papini M (2015) Abrasive waterjet micro-machining of channels in metals: model to predict high aspect-ratio channel profiles for submerged and unsubmerged machining. J Mater Processing Technol 222:399–409

Haghbin N, Spelt JK, Papini M (2014) Abrasive waterjet micro-machining of channels in metals: comparison between machining in air and submerged in water. Int J Mach Tools Manuf 88:108–117

Haghbin N, Ahmadzadeh F, Spelt JK, Papini M (2015) Effect of entrained air in abrasive water jet micro-machining: reduction of channel width and waviness using slurry entrainment. Wear 344- 345:99–109

Tamannaee N, Spelt JK, Papini M (2009) Abrasive slurry jet micro-machining of edges, planar areas and transitional slopes in a talc-filled co-polymer. J Mater Processing Technol 209:5123–5132

Miller DS (2004) Micromachining with abrasive waterjets. J Mater Processing Technol 149:37–42

Folkes J (2009) Waterjet—an innovative tool for manufacturing. J Mater Processing Technol 209:6181–6189

Nouraei H, Wodoslawsky A, Papini M, Spelt JK (2013) Characteristics of abrasive slurry jet micro-machining: A comparison with abrasive air jet micro-machining. J Mater Processing Technol 213:1711–1724

Nouraei H, Kowsari K, Spelt JK, Papini M (2014) Surface evolution models for abrasive slurry jet micro-machining of channels and holes in glass. Wear 309:65–73

Kowsari K, James DF, Papini M, Spelt JK (2014) The effects of dilute polymer solution elasticity and viscosity on abrasive slurry jet micro-machining of glass. Wear 309:112–119

Kowsari K, Nouraei H, James DF, Spelt JK, Papini M (2014) Abrasive slurry jet micro-machining of holes in brittle and ductile materials. J Mater Processing Technol 214:1909–1920

Nguyen T, Shanmugam DK, Wang J (2008) Effect of liquid properties on the stability of an abrasive waterjet. Int J Mach Tools Manuf 48:1138–1147

Liu Z, Nouraei H, Spelt JK, Papini M (2015) Electrochemical slurry jet micro-machining of tungsten carbide with a sodium chloride solution. Precis Eng 40:189–198

Liu Z, Nouraei H, Papini M, Spelt JK (2014) Abrasive enhanced electrochemical slurry jet micro-machining: comparative experiments and synergistic effects. J Mater Processing Technol 214:1886–1894

Haj Mohammad Jafar R, Nouraei H, Emamifar M, Papini M, Spelt JK (2015) Erosion modeling in abrasive slurry jet micro-machining of brittle materials. J Manuf Process 17:127–140

Momber A.W, Kovacevi R. (1998) Principles of abrasive water jet machining, Springer, London

Wang J (2006) Abrasive waterjet machining of engineering materials. Trans Tech Publications, Uetikon-Zuerich

Zeng J., Kim T. J. (1992) Development of an abrasive waterjet kerf cutting model for brittle materials, in: 11th Int Conf Jet Cut. Technol., St Andrews, Scotland, 43–47

Arola D., Ramulu M. (1993) Mechanism of material removal in abrasive waterjet machining of common aerospace materials, in: The seventh American water jet conference, 43–64

Momber AW, Eusch I, Kovacevic R (1996) Machining refractory ceramics with abrasive waterjet. J Mater Sci 31:6485–6493

Arola D, Ramulu M (1996) A study of kerf characteristics in abrasive waterjet machining of graphite/epoxy composite. J Eng Mater Technol ASME 118:256–265

Shanmugam DK, Nguyen T, Wang J (2008) A study of delamination on graphite/epoxy composites in abrasive waterjet machining. Composites Part A: Appl Sci Manuf 39:923–929

Wang J (1999) Abrasive waterjet machining of polymer matrix composites-cutting performance erosive process and predictive models. Int J Adv Manuf Technol 15:757–768

Lebar A, Junkar M (2003) Simulation of abrasive waterjet machining based on unit event features. Proc IMechE Part H: J Eng M 217:699–703

Wang J (2007) Predictive depth of jet penetration models for abrasive waterjet cutting of alumina ceramics. Int J Mech Sci 49:306–316

Feng YX, Huang CZ, Wang J, Lu XY (2007) An experimental study on milling Al2O3 ceramics with abrasive waterjet. Key Eng Mater 339:500–504

Shipway PH, Fowler G, Pashby IR (2005) Characteristics of the surface of a titanium alloy following milling with abrasive waterjets. Wear 258:123–132

Hocheng H, Tsai HY, Shiue J, Wang B (1997) Feasibility study of abrasive waterjet milling of fiber-reinforced plastics. J Manuf Sci Eng, Trans ASME 119:133–142

Xu S, Wang J (2006) A study of abrasive waterjet cutting of alumina ceramics with controlled nozzle oscillation. Int J Adv Manuf Technol 27:693–702

Hashish M (1984) Cutting with abrasive waterjets. Mech Eng 106:60–69

Zeng J, Kim TJ (1996) Erosion model of poly crystalline ceramics in abrasive waterjet cutting. Wear 193:207–217

Liu H, Wang J, Kelson N, Brown RJ (2004) A study of abrasive waterjet characteristics by CFD simulation. J Mater Processing Technol 153–154:488–493

Hashish M (1991) Optimization factors in abrasive-waterjet machining. J Eng Industry, Trans ASME 113:29–37

Kovacevic R, Fang M (1994) Modeling of the influence of the abrasive waterjet cutting parameters on the depth of cut based on fuzzy rules. Int J Mach Tools Manuf 34:55–72

Chen L, Siores E, Wong WCK (1996) Kerf characteristics in abrasive waterjet cutting of ceramic materials. Int J Mach Tools Manuf 36:1201–1206

Wang J, Kuriyagawa T, Huang CZ (2003) An experimental study to enhance the cutting performance in abrasive waterjet machining. Mach Sci Technol 7:191–207

Wang J, Guo DM (2003) The cutting performance in multi-pass abrasive waterjet machining of industrial ceramics. J Mater Processing Technol 133:371–377

Siores E, Wong WCK, Chen L, Wager JG (1996) Enhancing abrasive waterjet cutting of ceramics by head oscillation techniques. CIRP Annals—Manuf Technol 45:327–330

Hashish M (1989) Investigation of milling with abrasive-waterjets. J Eng Industry, Trans ASME 111:158–166

Zeng J, Kim TJ (1996) Erosion model for abrasive waterjet milling of poly crystalline ceramics. Wear 199:275–282

Feng YX, Huang CZ, Wang J, Lu XY, Zhu HT (2007) Surface characteristics of ceramics milled with abrasive waterjet technology. Key Eng Mater 329:335–340

Guo Z, Ramulu M (2001) Investigation of displacement fields in an abrasive waterjet drilling process: part 1. Experimental measurements. Exp Mechanics 41:375–387

Guo Z, Ramulu M (2001) Investigation of displacement fields in an abrasive water jet drilling process: part 2. Numerical analysis. Exp Mechanics 41:388–402

Hashish M. (1993) Precision drilling of composites with abrasive-waterjets. American Society of Mechanical Engineers, Materials Division (Publication) MD45, Machining of Advanced Composites: 217–225

Hashish M, Whalen J (1993) Precision drilling of ceramic-coated components with abrasive- waterjets. J Eng Gas Turbines Power 115:148–154

Piotr L, Krzysztof J, Piotr N (2016) Investigation of the effect of cutting speed on surface quality in abrasive water jet cutting of 316L stainless steel. Procedia Eng 149:276–282

Rupam T, Madhulika S, Sergej H, Pavel A, Somnath C, Alok KD (2016) Instantaneous monitoring of acoustic emission during the disintegration of rock. Procedia Eng 149:481–488

Thai N, Wang J, Li W (2015) Process models for controlled-depth abrasive waterjet milling of amorphous glasses. Int J Adv Manuf Technol 77:1177–1189

Libor MH (2015) Application of water jet description on the de-scaling process. Int J Adv Manuf Technol 80:721–735

Amir R, Iulian M, Dragos A (2012) Acoustic emission energy transfer rate: a method for monitoring abrasive waterjet milling. Int J Mach Tools Manuf 61:80–89

Axinte DA, Stepanian JP, Kong MC, McGourlay J (2009) Abrasive waterjet turning—an efficient method to profile and dress grinding wheels. Int J Mach Tools Manuf 49:351–356

