Abstract

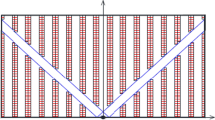

Non-traditional warehouses shorten the travelled paths to store and retrieve (S/R) the loads, thanks to additional aisles crossing the parallel racks. This paper provides the analytic model to best design a non-traditional warehouse for unit-load (UL) with diagonal cross-aisles and storage policy according to the class-based storage (CBS) strategy. The model minimizes the average single-command cycle time to S/R the loads, best sizing the classes, their shape, and the position/numbers of additional aisles. The focus is on both 2- and 3-CBS optimizing the number of diagonal cross-aisles to best balance the travel time reduction and the loss of storage space due to the aisles. Furthermore, benchmarking toward standard warehouses with no diagonal cross-aisles and random assignment strategy allows quantifying the positive impact of the proposed design configuration on the daily warehouse operations.

Similar content being viewed by others

References

Horta M, Coelho F, Relvas S (2016) Layout design modelling for a real world just-in-time warehouse. Comput Ind Eng 101:1–9

Zhang G, Nishi T, Turner SDO, Oga K, Li X (2017) An integrated strategy for a production planning and warehouse layout problem: modeling and solution approaches. Omega 68:85–94

Boysen N, de Koster R, Weidinger F (2018) Warehousing in the e-commerce era: a survey. Eur J Oper Res

Gu J, Goetschalckx M, McGinnis L (2007) Research on warehouse operation: a comprehensive review. Eur J Oper Res 177(1):1–21

Rouwenhorst B, Reuter B, Stockrahm V, van Houtum G, Mantel R, Zijm W (2000) Warehouse design and control: framework and literature review. Eur J Oper Res 122:515–533

Baker P, Canessa M (2009) Warehouse design: a structured approach. Eur J Oper Res 193:425–436

Gu J, Goetschalckx M, McGinnis L (2010) Research on warehouse design and performance evaluation: a comprehensive review. Eur J Oper Res 203(3):539–549

Cormier G, Gunn EA (1992) A review of warehouse models. Eur J Oper Res 58:3–13

Accorsi R, Bortolini M, Gamberi M, Manzini R, Pilati F (2017) Multi-objective warehouse building design to optimize the cycle time, total cost, and carbon footprint. Int J Adv Manuf Technol 92(1–4):839–854

Staudt FH, Alpan G, Di Mascolo M, Taboada Rodriguez CM (2015) Warehouse performance assessment: a literature review. Int J Prod Res 53(18):5524–5544

Dotoli M, Epicoco N, Falagario M, Costantino N, Turchiano B (2015) An integrated approach for warehouse analysis and optimization: a case study. Comput Ind 70:56–69

Gue KR, Meller RD (2009) Aisle configurations for unit-load warehouses. IIE Trans 41(3):171–182

De Koster R, Le-Duc T, Roodbergen KJ (2007) Design and control of warehouse order picking: a literature review. Eur J Oper Res 182:481–501

Bartholdi JJ, Hackman ST (2017) Warehouse and distribution science, version 0.98. https://www.warehouse-science.com/book/editions/wh-sci-0.98.pdf. Accessed 5 February 2018

Roodbergen KJ, De Koster R (2001) Routing order pickers in a warehouse with a middle aisle. Eur J Oper Res 133:32–43

Accorsi R, Manzini R, Maranesi F (2014) A decision-support system for the design and management of warehousing systems. Comput Ind 65:175–186

Öztürkoglu O, Gue KR, Meller RD (2012) Optimal unit-load warehouse designs for single-command operations. IIE Trans 44:459–475

Le-Duc T, De Koster R (2005) Travel distance estimation and storage zone optimization in a 2-block class-based storage strategy warehouse. Int J Prod Res 43(17):3561–3581

Hausman WH, Schwarz LB, Graves SC (1976) Optimal storage assignment in automatic warehousing systems. Manag Sci 22(6):629–638

Bortolini M, Accorsi R, Gamberi M, Manzini R, Regattieri A (2015) Optimal design of AS/RS storage systems with three-class-based assignment strategy under single and dual command operations. Int J Adv Manuf Technol 79(9–12):1747–1759

Zaerpour N, Yu Y, de Koster RBM (2017) Optimal two-class-based storage in a live-cube compact storage system. IISE Trans 49(7):653–668

Bortolini M, Faccio M, Gamberi M, Manzini R (2015) Diagonal cross-aisle in unit-load warehouses to increase handling performance. Int J Prod Econ 170:838–849

Gabbard M, Reinholdt E (1975) Warehouse cost analysis. West Electr Eng 19:52–60

Rai D, Sodegar B, Fieldson R, Hu X (2011) Assessment of CO2 emissions reduction in a distribution warehouse. Energy 36:2271–2277

Chew EP, Tang LC (1999) Cycle time analysis for general item location assignment in a rectangular warehouse. Eur J Oper Res 112:582–597

Wang G, Feng G, Kang Z, Wang H (2017) Research on the heat load of food freezing in refrigerated warehouse. Procedia Eng 205:1843–1849

