Abstract

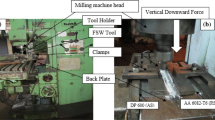

In this research, AA5005-O aluminum-magnesium alloy and St-52 low carbon steel sheets were friction-stir welded in a butt-dissimilar joint design. Effects of different processing parameters including tool rotational speed (w), traverse velocity (v), plunge depth, and offset distance on the solid-state weldability of these dissimilar materials were assessed in terms of formation of intermetallic compound (IMC) layer at the interface. A 3D thermo-mechanical finite element modeling procedure was employed to predict the nucleation and growth of IMC layer. Formation of various FeAl, FeAl3, and Fe2Al5 IMCs at the interface, layer morphology, and thickness were experimentally studied as well, by using X-ray diffraction (XRD) and field emission scanning electron microscopy (FE-SEM) analysis techniques. A good agreement between the simulated thermal results and experimental data was noticed. The results showed that the thickness of IMC layer at the interface as the main controlling parameter in transverse tensile property and fracture behavior of produced dissimilar joints can be varied extremely as a function of processing parameters. By decreasing the heat input and suppressing the kinetics of IMCs layer formation, the tensile performance of dissimilar welded joints is improved, considerably. However, the soundness of these dissimilar welds played another main role as a restriction mechanism against this trend. The maximum joining efficiency is attained around 90% at an optimized working window of w = 1200 rpm, v = 90 mm/min, and a plunge depth of 0.3 mm with an offset distance of 0.5 mm toward the Al side. The hardness of this optimized dissimilar weld is enhanced even more than the steel base metal caused by the formation of IMC layer at the interface as well as the dispersion of reinforcing intermetallic particles (IMPs).

Similar content being viewed by others

References

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R 50(1–2):1–78

Nandan R, DebRoy T, Bhadeshia HKDH (2008) Recent advances in friction-stir welding—process, weldment structure and properties. Prog Mater Sci 53(6):980–1023

Martinez N, Kumar N, Mishra RS, Doherty KJ (2017) Microstructural variation due to heat gradient of a thick friction stir welded aluminum 7449 alloy. J Alloys Compd 713:51–63

Tang J, Shen Y (2016) Numerical simulation and experimental investigation of friction stir lap welding between aluminum alloys AA2024 and AA7075. J Alloys Compd 666:493–500

Khodabakhshi F, Haghshenas M, Chen J, Shalchi Amirkhiz B, Li J, Gerlich A (2016) Bonding mechanism and interface characterisation during dissimilar friction stir welding of an aluminium/polymer bi-material joint. Sci Technol Weld Join 1–9

Khan NZ, Siddiquee AN, Khan ZA, Mukhopadhyay AK (2017) Mechanical and microstructural behavior of friction stir welded similar and dissimilar sheets of AA2219 and AA7475 aluminium alloys. J Alloys Compd 695:2902–2908

Rafiei R, Shamanian M, Fathi M, Khodabakhshi F (2017) Dissimilar friction-stir lap-welding of aluminum-magnesium (AA5052) and aluminum-copper (AA2024) alloys: microstructural evolution and mechanical properties. Int J Adv Manuf Technol:1–18

Khodabakhshi F, Ghasemi Yazdabadi H, Kokabi AH, Simchi A (2013) Friction stir welding of a P/M Al–Al2O3 nanocomposite: microstructure and mechanical properties. Mater Sci Eng A 585:222–232

Khodabakhshi F, Simchi A, Kokabi AH, Gerlich AP (2016) Similar and dissimilar friction-stir welding of an PM aluminum-matrix hybrid nanocomposite and commercial pure aluminum: microstructure and mechanical properties. Mater Sci Eng A 666:225–237

Khodabakhshi F, Haghshenas M, Sahraeinejad S, Chen J, Shalchi B, Li J, Gerlich AP (2014) Microstructure-property characterization of a friction-stir welded joint between AA5059 aluminum alloy and high density polyethylene. Mater Charact 98:73–82