Wang H, Lin W (2017) Removal model of rotation, revolution type polishing method. Precis Eng 50:515–521

Somjet T, Thanya K (2016) Simulation study of cutting sugarcane using fine sand abrasive waterjet. Agr Nat Res 50:146–153

Faehnle OW, Brug HV, Frankena HJ (1998) Fluid jet polishing of optical surfaces. Appl Opt 37:6771–6773

Faehnle O.W. (1998) Shaping and finishing of aspherical optical surfaces (PhD thesis). Delft University

Axinte DA, Karpuschewski B, Kong MC, Beaucamp A, Anwar S, Miller D, Petzel M (2014) High energy fluid jet machining (HEFJet-Mach): from scientific and technological advances to niche industrial applications. CIRP Annals – Manuf Technol 63:751–771

Kong MC, Anwar S, Billingham J, Axinte DA (2012) Mathematical modelling of abrasive waterjet footprints for arbitrarily moving jets: part I—single straight paths. Int J Mach Tools Manuf 53:58–68

Kulekci MK (2002) Processes and apparatus developments in industrial waterjet applications. Int J Mach Tools Manuf 42:1297–1306

Beaucamp A, Namba Y, Freeman R (2012) Dynamic multiphase modeling and optimization of fluid jet polishing process. CIRP Ann–Manuf Technol 61:315–318

Booij S.M. (2003) Fluid jet polishing—possibilities and limitations of a new fabrication technique (Ph.D. thesis). Delft University

Beaucamp A, Namba Y (2013) Super-smooth finishing of diamond turned hard X-ray molding dies by combined fluid jet and bonnet polishing. CIRP Annals – Manuf Technol 62:315–318

Tsai FC, Yan BH, Kuan CY, Huang FY (2008) A Taguchi and experimental investigation into the optimal processing conditions for the abrasive jet polishing of SKD61 mold steel. Int J Mach Tools Manuf 48:932–945

Beaucamp A, Namba Y, Messelink W, Walker D, Charlton P, Freeman R (2014) Surface integrity of fluid jet polished tungsten carbide. Procedia CIRP 13:377–381

Zhu HT, Huang CZ, Wang J, Li QL, Che CL (2009) Experimental study on abrasive waterjet polishing for hard-brittle materials. Int J Mach Tools Manuf 49:569–578

Ho L. T. (2015) Theoretical and experimental investigation of 3D-structured surface generation by computer controlled ultra-precision polishing (Ph.D. thesis). The Hong Kong PolyTechnic University

Messelink W. M., Waeger R., Wons T., Meeder M., Heiniger K. C., Faehnle O. W. (2005) Prepolishing and finishing of optical surfaces using fluid jet polishing, optics, Proceeding of SPIE 5869, Opt. Manuf Test. VI, 586908

Cao Z, Walsh JL, Kong MG (2009) Atmospheric plasma jet array in parallel electric and gas flow fields for three-dimensional surface treatment. Appl Phy Lett 94:R55

Kim JY, Ballato J, Kim SO (2012) Intense and energetic atmospheric pressure plasma jet arrays. Plasma Process Polym 9:253–260

Pan A, Chen T, Li CX, Hou X (2016) Parallel fabrication of silicon concave microlens array by fem to second laser irradiation and mixed acid etching. Chin Opt Lett 14:78–82

Takino H, Hosaka T (2014) Shaping of steel mold surface of lens array by electrical discharge machining with single rod electrode. Appl Opt 53:8002–8005

Takino H, Hosaka T (2016) Shaping of steel mold surface of lens array by electrical discharge machining with spherical ball electrode. Appl Opt 55:4967–4973

Mohammad AM, Seyed JH (2017) Modeling of abrasive flow rotary machining process by artificial neural network. Int J Adv Manuf Technol 89:125–132

Azlan MZ, Habibollah H, Safian S (2011) Optimization of process parameters in the abrasive waterjet machining using integrated SA–GA. Appl Soft Comput 11:5350–5359

Liu D, Huang C, Wang J, Zhu H, Yao P, Liu Z (2014) Modeling and optimization of operation parameters for abrasive waterjet turning alumina ceramics using response surface methodology combined with Box–Behnken design. Ceram Int 40:7899–7908

Schwartzentruber J, Papini M (2015) Abrasive waterjet micro-piercing of borosilicate glass. J Mater Processing Technol 219:143–154

Huang R, Luo X, Ji B, Wang P, Yu A, Zhai Z, Zhou J (2015) Multi-objective optimization of a mixed-flow pump impeller using modified NSGA-II algorithm. Sci Chin Technol Sci 58:2122–2130

Znamenskaya A, Nersesyan DA, Sysoev NN, Yu E, Koroteeva Y, Shirshov N (2016) An optical study of high-pressure waterjet dynamics. Mosc Univ Phys Bull 71:405–412

Guillerna AB, Axinte D, Billingham J (2015) The linear inverse problem in energy beam processing with an application to abrasive waterjet machining. Int J Mach Tools Manuf 99:34–42

Wang R, Wang M (2010) A two-fluid model of abrasive waterjet. J Mater Processing Technol 210:190–196

Liang Z, Xie B, Liao S, Zhou J (2015) Concentration degree prediction of AWJ grinding effectiveness based on turbulence characteristics and the improved ANFIS. Int J Adv Manuf Technol 80:887–905

Droubi MG, Reuben RL, White G (2015) Monitoring acoustic emission (AE) energy in slurry impingement using a new model for particle impact. Mech Syst Signal Pr 62-63:415–430

Zhou J, Andrea V, Paolo C (2014) A novel approach for predicting the operation of external gear pumps under cavitating conditions. Simul Model Pract Th 45:35–49

Liang Z, Ye B (2012) Performance comparison between fluid models in turbulence kinetic energy computation. J Dig Content Technol Appl 6:335–342

Liang ZW, Liu X, Ye BY (2012) Optimization of turbulence image chromatic data based on surface construction and RANSAC estimation. J Comput 7:1786–1795

Liang Z, Ye B (2011) Multi-resolution vector optimization of integrated chip image chromatic vectors. Int J Adv Comput Technol 3:170–177

Anwar S, Axinte DA, Becker AA (2013) Finite element modelling of over lapping abrasive waterjet milled footprints. Wear 303:426–436

Shimizu K, Noguchi T, Seitoh H, Okada M, Matsubara Y (2001) FEM analysis of erosive wear. Wear 250:779–784

Chen Q, Li DY (2003) Computer simulation of solid particle erosion. Wear 254:203–210

ElTobgy MS, Ng E, Elbestawi MA (2005) Finite element modeling of erosive wear. Int J Mach Tools Manuf 45:1337–1346

Johnson G.R., Cook W.H. (1983) A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures, Proc. the 7th Int Sym. on Ballistics, the Hague, the Netherlands

Takaffoli M, Papini M (2012) Material deformation and removal due to single particle impacts on ductile materials using smoothed particle hydrodynamics. Wear 274–275:50–59

Takaffoli M, Papini M (2012) Numerical simulation of solid particle impacts on Al6061-T6. Part I: three-dimensional representation of angular particles. Wear 100–110:s292–s293

Takaffoli M, Papini M (2012) Numerical simulation of solid particle impacts on Al6061-T6. Part II: materials removal mechanisms for impact of multiple angular particles. Wear 296:648–655

Junkar M, Jurisevic B, Fajdiga M, Grah M (2006) Finite element analysis of single-particle impact in abrasive waterjet machining. Int J Impact Eng 32:1095–1112

Nicholls JR, Stephenson DJ (1995) Monte Carlo modelling of erosion processes. Wear 186–187:64–77

Verspui MA, De G, Corbijn A, Slikkerveer PJ (1999) Simulation model for the erosion of brittle materials. Wear 233–235:436–443

Lebar A, Junkar M (2004) Simulation of abrasive waterjet cutting process: part 1. Unit event approach. Model Simul Mater Sci Eng 12:1159–1170

Orbanic H, Junkar M (2004) Simulation of abrasive waterjet cutting process: part 2. Cellular automata approach. Model Simul Mater Sci Eng 12:1171–1184

Wang Y, Yang Z (2008) Finite element model of erosive wear on ductile and brittle materials. Wear 265:871–878