Bortolini M, Faccio M, Ferrari E, Gamberi M, Pilati F (2016) Fresh food sustainable distribution: cost, delivery time and carbon footprint three-objective optimization. J Food Eng 174:56–67

Ding B (2018) Pharma Industry 4.0: literature review and research opportunities in sustainable pharmaceutical supply chains. Process Saf Environ Prot 119:115–130

Liu X, Li J, Li X (2017) Study of dynamic risk management system for flammable and explosive dangerous chemicals storage area. J Loss Prev Process Ind 49:983–988

Khakzad N, Van Gelder P (2017) Fragility assessment of chemical storage tanks subject to floods. Process Saf Environ Prot 111:75–84

Bassan Y, Roll Y, Rosenblatt MJ (1980) Internal layout design of a warehouse. IIE Trans 12(4):317–322

White J (1972) Optimum design of warehouses having radial aisles. AIIE Trans 4(4):333–336

Arlinghaus SL, Nystuen JD (1991) Street geometry and flows. Geogr Rev 81(2):206–214

Clark KA, Meller RD (2013) Incorporating vertical travel into non-traditional cross-aisles for unit-load warehouse designs. IIE Trans 45(12):1322–1331

Cardona LF, Soto DF, Rivera L, Martínez HJ (2015) Detailed design of fishbone warehouse layouts with vertical travel. Int J Prod Econ 170:825–837

Çelk M, Süral H (2014) Order picking under random and turnover-based storage policies in fishbone aisle warehouses. IIE Trans 46(3):283–300

Pohl LM, Meller RD, Gue KR (2009) An analysis of dual-command operations in common warehouse designs. Transport Res E-Log 45(3):367–379

Pohl LM, Meller RD, Gue KR (2009) Optimizing fishbone aisles for dual-command operations in a warehouse. Nav Res Logist 56(5):389–403

Gue KR, Ivanovic G, Meller RD (2012) A unit-load warehouse with multiple pickup and deposit points and non-traditional aisles. Transp Res E 48(4):795–806

Thomas LM, Meller RD (2014) Analytical models for warehouse configuration. IIE Trans 46(9):928–947

Pferschy U, Schauer J (2018) Order batching and routing in a non-standard warehouse. Electron Notes Discrete Math 69:125–132

Heskett J (1963) Cube-per-order index: a key to warehouse stock location. Transp Distrib Manag 3:27–31

Kallina C, Lynn J (1976) Application of the cube-per-order index rule for stock location in a distribution warehouse. Interfaces 7:37–46

Manzini R, Gamberi M, Persona A, Regattieri A (2007) Design of a class based storage picker to product order picking system. Int J Adv Manuf Technol 32(7–8):811–821

Larson TN, March H, Kusiak A (1997) Heuristic approach to warehouse layout with class-based storage. IIE Trans 29(4):337–348

Kovács A (2011) Optimizing the storage assignment in a warehouse served by milkrun logistics. Int J Prod Econ 133(1):312–318

Ene S, Öztürk N (2012) Storage location assignment and order picking optimization in the automotive industry. Int J Adv Manuf Technol 60(5–8):787–797

Rao SS, Adil GK (2013) Class-based storage with exact S-shaped traversal routing in low-level picker-to-part systems. Int J Prod Res 51(16):4979–4996

Yu Y, De Koster R (2013) On the suboptimality of full turnover-based storage. Int J Prod Res 51(6):1635–1647

Ekren BY, Sari Z, Lerher T (2015) Warehouse design under class-based storage policy of shuttle-based storage and retrieval system. IFAC Pap Online 48(3):1152–1154

Flores B, Whybark C (1986) Multiple criteria ABC analysis. Int J Oper Prod Manag 6:38–46

Lolli F, Ishizaka A, Gamberini R, Rimini B (2017) A multicriteria framework for inventory classification and control with application to intermitted demand. J Multi-Criteria Decis Anal 24:275–285

Lolli F, Ishizaka A, Gamberini R (2014) New AHP-based approaches for multi-criteria inventory classification. Int J Prod Econ 156:62–74

Ishizaka A, Lolli F, Balugani E, Cavallieri R, Gamberini R (2018) DEASort: assigning items with data envelopment analysis in ABC classes. Int J Prod Econ 199:7–15

Soylu B, Akyol B (2014) Multi-criteria inventory classification with reference items. Comput Ind Eng 69:12–20

Douissa MR, Jabeur K (2016) A new model for multi-criteria ABC inventory classification: PROAFTN method. Procedia Comput Sci 96:550–559

Torabi SA, Hatefi SM, Salek Pay B (2012) ABC inventory classification in the presence of both quantitative and qualitative criteria. Comput Ind Eng 63:530–537

Bonnans JF, Gilbert JC, Lemaréchal C, Sagastizábal CA (2006) Numerical optimization: theoretical and practical aspects. Universitext (Second revised ed. of translation of 1997 French ed.) Springer-Verlag, Berlin

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bortolini, M., Faccio, M., Ferrari, E. et al. Design of diagonal cross-aisle warehouses with class-based storage assignment strategy. Int J Adv Manuf Technol 100, 2521–2536 (2019). https://doi.org/10.1007/s00170-018-2833-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2833-9