Lee IS, Kao PW, Ho NJ (2008) Microstructure and mechanical properties of Al-Fe in situ nanocomposite produced by friction stir processing. Intermetallics 16(9):1104–1108

Ding Y, Shen Z, Gerlich AP (2017) Refill friction stir spot welding of dissimilar aluminum alloy and AlSi coated steel. J Manuf Process 30:353–360

Hsieh MJ, Lee RT, Chiou YC (2017) Friction stir spot fusion welding of low-carbon steel to aluminum alloy. J Mater Process Technol 240:118–125

Huang Y, Wang J, Wan L, Meng X, Liu H, Li H (2016) Self-riveting friction stir lap welding of aluminum alloy to steel. Mater Lett 185:181–184

Piccini JM, Svoboda HG (2017) Tool geometry optimization in friction stir spot welding of Al-steel joints. J Manuf Process 26:142–154

Haghshenas M, Abdel-Gwad A, Omran AM, Gökçe B, Sahraeinejad S, Gerlich AP (2014) Friction stir weld assisted diffusion bonding of 5754 aluminum alloy to coated high strength steels. Mater Des 55:442–449

Leitao C, Arruti E, Aldanondo E, Rodrigues DM (2016) Aluminium-steel lap joining by multipass friction stir welding. Mater Des 106:153–160

Liu X, Lan S, Ni J (2014) Analysis of process parameters effects on friction stir welding of dissimilar aluminum alloy to advanced high strength steel. Mater Des 59:50–62

Ramachandran KK, Murugan N, Shashi Kumar S (2015) Effect of tool axis offset and geometry of tool pin profile on the characteristics of friction stir welded dissimilar joints of aluminum alloy AA5052 and HSLA steel. Mater Sci Eng A 639:219–233

Pourali M, Abdollah-zadeh A, Saeid T, Kargar F (2017) Influence of welding parameters on intermetallic compounds formation in dissimilar steel/aluminum friction stir welds. J Alloys Compd 715:1–8

Yazdipour A, Heidarzadeh A (2016) Effect of friction stir welding on microstructure and mechanical properties of dissimilar Al 5083-H321 and 316L stainless steel alloy joints. J Alloys Compd 680:595–603

Tang J, Shen Y (2017) Effects of preheating treatment on temperature distribution and material flow of aluminum alloy and steel friction stir welds. J Manuf Process 29(Supplement C):29–40

Rafiei R, Moghaddam AO, Hatami M, Khodabakhshi F, Abdolahzadeh A, Shokuhfar A (2017) Microstructural characteristics and mechanical properties of the dissimilar friction-stir butt welds between an Al–Mg alloy and A316L stainless steel. Int J Adv Manuf Technol 90(9–12):2785–2801

Fei X, Jin X, Ye Y, Xiu T, Yang H (2016) Effect of pre-hole offset on the property of the joint during laser-assisted friction stir welding of dissimilar metals steel and aluminum alloys. Mater Sci Eng A 653:43–52

Khodabakhshi F, Kokabi A, Simchi A (2017) Reactive friction-stir processing of nanocomposites: effects of thermal history on microstructure–mechanical property relationships, Mater Sci Technol 1–14

Zheng Q, Feng X, Shen Y, Huang G, Zhao P (2016) Dissimilar friction stir welding of 6061 Al to 316 stainless steel using Zn as a filler metal. J Alloys Compd 686:693–701

Dehghani M, Amadeh A, Akbari Mousavi SAA (2013) Investigations on the effects of friction stir welding parameters on intermetallic and defect formation in joining aluminum alloy to mild steel. Mater Des 49(Supplement C):433–441

Elyasi M, Aghajani Derazkola H, Hosseinzadeh M (2016) Investigations of tool tilt angle on properties friction stir welding of A441 AISI to AA1100 aluminium. Proc Inst Mech Eng B J Eng Manuf 230(7):1234–1241

Derazkola HA, Aval HJ, Elyasi M (2015) Analysis of process parameters effects on dissimilar friction stir welding of AA1100 and A441 AISI steel. Sci Technol Weld Join 20(7):553–562