Li WY, Wang J, Zhu H, Huang C (2014) On ultrahigh velocity micro-particle impact on steels: a multiple impact study. Wear 309:52–64

Li WY, Wang J, Zhu H, Li H, Huang C (2013) On ultra high velocity micro-particle impact on steels: a single impact study. Wear 305:216–227

Lozano TP, Axinte DA, Billingham J (2015) Stochastic modelling of abrasive waterjet foot prints using finite element analysis. Int J Mach Tools Manuf 95:39–51

Nouraei H, Kowsari K, Samareh B, Spelta JK, Papini M (2016) Calibrated CFD erosion modeling of abrasive slurry jet micro-machining of channels in ductile materials. J Manuf Process 23:90–101

Lebar A, Marko J, Izidor S, Drešar P, Valentinčič J (2016) AWJ cutting process control by means of process visualisation. Procedia Eng 149:224–228

Manu R, Ramesh BN (2009) An erosion-based model for abrasive waterjet turning of ductile materials. Wear 266:1091–1097

Putz M, Dittrich M, Dix M (2016) Process instantaneous monitoring of abrasive waterjet formation. Procedia CIRP 46:43–46

Mieszala M, Lozano TP, Axinte DA, Schwiedrzik J, Guo Y, Mischler S, Michler J, Philippe L (2017) Erosion mechanisms during abrasive waterjet machining: model micro-structures and single particle experiments. J Mater Processing Technol 247:92–102

Kyriaki M, Thomas K, Nicholaos B, Aristomenis A (2007) A finite element-based model for pure waterjet process simulation. Int J Adv Manuf Technol 31:933–940

Romain L, Otman B, Antoine B, Mathieu M (2017) Discrete elements model of an abrasive waterjet through the focal canon to the work-piece. Procedia CIRP 58:529–534

Thomas DJ (2013) Characterization of aggregate notch cavity formation properties on abrasive waterjet cut surfaces. J Manuf Process 15:355–363

Alberdi A, Suárez A, Artaza T, Escobar-Palafox GA, Ridgway K (2013) Composite cutting with abrasive water jet. Procedia Eng 63:421–429

Zhu D, Zhang R, Liu C (2017) Flow field improvement by optimizing turning profile at electrolyte inlet in electrochemical machining. Int J Precis Eng Manuf 18:15–22

Yang F, Ren T, Wang H, Liu B, Chen M (2017) Analysis of flow field for electrochemical machining metal screw pump stator. Int J Adv Manuf Technol 89:1317–1326

Wang J, Gao N, Gong W (2010) Abrasive waterjet machining simulation by SPH method. Int J Adv Manuf Technol 50:227–234

Matsumura R, Muramatsu T, Fueki S (2011) Abrasive water jet machining of glass with stagnation effect. CIRP Annals - Manuf Technol 60:355–358

Hou R, Huang C, Zhu H (2014) Numerical simulation ultrahigh waterjet (WJ) flow field with the high-frequency velocity vibration at the nozzle inlet. Int J Adv Manuf Technol 71:1087–1092

Zhang D, Shi W, Esch MBP, Shi L, Michel D (2015) Numerical and experimental investigation of tip leakage vortex trajectory and dynamics in an axial flow pump. Comput Fluids 112:61–71

Phillip D, Karl D (2015) Scaling and numerical analysis of nonuniform waterjet pump inflows. IEEE J Ocean Eng 40:701–709

Huang R, Ji B, Luo X, Zhai Z, Zhou J (2015) Numerical investigation of cavitation-vortex interaction in a mixed-flow waterjet pump. J Mech Sci Technol 29:3707–3716

Long X, Ruan X, Liu Q, Chen Z, Xue S, Wu Z (2017) Numerical investigation on the internal flow and the particle movement in the abrasive waterjet nozzle. Powder Techno 314:635–640

EITobgy M, Ng EG, Elbestawi MA (2005) Modelling of abrasive waterjet machining: a new approach. CIRP Ann 54:285–288

Giovanna R, Domenico U (2014) Finite element modeling of microstructural changes in dry and cryogenic cutting of Ti6Al4V alloy. CIRP Annals - Manuf Technol 63:69–72

Cao Z, Cheung C, Ren M (2016) Modelling and characterization of surface generation in fluid jet polishing. Precis Eng 43:406–417

Cao Z, Cheung C (2014) Theoretical modelling and analysis of the material removal characteristics in fluid jet polishing. Int J Mech Sci 89:158–166

Jiang H, Liu Z, Gao K (2017) Numerical simulation on rock fragmentation by discontinuous waterjet using coupled SPH/FEA method. Powder Technol 312:248–259

Lee J, Park K, Kang M, Kang B, Shin B (2012) Experiments and computer simulation analysis of impact behaviors of micro-sized abrasive in waterjet cutting of thin multiple layered materials. Trans Nonferrous Metals Soc Chin 22:864–869

Li W, Wang J, Zhu H, Li H, Huang C (2014) On ultra high velocity micro-particle impact on steels—a single impact study. Wear 309:52–64

Li M, Bao R, Guo Y (2008) Waterjet penetration simulation by hybrid code of SPH and FEA. Int J Impact Eng 35:1035–1042

Zeng J, Kim TJ (1996) An erosion model of polycrystalline ceramics in abrasive waterjet cutting. Wear 193:207–217

Liang Z, Liu X, Ye B (2012) Fuzzy performance between surface fitting and energy distribution in turbulence runner. Sci World J 25:408949

Liang Z, Shan S, Liu X, Wen Y (2017) Fuzzy prediction of AWJ turbulence characteristics by using multi-phase flow models. Eng Appl Comput Fluid Dynamics 11:225–257

Liang Z, Tao J, Liu X, Wu D (2012) Engineering impact investigation of turbulence image features on the computation of flow kinetic energy. Int J Simul Process Model 7:3–15

Liang Z, Liu X (2014) Four-dimensional fuzzy relation investigation in turbulence kinetic energy distribution, surface cluster modeling. Arab J Sci Eng 39:2339–2351

Hocheng H, Chang KR (1994) Material removal analysis in abrasive waterjet cutting of ceramic plate. J Mater Processing Technol 40:287–304

Capello E., Monno M., Semeraro Q., Milano P. (1994) Delamination in water jet cutting of multi-layered composite material. In: Proc. the 12th conf jet cutting technol, 463–476

Wang J (1999) Abrasive waterjet machining of polymer matrix composites: cutting performance, erosive analysis and predictive models. Int J Adv Manuf Technol 15:757–768

Wang J, Guo D (2002) A predictive depth of penetration model for abrasive waterjet cutting of polymer matrix composites. J Mater Processing Technol 121:390–394

Kovacevic R, Hashish M, Mohan R (1997) State of the art of research and development in abrasive waterjet machining. J Manuf Sci Eng 119:776–785

van Luttervelt CA (1989) On the selection of manufacturing methods illustrated by an overview of separation techniques for sheet materials. Ann CIRP 38:587–607

Orbanic H, Junkar M (2008) Analysis of striation formation mechanism in abrasive water jet cutting. Wear 265:821–830

John RJJ, Ramesh BN (2016) Condition instantaneous monitoring of orifice in abrasive waterjet cutting system using high pressure sensor. Procedia Manuf 5:578–593

Orbanic H, Junkar M, Bajsic I, Lebar A (2009) An instrument for measuring abrasive waterjet diameter. Int J Mach Tools Manuf 49:843–849

Kahlmana L, Öjmertz KMC, Falk LKL (2001) Abrasive-waterjet testing of thermo-mechanical wear of ceramics. Wear 248:16–28

Gent M., Menéndez M., Torno S., Torano J., Schenk A. (2012) Experimental evaluation of the physical properties required of abrasives for optimizing waterjet cutting of ductile materials. Wear s284–285: 43–51

Andrzej P (2016) Abrasive suspension water jet cutting optimization using orthogonal array design. Procedia Eng 149:366–373

Wang J, Cheung CF, Ho L, Liu MY, Lee WB (2017) A novel multi-jet polishing process and tool for high-efficiency polishing. Int J Mach Tools Manuf 115:60–73

Ján C, Sergej H, Petr H, Miroslav G, Dagmar K, František B, Dušan M, Dominika L (2016) Hydro-abrasive disintegration of alloy Monel K-500—the influence of technological and abrasive factors on the surface quality. Procedia Eng 149:17–23

