Abstract

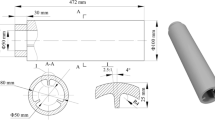

A small inter-electrode gap is necessary to improve the machining accuracy in electrochemical machining (ECM). In order to achieve a stable small gap processing, this paper proposes a new concept of ECM method with a floating cathode. Aiming at the problem of gap regulation in this method, the modeling and experimental research are carried out, taking the electrochemical machining with a large span floating cathode of dual round outlets for rotary parts as an example. A mathematical model of machining gap is established based on fluid mechanics and kinetics of electrode processes, from which the relationships between the gap and process parameters are analyzed. Through the experimental method, the influence law of the variation of process parameters on the gap is further studied, and the mathematical model is modified. Comparisons between the modified theoretical model calculation results and experimental results show that considering only the flow field conditions, the average error of the inter-electrode gap obtained by experiment and model during work-piece rest and work-piece rotation is 6.1% and 4.3%; considering the flow field and electric field conditions, the average error of the inter-electrode gap during work-piece rest and work-piece rotation is 4.1% and 5.1%. The study demonstrates that a stable inter-electrode gap can be formed in ECM through the liquid electrolyte to support the cathode, and the inter-electrode gap was correlated with the electrolyte flowrate, current, and electrolyte pressure, so it is a feasible method to regulate the gap by adjusting the electrolyte flow or the inter-electrode current during processing, which provides a new way for gap formation and control in high-precision electrochemical machining.

Similar content being viewed by others

References

Kong Q, Yong L, Zhu X, Hao T, Liu G (2013) Online detection method for inter-electrode gap in micro ECM based on capacitance of electric double layers. Nanotechnol Precis Eng 11(6):529–535

Fujisawa T (2008) Multi-physics simulation of electro-chemical machining process for three-dimensional compressor blade. J Fluids Eng 130(8):080201.1–081703.9

Wang W, Zhu D, Qu N, Huang S, Fang X (2010) Flow balance design and experimental investigation on electrochemical drilling of multiple holes. Acta Aeronautica Et Astronautica Sinica 31(8):1667–1673

Zhu Y, Shao J, Nan SU, Yun N (2014) Research on micro electro-discharged and electrolysis machining technology modulated by synchronizing ultrasonic vibrating. J Mech Eng 50(1):185–192

Li HY, Cheng XY, Zhang MQ (2011) Electrode processing technology of bipolar pulse precision vibration. In: Proceedings of the 14th National Conference on Special Processing

Yan Y, Zhang WM, Zhang ZJ, Jin X (2013) Research on technology of compound ECM with high-frequency group pulse and rotating magnetic field. Trans Beijing Inst Technol 33(4):353–356

Kozak J, Gulbinowicz Z, Rozenek M (2010) Selected problems of pulse electrochemical machining. In: Proceedings of the 16th International Symposium on Electromachining

Béjar MA, Gutiérrez F (1993) On the determination of current efficiency in electrochemical machining with a variable gap. J Mater Process Technol 37(1–4):691–699

Clifton D, Mount AR, Alder GM, Jardine D (2002) Ultrasonic measurement of the inter-electrode gap in electrochemical machining. Int J Mach Tool Manu 42(11):1259–1267

Wang X (2011) Research on intelligent monitoring method of electrolytic processing gap. Nanjing University of Aeronautics and Astronautics, Doctoral dissertation, pp 19–25

Lu Y, Liu K, Zhao D (2011) Experimental investigation on monitoring interelectrode gap of ECM with six-axis force sensor. Int J Adv Manuf Technol 55(5–8):565–572

Kong Q, Yong L, Zhu X, Hao T, Liu G (2013) Online detection method for inter-electrode gap in micro ECM based on capacitance of electric double layers. Nanotechnol Precis Eng 11(6):529–535

Natsu W, Terada A (2012) Approach to detect and control gap width with peak current in pulse ECM. Adv Mater Res 482–484:1973–1978

Chan HJ, Bo HK, Chong NC (2009) Micro electrochemical machining for complex internal micro features. CIRP Ann Manuf Technol 58(1):181–184

Pang GB, Xin KK, Cai X, Ji T, Zhang LP, Liu JY (2017) Modeling and experimental study of inter-electrode gaps in ECM for planes of floating cathode with a round mouth. China Mech Eng 28(22):2655–2661

Potter MC, Wiggert DC (2008) Mechanics of fluids. China Machine Press, Beijing

Cha QX (2012) Introduction to electrode process dynamics, Third edn. Science Press, Beijing

Xie YY, Ru SX, Chen YM (1982) Engineering fluid mechanics or hydraulics. Science and Technology Publishing, Sichuang, pp 36–40

Liu GQ, Liu J, Ma LX (2002) Chemical material data sheet. Chemical Industry Press, Beijing

Funding

This research was supported by the National Science Foundation of China (51675072 and 51275062) and Liaoning Province Million Talents Engineering Finance Project (201569).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pang, G., Xin, K., Bu, F. et al. Modeling and experiment study on inter-electrode gap in electrochemical machining with a floating cathode for rotary parts. Int J Adv Manuf Technol 101, 2151–2164 (2019). https://doi.org/10.1007/s00170-018-3051-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-3051-1