Sawada YK, Nakamura M (2013) Lapped friction stir welding between ductile cast irons and stainless steels. Weld Int 27(2):121–128

Khodabakhshi F, Simchi A, Kokabi A, Gerlich A, Nosko M, Švec P (2017) Influence of hard inclusions on microstructural characteristics and textural components during dissimilar friction-stir welding of an PM Al–Al2O3–SiC hybrid nanocomposite with AA1050 alloy. Sci Technol Weld Join 22(5):412–427

Xu L, Robson JD, Wang L, Prangnell PB (2017) The influence of grain structure on intermetallic compound layer growth rates in Fe-Al dissimilar welds. Metall Mater Trans A

Chen CM, Kovacevic R (2004) Joining of Al 6061 alloy to AISI 1018 steel by combined effects of fusion and solid state welding. Int J Mach Tools Manuf 44(11):1205–1214

Elrefaey A, Gouda M, Takahashi M, Ikeuchi K (2005) Characterization of aluminum/steel lap joint by friction stir welding. J Mater Eng Perform 14(1):10–17

Uzun H, Dalle Donne C, Argagnotto A, Ghidini T, Gambaro C (2005) Friction stir welding of dissimilar Al 6013-T4 to X5CrNi18-10 stainless steel. Mater Des 26(1):41–46

Watanabe T, Takayama H, Yanagisawa A (2006) Joining of aluminum alloy to steel by friction stir welding. J Mater Process Technol 178(1):342–349

Chen T (2009) Process parameters study on FSW joint of dissimilar metals for aluminum–steel. J Mater Sci 44(10):2573–2580

Dehghani M, Mousavi SAAA, Amadeh A (2013) Effects of welding parameters and tool geometry on properties of 3003-H18 aluminum alloy to mild steel friction stir weld. Trans Nonferrous Metals Soc China 23(7):1957–1965

Liu X, Lan S, Ni J (2014) Analysis of process parameters effects on friction stir welding of dissimilar aluminum alloy to advanced high strength steel. Mater Des 59(Supplement C):50–62

Ratanathavorn W, Melander A, Magnusson H (2016) Intermetallic compounds in friction stirred lap joints between AA5754/galvanised ultra-high strength steel. Sci Technol Weld Join 21(8):653–659

Leitao C, Arruti E, Aldanondo E, Rodrigues DM (2016) Aluminium-steel lap joining by multipass friction stir welding. Mater Des 106(Supplement C):153–160

Dong H, Chen S, Song Y, Guo X, Zhang X, Sun Z (2016) Refilled friction stir spot welding of aluminum alloy to galvanized steel sheets. Mater Des 94(Supplement C):457–466

Zheng Q, Feng X, Shen Y, Huang G, Zhao P (2016) Dissimilar friction stir welding of 6061 Al to 316 stainless steel using Zn as a filler metal. J Alloys Compd 686(Supplement C):693–701

Huang Y, Wang J, Wan L, Meng X, Liu H, Li H (2016) Self-riveting friction stir lap welding of aluminum alloy to steel. Mater Lett 185(Supplement C):181–184

Jamshidi Aval H (2015) Microstructure and residual stress distributions in friction stir welding of dissimilar aluminium alloys. Mater Des 87:405–413

Jamshidi Aval H, Serajzadeh S, Sakharova NA, Kokabi AH, Loureiro A (2012) A study on microstructures and residual stress distributions in dissimilar friction-stir welding of AA5086-AA6061. J Mater Sci 47(14):5428–5437

Choi DH, Ahn BW, Lee CY, Yeon YM, Song K, Jung SB (2011) Formation of intermetallic compounds in Al and Mg alloy interface during friction stir spot welding. Intermetallics 19(2):125–130

Choi DH, Ahn BW, Quesnel DJ, Jung SB (2013) Behavior of β phase (Al3Mg2) in AA 5083 during friction stir welding. Intermetallics 35:120–127