Milena K, Michal Ř, Jan V, Sergej H, Milan K (2012) Determination of technologically optimal factors of modulated waterjet. Int J Adv Manuf Technol 60:173–179

Iman Z., Mehdi Z., Massimiliano A. (2014) Investigation of the effects of machining parameters on material removal rate in abrasive waterjet turning. Adv Mec. Eng, Article 624203

Sookhak Lari MR, Ghazavi A, Papini M (2017) A rotating mask system for sculpting of three-dimensional features using abrasive jet micro-machining. J Mater Processing Technol 243:62–74

Libor MH, Daniel K, Irena MH, Sławomir S (2017) Precision comparison of analytical and statistical-regression models for AWJ cutting. Precis Eng 50:148–159

Azlan MZ, Habibollah H, Safian S (2011) Estimation of the minimum machining performance in the abrasive waterjet machining using integrated ANN-SA. Expert Syst Appl 38:8316–8326

Gupta TVK, Ramkumar J, Puneet T, Vyas NS (2015) Application of artificial neural networks in abrasive water jet milling. Procedia CIRP 37:225–229

Ashanira MD, Azlan MZ, Roselina S (2011) Overview of support vector machine in modeling machining performances. Procedia Eng. 24:308–312

Norfadzlan Y, Arezoo S, Azlan MZ, Siti ZMH, Norafida I (2014) Estimation of optimal machining control parameters using artificial bee colony. J Intell Manuf 25:1463–1472

Rabania A, Madariaga J, Bouvier C, Axinte D (2016) An approach for using iterative learning for controlling the jet penetration depth in abrasive waterjet milling. J Manuf Process 22:99–107

Vundavilli PR, Parappagoudar MB, Kodali SP, Surekha B (2012) Fuzzy logic-based expert system for prediction of depth of cut in abrasive water jet machining process. Knowledge-Based Syst 27:456–464

Iulian M, Axinte A (2011) An automated monitoring solution for avoiding an increased number of surface anomalies during milling of aerospace alloys. Int J Mach Tools Manuf 51:349–357

Axinte A, Kong MC (2009) An integrated monitoring method to supervise waterjet machining. CIRP Annals - Manuf Technol 58:303–306

Deepak D, Anjaiah D, Karanth KV, Sharma NY (2012) CFD simulation of flow in an abrasive water suspension jet: the effect of inlet operating pressure and volume fraction on skin friction and exit kinetic energy. Adv Mech Eng 2012:65–88

Deepak D, Devineni A, Sharma NY. (2011) Effect of diameter ratio, volume fraction and abrasive grain size on the exit velocity by numerical simulation of flow through abrasive water suspension jet nozzle using DOE. WaterJet Technology Association WJTA Conference

Azimi AH, Zhu DZ, Rajaratnam N (2012) Computational investigation of vertical slurry jets in water. Int J Multiphase Flow 47:94–114

Hu G, Zhu W, Cai H, Xu C, Bai Y, Cheng J, Yuan J, Yu T (2009) Mathematical model for abrasive suspension jet cutting based on orthogonal test design. J Shanghai Univ 13:37–44

Liu X, Yu T, Wang W (2006) Prediction of the cutting depth of abrasive suspension jet using a BP artificial neural network. IFIP Int Conf Theoretical Comput Sci 207:563–569

Wang W, Yu T, Liu X, Liu T (2006) Fuzzy decision on traverse speed for abrasive suspension jet. Springer, 327:1160–1161

Jiang S, Xia Y, Popescu R, Mihai C, Tan K (2005) Cutting capability equation at abrasive suspension jet. WaterJet Technology Association WJTA Conference

Kinik D, Gánovská B, Hloch S, Monka P, Monková K, Hutyrová Z (2015) On-line instantaneous monitoring of technological process of material abrasive water jet cutting. Tehnicki Vjesnik 22:351–357

Liang ZW, Ye BY (2012) Three-dimensional fuzzy influence analysis of fitting algorithms on integrated chip topographic modeling. J Mech Sci Technol 26:3177–3191

Liang Z, Liu X, Zhou J, Liao S (2016) Video tracking for high-similarity drug tablets based on reflective energy intensity matrix and fuzzy recognition system. Proc IMechE Part H: J Eng M 230:211–229

Liang Z., Zhou L., Liu X., Wang X. (2014) Image tracking for the high-similarly drug tablet based on light intensity reflective-energy and artificial neural network. Comput Math Methods M., Article ID 304685

Liang ZW, Liu X, Ye BY, Wang J (2013) Performance investigation of fitting algorithms in surface micro-topography grinding processes based on multi-dimensional fuzzy relation set. Int J Adv Manuf Technol 67:2779–2798

Ming CK, Devadula S, Axinte D, Wayne V, Jamie M, Bernard H (2013) On geometrical accuracy and integrity of surfaces in multi-mode abrasive waterjet machining of NiTi shape memory alloys. CIRP Annals - Manuf Technol. 62:555–558

Liu HT (2010) Waterjet technology for machining fine features pertaining to micromachining. J Manuf Process 12:8–18

Wang J (2009) A new model for predicting the depth of cut in abrasive waterjet contouring of alumina ceramics. J Mater Processing Technol 209:2314–2320

Derzija B, Ahmet C, Muhamed M, Almina D (2015) Experimental study on surface roughness in abrasive water jet cutting. Procedia Eng. 100:394–399

Krajcarz D (2014) Comparison metal water jet cutting with laser and plasma cutting. In: Proceeding of 24th DAAAM Int Sym. on intelligent manufacturing and automation. Procedia Eng 69:838–843

Hlavac LM, Hlavacova IM, Gembalova L, Kalicinsky J, Fabian S, Mestanek J, Kmec J, Madr V (2009) Experimental method investigation of the abrasive water jet cutting quality. J Mater Processing Technol 209:6190–6195

Kechagias J, Petropoulos G, Vaxevanidis N (2012) Application of Taguchi design for quality characterization of abrasive water jet machining of TRIP sheet steels. Int J Adv Manuf Technol 62:635–643

Akkurt A, Kulekci MK, Seker U, Ercan F (2004) Effect of feed rate on surface roughness in abrasive waterjet cutting applications. J Mater Processing Technol 147:389–396

Axinte DA, Srinivasu DS, Kong MC, Butler-Smith PW (2009) Abrasive waterjet cutting of polycrystalline diamond; a preliminary investigation. Int J Mach Tools Manuf 49:797–803

Gokhan A, Izzet K, Coskun H (2014) Artificial neural network and regression models for performance prediction of abrasive waterjet in rock cutting. Int J Adv Manuf Technol 75:1321–1330

Oh T, Cho G (2016) Rock cutting depth model based on kinetic energy of abrasive waterjet. Rock Mech Rock Eng 49:1059–1072

Sookhak Lari MR, Papini M (2016) Inverse methods to gradient etch three-dimensional features with prescribed topographies using abrasive jet micro-machining: part I—modeling. Precis Eng 45:272–284

Sookhak Lari MR, Teti M, Papini M (2016) Inverse methods to gradient etch three-dimensional features with prescribed topographies using abrasive jet micro-machining: part II—verification with micro-machining experiments. Precis Eng 45:262–271

Hassan AI, Chen C, Kovacevic R (2004) On-line instantaneous monitoring of depth of cut in AWJ cutting. Int J Mach Tools Manuf 44:595–605

Libor MH (2009) Investigation of the abrasive water jet trajectory curvature inside the kerf. J Mater Processing Technol 209:4154–4161

Iulian M, Axinte DA (2008) A critical analysis of effectiveness of acoustic emission signals to detect tool and workpiece malfunctions in milling operations. Int J Mach Tools Manuf 48:1148–1160

Liang Z, Liao S, Wen Y, Liu X (2016) Working parameter optimization of strengthen waterjet grinding with the orthogonal-experiment-design-based ANFIS. J Intel Manuf. 30:1–22

Liang ZW, Tan SS, Liao SP, Liu X (2016) Component parameter optimization of strengthen waterjet grinding slurry with the orthogonal-experiment-design-based ANFIS. Int J Adv Manuf Technol 90:1–25

Richerson D. W. (2006) Modern ceramic engineering: properties, processing and use in design, CRC, Boca Raton.

Samant AN, Dahotre NB (2009) Laser machining of structural ceramics—a review. J Eur Ceramic Soc 40:287–304

Tuersley IP, Jawaid A, Pashby IR (1994) Review: Various methods of machining advanced ceramic materials. J Mater Processing Technol 42:377–390

Hashish M. (1987) Milling with abrasive waterjets: a preliminary investigation. In: Proc. the 4th US waterjet conference, Berkeley, CA, 1–10

Chen L, Siores E, Wong WCK (1998) Optimising abrasive waterjet cutting of ceramic materials. J Mater Processing Technol 74:251–254

Zeng J, Munoz J., Kain I. (1997) Milling ceramics with abrasive waterjets—an experimental investigation, In: Proc. the 9th American waterjet conference dear born, Michigan, 93–107

Gudimetla P, Wang J, Wong W (2002) Kerf formation analysis in the abrasive waterjet cutting of industrial ceramics. J Mater Processing Technol 128:123–129

Momber AW, Kovacevic R (2003) Hydro abrasive erosion of refractory ceramics. J Mater Sci 38:2861–2874

Freist B., Haferkamp H., Laurinat A., Louis H. (1989) Abrasive waterjet machining of ceramic products. In: Proc. the 5th American waterjet conference, Toronto, Canada, 191–204

Laurinat A., Louis H., Wiechert G.M. (1993) A model formilling with abrasive water jets. In: Proc. the 7th American waterJet conference, Seattle, Washington, 119–139

Ojmertz K. M. C. (1997) A study on abrasive waterjet milling, Ph. D. thesis, Chalmers University of Technology

Ojmertz K. M. C., Amini N. (1994) A discrete approach to the abrasive waterjet milling process. In: Proc. the 12th Int Conf Jet Cutting Technol, 425–434

Momber A. W., Kovacevic R. (1997) Principles of abrasive waterjet machining, Springer, Texas

Hashish M (1993) The effect of beam angle in abrasive waterjet machining. Trans ASME, J Eng Industry 115:51–56

Wang J (2003) The effect of jet impinging angle on the cutting performance in AWJ machining of alumina ceramics. Key Eng Mater 238–239:117–122

Atmani Z, Haddag B, Nouari M, Zenasni M (2016) Combined micro-structure-based flow stress and grain size evolution models for multi-physics modelling of metal machining. Int J Mech Sci 118:77–90

Azizur RM, Mustafizur R, Senthil KA (2017) Modelling of flow stress by correlating the material grain size and chip thickness in ultra-precision machining. Int J Mach Tools Manuf 123:57–75

Lenka K, Radim K, Terry CL (2017) Advances in metals and alloys for joint replacement. Prog Mater Sci 88:232–280

Fu Y, Wang X, Gao H, Wei H, Li S (2016) Blade surface uniformity of blisk finished by abrasive flow machining. Int J Adv Manuf Technol 84:1725–1735

Axinte DA, Srinivasu DS, Kong MC, Butler-Smith PW (2009) Abrasive waterjet cutting of poly crystalline diamond: a preliminary investigation. Int J Mach Tools Manuf 49:797–803

Akshay H, Redouane Z, Laurent C, Sabine L, Francis C (2017) Surface and machining in duced damage characterization of abrasive waterjet milled carbon/epoxy composite specimens and their impact on tensile behavior. Wear 1356–1364:s376–s377

Dadkhahipour K, Nguyen T, Wang J (2012) Mechanisms of channel formation on glasses by abrasive waterjet milling. Wear 1–10:s292–s293

Shanmugam DK, Masood SH (2009) An investigation on kerf characteristics in abrasive waterjet cutting of layered composites. J Mater Processing Technol 209:3887–3893

Santhanakumar M, Adalarasan R, Rajmohan M (2016) Parameter design for cut surface characteristics in abrasive waterjet cutting of Al/SiC/Al2O3 composite using grey theory based RSM. J Mech Sci Technol 30:371–379

Alberdi A, Artaza T, Suárez A, Rivero A, Girot F (2016) An experimental study on abrasive waterjet cutting of CFRP/Ti6Al4V stacks for drilling operations. Int J Adv Manuf Technol 86:691–704

Gokhan A, Serkan K, Izzet K (2017) Utilization of solid-cutting waste of granite as an alternative abrasive in abrasive waterjet cutting of marble. J Cleaner Production 159:241–247

Vatul’yan AO, Nesterov SA (2017) Certain aspects of identification of the inhomogeneous prestressed state in thermoelastic bodies. J Appl Math Mech 81:71–76

Azizur RM, Mustafizur R, Senthil KA (2017) Chip perforation and ‘burnishing–like’ finishing of Al alloy in precision machining. Precis Eng 50:393–409

Hlavacova IM, Geryk V (2017) Abrasives for waterjet cutting of high-strength and thick hard materials. Int J Adv Manuf Technol 90:1217–1224

Yigit MA, Tugrul Ö (2015) Prediction of machining induced micro structure in Ti–6Al–4V alloy using 3-D FE-based simulations: effects of tool micro-geometry, coating and cutting conditions. J Mater Processing Technol 220:1–26

Kong MC, Axinte D, Voice W (2010) Aspects of material removal mechanism in plain waterjet milling on gamma titanium aluminide. J Mater Processing Technol 210:573–584

Fowler G, Pashby IR, Shipway PH (2009) The effect of particle hardness and shape when abrasive water jet milling titanium alloy Ti6Al4V. Wear 266:613–620

Liang Z, Liu X, Ye B, Xie B (2016) Experimental result comparisons of curve fitting algorithms on fluid path lines modeling in strengthen grinding flow field. Exp Tech 40:715–735

Liang ZW, Liu X, Ye BY (2013) Investigation of mutual cross-correlation between integrated chip topography modelling and its image features. Int J Comput Mater Sci Surf Eng 5:154–176

Kim T. J., Sylvia J. G., Posner L. (1985) Piercing and cutting of ceramics by abrasive waterjet. In: Proceedings PED of the Int Sym. on machining of ceramic materials and components, 1985 ASME winter annual meeting, 17: 19–24

Schwetz K. A., Knoch H. (1993) Tribological and erosion characteristics of silicon carbide and boron carbide structural ceramics. In: P. Durán, J. F. Fernández (Eds.), Third Euro-ceramics, Faenza Editrice Ibérica S. L. 1125–1144

Ness E., Dubensky E., Haney C., Mort G., Sing P. J. (1994) New developments in ROCTEC composite carbides for use in abrasive waterjet applications. In: Proc. the 12th Int Conf on Jet Cutting Technology, Rouen, France

Kahlman L., Hollander E., Carlsson R. (1994) Thermal spalling wear and mechanical behaviour of silicon carbide and ceramic composites. In: Proc. the 8th CIMTEC, World Ceramic Congress, Florence

Vijay KP, Choudhury SK (2014) Fabrication and analysis of micro-pillars by abrasive water jet machining. Procedia Mater Sci 6:61–71

Kantha BK, Krishnaiah COV (2006) A study on the use of single mesh size abrasives in abrasive waterjet machining. Int J Adv Manuf Technol 29:532–540

John RJJ, Ramesh BN (2005) A strategy for efficient and quality cutting of materials with abrasive waterjets considering the variation in orifice and focusing nozzle diameter. Int J Mach Tools Manuf 45:1443–1450

Yang F, Shiah S, Heh T (2009) The effect of orifice lead cutting edge distance and fluid viscosity on jet performance in high-velocity waterjet cutting systems. Int J Adv Manuf Technol 40:332–341

Vincent P, Pavol H, Sergej H, Hakan T, Jan V (2012) Vibration emission as a potential source of information for abrasive waterjet quality process control. Int J Adv Manuf Technol 61:285–294

Kim J, Song J, Han S, Lee C (2012) Slotting of concrete and rock using an abrasive suspension waterjet system. KSCE J Civil Eng 16:571–578

Gokhan A, Izzet K, Kerim A (2011) An investigation on surface roughness of granite machined by abrasive waterjet. Bull Mater Sci 34:985–992

Libor MH, Bohumír S, Jiří K, Lucie G (2012) The model of product distortion in AWJ cutting. Int J Adv Manuf Technol 62:157–166

Santhanakumar M, Adalarasan R, Rajmohan M (2015) Experimental modelling and analysis in abrasive waterjet cutting of ceramic tiles using Grey-based response surface methodology. Arab J Sci Eng 40:3299–3311