Esmaeili A, Zareie Rajani HR, Sharbati M, Givi MKB, Shamanian M (2011) The role of rotation speed on intermetallic compounds formation and mechanical behavior of friction stir welded brass/aluminum 1050 couple. Intermetallics 19(11):1711–1719

Galvão I, Oliveira JC, Loureiro A, Rodrigues DM (2012) Formation and distribution of brittle structures in friction stir welding of aluminium and copper: influence of shoulder geometry. Intermetallics 22:122–128

Khodabakhshi F, Marzbanrad B, Shah L, Jahed H, Gerlich A (2017) Friction-stir processing of a cold sprayed AA7075 coating layer on the AZ31B substrate: structural homogeneity, microstructures and hardness. Surf Coat Technol 331:116–128

Khodabakhshi F, Simchi A, Kokabi A (2017) Surface modifications of an aluminum-magnesium alloy through reactive stir friction processing with titanium oxide nanoparticles for enhanced sliding wear resistance. Surf Coat Technol 309:114–123

Khodabakhshi F, Simchi A, Kokabi AH, Gerlich AP (2015) Friction stir processing of an aluminum-magnesium alloy with pre-placing elemental titanium powder: in-situ formation of an Al3Ti-reinforced nanocomposite and materials characterization. Mater Charact 108:102–114

Cole GS, Sherman AM (1995) Light weight materials for automotive applications. Mater Charact 35(1):3–9

Hussein SA, Tahir ASM, Hadzley AB (2015) Characteristics of aluminum-to-steel joint made by friction stir welding: a review. Mater Today Commun 5:32–49

Jamshidi Aval H, Serajzadeh S, Kokabi AH, Loureiro A (2011) Effect of tool geometry on mechanical and microstructural behaviours in dissimilar friction stir welding of AA 5086-AA 6061. Sci Technol Weld Join 16(7):597–604

Zhang J, Shen Y, Li B, Xu H, Yao X, Kuang B, Gao J (2014) Numerical simulation and experimental investigation on friction stir welding of 6061-T6 aluminum alloy. Mater Des 60:94–101

Zhu X, Chao Y (2004) Numerical simulation of transient temperature and residual stresses in friction stir welding of 304L stainless steel. J Mater Process Technol 146(2):263–272

Nandan R, Roy GG, Lienert TJ, Debroy T (2007) Three-dimensional heat and material flow during friction stir welding of mild steel. Acta Mater 55(3):883–895

Rituraj Nandan (2008) Phd thesis, Computational modeling of heat transfer and visco-elastic flow in friction stir welding. The Pennsylvania State University

Amit Arora (2011) Phd thesis, Thermomechanical conditions and stresses on the friction stir welding tool. The Pennsylvania State University The Graduate School

Gale WF, Totemeier TC (2004) Smithells metals reference book. 8th ed. Elsevier Inc. All rights reserved

Khodabakhshi F, Arab S, Švec P, Gerlich A (2017) Fabrication of a new Al-Mg/graphene nanocomposite by multi-pass friction-stir processing: dispersion, microstructure, stability, and strengthening. Mater Charact 132:92–107

Khodabakhshi F, Gerlich AP, Švec P (2017) Fabrication of a high strength ultra-fine grained Al-Mg-SiC nanocomposite by multi-step friction-stir processing. Mater Sci Eng A 698:313–325

Khodabakhshi F, Gerlich AP, Švec P (2017) Reactive friction-stir processing of an Al-Mg alloy with introducing multi-walled carbon nano-tubes (MW-CNTs): microstructural characteristics and mechanical properties. Mater Charact 131:359–373

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aghajani Derazkola, H., Khodabakhshi, F. Intermetallic compounds (IMCs) formation during dissimilar friction-stir welding of AA5005 aluminum alloy to St-52 steel: numerical modeling and experimental study. Int J Adv Manuf Technol 100, 2401–2422 (2019). https://doi.org/10.1007/s00170-018-2879-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2879-8