Li W, Zhu H, Wang J, Yasser MA, Huang C (2013) An investigation into the radial-mode abrasive waterjet turning process on high tensile steels. Int J Mech Sci 77:365–376

Gokhan A, Izzet K, Kerim A (2013) Prediction of the cut depth of granitic rocks machined by abrasive waterjet (AWJ). Rock Mech Rock Eng 46:1223–1235

Gulay C, Can C (2012) An investigation on use of colemanite powder as abrasive in abrasive waterjet cutting (AWJC). J Mech Sci Technol 26:2371–2380

Yue Z, Huang C, Zhu H, Wang J, Yao P, Liu Z (2014) Optimization of machining parameters in the abrasive waterjet turning of alumina ceramic based on the response surface methodology. Int J Adv Manuf Technol 71:2107–2114

Zhang Y, Li C, Ji H, Yang X, Yang M, Jia D, Zhang X, Li R, Wang J (2017) Analysis of grinding mechanics and improved predictive force model based on material-removal and plastic-stacking mechanisms. Int J Mach Tools Manuf 122:81–97

Daniel K, Damian B, Piotr M (2017) The effect of traverse speed on kerf width in AWJ cutting of ceramic tiles. Procedia Eng. 192:469–473

Ulas C, Ahmet H (2008) A study on surface roughness in abrasive waterjet machining process using artificial neural networks and regression analysis method. J Mater Processing Technol 202:574–582

Farayibi PK, Murray JW, Huang L, Boud F, Kinnell PK, Clare AT (2014) Erosion resistance of laser clad Ti-6Al-4V/WC composite for waterjet tooling. J Mater Processing Technol 214:710–721

Strnadel B, Hlavac LM, Gembalova L (2013) Effect of steel structure on the declination angle in AWJ cutting. Int J Mach Tools Manuf 64:12–19

Ozcelik Y, Tercan AE, Yilmazkaya E, Ciccu R, Costa G (2011) A study of nozzle angle in stone surface treatment with water jets. Constr Build Mater 25:4271–4278

Shanmugam DK, Wang J, Liu H (2008) Minimisation of kerf tapers in abrasive waterjet machining of alumina ceramics using a compensation technique. Int J Mach Tools Manuf 48:1527–1534

Naser H, Farbod A, Jan KS, Marcello P (2015) Effect of entrained air in abrasive waterjet micro-machining: reduction of channel width and waviness using slurry entrainment. Wear 344-345:99–109

Zhao J, Zhang G, Xu Y, Wang R, Zhou W, Han L, Zhou Y (2017) Mechanism and effect of jet parameters on particle waterjet rock breaking. Powder Technol 313:231–244

Azmir MA, Ahsan AK (2009) A study of abrasive water jet machining process on glass/epoxy composite laminate. J Mater Processing Technol 209:6168–6173

Hou R, Huang C, Zhu H (2017) Experimental study on pulsation behavior of the ultrasonic vibration-assisted abrasive waterjet. Int J Adv Manuf Technol 91:3851–3859

Hou R, Wang T, Lv Z, Tian Y (2018) Investigation of the pulsed waterjet flow field inside and outside of the nozzle excited by ultrasonic vibration. Int J Adv Manuf Technol 99:453–460

Yu F, Wang J, Liu F (2012) Numerical simulation of single particle acceleration process by SPH coupled FEM for abrasive waterjet cutting. Int J Adv Manuf Technol 59:193–200

Liu D, Zhu H, Huang C, Wang J, Yao P (2016) Prediction model of depth of penetration for alumina ceramics turned by abrasive waterjet—finite element method and experimental study. Int J Adv Manuf Technol 87:2673–2682

Lv Z, Huang C, Zhu H, Wang J, Hou R (2016) A 3D simulation of the fluid field at the jet impinging zone in ultrasonic-assisted abrasive waterjet polishing. Int J Adv Manuf Technol 87:3091–3103

Lv Z, Hou R, Tian Y, Huang C, Zhu H (2018) Numerical study on flow characteristics and impact erosion in ultrasonic assisted waterjet machining. Int J Adv Manuf Technol 98:373–383

Liu C, Liu X, He Q, Zhang Y, Zhong RY (2018) An ultra-high-speed centrifugal grinding approach for thin-walled bearing rings. Int J Adv Manuf Technol 98:305–315

Dominik W, Krzysztof T, Ireneusz M, Grzegorz D (2018) Estimation of the perforation force for polymer composite conveyor belts taking into consideration the shape of the piercing punch. Int J Adv Manuf Technol 98:2539–2561

Miao X, Qiang Z, Wu M, Song L, Ye F (2018) Research on quality improvement of the cross section cut by abrasive water jet based on secondary cutting. Int J Adv Manuf Technol 97:71–80

Miao X, Qiang Z, Wu M, Song L, Ye F (2018) The optimal cutting times of multipass abrasive water jet cutting. Int J Adv Manuf Technol 97:1779–1786

Kushendarsyah S, Mebrahitom AG, Mohd AB, Mohd A (2018) Machining of biocompatible materials: a review. Int J Adv Manuf Technol 97:2255–2292

Lehocká D, Klich FBJ, Foldyna J, Hloch S, Kepič J, Kovaľ K, Krejči L, Storkan Z (2018) Pulsating water jet erosion effect on a brass flat solid surface. Int J Adv Manuf Technol 97:1099–1112

Andrzej P (2018) Experimental research into alternative abrasive material for the abrasive water-jet cutting of titanium. Int J Adv Manuf Technol 97:1529–1540

Huang N, Yin C, Liang L, Hu J, Wu S (2018) Error compensation for machining of large thin-walled part with sculptured surface based on on-machine measurement. Int J Adv Manuf Technol 96:4345–4352

Amer A, Dong R, Syed M, Igor S, Batool F (2018) An investigation of in-plane tensile properties of re-entrant chiral auxetic structure. Int J Adv Manuf Technol 96:2013–2029

Shikha A, Vijay KP, Choudhury SK (2018) Effect of surface modifications by abrasive water jet machining and electrophoretic deposition on tribological characterisation of Ti6Al4V alloy. Int J Adv Manuf Technol 96:1769–1777

Lv Z, Hou R, Tian Y, Huang C, Zhu H (2018) Investigation on flow field of ultrasonic-assisted abrasive waterjet using CFD with discrete phase model. Int J Adv Manuf Technol 96:963–972

Irina W, Ming M, Azwan IA, Lee C, Ahmad FM (2018) Experimental study and empirical analyses of abrasive waterjet machining for hybrid carbon/glass fiber-reinforced composites for improved surface quality. Int J Adv Manuf Technol 95:3809–3822

Ján C, Sergej H, Jana P, Akash N, Miroslav G, Monika H (2018) Hydroabrasive disintegration of rotating Monel K-500 workpiece. Int J Adv Manuf Technol 96:981–1001

Feng D, Shi L, Guo C, Wang F, Chen Y (2018) Numerical and experimental study on the flow characteristics of abrasive slurry jet with polymer additives. Int J Adv Manuf Technol 95:3289–3299

Qiang Z, Wu M, Miao X, Rupy S (2018) CFD research on particle movement and nozzle wear in the abrasive water jet cutting head. Int J Adv Manuf Technol 95:4091–4100

Li L, Kim M, Lee S, Kim J, Kim H, Lee D (2018) Study on surface modification of aluminum 6061 by multiple ultrasonic impact treatments. Int J Adv Manuf Technol 96:1255–1264

Madhu S, Balasubramanian M (2018) Effect of swirling abrasives induced by a novel threaded nozzle in machining of CFRP composites. Int J Adv Manuf Technol 95:4175–4189

Jonas H, Anders W, Johan B, Tomas B (2018) Surface integrity after post processing of EDM processed Inconel 718 shaft. Int J Adv Manuf Technol 95:2325–2337

Wang F, Xu Q, Feng D, Guo C (2018) Experiment study on performance of abrasive slurry jet with or without high polymer in stainless steel machining. Int J Adv Manuf Technol 95:2449–2456

Han Y, Zhang L, Guo M, Fan C, Liang F (2018) Tool paths generation strategy for polishing of freeform surface with physically uniform coverage. Int J Adv Manuf Technol 95:2125–2144

Song J, Yao Y, Dong Y, Dong B (2018) Prediction of surface quality considering the influence of the curvature radius for polishing of a free-form surface based on local shapes. Int J Adv Manuf Technol 95:11–25

Rivero A, Alberdi A, Artaza T, Mendia L, Lamikiz A (2018) Surface properties and fatigue failure analysis of alloy 718 surfaces milled by abrasive and plain waterjet. Int J Adv Manuf Technol 94:2929–2938

Lv Z, Hou R, Zhu H, Wang J (2018) Investigation on erosion mechanism in ultrasonic assisted abrasive waterjet machining. Int J Adv Manuf Technol 94:3741–3755

Irina W, Mai A, Lee CC, Mansor AF (2018) Kerf taper and delamination damage minimization of FRP hybrid composites under abrasive water-jet machining. Int J Adv Manuf Technol 94:1727–1744

Akash N, Jiří Š, Petr H, Dagmar K, Ashish KS, Sergej H, Amit RD, Josef F, Michal Z (2018) Hybrid aluminium matrix composite AWJ turning using olivine and Barton garnet. Int J Adv Manuf Technol 94:2293–2300

Liu S, Ji H, Han D, Guo C (2018) Experimental investigation and application on the cutting performance of cutting head for rock cutting assisted with multi-water jets. Int J Adv Manuf Technol 94:2715–2728

Wang Q, Wu Y, Teruo B, Mitsuyoshi N, Tatsuya F (2018) Proposal of a tilted helical milling technique for high quality hole drilling of CFRP: kinetic analysis of hole formation and material removal. Int J Adv Manuf Technol 94:4221–4235

Paweł S, Robert Ś (2018) The estimation of machining results and efficiency of the abrasive electro-discharge grinding process of Ti6Al4V titanium alloy using the high-frequency acoustic emission and force signals. Int J Adv Manuf Technol 94:1263–1282

Salman P, Ibrahim D, Essam W, Amir R, Mihai N (2018) A numerical and experimental study to investigate convective heat transfer and associated cutting temperature distribution in single point turning. Int J Adv Manuf Technol 94:897–910

Nath C, Rahman M (2008) Effect of machining parameters in ultrasonic vibration waterjet cutting. Int J Mach Tools Manuf 48:965–974

Xiao M, Karube S, Soutome T, Sato K (2002) Analysis of chatter suppression in vibration waterjet cutting. Int J Mach Tools Manuf 42:1677–1685

Geng D. X., Zhang D. Y., Xu Y. G., He F. T., Liu D. P., Duan Z. H. (2015) Rotary ultrasonic elliptical machining for side milling of CFRP: tool performance and surface integrity, Ultrasonics 59: 128–137

Mitrofanov AV, Ahmed N, Babitsky VI, Silberschmidt VV (2005) Effect of lubrication and cutting parameters on ultrasonically assisted turning of Inconel 718. J Mater Processing Technol s162–163:649–654

Skelton RC (1969) Effect of ultrasonic vibration on the turning process. Int J Mach Tool D R 9:363–374

Kim JD, Lee ES (1994) A study of the ultrasonic-vibration waterjet cutting of carbon-fiber reinforced plastics. J Mater Processing Technol 43:259–277

Shamoto E, Moriwaki T (1994) Study on elliptical vibration waterjet cutting. CIRP Ann Manuf Technol 43:35–38

Hew F. L., Timchenko V., Reizes J. A., Leonardi E. (2009) Numerical evaluation of the effectiveness of micro pulsating water jets for cooling of microchips. In: Proc. the ASME Micro/Nanoscale Heat Mass Transfer Int Conf, 2: 625–633

Klich J, Klichová D, Hlavácek P (2013) Effects of pulsating water jet on aluminium alloy with variously modifed surface. Tehnicki Vjesnik 24:341–345

Shamoto E, Moriwaki T (1999) Ultaprecision diamond cutting of hardened steel by applying elliptical vibration waterjet cutting. CIRP Annals – Manuf Technol 48:441–444

Brehl DE, Dow TA (2008) Review of vibration-assisted machining. Precis Eng 32:153–172

Zhou M, Hu LH (2015) Development of an innovative device for ultrasonic elliptical vibration waterjet cutting. Ultrasonics 60:76–81

Suzuki N, Yokoi H, Shamoto E (2011) Micro/nano sculpturing of hardened steel by controlling vibration amplitude in elliptical vibration waterjet cutting. Precis Eng 35:44–50

Liu K, Li XP, Rahman M, Liu XD (2004) A study of the cutting modes in the grooving of tungsten carbide. Int J Adv Manuf Technol 24:321–326

Kim GD, Loh BG (2008) Characteristics of elliptical vibration waterjet cutting in micro-V grooving with variations in the elliptical cutting locus and excitation frequency. J Micromech Microeng 18:025002

Ohnishi O., Onikura H., Min S. K., Aziz M., Tsuruoka S. (2008) Effect of ultrasonic vibration on micro grooving. Memoirs of the Faculty of Engineering, Kyushu University, 68: 1–9

Bourne K. A., Kapoor S. G., DeVor R. E. (2011) Study of the mechanics of the microgroove cutting process. Proc. the ASME 2011 Int Manuf Sci Eng Conf

Lu H, Lee D, Kim JG, Kim SY (2014) Modeling and machining evaluation of micro-structure fabrication by fast tool servo-based diamond machining. Precis Eng 38:212–216

Shamoto E, Suzuki N, Hino R (2008) Analysis of 3D elliptical vibration waterjet cutting with thin shear plane model. CIRP Annals – Manuf Technol 57:57–60

Zhang XQ, Kumar AS, Rahman M, Nath C, Liu K (2012) An analytical force model for orthogonal elliptical vibration waterjet cutting technique. J Manuf Process 14:378–387

Zhang XQ, Kumar AS, Rahman M, Nath C, Liu K (2013) Modeling of the effect of tool edge radius on surface generation in elliptical vibration waterjet cutting. Int J Adv Manuf Technol 65:35–42

Guo P, Ehmann KP (2013) Development of a tertiary motion generator for elliptical vibration texturing. Precis Eng 37:364–371

Guo P, Ehmann KP (2013) An analysis of the surface generation mechanics of the elliptical vibration texturing process. Int J Mach Tools Manuf 64:85–95

Zhang C, Ehmann KP, Li YG (2015) Analysis of cutting forces in the ultrasonic elliptical vibration-assisted micro-groove turning process. Int J Adv Manuf Technol 78:139–152

Nebeker E. B., Rodriguez S. E. (1976) Percussive water jets for rock cutting. In: Proc. the 3rd Int Sym. on Jet Cutting Technology, BHRA, B1-1–B1-9

Johnson Jr. V. E., Conn A. F. (1982) Self-resonating cavitating jets. In: Proc. the 6th Int Sym. on Jet Cutting Technology, BHRA, Paper A1, 1–25

Chahine G. L., Conn A. F., Johnson Jr. V. E., Frederick G. S. (1983) Cleaning and cutting with self-resonating pulsed water jets. In: Proc. the 2nd U.S. Water Jet Symposium, WJTA, 167–173

Gao C., Zhao L., Liu X., Huang X. (2012) Experiment research on erosion of self-excited inspired pulsatile jet in submerged conditions. J. Drain. Irrigation Mach Eng. 30:53–56 +63

Puchala RJ, Vijay MM (1984) Study of an ultrasonically generated cavitating or interrupted jet: aspects of design. In: Proc. the 7th Int Sym. Jet Cutting Technology, BHRA B2:69–82

Vijay M. M., Ultrasonically generated cavitating or interrupted jet [P], U.S. Patent 5, 154, 347

Foldyna J., Švehla B. (2008) Method of generation of pressure pulsations and apparatus for implementation of this method [P]. Czech patent 299412

Foldyna J, Sitek L, Švehla B, Švehla S (2004) Utilization of ultrasound to enhance high-speed water jet effects. Ultrason Sonochem 11:131

Ríha Z, Foldyna J (2012) Ultrasonic pulsations of pressure in a water jet cutting tool. Tehnical Gaz 19:487–491

Vijay M. M., Remisz J., Foldyna J., Grattan B. P. E. (1994) Preweakening of hard rocks with ultrasonically modulated high speed pulsed jets. In: Preceedings of the 12th Int Conf on Jet Cutting Technology

Sitek L, Foldyna J, Martinec P, Šcucka J, Bodnárová L, Hela R (2011) Use of pulsating water jet technology for removal of concrete in repair of concrete structures. Baltic J Road Bridge Eng 6:235–242

Dehkhoda S, Hood M (2013) An experimental study of surface and sub-surface damage in pulsed waterjet breakage of rocks. Int J Rock Mech Mining Sci 63:138–147

Bortolussi A. (2013) Ornamental stones surface finishing by pulsating jet: a project for an industrial application, Water Jet 2013–Research, Development, Applications, 17–24

Hnizdil M., Raudensky M. (2010) Descaling by pulsating water jet, METAL 2010—19th Int Conf on Metallurgy and Materials, 209–213

Sharma NC, Lyle DM, Qaqish JG, Galustians J, Schuller R (2008) The effect of a dental water jet with orthodontic tip on plaque and bleeding in adolescent patients with fixed orthodontic appliances. Am J Orthod Dentofac 133:565–571

Sergej H, Josef F, Libor S (2013) Disintegration of bone cement by continuous and pulsating water jet. Tehnicki Vjesnik 20:593–598

Stutz J, Krahl D (2009) Water jet-assisted liposuction for patients with lipoedema: histologic and immunohistologic analysis of the aspirates of 30 lipoedema patients. Aesthet Plast Surg 33:153–162

Michalik P, Zajac J, Hatala M, Mital D, Fecova V (2014) Monitoring surface roughness of thin-welled components from steel C45 machining down and up milling. Measurement 58:416–428

Foldyna J, Sitek L, Šcucka J, Martinec P, Valícek J, Páleníková K (2009) Effects of pulsating water jet impact on aluminium surface. J Mater Processing Technol 209:6174–6180

Foldyna J, Klich J, Hlavacek P, Zelenak M, Scucka J (2012) Erosion of metals by pulsating water jet. Tehnicki Vjesnik 19:381–386

Lehocka D, Klich J, Foldyna J, Hloch S, Krolczyk JB, Carach J (2016) Copper alloys disintegration using pulsating water jet. Measurement 82:375–383

Lehocka D., Klich J., Foldyna J., Hloch S., Hvizdoš P., Fides M. (2016) Surface integrity evaluation of brass CW614N after impact of acoustically excited pulsating water jet. Int Conf on manufacturing engineering and materials, Int Conf on Management in Emerging Markets 2016, in: Procedia Eng, 149: 236–244

Zhang C, Guo P, Ehmann KF, Li Y (2016) Effects of ultrasonic vibrations in micro-groove turning. Ultrasonics 67:30–40

Wang X, Han P, Marco G, Ehmann K (2017) Modeling of machined depth in laser surface texturing of medical needles. Precis Eng 47:10–18

Debaprasanna P, Siba SM, Jambeswar S, Layatitdev D (2013) A hybrid approach for multi-response optimization of non-conventional machining on AlSiCp MMC. Measurement 46:3581–3592

Lehocká D, Klichová D, Foldyna J, Hloch S, Hvizdoš P, Fides M, Botko F (2017) Comparison of the influence of acoustically enhanced pulsating water jet on selected surface integrity characteristics of CW004A copper and CW614N brass. Measurement 110:230–238

Qi H, Wen D, Lu C, Li G (2016) Numerical and experimental study on ultrasonic vibration-assisted micro-channeling of glasses using an abrasive slurry jet. Int J Mech Sci 110:94–107

Tangwarodomnukun V, Likhitangsuwat P, Tevinpibanphan O, Dumkum C (2015) Laser ablation of titanium alloy under a thin and flowing water layer. Int J Mach Tools Manuf 89:14–28

Marko J, Henri O, Andrej L, Izidor S, Pavel D, Joško V (2016) Measuring the water temperature changes in ice abrasive water jet prototype. Procedia Eng. 149:163–168

Suvradip M, Yuvraj KM, Subhransu R, Shailesh K, Dinesh KS, Ashish KN (2013) Development and parametric study of a waterjet assisted underwater laser cutting process. Int J Mach Tools Manuf 68:48–55

Zhua H, Wang J, Yao P, Huang C (2017) Heat transfer and material ablation in hybrid laser-waterjet micro grooving of single crystalline germanium. Int J Mach Tools Manuf 116:25–39

The Laser MicroJet® Technology (2017) https://www.synova.ch/technology/laser- microjet.html. Accessed 20 Dec 2017

Liang Z, Zhang C, Hu Y (2011) Study of fuzzy relational degrees between turbulence features and topography construction. Int J Adv Comput Technol 3:15–22

Liang ZW, Ye BY (2012) Drug appearance quality selecting method based on image probability density recognition. J Convergence Info Technol 7:37–43

Liang ZW, Ye BY (2012) Assessment of surface fitting algorithm’s influence on integrated chip topography characteristics. J Convergence Info Technol 7:131–139

Liang ZW, Ye BY (2014) A new vehicle image dynamic tracking approach. Sensors Transducers 165:53–60

Zhang Z, Yao P, Zhang Z, Xue D, Wang C, Huang C, Zhu H (2017) A novel technique for dressing metal-bonded diamond grinding wheel with abrasive waterjet and touch truing. Int J Adv Manuf Technol 93:3063–3073

Wang J, Sun L, Jia Z (2017) Research on electrochemical discharge-assisted diamond wire cutting of insulating ceramics. Int J Adv Manuf Technol 93:3043–3051

Sedighi M, Shamsi M (2017) A new approach in producing metal bellows by local arc heating: a parametric study. Int J Adv Manuf Technol 93:3211–3219

Wang S, Zhang S, Wu Y, Yang F (2017) Exploring kerf cut by abrasive waterjet. Int J Adv Manuf Technol 93:2013–2020

Van HB, Patrick G, Tarek S, Guillaume C, Walter R (2017) A new cutting depth model with rapid calibration in abrasive water jet machining of titanium alloy. Int J Adv Manuf Technol 93:1499–1512

Ramírez LA, Muñoz ND, Palomar PM, Romero RMA, Gonzalez TJ (2017) Heat removal analysis on steel billets and slabs produced by continuous casting using numerical simulation. Int J Adv Manuf Technol 93:1545–1565

Miao X, Wu M, Qiang Z, Wang Q, Miao X (2017) Study on optimization of a simulation method for abrasive water jet machining. Int J Adv Manuf Technol 93:587–593

Zhang L, Han Y, Fan C, Tang Y, Song X (2017) Polishing path planning for physically uniform overlap of polishing ribbons on freeform surface. Int J Adv Manuf Technol 92:4525–4541

Adalarasan R, Santhanakumar M, Thileepan S (2017) Selection of optimal machining parameters in pulsed CO2 laser cutting of Al6061/Al2O3 composite using Taguchi-based response surface methodology (T-RSM). Int J Adv Manuf Technol 93:305–317

Viboon T, Taweeporn W (2017) Evolution of milled cavity in the multiple laser scans of titanium alloy under a flowing water layer. Int J Adv Manuf Technol 92:293–302

Srinivasu DS, Venkaiah N (2017) Minimum zone evaluation of roundness using hybrid global search approach. Int J Adv Manuf Technol 92:2743–2754

Acknowledgements

The helpful instruction from Prof. Kornel F. Ehmann and facility provision offered by the Advanced Manufacturing Processing Laboratory, Northwestern University, USA, deserve high appreciation. We also want to thank the editors for their hard work and the referees for their kind comments and valuable suggestions to improve this paper.

Funding

The authors acknowledge the funding of the following science foundations: National Natural Science Foundation of China (51575116, U1601204), China National Spark Program (2015GA780065), The Science and Technology Innovative Research Team Program in Higher Educational Universities of Guangdong Province (2017KCXTD025), The Innovative Academic Team Project of Guangzhou Education System (1201610013), The Science and Technology Planning Project of Guangdong Province (2017A010102014, 2016A010102022), The Science and Technology Planning Project of Guangzhou Municipal Government (201707010293), The Water Resource Science and Technology Program of Guangdong Province of China (2012–11), Guangzhou University’s 2017 training program for young top-notch personnel (BJ201701), and The Postgraduate Education Innovation Program of Guangdong Province (2016SQXX14, 2016XSLT24).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Liu, X., Liang, Z., Wen, G. et al. Waterjet machining and research developments: a review. Int J Adv Manuf Technol 102, 1257–1335 (2019). https://doi.org/10.1007/s00170-018-3094-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-3094-3